Maintaining your outdoor machinery is essential for achieving a well-groomed landscape. Knowledge of the components that make up these machines can significantly enhance their performance and longevity. Whether you are a seasoned landscaper or a weekend warrior, familiarizing yourself with the various elements of your equipment is crucial.

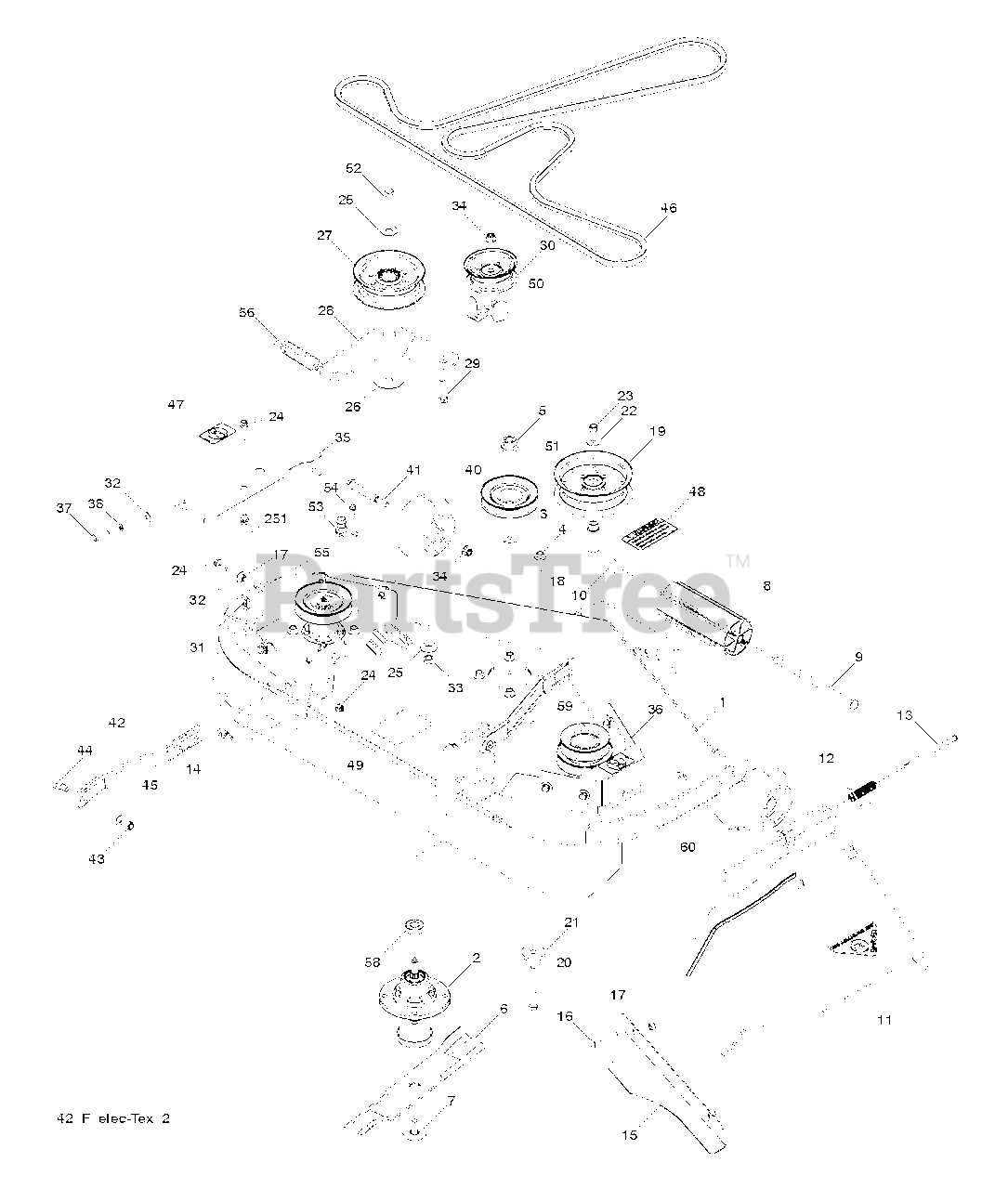

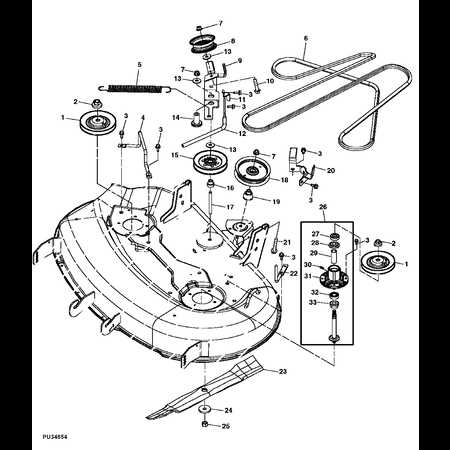

In this section, we will explore a detailed representation of a specific assembly crucial for lawn maintenance. This visual guide will assist you in identifying each segment and understanding its function within the whole system. By gaining insights into these components, you will be better equipped to troubleshoot issues and perform necessary upkeep.

Additionally, understanding the intricacies of your equipment will empower you to make informed decisions when it comes to repairs or replacements. With this knowledge, you can ensure that your machinery operates at its peak efficiency, providing you with the best results for your landscaping endeavors.

Understanding Husqvarna Mower Deck Components

When it comes to maintaining a high-performance grass cutting machine, familiarity with its individual elements is crucial. Each component plays a vital role in ensuring efficiency and effectiveness, ultimately impacting the overall performance of the equipment. A comprehensive grasp of these elements helps users optimize their operations and troubleshoot issues as they arise.

Typically, these assemblies consist of various integral parts that work in unison. Here’s a breakdown of some key components commonly found in such machinery:

| Component | Description |

|---|---|

| Blades | Sharp edges designed for cutting grass evenly and efficiently. |

| Spindles | Support the rotating blades and enable smooth operation. |

| Belt | Transmits power from the engine to the blades for operation. |

| Chassis | Framework that houses and supports all the components. |

| Deck Housing | Encloses the blades and protects them while allowing grass to be discharged. |

| Anti-Scalp Wheels | Prevent the blades from scalping the ground, ensuring a uniform cut. |

Understanding these components can significantly enhance your ability to care for and operate your cutting machine effectively. Regular maintenance and timely replacement of worn parts ensure longevity and optimal performance.

Key Features of the 42 Inch Deck

This section highlights the essential characteristics of a specific cutting platform designed for effective grass management. Understanding these features helps users appreciate the advantages of this model and its performance capabilities.

Durability and Design

The robust construction ensures longevity and reliability in various weather conditions. This design not only enhances performance but also supports efficient cutting efficiency.

Cutting Performance

Equipped with advanced blades, this platform delivers a clean and even cut. The optimized shape allows for superior grass handling and reduced clumping.

| Feature | Description |

|---|---|

| Material | High-strength steel for durability |

| Blade Type | High-performance, sharpened blades |

| Cutting Width | Generous width for efficient coverage |

| Adjustability | Multiple height settings for customized cutting |

Common Issues with Mower Parts

Maintaining a lawn care machine involves understanding various components that can lead to performance problems. Whether it’s wear and tear or improper maintenance, several common issues can arise that affect functionality and efficiency. Identifying these challenges early can save time and resources in the long run.

Worn Blades: One frequent issue is dull or damaged cutting tools. When they lose their sharpness, they can tear rather than cut grass, resulting in an uneven lawn and potential harm to the plant. Regular inspection and replacement of these components are essential for optimal performance.

Drive Belt Failures: Another common problem involves the drive mechanisms. Belts can wear out or become misaligned, leading to a loss of power transfer. This can result in sluggish operation or complete failure to engage. Regular checks can prevent unexpected breakdowns.

Corroded Fasteners: Over time, fasteners can corrode due to exposure to the elements, which can lead to loose connections and instability in the assembly. Keeping these components clean and securely tightened is vital for overall machine safety and performance.

Fuel System Issues: Fuel-related problems often stem from dirty filters or stale fuel. These can lead to poor starting or inconsistent operation. Regular maintenance of the fuel system can enhance reliability and efficiency.

Electrical Problems: Lastly, electrical components may develop faults that impact ignition or operational controls. Inspecting wiring and connections for wear can prevent inconvenient malfunctions.

By being proactive in identifying these common issues, operators can ensure their equipment remains in good working order and extends its lifespan.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and efficiency of your equipment. By following a few key practices, you can significantly enhance performance and reduce the need for repairs over time. Regular maintenance not only saves money but also keeps your machine running smoothly.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Blades | Every Use | Check for sharpness and any signs of damage to ensure clean cuts. |

| Clean Undercarriage | Weekly | Remove debris buildup to prevent corrosion and improve airflow. |

| Check Fluid Levels | Monthly | Ensure oil and coolant levels are adequate for optimal performance. |

| Battery Maintenance | Seasonally | Clean terminals and ensure connections are secure to prevent starting issues. |

| Tire Pressure | Monthly | Regularly check and adjust tire pressure for better traction and efficiency. |

Tools Needed for Repairs

When it comes to performing maintenance or fixing issues on outdoor equipment, having the right tools is essential for a successful and efficient process. A well-equipped toolkit not only streamlines the repair work but also ensures safety and precision in handling various components.

First and foremost, basic hand tools such as wrenches, sockets, and screwdrivers are crucial. These instruments allow for easy access to fasteners and fittings, making disassembly and reassembly straightforward. Additionally, pliers and cutting tools are often necessary for managing wires and other materials.

Specialty tools may also be required, depending on the specific repair tasks. For example, torque wrenches are useful for ensuring that screws are tightened to the manufacturer’s specifications, while blade sharpeners can help maintain cutting efficiency.

Finally, safety gear should not be overlooked. Protective gloves, goggles, and hearing protection are vital for safeguarding oneself during repairs. Investing in a comprehensive toolkit can greatly enhance the repair experience and prolong the life of the equipment.

How to Identify Replacement Parts

Identifying the necessary components for your equipment can be a straightforward process if you follow the right steps. Understanding the specific elements involved will help ensure you select the correct replacements and maintain optimal performance.

Step-by-Step Identification Process

- Consult the Manual: Always start by referring to the user guide. It typically contains detailed information on each component.

- Take Inventory: Examine the current setup and list down all the parts you need to replace. Note any visible wear or damage.

- Search for Model Numbers: Look for any identification numbers on the equipment, as these will assist in finding compatible components.

- Check Online Resources: Use manufacturer websites or forums for insights and additional information on specific components.

Common Identifying Features

- Shape and Size: Compare the dimensions and shapes of existing components to potential replacements.

- Material Composition: Identify the material of each part, as this can impact durability and compatibility.

- Connection Points: Assess how each component connects to others; mismatched connection types can lead to functionality issues.

By following these guidelines, you can confidently determine which components need replacing, ensuring your equipment runs smoothly and efficiently.

Assembly Guide for the Mower Deck

This section provides a comprehensive overview of the steps needed to correctly assemble the cutting apparatus. Following these instructions will ensure optimal performance and longevity of your equipment.

Step 1: Begin by gathering all necessary components and tools. Ensure everything is clean and free of debris before starting the assembly process.

Step 2: Align the support structures and secure them using the designated fasteners. Double-check that all connections are tight to avoid any instability during operation.

Step 3: Attach the cutting elements to the main body, ensuring they are evenly spaced and properly oriented. This alignment is crucial for achieving the ultimate cutting efficiency.

Step 4: Finally, inspect all connections and ensure that moving parts are well-lubricated. A thorough check will prevent premature wear and enhance performance.

By following these steps, you can confidently assemble the equipment for an optimal experience.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. Reliable sources provide not only the necessary items but also peace of mind that they meet quality standards set by the manufacturer. This section outlines the best options for acquiring genuine replacements.

Authorized Retailers

One of the most dependable ways to obtain authentic components is through authorized retailers. These establishments are officially recognized by the manufacturer and offer a wide selection of items. Additionally, shopping at these locations often guarantees that you receive products that are compatible and meet the specifications required for your machinery.

Online Marketplaces

The internet offers a plethora of options for purchasing authentic components. Reputable online platforms feature genuine items along with customer reviews and ratings. Always ensure that you are buying from sellers with a solid reputation to avoid counterfeit products. Look for verified listings that clearly indicate the brand’s name and provide details about compatibility.

In summary, whether visiting a local authorized dealer or exploring trustworthy online marketplaces, obtaining authentic components is essential for maintaining your equipment’s efficiency and reliability.

Importance of Regular Inspections

Routine evaluations of your lawn care equipment are essential for maintaining optimal performance and longevity. Regular checks help identify potential issues before they escalate into more significant problems, ensuring that your machinery operates efficiently. This proactive approach not only saves time and money but also enhances safety during operation.

Conducting inspections allows you to assess the wear and tear on various components. By addressing minor repairs promptly, you can avoid unexpected breakdowns that could disrupt your landscaping schedule. Additionally, a well-maintained machine promotes a healthier lawn by providing consistent cutting and reducing the risk of uneven growth.

Moreover, regular assessments contribute to better fuel efficiency and reduced emissions. When machinery is in top condition, it operates more smoothly, leading to less strain on the engine and other systems. Ultimately, making inspections a routine part of your maintenance schedule ensures that your equipment remains reliable, efficient, and ready for any task at hand.