In the realm of mechanical devices, having a comprehensive overview of individual elements is crucial for effective maintenance and repair. This section delves into the intricate relationships and functionalities of various components that contribute to the overall performance of machinery. By grasping how these elements interact, users can enhance their skills in troubleshooting and enhancing their tools.

Whether you are an experienced technician or a novice enthusiast, familiarizing yourself with the intricate layout of these items empowers you to undertake repairs with confidence. With clarity in the arrangement and purpose of each segment, you will be better equipped to address issues promptly and effectively. Understanding these assemblies not only facilitates efficient work but also fosters a deeper appreciation for the craftsmanship involved.

This exploration aims to provide valuable insights that will aid in mastering the essentials of assembly structures. By breaking down the complexities into manageable parts, readers can engage more deeply with their equipment and optimize its functionality. Let’s embark on this informative journey to uncover the specifics of how these components come together to create a cohesive unit.

Understanding Craftsman Eager 1 Parts

Grasping the components of a specific tool can significantly enhance its usability and maintenance. Recognizing the individual elements that contribute to the overall functionality is essential for both novice users and seasoned professionals. By familiarizing oneself with these essential building blocks, one can ensure optimal performance and longevity of the equipment.

Key Components

Every machine consists of various elements that work together to achieve desired results. From the power source to the operational mechanisms, understanding how these elements interact is crucial. This knowledge not only aids in effective operation but also facilitates troubleshooting and repair when issues arise.

Maintenance and Care

Proper upkeep of each component can prevent breakdowns and enhance performance. Regular inspections and timely replacements of worn-out elements can prolong the life of the equipment. Engaging with the specific features and their functions enables users to make informed decisions regarding care and maintenance, ensuring that the tool remains reliable over time.

Overview of the Craftsman Eager 1

This section provides an insight into a widely recognized tool that has become a staple for enthusiasts and professionals alike. Renowned for its reliability and performance, this equipment is designed to meet various needs in both gardening and landscaping tasks. Its robust construction ensures longevity while maintaining ease of use, making it an excellent choice for users of all skill levels.

Key Features

The highlighted model boasts a range of features that enhance its functionality. Users appreciate its lightweight design, which allows for easy maneuverability, alongside powerful engine performance that ensures efficiency. Additionally, the adjustable components cater to diverse applications, making it versatile for different gardening tasks.

Specifications

| Feature | Description |

|---|---|

| Engine Type | 2-Cycle |

| Weight | Approximately 10 lbs |

| Cutting Width | 18 inches |

| Fuel Capacity | 0.5 gallons |

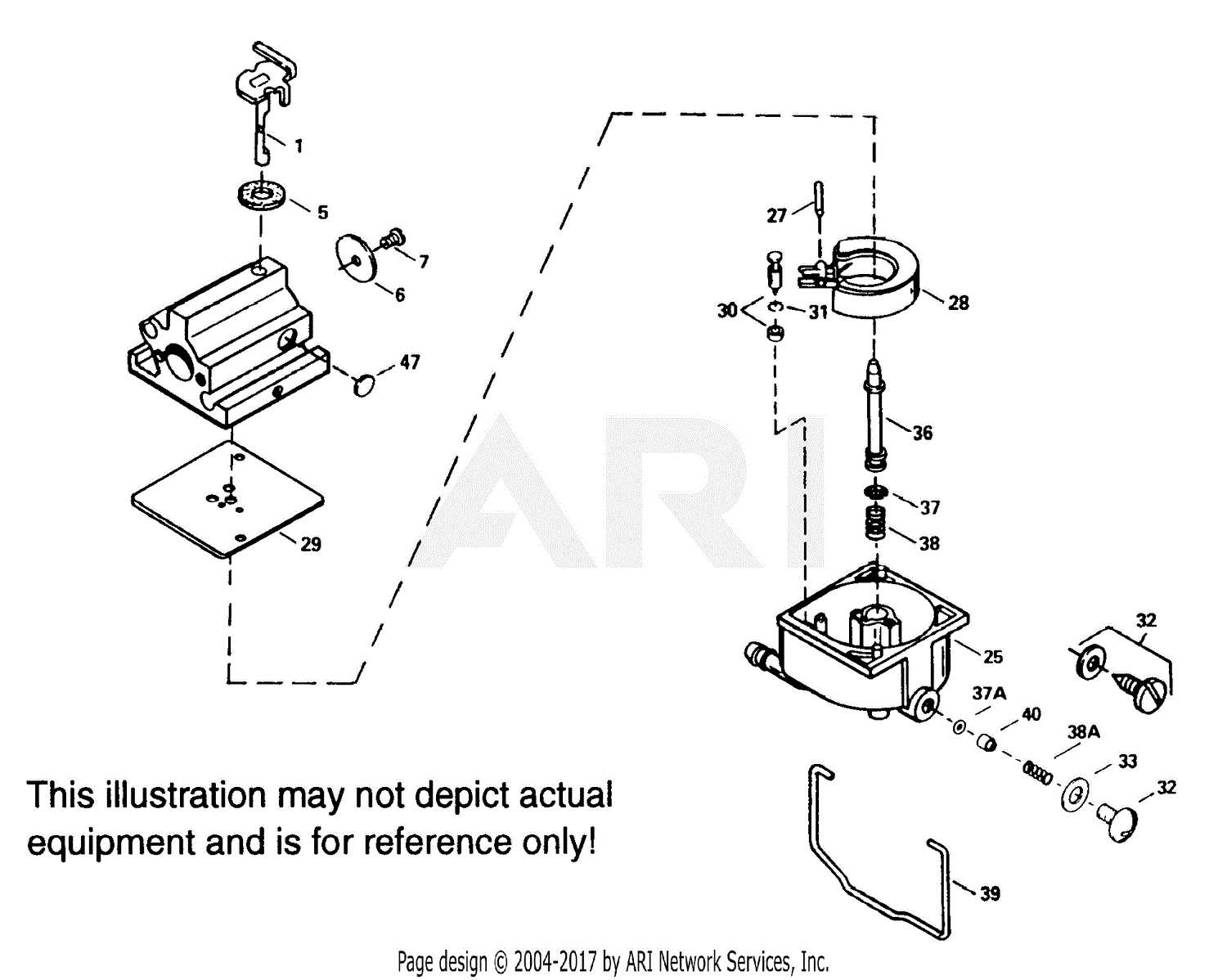

Importance of a Parts Diagram

Understanding the components of any machine is crucial for effective maintenance and repair. A visual representation of these elements offers clarity and enhances the user’s ability to interact with the equipment.

Here are several key reasons why such a visual guide is essential:

- Enhanced Understanding: A visual layout helps users identify and comprehend individual components quickly.

- Streamlined Repairs: Knowing the exact location and function of each part can significantly reduce repair time.

- Accurate Replacements: Ensuring that the correct replacements are obtained and installed can prevent future malfunctions.

- Improved Safety: Familiarity with components helps in safely handling and operating machinery.

In summary, a comprehensive visual representation serves as an invaluable resource for users, promoting efficiency and safety in the maintenance process.

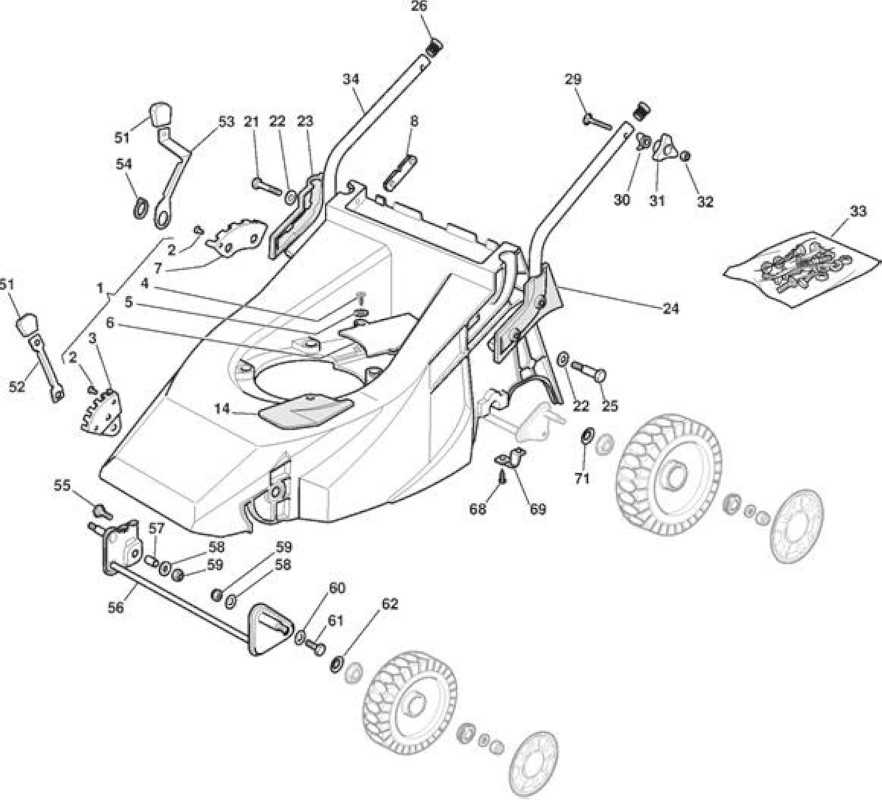

Key Components of the Eager 1

This section explores the essential elements that contribute to the functionality and performance of this versatile tool. Understanding these components is crucial for users who want to maximize its potential and ensure efficient operation.

Core Elements

- Motor: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Handle: Designed for comfort and control, enabling easy maneuverability during use.

- Blade: The cutting instrument that determines the precision and efficiency of tasks performed.

- Base: Provides stability and support, ensuring safe operation while preventing vibrations.

Additional Features

- Safety Switch: A critical feature that enhances user safety by preventing accidental activation.

- Adjustable Settings: Allows users to customize performance according to specific needs and materials.

- Storage Compartment: Conveniently holds accessories and tools, promoting organization and efficiency.

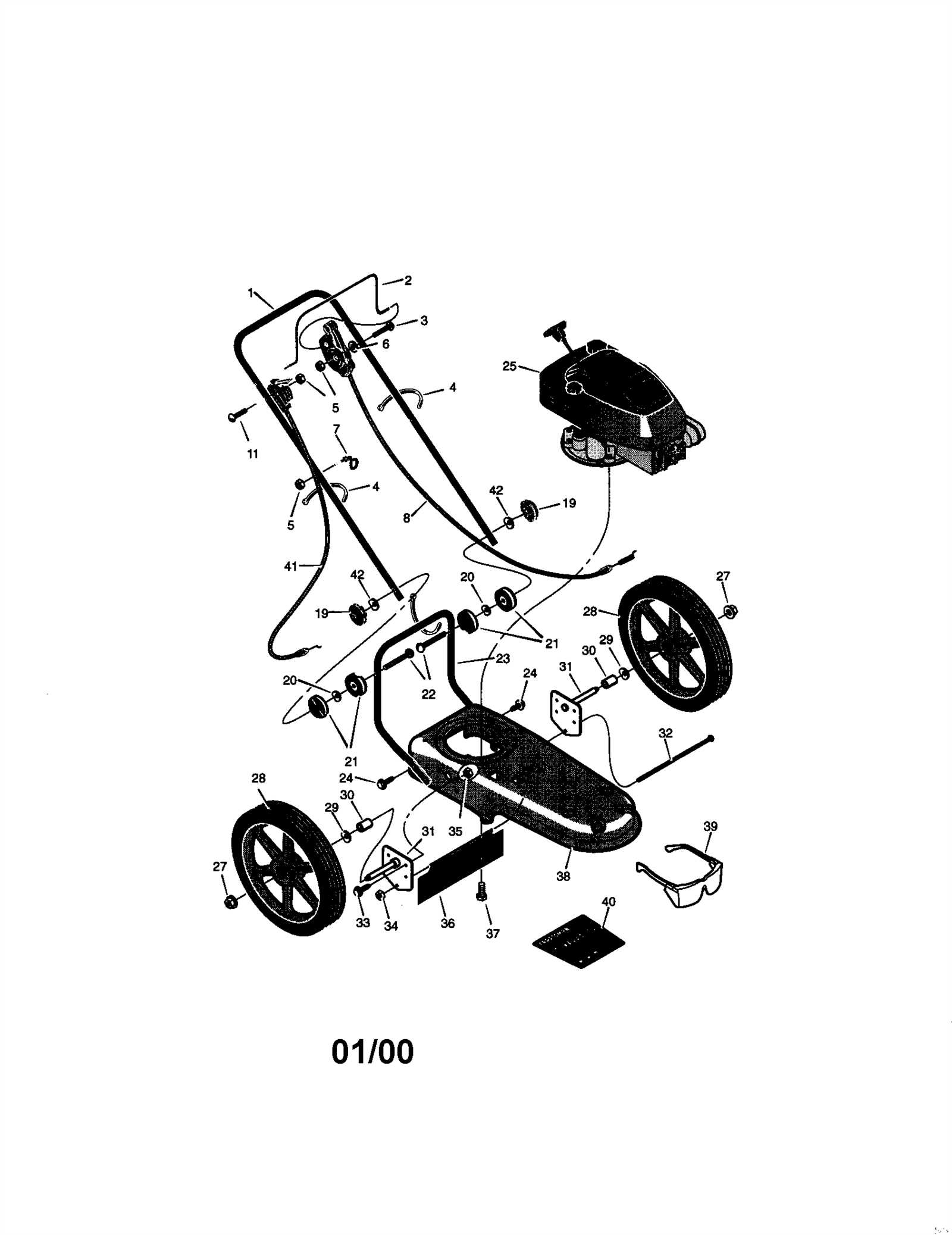

Common Issues and Solutions

In any mechanical system, challenges can arise that hinder optimal performance. Identifying these issues promptly and understanding effective remedies is crucial for maintaining functionality and extending the lifespan of the equipment. Below are some prevalent problems encountered and their corresponding solutions.

One frequent issue involves unexpected noises during operation. This may indicate loose components or inadequate lubrication. To address this, ensure that all screws and bolts are tightened and that moving parts are properly greased. Regular maintenance checks can help prevent such occurrences.

Another common concern is the failure of the device to start. This can often be traced back to electrical problems, such as a dead battery or faulty connections. Inspecting the power source and ensuring all wiring is secure can often resolve the issue. If problems persist, consider consulting a professional for a thorough diagnosis.

Overheating is also a significant problem that can lead to malfunction. This typically occurs due to blockages or insufficient airflow. Cleaning air filters and ensuring that vents are unobstructed can help mitigate this risk. Regular monitoring of temperature levels during use can prevent overheating issues.

Finally, wear and tear of various components is an inevitable part of use. Regular inspections can help identify parts that may need replacement before they cause significant problems. Keeping a stock of essential replacements on hand can facilitate timely repairs, ensuring continued efficiency and performance.

How to Use the Parts Diagram

Understanding the layout of components is essential for effective maintenance and repair of your equipment. A visual representation serves as a valuable tool, providing clarity and guidance in identifying individual elements. This section will outline key steps to navigate and utilize this resource efficiently.

1. Familiarize Yourself with the Layout: Begin by examining the overall structure. Note how various components are organized, as this will help you locate specific sections quickly.

2. Identify Key Elements: Look for labels or numbers associated with each component. These identifiers will be crucial when searching for replacement items or understanding the assembly process.

3. Reference the Manual: Cross-reference the visual guide with your user manual. This will provide additional context and instructions for each part, ensuring you understand their functions.

4. Plan Your Repairs: Before starting any work, outline the steps based on the visual aid. This will save time and minimize errors during the disassembly or reassembly of parts.

5. Keep It Accessible: Print or bookmark the representation for easy access during repairs. Having it on hand will streamline your process and enhance efficiency.

By following these guidelines, you can maximize the effectiveness of the visual guide, ensuring a smoother repair experience.

Where to Find Replacement Parts

When it comes to maintaining tools and equipment, sourcing the necessary components can be a crucial step. Understanding where to locate suitable alternatives ensures that your devices remain in optimal condition, prolonging their lifespan and functionality.

One of the most reliable methods for acquiring these items is through official manufacturer websites. They typically offer a comprehensive catalog of components, along with detailed descriptions and specifications. Additionally, many online retailers specialize in providing a wide range of options, making it easy to compare prices and availability.

Local hardware stores can also be a valuable resource. They often stock a variety of items, and staff can assist in identifying the correct replacements. Furthermore, online marketplaces and auction sites present another avenue, where users can find both new and used components at competitive prices.

Lastly, community forums and social media groups dedicated to tool enthusiasts may provide leads on where to find rare or discontinued items. Engaging with fellow users can lead to recommendations and tips for securing hard-to-find components.

Tips for Maintaining Your Craftsman Eager 1

Regular upkeep of your equipment is essential for ensuring its longevity and optimal performance. By following a few straightforward guidelines, you can significantly enhance its reliability and efficiency. Proper care not only extends the lifespan but also improves the overall user experience.

Routine Inspections

Conducting regular checks can help identify potential issues before they escalate. Look for signs of wear and tear, such as frayed cables or loose components. Addressing these problems early can prevent more significant breakdowns in the future.

Cleaning and Lubrication

Keeping your equipment clean is crucial. Remove any debris or buildup that may obstruct functionality. Additionally, regular lubrication of moving parts will reduce friction, preventing premature wear. Use recommended lubricants for the best results, and follow the manufacturer’s guidelines.

Incorporating these maintenance practices into your routine will ensure that your equipment remains in peak condition, ready to tackle any task efficiently.

FAQs About Craftsman Eager 1 Repairs

This section addresses common inquiries related to maintenance and troubleshooting of a specific brand’s outdoor equipment. Understanding these aspects can significantly enhance your repair experience and prolong the lifespan of your device.

Common Questions

- What are the typical issues that arise with this equipment?

- How can I identify the right components needed for repairs?

- Are there any recommended tools for effective maintenance?

- How often should I perform routine checks to ensure optimal performance?

Troubleshooting Tips

- Always consult the user manual for guidance on specific problems.

- Regularly inspect for wear and tear, especially on moving parts.

- Keep the device clean and free of debris to prevent malfunctions.

- If issues persist, consider reaching out to professional repair services.