When it comes to maintaining and understanding the inner workings of your vehicle, knowing the layout and functionality of the various elements beneath the cover is essential. This section will provide a detailed exploration of the core systems that make up this area, offering insights into their roles and how they interconnect to ensure optimal performance.

Each section under the hood plays a critical part in ensuring the smooth operation of your car. From fluid circulation to temperature regulation, and the seamless interaction of mechanical and electronic systems, all these elements work in harmony. Whether you’re a seasoned mechanic or a car enthusiast, this guide aims to simplify the identification and understanding of these components.

By gaining a better grasp of the intricate setup, you can not only perform basic maintenance but also troubleshoot potential issues more efficiently. The following sections will take you through the most important elements, helping you navigate the complexity of modern vehicles with confidence.

Overview of Key Components in the Engine Bay

The front compartment of a vehicle houses several crucial mechanical and electrical elements, each playing a vital role in ensuring the functionality and efficiency of the vehicle. These elements work together to deliver power, control temperature, and manage essential systems that contribute to the smooth operation of the car.

Power Generation System

At the core of any vehicle’s operational setup is the component responsible for generating power. This system is supported by multiple devices designed to regulate energy flow and maintain stable performance. The efficient distribution of energy ensures that the vehicle remains responsive and reliable in various driving conditions.

Cooling and Temperature Control

Temperature management is another essential function carried out by specific devices located within this compartment. These components work together to prevent overheating and maintain an optimal temperature for all systems. Proper airflow and heat dissipation are critical to maintaining the longevity and efficiency of the entire setup.

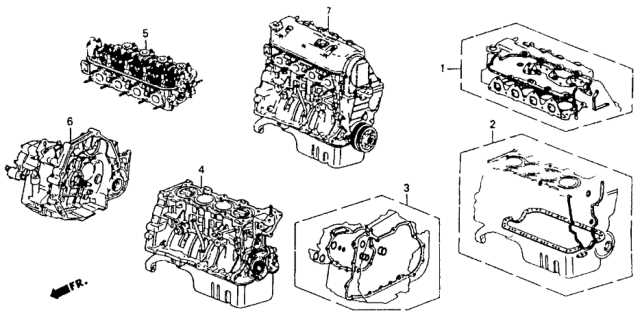

Main Elements of Honda Civic’s Powertrain

The heart of a vehicle’s propulsion system consists of multiple components working together to ensure efficient power delivery. These elements are crucial for converting fuel into motion, distributing energy, and maintaining smooth operation under various driving conditions. Below, we explore the key components responsible for the movement and control of the power generated.

- Power Generator: This component is responsible for converting fuel into mechanical energy, which is then used to propel the vehicle forward.

- Transmission System: This mechanism transfers the generated energy to the wheels, adjusting speed and torque as needed to match driving demands.

- Axles: These structures deliver the force from the transmission system to the wheels, ensuring smooth movement and stability.

- Cooling Mechanism: A vital part that regulates the temperature, preventing overheating and ensuring the longevity of the entire system.

- Lubrication System: Ensures that all moving parts function without excessive friction, promoting efficiency and reducing wear.

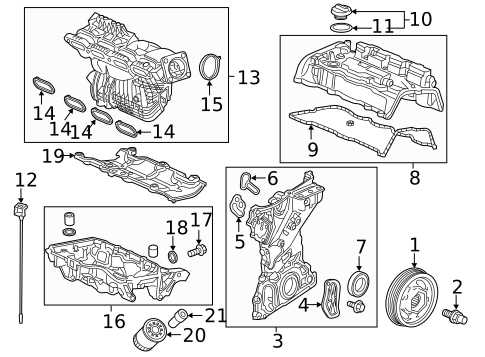

Cooling System Parts and Their Function

The cooling mechanism in a vehicle plays a crucial role in maintaining optimal temperatures for proper functioning. This system ensures that the heat generated during operation is managed effectively, preventing excessive warmth that could cause significant damage to various components.

One of the key elements in this setup is the radiator, which dissipates heat by circulating fluid through its channels. The thermostat regulates the temperature, allowing the flow of coolant when necessary. Another essential part is the water pump, responsible for moving the liquid throughout the entire system. Lastly, cooling fans support airflow to maintain the ideal thermal balance during operation.

Air Intake Mechanism and Its Role

The air intake system plays a crucial role in ensuring that the necessary flow of fresh air reaches the system that powers the vehicle. It optimizes airflow, improving the overall performance and efficiency of the vehicle by allowing the proper mix of air to combine with other essential components.

Here are some of the key elements of the air intake mechanism:

- Filter: This component ensures that the incoming air is free of dust, dirt, and other particles before it enters the combustion process.

- Throttle Body: Regulates the amount of airflow entering the system, which directly affects the vehicle’s responsiveness.

- Intake Manifold: Evenly distributes the air to all required sections, ensuring smooth and consistent performance.

Understanding how the air intake mechanism functions and its importance in vehicle performance can help in diagnosing issues and maintaining optimal operational efficiency.

Understanding the Fuel System Layout

In any vehicle, the fuel system plays a vital role in ensuring efficient performance. This system is designed to store and deliver fuel to the necessary components in an organized and controlled manner. Understanding its structure can help diagnose potential issues and enhance overall functionality.

Main Components and Their Functions

The system consists of several key elements working together to ensure smooth operation. Each component has a specific role in transporting fuel and maintaining pressure levels to meet the vehicle’s requirements.

- Fuel Tank: Serves as the primary reservoir for storing the necessary liquid, equipped with safety features to prevent leaks.

- Pump: Responsible for moving the fuel from the tank to the distribution channels, ensuring consistent flow under varying conditions.

- Fuel Filter: Protects the system by removing impurities and contaminants, preventing damage to sensitive parts.

- Fuel Lines: These are the conduits that transport the fuel throughout the system, connecting the tank, pump, and injectors.

- Injectors: These precisely control the delivery into the combustion area, optimizing the mixture for proper performance.

Ensuring Proper Maintenance

Routine checks of the fuel system can prevent issues such as clogging or leaks. It’s essential to ensure the filter is replaced regularly, and the pump is inspected for consistent operation. Addressing these aspects can greatly improve overall

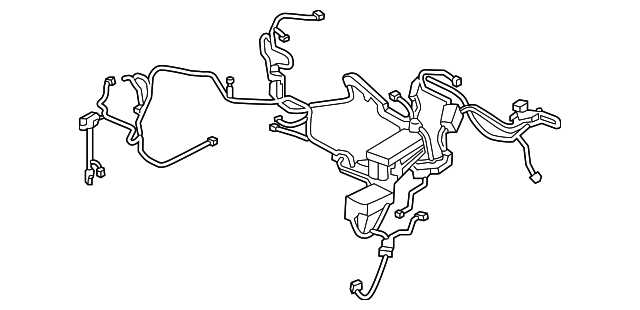

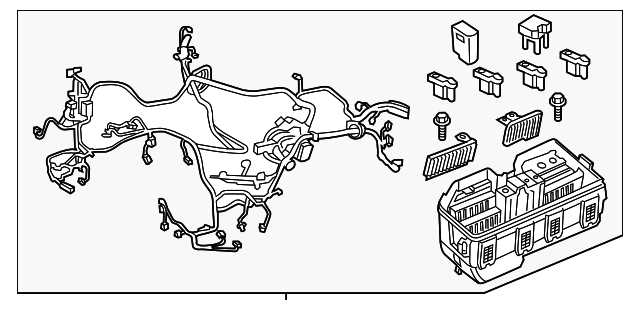

Electrical Components and Wiring Overview

This section provides a comprehensive look at the various electrical elements and their connections within the vehicle’s compartment. Understanding these components is essential for troubleshooting and ensuring proper functionality, as they play a crucial role in the overall performance of the system.

Key Electrical Elements

- Battery: The primary power source that provides energy for starting the vehicle and powering electrical accessories.

- Alternator: A device that generates electricity while the vehicle is running, recharging the battery and powering the electrical system.

- Fuses: Safety devices that protect electrical circuits from overloads by breaking the connection when the current exceeds safe levels.

- Relays: Electromechanical switches that control the flow of electricity to various components, allowing for remote operation.

- Wiring Harness: A collection of wires that transmit electrical signals between various components, organized to prevent tangling and damage.

Common Wiring Issues

- Corrosion: Deterioration of electrical connections due to moisture, leading to poor conductivity and potential failures.

- Frayed Wires: Damage to insulation that exposes wires, which can cause short circuits or electrical shorts.

- Loose Connections: Poorly connected terminals that can result in intermittent power loss or malfunctioning components.

- Short Circuits: Unintentional paths created in the wiring that allow current to flow outside of its intended route, potentially causing component damage.

Brake System Components in the Engine Bay

The braking system is a crucial aspect of any vehicle’s performance, ensuring safe stopping and control. Within the confines of the under-hood area, several vital elements work together to achieve optimal braking functionality. Understanding these components is essential for maintaining and troubleshooting the overall system.

Master Cylinder: This component serves as the heart of the braking mechanism, generating hydraulic pressure that activates the brakes. It converts the force applied on the brake pedal into hydraulic force, ensuring effective stopping power.

Brake Booster: The brake booster enhances the braking effort applied by the driver, utilizing vacuum pressure to multiply the force exerted on the pedal. This mechanism makes it easier to engage the brakes, requiring less effort from the driver.

Brake Lines: These tubes transport brake fluid from the master cylinder to the braking units at each wheel. Made of durable materials, they must withstand high pressures and various environmental conditions.

ABS Control Module: For vehicles equipped with Anti-lock Braking System (ABS), this electronic module plays a vital role. It monitors wheel speed and adjusts brake pressure accordingly to prevent wheel lock-up during sudden stops, improving stability and control.

Calipers: Mounted over the brake rotors, calipers house the brake pads and are responsible for applying pressure to the pads against the rotors, creating the necessary friction to slow down the vehicle.

Brake Pads: These friction materials are essential for the braking process. When the calipers compress the pads against the rotors, they generate the friction required to halt the motion of the wheels.

Each of these components plays an integral role in the overall effectiveness of the braking system. Regular inspection and maintenance of these elements ensure safety and reliability on the road.

Exhaust System and Emission Control Parts

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. It is responsible for directing exhaust gases away from the combustion area, ensuring a smooth and effective expulsion of byproducts created during the fuel-burning process. Additionally, this system contributes to minimizing harmful emissions, thereby adhering to environmental regulations and improving air quality.

Components of the exhaust system include various elements that work in harmony to achieve optimal functionality. The primary component is the manifold, which collects exhaust gases from multiple cylinders and directs them toward the rest of the system. Following the manifold is the catalytic converter, a vital element that transforms harmful pollutants into less harmful substances before they exit the vehicle. This converter utilizes chemical reactions to break down toxins, significantly reducing the environmental impact.

Another essential component is the muffler, which serves to minimize noise produced by the exhaust gases as they exit the vehicle. It does this through a series of chambers and perforated tubes that dissipate sound waves. In addition to these elements, the exhaust system includes pipes that connect all components, ensuring an efficient flow of gases.

Emission control devices are integral to maintaining compliance with environmental standards. These devices, such as the oxygen sensors, monitor the oxygen levels in the exhaust gases and provide feedback to the vehicle’s management system for optimal performance. By doing so, they ensure that the combustion process is as clean and efficient as possible.

Overall, the exhaust system and associated emission control mechanisms are critical for both vehicle performance and environmental protection. Their proper function not only enhances driving experience but also plays a significant role in reducing harmful emissions.