When maintaining your garden machinery, having a clear representation of its components is essential for efficient repairs and upgrades. A well-organized visual reference can significantly simplify the process of identifying each element within the system, enhancing both understanding and functionality.

In this section, we will delve into a detailed illustration that showcases the various segments of a popular riding mower model. By examining this visual guide, enthusiasts and professionals alike can better grasp how each piece interacts and contributes to the overall performance of the machine.

Whether you are troubleshooting an issue or planning for a seasonal tune-up, familiarizing yourself with these elements will empower you to tackle maintenance tasks with confidence. Let’s explore the intricacies of your machinery and unlock the potential for optimal operation.

Understanding the Cub Cadet LT1046

This section explores the intricacies of a specific model of lawn equipment, emphasizing its components and how they function together. Gaining insight into the various elements of this machine will enhance your maintenance skills and overall appreciation of its design. From the engine to the cutting system, each part plays a critical role in ensuring optimal performance.

Key Features

Understanding the essential features of this mower is vital for effective operation. This model is designed to deliver a reliable and efficient cutting experience, with several aspects contributing to its functionality:

| Feature | Description |

|---|---|

| Engine | Powerful and efficient engine providing robust performance. |

| Cutting Deck | Durable deck ensuring even grass trimming. |

| Transmission | Smooth and responsive transmission for ease of control. |

| Wheels | Sturdy wheels designed for maneuverability on various terrains. |

Maintenance Considerations

Proper upkeep is essential for prolonging the life of your equipment. Regular checks and timely replacements of key elements can prevent breakdowns and enhance performance. Be attentive to the following aspects:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours of operation |

| Blade Sharpening | Every 25 hours of use |

| Air Filter Cleaning | Monthly |

| Tire Pressure Check | Before each use |

Key Components of the LT1046

The efficient operation of any lawn care machine relies heavily on its essential elements, each playing a critical role in overall performance. Understanding these fundamental parts allows users to maintain their equipment effectively and ensure longevity in service. In this section, we will explore the primary components that contribute to the functionality and reliability of the model in question.

At the heart of the machine is the powerful engine, designed to deliver robust performance while optimizing fuel efficiency. This engine not only provides the necessary power for cutting but also drives various attachments, enhancing versatility. Equally important is the cutting deck, which is engineered to offer precision and durability. Its design allows for a clean cut, promoting healthy grass growth and an attractive lawn appearance.

The transmission system is another vital aspect, enabling smooth operation and ease of use. This component ensures that power is effectively transmitted from the engine to the wheels, allowing for seamless navigation across different terrains. Additionally, the steering mechanism plays a crucial role in maneuverability, allowing operators to navigate tight spaces with ease.

Lastly, the safety features integrated into the design cannot be overlooked. These components are essential for protecting the user during operation, providing peace of mind while maintaining the landscape. By familiarizing oneself with these key elements, users can better appreciate their equipment and ensure it remains in optimal condition for years to come.

Importance of Regular Maintenance

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Consistent maintenance helps prevent unexpected failures and can significantly reduce repair costs over time. By investing time in routine checks and services, users can enjoy enhanced efficiency and reliability from their equipment.

Benefits of Routine Upkeep

Implementing a systematic maintenance schedule offers numerous advantages. These include:

| Benefit | Description |

|---|---|

| Increased Lifespan | Regular checks and repairs can extend the operational life of the machine. |

| Improved Efficiency | Well-maintained equipment operates more effectively, saving time and energy. |

| Cost Savings | Preventive measures help avoid costly repairs and replacements. |

| Safety | Routine maintenance ensures that the machinery is safe to operate, reducing the risk of accidents. |

Key Maintenance Practices

To achieve the best results, it’s important to adopt a few key practices:

- Regularly check and change fluids.

- Inspect belts and hoses for wear and tear.

- Clean air filters to ensure proper airflow.

- Sharpen blades or cutting tools to maintain performance.

By following these guidelines, users can ensure that their machinery remains in excellent condition and performs efficiently for years to come.

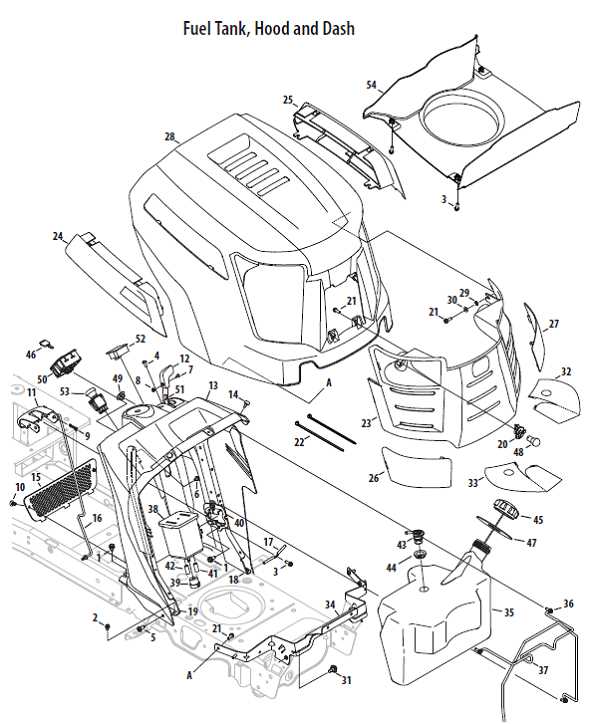

How to Access the Parts Diagram

Finding the schematic representation of components for your equipment can significantly streamline maintenance and repair tasks. This visual guide is essential for identifying individual elements and understanding their relationships within the machine. Accessing this illustration is a straightforward process if you know where to look.

To obtain the schematic, start by visiting the manufacturer’s official website. Look for the section dedicated to support or resources, where you can typically find documentation and manuals related to your specific model. You may need to input the model number to narrow down the search.

Another effective method is to consult online forums or community groups dedicated to similar equipment. Enthusiasts and professionals often share valuable resources, including links to diagrams and user experiences that can help you navigate the schematic more effectively.

If digital resources are not available, consider reaching out to local dealerships or repair shops. They usually have access to detailed guides and can provide you with the necessary illustrations upon request.

Common Replacement Parts for LT1046

When maintaining outdoor equipment, certain components often require replacement due to wear and tear. Understanding which items are most commonly needed can significantly enhance the longevity and performance of your machine. Here, we explore essential elements that may need attention over time.

Blades: One of the most frequently replaced components is the cutting blade. Over time, blades can become dull or damaged, impacting cutting efficiency. Regularly inspecting and replacing these can ensure a clean and precise cut.

Belts: Drive and mower belts are crucial for optimal operation. They can wear out due to friction and tension, necessitating periodic replacement to avoid breakdowns during use.

Filters: Air and oil filters play a vital role in maintaining engine health. Clogged filters can hinder performance, making it essential to replace them regularly for smooth operation.

Battery: The battery is a key component that provides power to the engine. Over time, batteries can lose their ability to hold a charge, requiring replacement to ensure reliable starting and operation.

Wheels and Tires: As with any equipment that experiences regular movement, wheels and tires can wear down. Inspecting and replacing them when necessary can improve maneuverability and safety.

Staying proactive about these common replacements can lead to a more efficient and reliable machine, ensuring that it meets your needs season after season.

Identifying Parts by Model Number

Understanding how to identify components by their unique identifiers is crucial for efficient maintenance and repair. Each model comes with specific numbers that help users find the exact elements they need for replacement or enhancement. This section will guide you through the process of recognizing these identifiers and utilizing them effectively.

Why Model Numbers Matter

Model numbers serve several important purposes:

- They ensure compatibility with various components.

- They simplify the ordering process from suppliers.

- They help in locating user manuals and technical resources.

How to Find Model Numbers

Locating the model number can be straightforward if you know where to look:

- Check the manufacturer’s label, usually found on the chassis or underneath the seat.

- Refer to the original purchase documentation or user manual.

- Look for it in online resources or databases dedicated to machinery parts.

By accurately identifying these numbers, you can streamline your maintenance tasks and ensure your equipment operates smoothly.

Tips for Ordering Replacement Parts

When it comes to maintaining your outdoor equipment, ensuring you have the correct components is essential for optimal performance. Whether you are dealing with a mower or any other machinery, understanding how to effectively procure the necessary items can save you time and money.

Identify Your Equipment

Before placing an order, make sure to accurately identify your machinery. Check the model and serial numbers, as these details are crucial when searching for specific items. This information will help you avoid the hassle of incorrect orders and ensure compatibility with your existing system.

Research Suppliers

Not all suppliers offer the same quality or pricing. Take the time to compare various vendors, looking for reviews and ratings from other customers. A reliable source will often provide warranties and return policies, which can be beneficial if the component doesn’t meet your expectations. Additionally, consider reaching out to your community for recommendations on trustworthy retailers.

By following these guidelines, you can streamline the process of obtaining necessary components, ensuring your equipment runs smoothly and efficiently.

Using the Diagram for Repairs

Understanding the layout of components is essential for effective maintenance and troubleshooting. A visual representation can significantly simplify the repair process by clearly illustrating the relationships between various elements. This guide will help you utilize such illustrations to identify issues and ensure that you can address them efficiently.

When examining the illustration, pay close attention to each section. Start by locating the problematic area and cross-referencing it with the accompanying labels. This approach allows you to pinpoint specific parts that may need attention or replacement. Familiarizing yourself with the assembly will enable you to work systematically, reducing the likelihood of overlooking crucial details.

In addition, understanding how components fit together aids in reassembly. Having a clear visual reference minimizes confusion and ensures that everything is returned to its correct position. Always take your time to compare your progress against the illustration, especially when dealing with intricate systems.

Overall, leveraging a well-structured visual reference is a powerful tool for anyone looking to perform repairs confidently and accurately. By breaking down the task into manageable parts, you can enhance both your efficiency and the quality of your work.

Resources for LT1046 Owners

Maintaining your equipment efficiently requires access to various tools and information. For enthusiasts and users, finding reliable resources can greatly enhance the ownership experience and ensure optimal performance.

Essential Online Guides

Numerous websites offer comprehensive manuals, troubleshooting tips, and community forums. These platforms enable users to share experiences and solutions, creating a valuable knowledge base.

Local Retailers and Service Centers

Visiting nearby shops can provide hands-on assistance and access to necessary supplies. Local experts can offer personalized advice tailored to specific needs.

| Resource Type | Description |

|---|---|

| Online Manuals | Detailed guides for operation and maintenance. |

| Forums | Community discussions for troubleshooting and tips. |

| Retail Shops | Local stores for parts and expert advice. |