The efficient operation of any outdoor machine depends largely on the proper function and alignment of its various mechanical elements. These components work together to ensure smooth performance and reliability, making it essential to have a clear understanding of their structure and how they interact. Whether you are performing maintenance or simply exploring how these systems operate, gaining insight into the assembly is crucial.

In this guide, we will explore the main sections of the equipment, providing a breakdown of key elements and their positioning. Knowing where each part fits into the overall system can significantly improve your ability to handle troubleshooting or repairs. By familiarizing yourself with the setup, you’ll be better equipped to manage upkeep and ensure consistent performan

Overview of Powersmart Lawn Mower Components

Modern cutting machines consist of various interconnected systems that work together to ensure efficient grass cutting and smooth operation. These systems typically include mechanisms for propulsion, blade movement, and user control, which are crucial for providing optimal performance and ease of use. Each part has a specific role, contributing to the overall functionality of the machine, and ensuring that it runs smoothly under different conditions.

The engine, cutting deck, and control handles form the core of the structure. These elements, along with the wheels and other support components, help achieve both power and maneuverability. By understanding how each section operates, users can better maintain the machine and ensure its long-lasting performance in different terrains.

Main Features and Functions of Mower Parts

The various components of a cutting machine work together to ensure efficient operation and optimal performance. Understanding the key characteristics and roles of each element can help maintain the equipment in top condition, ensuring smooth and precise trimming results.

Engine system: The core of the machine, the engine provides the necessary power to drive the cutting blades and move the unit across the surface. It is designed to handle a range of terrains while maintaining a consistent level of performance.

Blade mechanism: The cutting blades are crucial for ensuring a clean and even trim. They rotate at high speeds to slice through different types of grass, and their sharpness and design are critical for achieving smooth cuts.

Height adjustment: This function allows users to modify the cutting height to suit various grass lengths and preferences. The flexibility in setting the desired height enhances the versatility of the equipment.

Wheels and traction: The wheels, along with the traction sys

Blade Mechanism and Cutting Efficiency

The efficiency of the cutting mechanism is crucial for achieving precise and consistent results. The design and function of the blades directly influence the sharpness and precision of the cutting process, ensuring smooth operation under various conditions. Understanding how the mechanism works helps in optimizing performance and prolonging the lifespan of the equipment.

| Component | Function |

|---|---|

| Blade | Responsible for slicing through materials efficiently, ensuring a clean and uniform cut. |

| Spindle | Connects the blade to the motor, transferring rotational force for effective cutting. |

| Deck | Houses the blade, creating a controlled environment for optimized cutting performance. |

Engine and Power System Structure

The core of any outdoor machine’s functionality lies in the design and arrangement of its engine and power system. These components work together to provide the necessary energy to operate the equipment efficiently. The engine converts fuel into mechanical energy, while the power system distributes this energy to different parts, ensuring smooth and consistent performance.

Internal combustion engines are commonly used, where fuel ignites inside a chamber, creating controlled explosions that drive pistons. The power system then directs this motion through a series of belts and gears, translating it into the needed mechanical force.

Additionally, various safety mechanisms and regulators are integrated into the engine structure to maintain proper energy flow and prevent overload. The careful balance of all these elements ensures that the machine runs smoothly and responds well to different conditions, making it a reliable tool for various tasks.

Wheels and Maneuverability Enhancements

Improving the movement capabilities of outdoor equipment can significantly affect its overall functionality, allowing smoother control over various terrains. Key features of these adjustments focus on the design and flexibility of the wheels, aiming to provide better handling and adaptability for users.

Wheel Design and Material

Wheels crafted from durable materials are essential for long-lasting use and efficient motion. These components often include reinforced rubber or composite materials, ensuring both resilience and traction. The wheel diameter can also influence how easily the machine can navigate uneven surfaces or tight spaces.

Maneuverability Adjustments

Enhancing the ability to steer or rotate the equipment often involves adjustments in wheel positioning or adding additional sw

Handle and Control Adjustments

Making the necessary adjustments to the handle and controls of your equipment is essential for optimal performance and user comfort. Proper alignment and settings can enhance maneuverability and ease of use, ensuring that you can operate the machine efficiently while minimizing fatigue.

Adjusting the Handle Height

The handle height can significantly affect your experience when operating the device. Ensuring that it is at a comfortable level is crucial for maintaining good posture and control. Many models feature adjustable handles that allow you to set the height according to your preferences.

Control Settings

In addition to handle adjustments, fine-tuning the control settings is equally important. This includes adjusting the throttle response and ensuring that all controls are easily accessible and functional. Regular maintenance of these components will help maintain the equipment’s reliability and performance.

| Adjustment Type | Description | Recommended Action |

|---|---|---|

| Handle Height | Setting the handle to a comfortable position for effective operation. | Loosen the adjustment knobs and raise or lower as needed. |

| Throttle Control | Adjusting the responsiveness of the speed settings. | Test the throttle response and adjust the tension accordingly. |

| Control Accessibility | Ensuring that all controls are within easy reach and functional. | Inspect controls for wear and tear, replacing any faulty components. |

Fuel System and Maintenance Tips

Proper care and attention to the fuel system can significantly enhance the performance and longevity of your equipment. Regular maintenance ensures that fuel delivery remains efficient and reduces the risk of operational issues.

Here are some essential tips for maintaining the fuel system:

- Always use fresh fuel to prevent clogging and buildup in the system.

- Check and clean the fuel filter regularly to ensure optimal fuel flow.

- Inspect fuel lines for any signs of wear, leaks, or damage that could lead to contamination.

- Store fuel in a cool, dry place to maintain its quality and prevent degradation.

Additionally, it’s beneficial to follow these maintenance practices:

- Replace the fuel filter according to the manufacturer’s recommendations.

- Flush the fuel system if the equipment has been unused for an extended period.

- Keep the fuel tank clean and free from debris or contaminants.

- Consider adding a fuel stabilizer to enhance the fuel’s shelf life.

By adhering to these guidelines, you can ensure the reliability and efficiency of your equipment’s fuel system.

Safety Features and Protective Elements

Ensuring user safety during operation is crucial when working with outdoor equipment. Various protective components are integrated to minimize the risk of accidents and enhance overall safety. These features are designed to safeguard the operator while maintaining the equipment’s performance and reliability.

Key Protective Components

Several essential elements contribute to the safe usage of this machinery. These include mechanisms that prevent accidental activation, shields that protect users from debris, and systems that automatically shut down the device in case of malfunction. Understanding these components is vital for safe operation.

Operational Safety Enhancements

Incorporating advanced safety measures can significantly reduce the likelihood of injuries. Features such as emergency stop buttons and operator presence controls are crucial in ensuring that the equipment functions safely. Additionally, routine maintenance checks can further enhance safety and performance.

| Safety Feature | Description |

|---|---|

| Emergency Stop Button | A control that immediately halts operation when pressed, ensuring quick cessation of activity in emergencies. |

| Operator Presence Control | A system that requires the operator to be in a designated position for the equipment to function, preventing unintended activation. |

| Debris Shield | A protective barrier that minimizes the risk of flying objects harming the operator during operation. |

| Automatic Shut-off | A feature that disables the machinery in case of a detected malfunction, promoting safety and preventing further damage. |

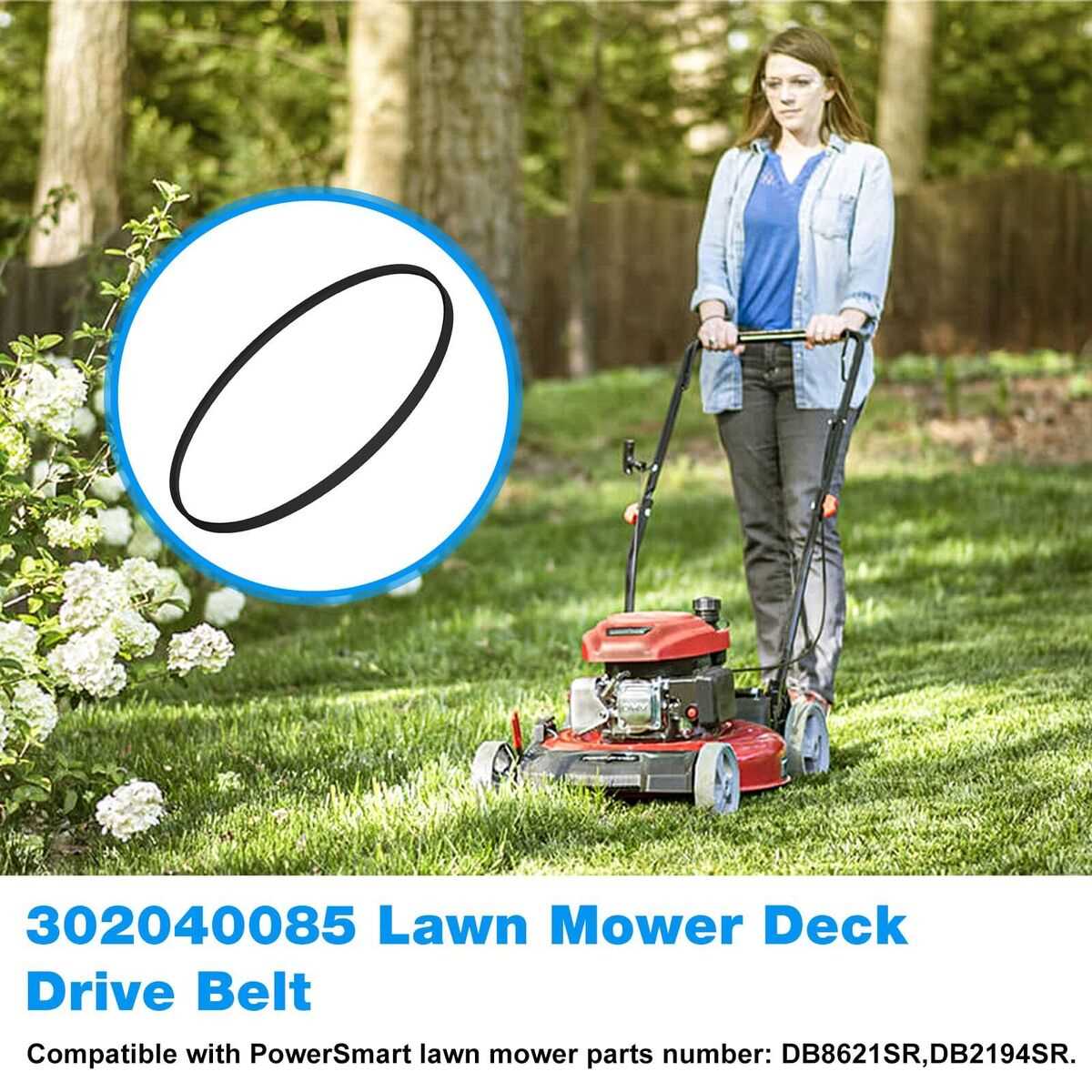

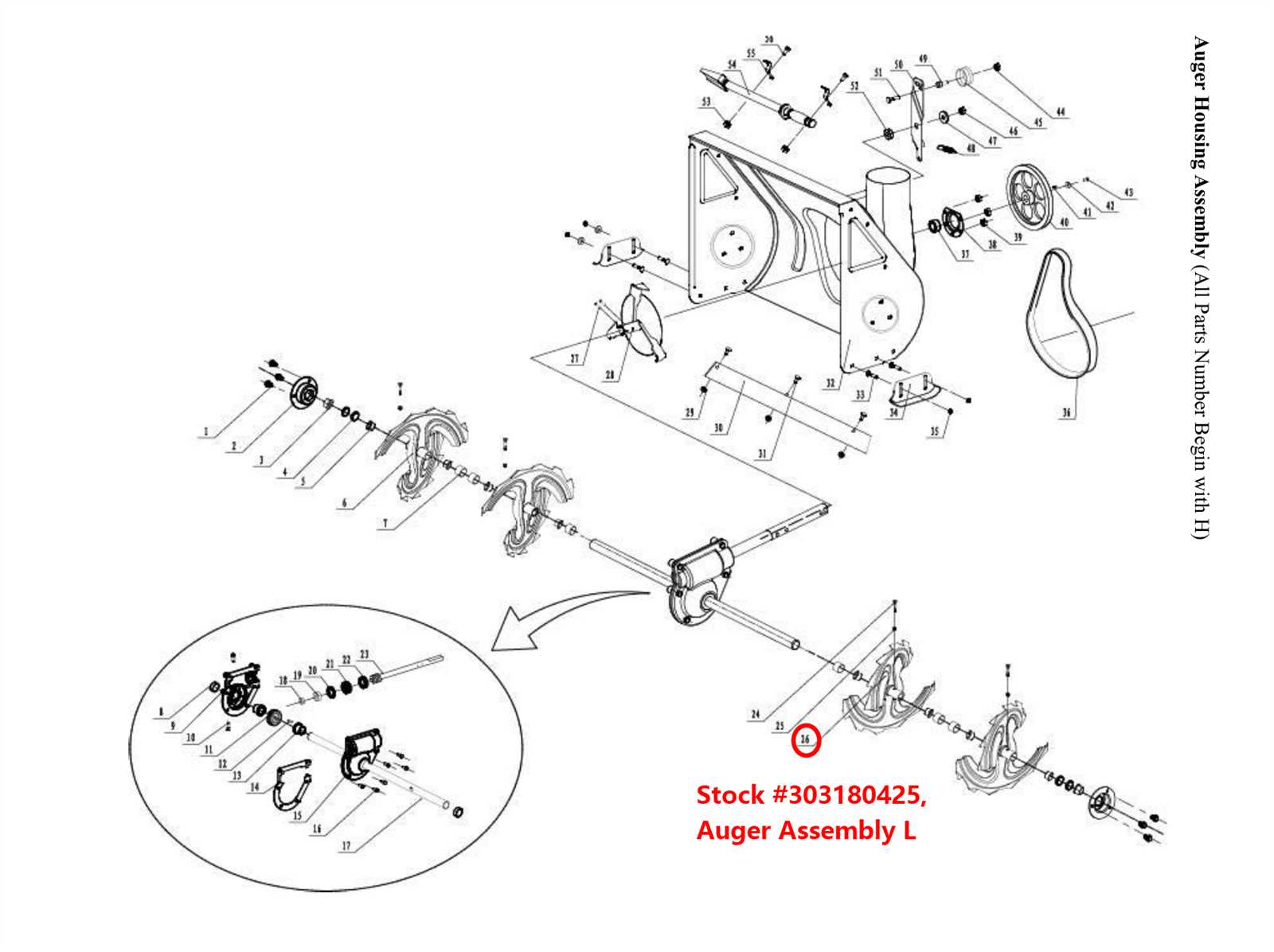

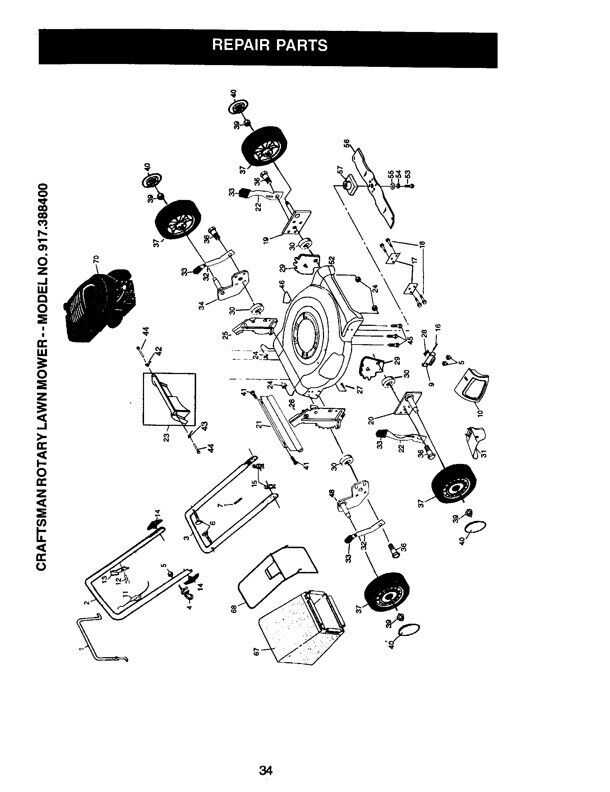

Replacement Parts and Compatibility Guide

When it comes to maintaining and enhancing your equipment, understanding the available components and their compatibility is crucial. Ensuring that the right elements are utilized can significantly impact performance and longevity. This section provides insights into various replacement options and guidance on how to select suitable alternatives that align with your specific model.

Identifying Components: To begin, it is essential to accurately identify the elements you need to replace. Common components may include blades, belts, and filters. Each piece plays a vital role in the overall functionality, so recognizing their condition is paramount. Regular inspections can help determine when a substitution is necessary.

Compatibility Considerations: Not all replacements are created equal. It is vital to verify that any new component is compatible with your device. This may involve checking model specifications or consulting with professionals. Using mismatched elements can lead to operational issues or even damage. Therefore, always refer to compatibility information before making a purchase.

Quality and Performance: Opting for high-quality replacements is another key factor in ensuring efficient operation. While it might be tempting to select cheaper options, investing in quality can yield better performance and durability in the long run. Researching trusted manufacturers can aid in making informed decisions that benefit your equipment.