Every mechanical device consists of a myriad of elements that work in harmony to ensure optimal performance. Grasping the intricate relationships between these individual components can significantly enhance your maintenance and troubleshooting skills. By examining these parts, users can gain valuable insights into their equipment’s functionality.

Identifying each segment is crucial for anyone looking to repair or optimize their machinery. A comprehensive overview of these essential elements not only aids in efficient upkeep but also extends the lifespan of the device. Whether you’re a seasoned professional or a novice, understanding the composition of your equipment is the ultimate key to successful operation.

Additionally, familiarizing yourself with the layout and roles of each piece can lead to a more intuitive handling experience. This knowledge empowers users to tackle issues with confidence, transforming potential challenges into manageable tasks. Delve into the specifics, and you will uncover the secrets to maximizing performance and reliability.

Powersmart DB7651-24 Overview

This section provides a comprehensive insight into a specific outdoor equipment model known for its efficiency and reliability. Understanding its design and functionality can help users make informed decisions regarding maintenance and upgrades.

- Engine Performance: Equipped with a robust engine, it ensures optimal power delivery.

- Durability: Built with high-quality materials, it offers long-lasting performance even in challenging conditions.

- User-Friendly Design: Features that enhance usability, making operation straightforward for users of all experience levels.

- Maintenance: Regular upkeep tips to maximize the lifespan of the equipment.

By exploring these aspects, users can delve deeper into the advantages this model offers for outdoor tasks.

Key Features of the Model

This model stands out due to its exceptional design and functionality, making it a reliable choice for various tasks. Users appreciate its innovative features that enhance performance and efficiency, ultimately contributing to a more seamless experience.

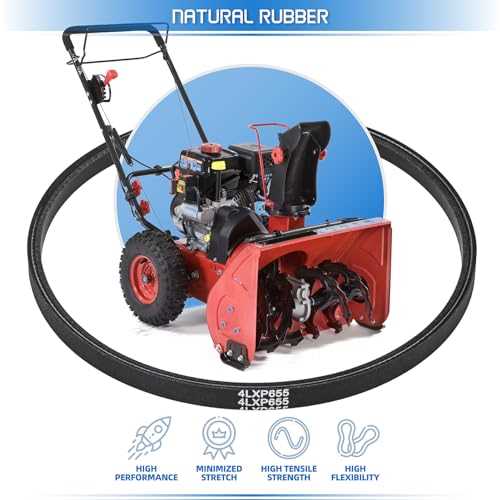

Durability: Constructed with high-quality materials, this device promises longevity, ensuring it withstands rigorous use in diverse conditions.

Power Efficiency: Engineered to optimize energy consumption, it provides impressive results while minimizing environmental impact.

Versatility: With multiple settings and attachments, it caters to a wide range of applications, making it suitable for both professional and personal use.

User-Friendly Interface: The intuitive controls and clear indicators allow for effortless operation, even for those new to such devices.

In summary, the standout characteristics of this model not only enhance its functionality but also make it an ultimate choice for those seeking reliability and effectiveness.

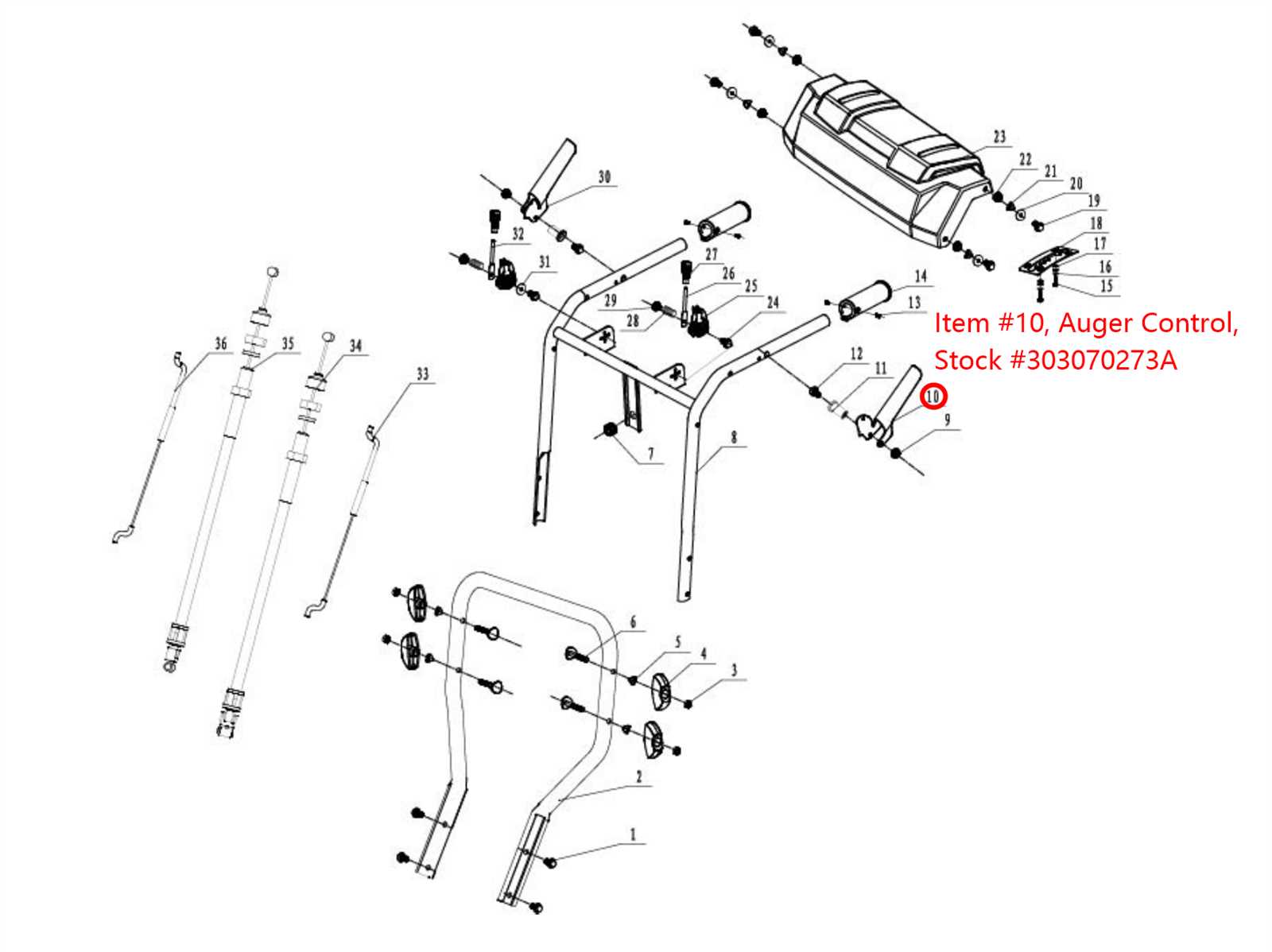

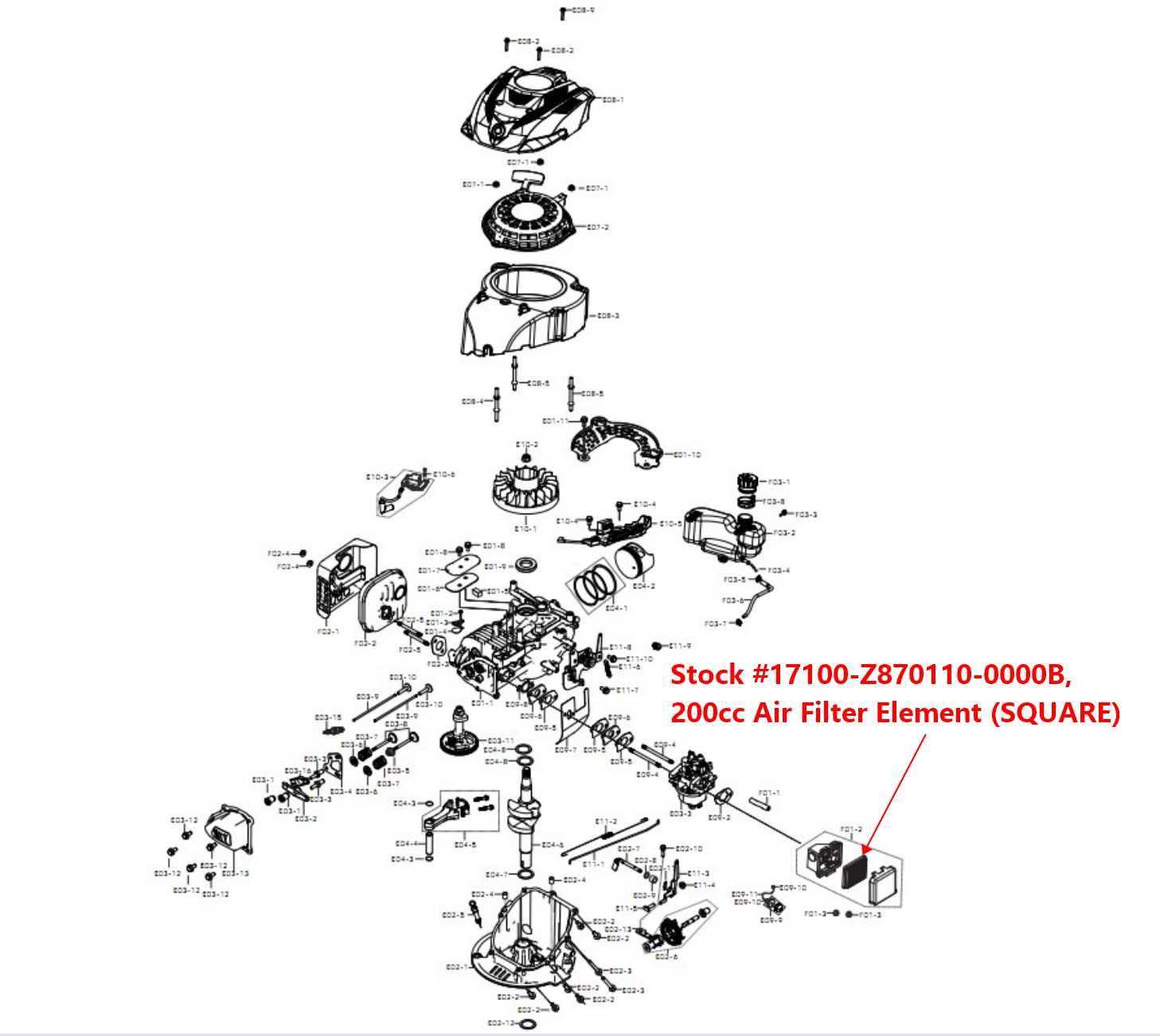

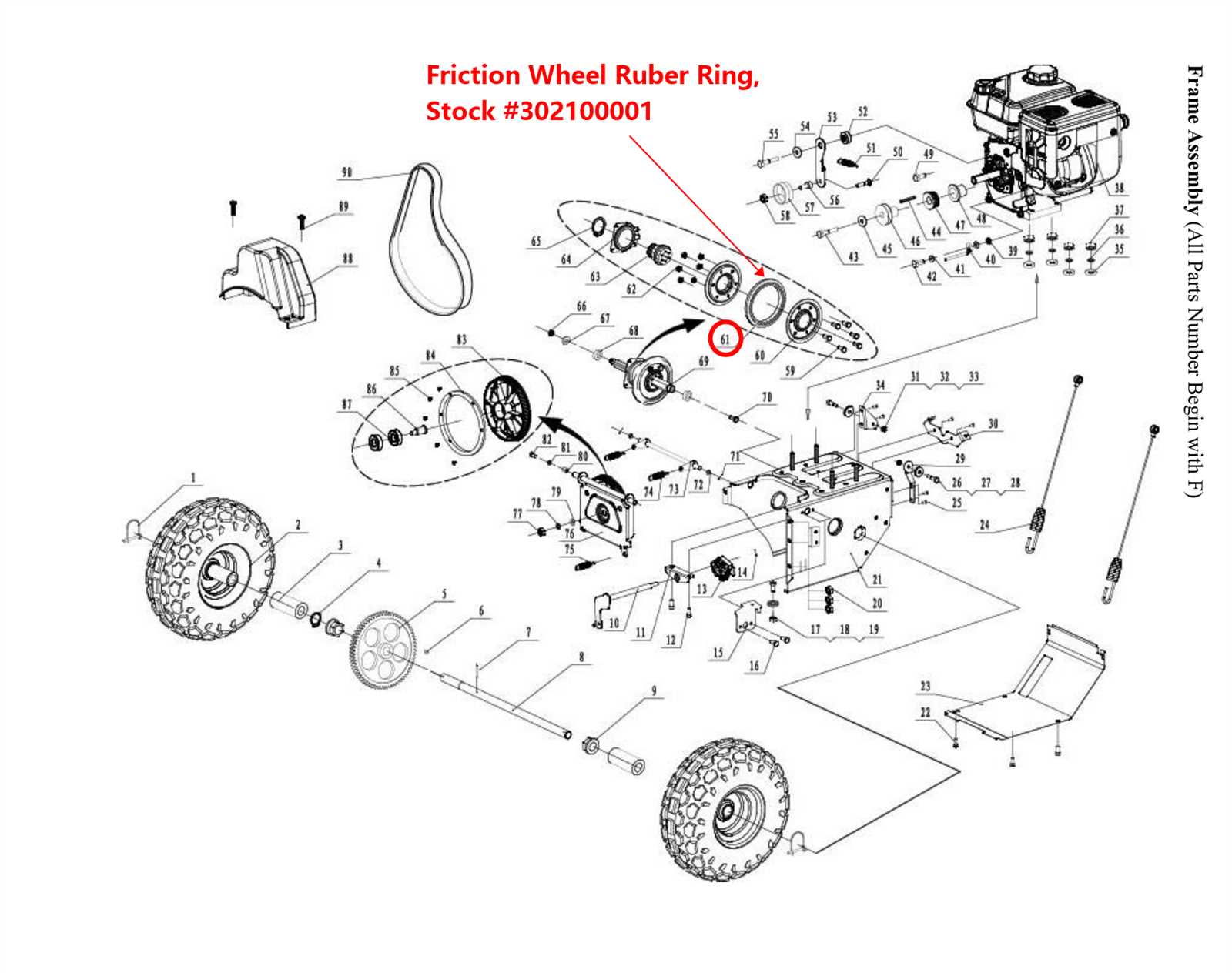

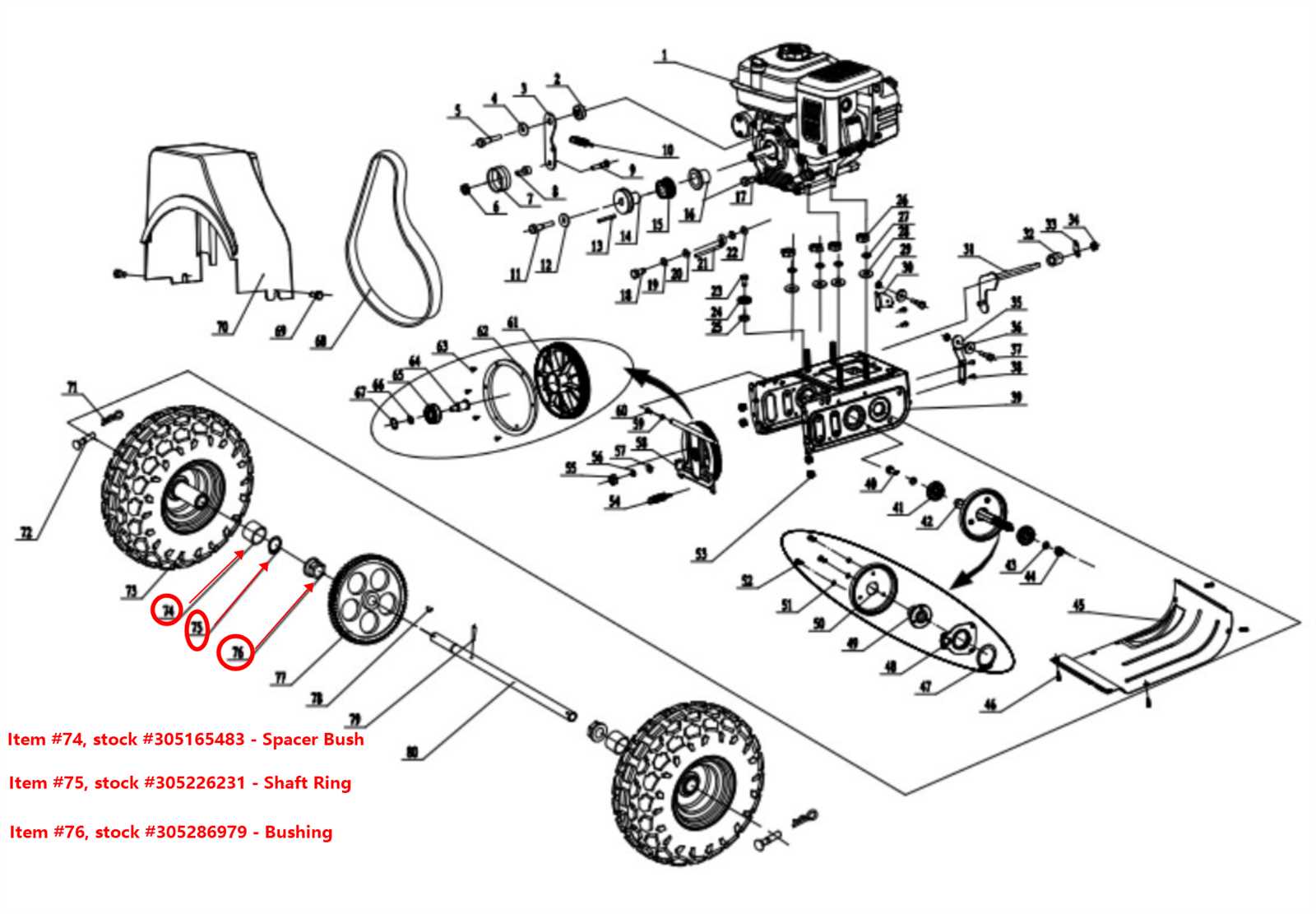

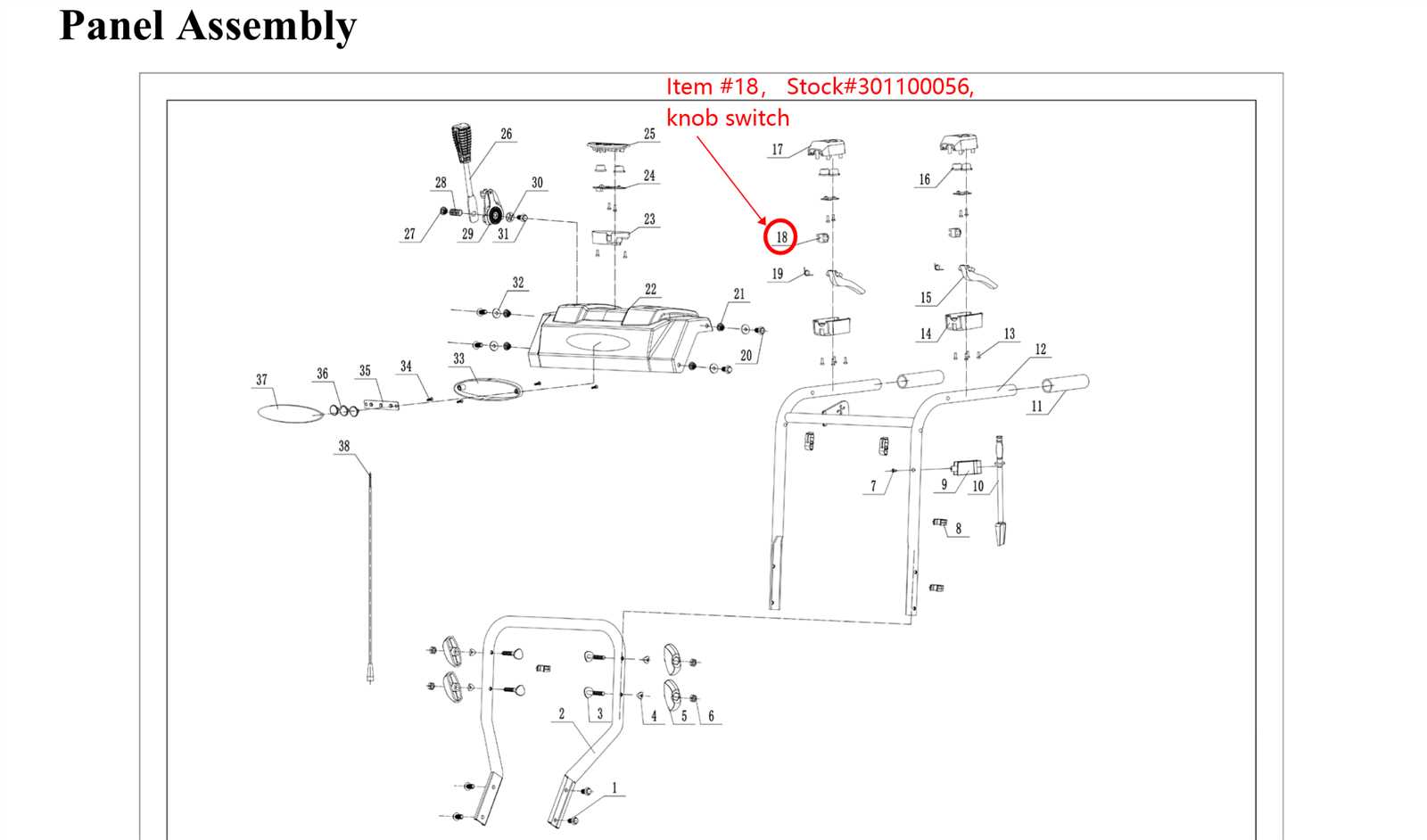

Understanding the Parts Diagram

Comprehending a technical illustration is essential for efficient maintenance and repair. Such representations serve as a visual guide, allowing users to identify components and their relationships within a device. By familiarizing oneself with this visual tool, users can enhance their troubleshooting skills and streamline the repair process.

To effectively interpret the illustration, consider the following aspects:

- Component Identification: Each part is labeled, making it easier to find and reference specific elements.

- Functionality: Understanding the role of each component aids in diagnosing issues and planning repairs.

- Assembly Structure: Observing how parts fit together helps in reassembly and ensures proper functioning.

When studying the illustration, keep these tips in mind:

- Take your time to explore each label carefully.

- Cross-reference the illustration with the user manual for additional context.

- Make notes of any parts that may need replacement or attention during maintenance.

By developing a solid grasp of the technical illustration, users can significantly improve their repair and maintenance efforts, leading to better performance and longevity of the equipment.

Common Components Explained

Understanding the essential elements of machinery is crucial for effective maintenance and operation. This section delves into the typical parts found in various models, highlighting their functions and importance in ensuring optimal performance.

Engine Components

At the heart of any equipment lies the engine, which is responsible for generating power. Key components include the cylinder head, which houses the valves and spark plugs, and the crankshaft, which converts linear motion into rotational force. Proper maintenance of these elements is vital for maximizing efficiency and longevity.

Transmission Elements

The transmission system is essential for transferring power from the engine to the wheels. Components such as the gearbox and clutch play a significant role in controlling speed and torque. Regular inspection of these parts helps in preventing operational failures and enhancing the overall driving experience.

How to Interpret the Diagram

Understanding a schematic representation of a machine can greatly enhance your ability to maintain and repair it. Such visuals serve as a roadmap, guiding users through the various components and their interrelations. Familiarity with the layout and symbols is essential for effective troubleshooting and assembly.

Firstly, it’s important to identify the key elements depicted. Look for labels and annotations that clarify each component’s function. These identifiers are typically placed alongside the respective parts, making it easier to understand their roles within the larger system. Pay close attention to any numerical or alphabetical codes, as they often indicate specific features or connections.

Next, observe how the elements are interconnected. Lines and arrows may represent physical connections or electrical pathways. Recognizing these linkages will aid in grasping how each part operates in conjunction with others. If you’re faced with a malfunction, tracing these connections can pinpoint the issue more effectively.

Additionally, take note of the overall layout. The arrangement often reflects the order of assembly or the flow of operation. Understanding this structure can facilitate more efficient repairs and modifications. If you’re ever uncertain, cross-reference with manuals or other resources for clarification.

Finally, practice is key. The more time you spend studying these illustrations, the more intuitive interpreting them will become. Hands-on experience combined with a solid understanding of the visual representation will empower you in your repair and maintenance endeavors.

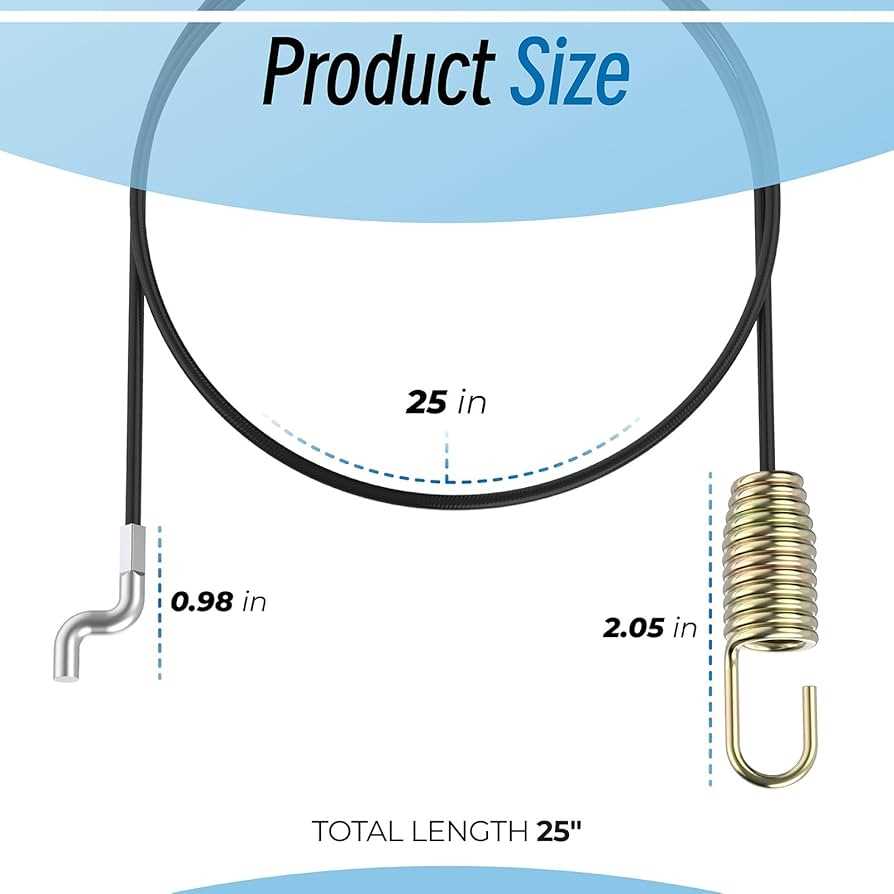

Identifying Replacement Parts

When maintaining or repairing machinery, recognizing the correct components is essential for ensuring optimal performance and longevity. Knowing how to identify specific elements can save time and resources, preventing unnecessary delays in the repair process. This section will guide you through the methods of determining which items require replacement.

Common Indicators for Replacement

- Visual Inspection: Look for signs of wear, damage, or corrosion.

- Performance Issues: Notice any irregularities in operation, such as unusual noises or decreased efficiency.

- Manufacturer’s Guidelines: Consult documentation for recommended service intervals and replacement suggestions.

Resources for Identification

- Consult the user manual for reference images and specifications.

- Visit manufacturer websites for detailed information and support.

- Engage with online forums or communities for insights from other users.

By utilizing these strategies, you can effectively pinpoint the necessary elements that need attention, ensuring your equipment remains in peak condition.

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor equipment requires regular attention and care. By following a structured maintenance routine, you can enhance performance, prevent issues, and ultimately save on costly repairs. Here are some essential tips to keep your machinery running smoothly for years to come.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 25 hours of operation | Use high-quality oil and check the level regularly. |

| Filter Cleaning | Every 10 hours of operation | Clean or replace air filters to ensure proper airflow. |

| Blade Sharpening | Every season | Keep blades sharp for better cutting efficiency and to reduce strain. |

| Spark Plug Inspection | Every 50 hours of operation | Replace if worn to ensure optimal ignition. |

| Fuel System Check | Every 3 months | Drain old fuel and replace with fresh to avoid clogging. |

By adhering to these guidelines, you can enhance the durability and efficiency of your equipment, ensuring that it remains reliable throughout its lifespan. Regular maintenance not only protects your investment but also contributes to safer operation.

Where to Purchase Parts

Finding the right components for your equipment is essential for maintaining its functionality and performance. Whether you need a replacement item or an upgrade, knowing where to look can save you time and money.

Online Retailers

Numerous online platforms offer a wide selection of components. Consider the following options:

- Amazon – A vast marketplace with numerous sellers.

- eBay – Great for finding both new and used items.

- Specialty Websites – Sites dedicated to specific brands often have exclusive parts.

Local Stores

Visiting local retailers can provide immediate access to needed components. Here are some places to check:

- Home Improvement Stores – Large chains often stock essential items.

- Hardware Stores – Local shops may have specialized parts.

- Authorized Dealers – Manufacturers’ representatives can be helpful.