In the world of outdoor machinery, comprehending the intricate assembly of various equipment is essential for efficient maintenance and repair. A clear visual representation of the individual elements can significantly enhance the understanding of how these machines function as a whole. This knowledge is not only beneficial for enthusiasts but also for those engaged in routine upkeep.

Having access to a detailed schematic allows users to identify each segment effectively, facilitating easier troubleshooting and replacement. With a well-organized illustration, it becomes simpler to pinpoint the specific parts that may require attention, ensuring that the mower operates smoothly and efficiently.

In this discussion, we will delve into the essential features of the machine, highlighting key components and their relationships. By breaking down the assembly, we aim to provide valuable insights that will assist in maintaining optimal performance and longevity of your equipment.

Understanding John Deere F525

This section explores the key aspects of a well-regarded outdoor machinery model, highlighting its features and functionality. Recognized for its reliability and performance, this equipment is designed for efficient operation in various landscaping tasks. A thorough understanding of its components and maintenance is essential for maximizing its capabilities.

Key Features

Renowned for its robust construction and user-friendly design, this machine offers several standout features that enhance user experience. It is equipped with a powerful engine, ergonomic controls, and a compact frame, making it suitable for both residential and commercial use. Additionally, its maneuverability allows for effective navigation in tight spaces, ensuring that every task is completed with precision.

Maintenance and Care

Regular upkeep is vital to ensure longevity and optimal performance. Following a structured maintenance schedule can prevent potential issues and enhance the overall efficiency of the equipment. Below is a summary of recommended maintenance practices:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Air Filter Check | Every 25 hours |

| Blade Sharpening | As needed |

| Tire Inspection | Monthly |

By adhering to these guidelines, users can ensure that their equipment remains in peak condition, providing reliable service for years to come.

Key Features of F525 Model

The model is renowned for its versatility and efficiency, making it an excellent choice for various landscaping tasks. With a combination of innovative design and reliable performance, it caters to both residential and commercial users. Understanding its standout features can help users maximize their experience and productivity.

Engine Performance

Equipped with a powerful engine, this model ensures consistent performance under varying conditions. The efficient fuel consumption allows for extended operation without frequent refueling, making it ideal for larger areas.

Maneuverability and Design

The compact design enhances maneuverability, allowing users to navigate tight spaces with ease. This characteristic is particularly beneficial for intricate landscaping and maintenance tasks.

| Feature | Description |

|---|---|

| Engine Type | Robust engine providing reliable power |

| Fuel Efficiency | Designed for extended usage without frequent stops |

| Compact Design | Allows for easy navigation in confined areas |

| Durability | Constructed with high-quality materials for longevity |

| Versatile Attachments | Compatible with a range of accessories for varied tasks |

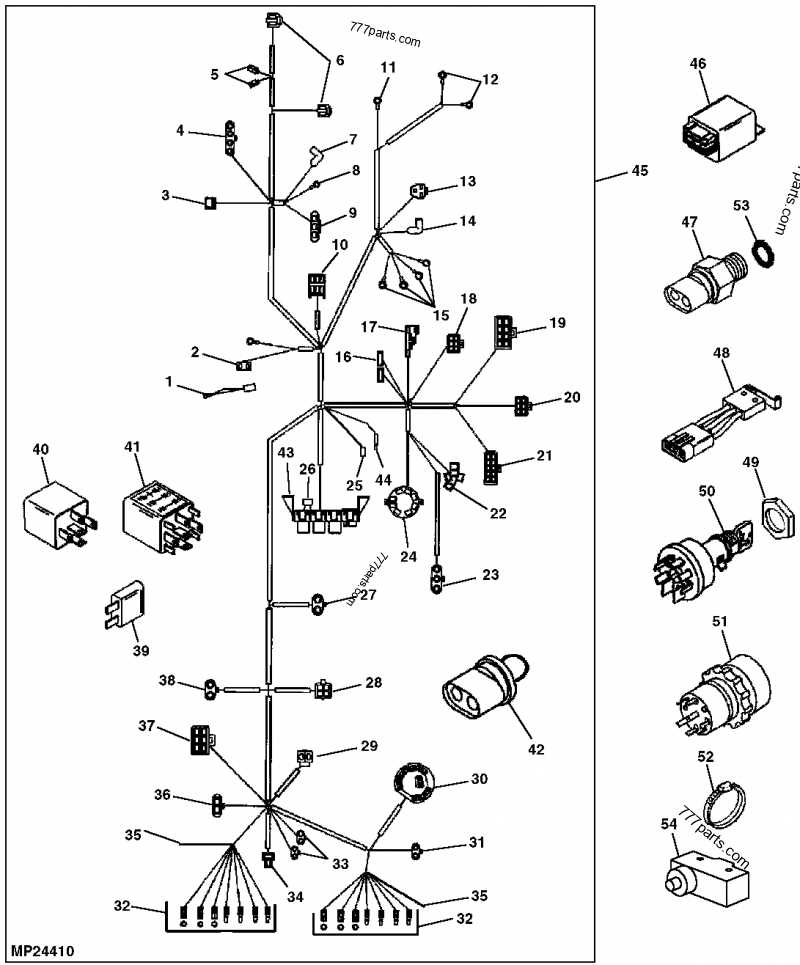

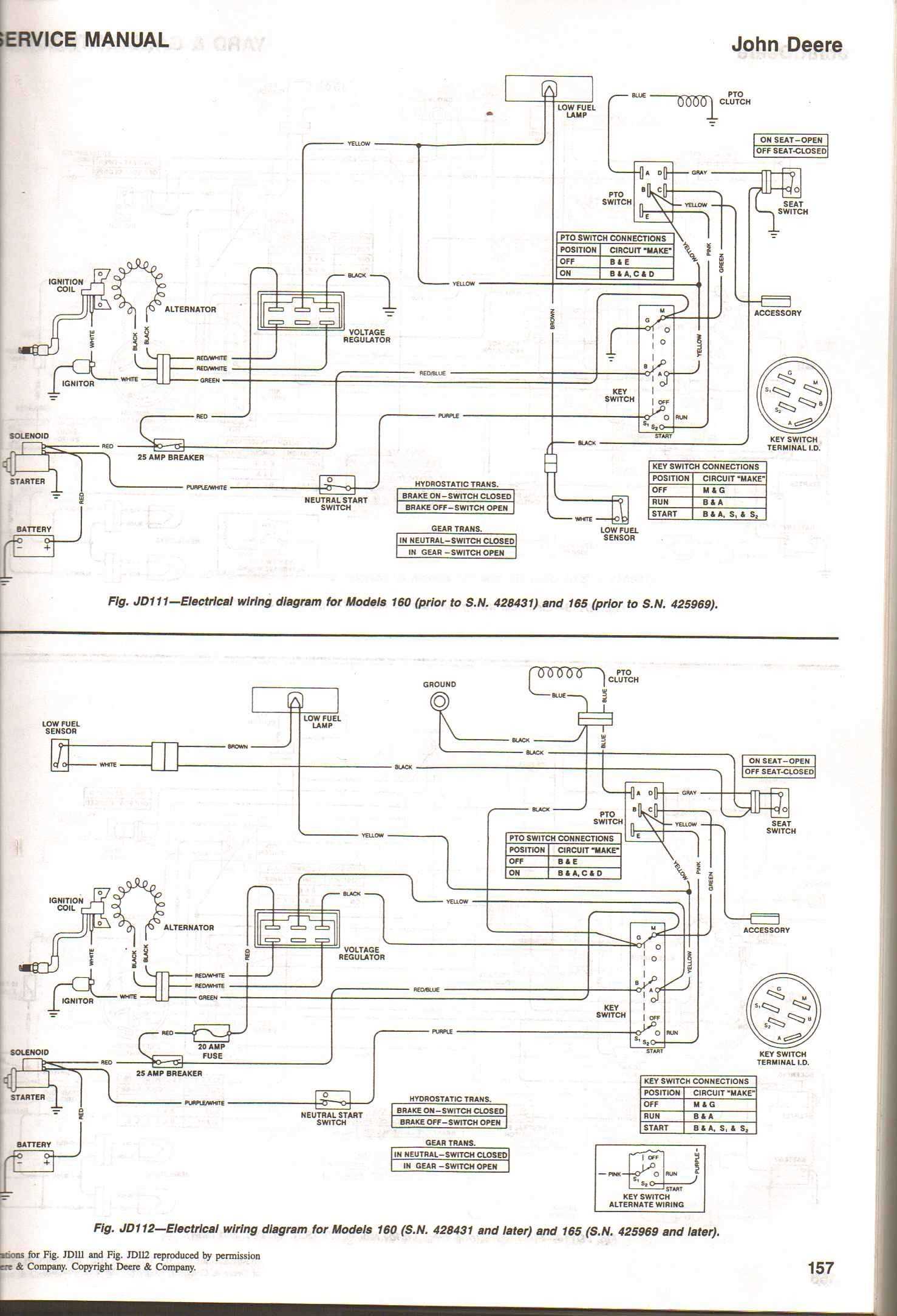

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools, providing clarity on how individual elements fit together and function. These illustrations help users identify specific components quickly, streamlining the process of locating and addressing issues.

Effective communication is another key benefit of these visual aids. They bridge the gap between technical terminology and practical understanding, enabling technicians and operators to collaborate more efficiently. With a clear overview, it becomes easier to share information regarding repairs and replacements, reducing the risk of miscommunication.

Moreover, having access to such visuals enhances educational opportunities. Newcomers to machinery maintenance can grasp complex systems more effectively, gaining insights into how everything operates in tandem. This foundational knowledge fosters a more skilled workforce, ultimately leading to better performance and reduced downtime.

In summary, visual guides play an indispensable role in the maintenance and repair of equipment, promoting understanding, efficiency, and effective collaboration among users.

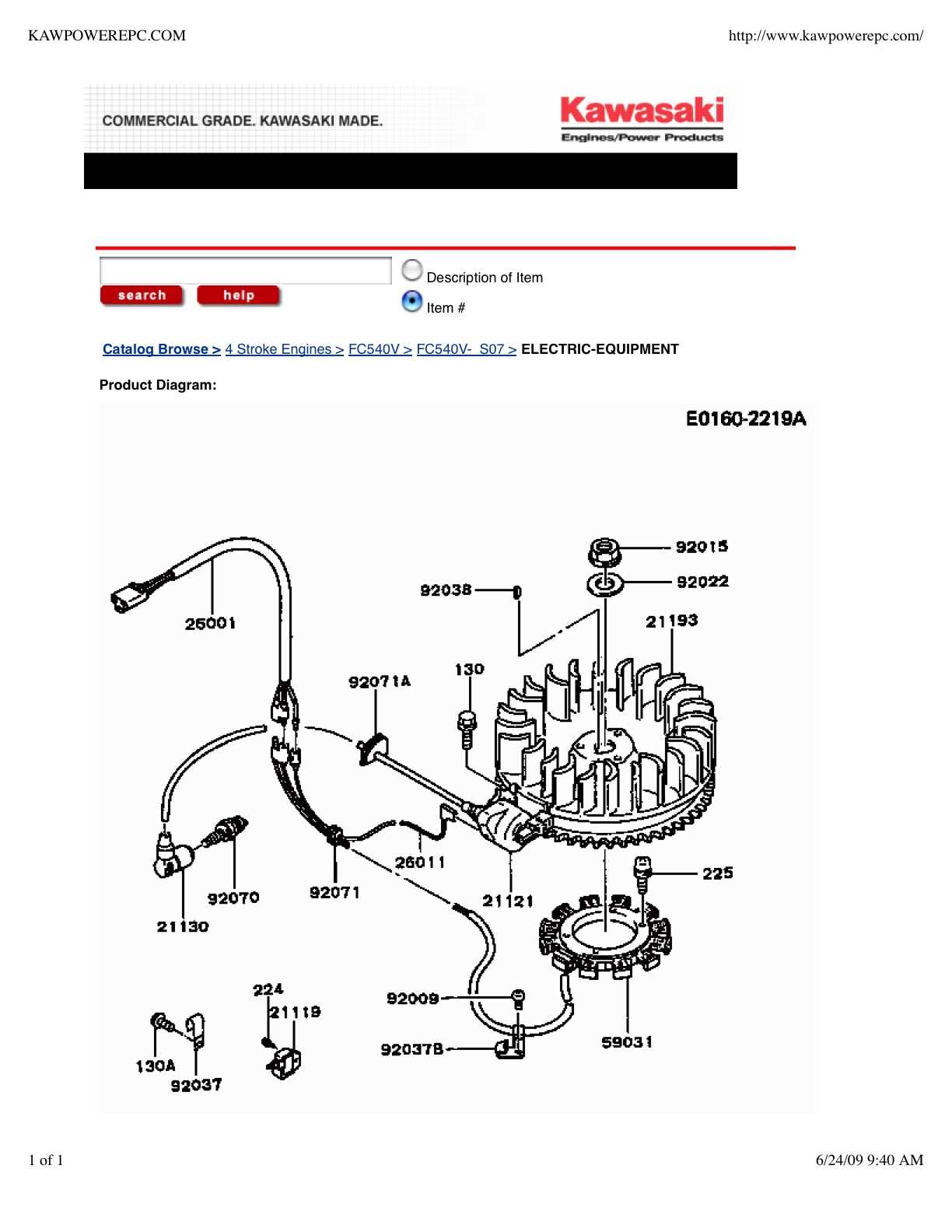

Common Parts for F525 Maintenance

Regular upkeep of your machine is essential for optimal performance and longevity. Understanding the key components involved in maintenance can help ensure that everything runs smoothly. Various elements contribute to the efficient functioning of your equipment, and recognizing these can simplify the maintenance process.

Essential Components

One of the primary elements to consider is the engine filter. This component plays a critical role in keeping the engine clean and functioning effectively. Regular replacement helps maintain proper airflow and prevents debris from causing damage.

Additionally, checking the spark plugs is vital. These components ignite the fuel-air mixture, and worn or dirty plugs can lead to starting issues and reduced performance. Ensuring they are in good condition can significantly enhance efficiency.

Other Key Elements

Don’t overlook the importance of the belts and blades. The belts are crucial for transferring power, while sharp blades ensure a clean cut. Regular inspection and replacement of these items are necessary to maintain the overall effectiveness of your machine.

Lastly, keeping an eye on the battery condition is essential for reliable operation. A well-maintained battery not only starts your equipment reliably but also supports all electrical systems. Regular checks can prevent unexpected breakdowns and prolong the lifespan of your machine.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair tasks. These visual representations serve as guides, helping users identify components and their interconnections. By familiarizing oneself with the structure of these images, anyone can navigate the complexities of machinery with greater confidence.

Key Elements of Technical Illustrations

- Labels: Each component is often marked with a unique identifier, facilitating easy reference.

- Numbers: Numerical codes frequently accompany labels to provide clarity on quantities or specific models.

- Connections: Arrows or lines may illustrate how parts interact, showing their relationships within the overall assembly.

Steps to Interpret the Illustration

- Examine the Legend: Start by reviewing any accompanying legend or key, which explains the symbols used.

- Identify Main Components: Locate major sections to gain an understanding of the overall layout.

- Trace Connections: Follow the lines or arrows to see how various elements fit together.

- Consult Documentation: Refer to manuals or specifications for additional information on each part.

By following these steps, anyone can become proficient at reading and interpreting these valuable tools, ultimately enhancing their repair and maintenance capabilities.

Ordering Replacement Parts Effectively

When it comes to maintaining your machinery, securing the correct components is essential for optimal performance and longevity. A well-organized approach to procurement can save time and money, ensuring you have what you need without unnecessary delays.

Steps to Follow

- Identify Your Needs: Before placing an order, assess the specific items required for your equipment. Check for model numbers and any relevant specifications.

- Research Suppliers: Look for reliable vendors that specialize in the items you need. Read reviews and compare prices to find the best options.

- Gather Information: Make a list of the necessary components, including part numbers, descriptions, and quantities.

- Contact Suppliers: Reach out to potential vendors to confirm availability and ask about shipping options. This step is crucial to avoid unexpected delays.

- Place Your Order: Once you’ve selected a supplier, complete your order with accuracy. Double-check all details before finalizing the transaction.

Tips for Successful Procurement

- Keep Records: Maintain a log of orders and receipts to track your spending and make future purchases easier.

- Check Return Policies: Understand the return policies of your suppliers in case you need to exchange or return items.

- Plan Ahead: Anticipate future needs by keeping an inventory of commonly used items to avoid last-minute rush orders.

- Build Relationships: Establish good rapport with suppliers for better service and potential discounts on bulk purchases.

Identifying Compatible Components

Understanding how to pinpoint suitable components for machinery is essential for maintaining optimal performance. Compatibility ensures that each element functions harmoniously with others, preventing issues that could arise from mismatched parts. This section focuses on methods and resources to help identify components that will work well together.

When selecting new elements for your equipment, consider the following factors:

| Factor | Description |

|---|---|

| Manufacturer Specifications | Refer to the manufacturer’s guidelines to ensure parts meet the required standards. |

| Model Compatibility | Check if the component is designed for the specific model you are working with. |

| Material Quality | Ensure that materials used are durable and suitable for the operational environment. |

| Performance Ratings | Look for ratings that indicate how well a component performs under stress. |

| Warranty and Support | Consider products that come with a warranty and accessible customer support. |

Utilizing online resources, forums, and expert consultations can further aid in making informed choices regarding component compatibility. By focusing on these critical aspects, users can enhance the reliability and longevity of their machinery.

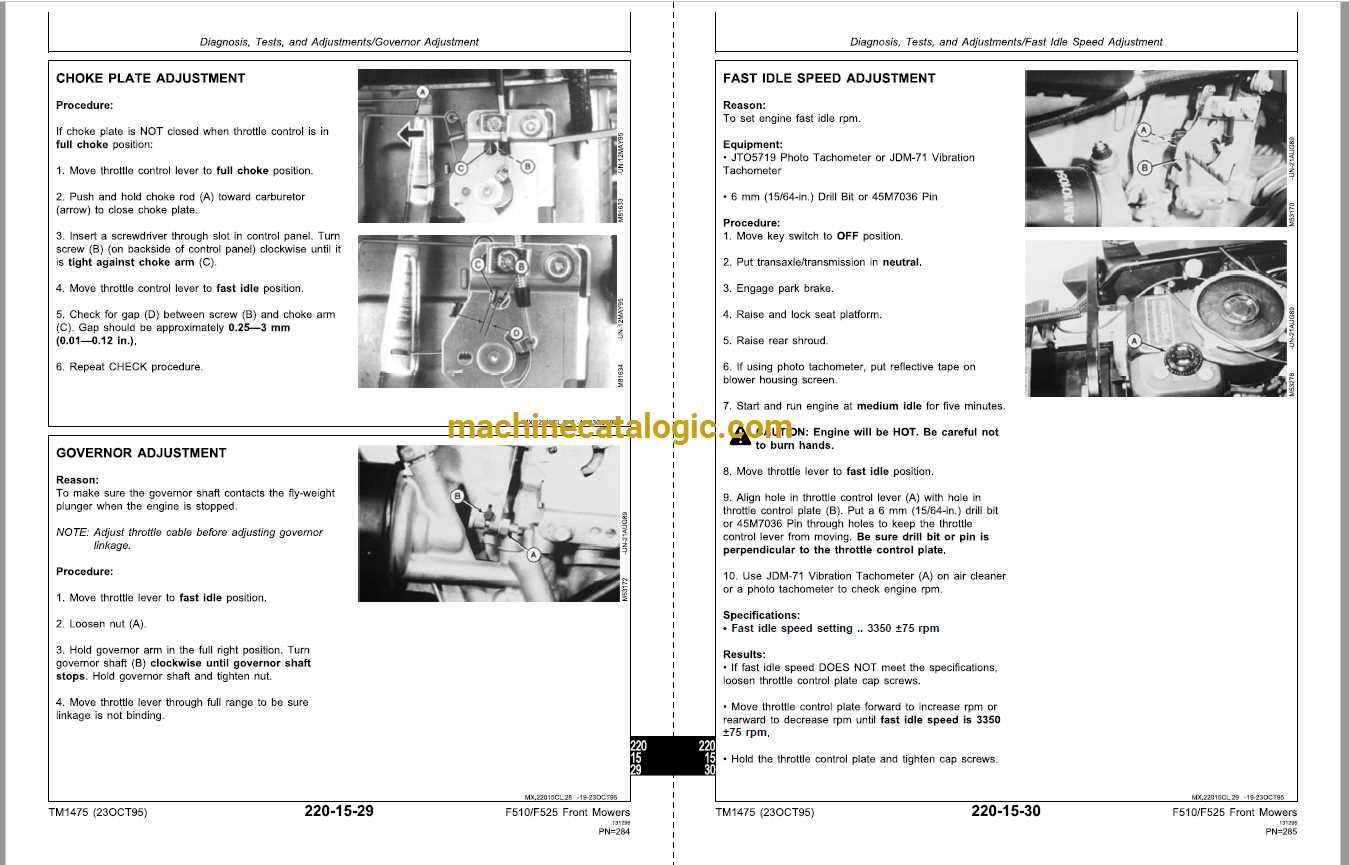

Troubleshooting Common Issues

When dealing with outdoor equipment, encountering problems can be frustrating. Understanding the most frequent issues and their solutions can help streamline maintenance and enhance performance. This section outlines common difficulties users face and provides straightforward troubleshooting steps to resolve them effectively.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel issues | Check the fuel level and ensure it’s fresh. Replace if necessary. |

| Uneven cutting | Dull blades | Sharpen or replace blades to ensure a clean cut. |

| Excessive vibration | Loose components | Tighten all bolts and check for damaged parts. |

| Overheating | Blocked airflow | Clean air filters and check for obstructions around the engine. |

| Poor performance | Old spark plug | Inspect and replace the spark plug if worn or dirty. |

Benefits of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. Regular inspections and servicing help identify potential issues before they escalate, leading to improved reliability and efficiency. A well-maintained machine not only performs better but also saves time and resources in the long run.

| Benefit | Description |

|---|---|

| Increased Lifespan | Routine maintenance extends the life of equipment by preventing wear and tear. |

| Enhanced Performance | Regular checks ensure that all components function optimally, improving overall output. |

| Cost Savings | Preventative measures can reduce the need for costly repairs and replacements. |

| Safety | Frequent inspections help identify safety hazards, protecting operators and surroundings. |

| Resale Value | A well-maintained machine retains higher market value compared to neglected ones. |