Understanding the various elements that make up a complex machine is crucial for anyone looking to maintain or repair it effectively. By examining the structure and functionality of individual components, one can ensure the longevity and smooth operation of their equipment.

Detailed insight into the assembly provides clarity on how different pieces fit together and interact. This knowledge is essential for those aiming to optimize performance or troubleshoot potential issues. The more familiar you are with each element, the easier it becomes to identify the root of any problems.

Whether you’re performing regular upkeep or looking to replace specific elements, having a clear view of the overall system is invaluable. This allows for more efficient planning and execution, saving time and resources in the long run.

Husqvarna YTH24V48: Understanding the Key Components

The machine’s essential elements are designed to work together for optimal performance. Each part plays a crucial role in ensuring efficiency, longevity, and smooth operation. By recognizing the primary components, users can maintain and troubleshoot the equipment more effectively.

Focusing on the mechanical structure, these units include elements like the engine system, the transmission, and the cutting deck. Proper care of these components is essential for reliable function. Regular maintenance helps ensure that all sections operate at their best and that any wear is detected early.

For the best results, it’s important to familiarize yourself with the main mechanisms, as understanding how each works individually and in unison can improve overall usage and maintenance practices. Ensuring the right fit and compatibility between these elements is key to maintaining top-tier performance.

Engine System Overview and Maintenance Tips

The engine system plays a crucial role in ensuring reliable and efficient operation of any outdoor equipment. Proper upkeep of the engine components is essential for longevity and performance. Understanding the basic functions and key areas of maintenance can help in preventing issues and extending the life of the equipment.

Regular Inspections and Cleaning

One of the most effective ways to maintain an engine is through regular inspections. Checking for signs of wear, oil leaks, and debris buildup should be a routine task. Keeping the engine clean from dust and dirt ensures that it operates smoothly without unnecessary strain. Air filters should be cleaned or replaced periodically, as clogged filters can lead to poor performance and overheating.

Fluid Management and Lubrication

Maintaining proper fluid levels, including oil and coolant, is key to preventing overheating and internal damage. It’s important to regularly check oil levels and change it according to the manufacturer’s recommendations. High-quality lubricants help reduce friction between moving parts, ensuring smoother operation and minimizing wear over time.

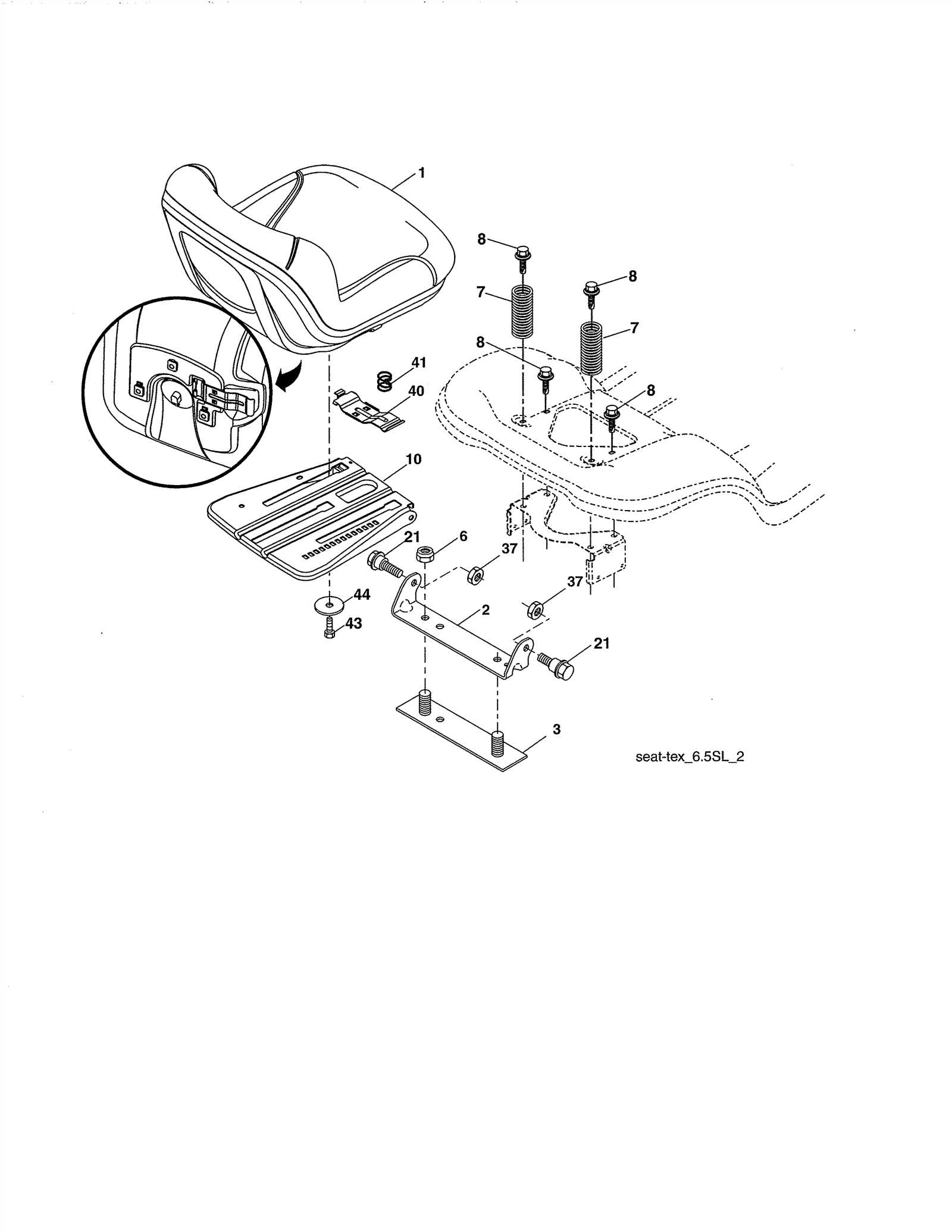

Blade and Deck Assembly Breakdown

The proper alignment and configuration of the cutting components and their surrounding structure play a crucial role in ensuring smooth operation. This section focuses on the key elements involved in the setup of the blades and the deck, outlining their relationship to the overall system. Understanding the individual parts and their positioning helps in maintaining efficiency and prolonging the lifespan of the machinery.

Main Components of the Blade Assembly

- Blades: Sharp and durable, responsible for the cutting action, ensuring clean cuts and smooth operation.

- Spindle Assembly: Connects the blades to the power source, allowing rotation at high speeds for effective grass cutting.

- Blade Bolts: Secure the blades firmly to the spindle, ensuring they remain in place during operation.

Deck Structure Overview

- Deck Shell: The main body that houses the blade system, designed for durability and proper airflow.

- Discharge Chute: Allows clippings to exit the deck, maintaining a clear cutting path.

- Deck Wheels: Support the structure, ensuring smooth movement and consistent cutting height.

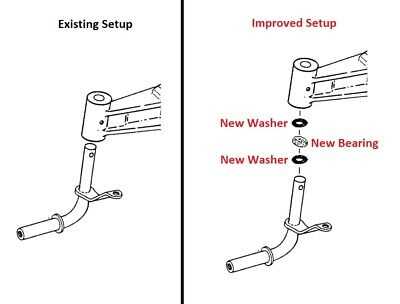

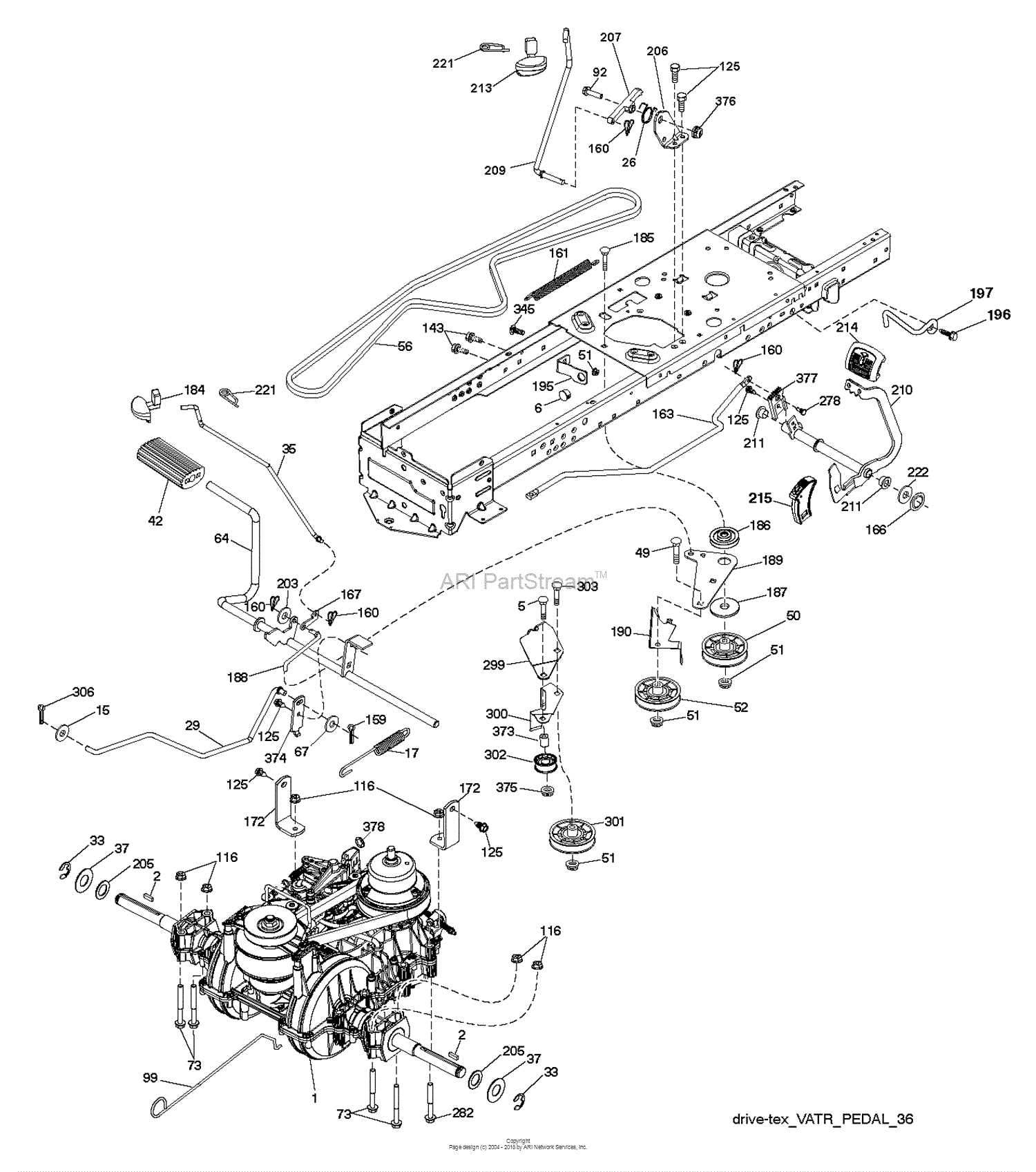

Drive Belt Configuration and Replacement Guide

The drive belt plays a crucial role in transferring power efficiently within the machine’s mechanical system. A well-maintained belt ensures smooth operation and prolongs the equipment’s life. In this section, we will outline the process of configuring and replacing the belt to ensure optimal performance.

To begin, it’s important to check the current belt setup and identify any signs of wear or misalignment. Proper tension and alignment are key factors in maintaining smooth functionality.

- First, ensure that the equipment is safely powered off and all necessary precautions are taken to avoid accidents.

- Locate the drive system, and identify the current position of the belt within the pulleys and tensioners.

- Loosen the tensioner to relieve the tension on the belt, allowing for easy removal.

- Carefully remove the old belt, inspecting it for cracks or excessive wear that might have caused operational issues.

- Position the new belt in the correct configuration, ensuring it sits securely within the pulleys and aligns correctly with the tensioner.

- Tighten the tensioner to apply proper tension to the new belt. This step is crucial for avoiding slippage or inefficient power transfer.

- Double-check the alignment to ensure that the belt runs smoothly through the entire system.

- Finally, perform a test run to verify that the installation was successful and the machine operates without unusual noises or vibrations.

Regular inspection and timely replacement of the drive belt can prevent unexpected breakdowns and ensure that your machine operates at peak efficiency.

Electrical System and Wiring Diagram

The electrical system plays a critical role in ensuring smooth operation, providing power to essential components. Understanding how the wiring is organized can simplify troubleshooting and maintenance tasks, ensuring everything functions as intended.

Main Components

- Battery: The central source of power for the entire electrical setup.

- Starter Motor: Engages the engine to initiate operation.

- Ignition Switch: Controls the flow of current to start or stop the system.

- Alternator: Recharges the battery while the machine is running.

Wiring Layout

The wiring connects each electrical component in a structured layout, ensuring that power is distributed effectively. Color-coded wires are used to differentiate between various circuits and prevent confusion during repairs.

- Power from the battery flows through the ignition switch.

- The switch then directs current to the starter motor.

- As the engine runs, the alternator restores charge to the battery.

Careful attention to the wiring structure can prevent electrical issues and prolong the lifespan of the machine’s systems.

Transmission and Axle Components Explained

The transmission and axle are essential elements in ensuring smooth movement and power distribution in various mechanical systems. These components work together to transfer energy from the engine to the wheels, allowing for precise control over speed and direction.

Understanding the role of each component is key to maintaining optimal performance. Below is a detailed breakdown of the main elements involved:

| Component | Description |

|---|---|

| Transmission | This unit manages the distribution of power, enabling the adjustment of speed and torque as needed for different conditions. |

| Axle | The axle supports the weight and facilitates the rotation of the wheels, ensuring the vehicle moves efficiently and smoothly. |

| Drive Belt | A belt that connects the transmission to the axle, responsible for transferring power between the two components. |

| Differential | Allows wheels to rotate at different speeds, crucial for smooth turns and better handling during operation. |

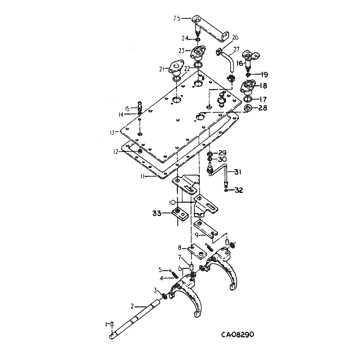

Steering Mechanism Parts and Adjustments

The steering system plays a crucial role in ensuring smooth and precise control of the machine’s movement. To maintain its optimal functionality, it’s important to regularly check the components and make necessary adjustments to avoid any issues during operation.

Key Components of the steering system include several interconnected elements responsible for guiding the wheels effectively. These elements need to be in sync to allow for accurate maneuvering, ensuring safety and efficiency.

Adjustments are often needed when handling becomes difficult or unresponsive. By tightening or aligning certain components, the system can be recalibrated to restore smooth directional control.

Regular inspections and timely corrections can prevent wear and extend the lifespan of the system, ultimately ensuring reliable performance during use.

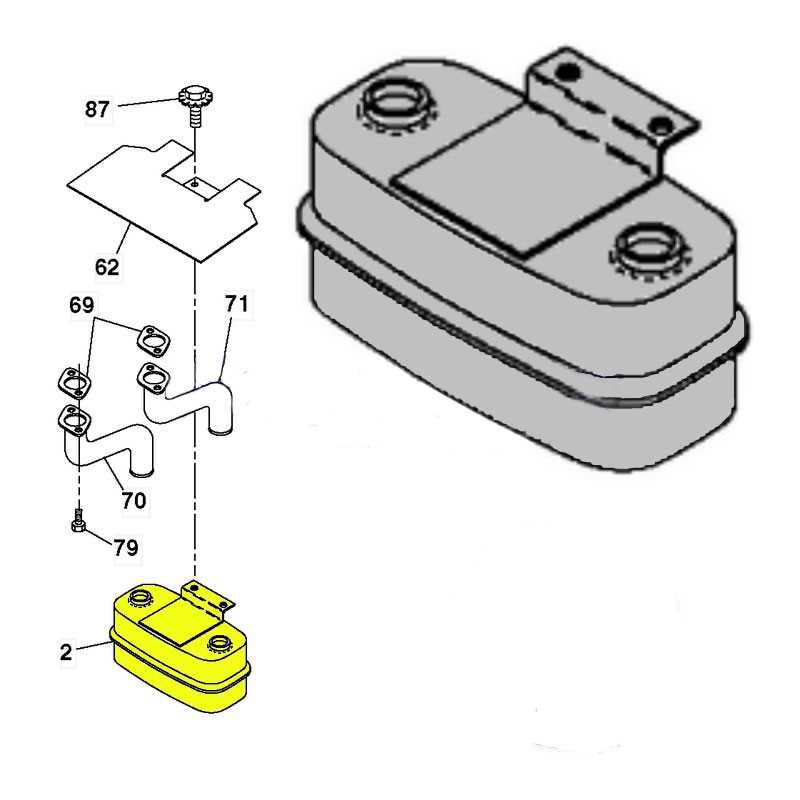

Fuel System Components and Troubleshooting

The fuel system plays a crucial role in ensuring smooth operation and reliable performance. Understanding its key elements and how to identify potential issues can help maintain proper functioning and prevent disruptions.

Main components of the fuel system include various channels and mechanisms responsible for delivering the right amount of fuel. Regular inspection is essential to detect any blockages or damage that could hinder performance.

Common troubleshooting involves checking for fuel leaks, clogged filters, and malfunctioning valves. When symptoms like poor engine start or irregular power arise, these areas are often the main culprits. Addressing such issues promptly ensures continued efficiency.

Brake and Safety System Breakdown

The braking and safety mechanisms are critical for ensuring control and protection during operation. These systems work in unison to provide secure halting and prevent potential mishaps while navigating different terrains. Regular maintenance of these components is vital for optimal performance.

Main Components Overview

The system is composed of various interconnected parts that regulate both stopping power and safety features. Proper alignment and adjustment of these elements guarantee efficient braking and safety measures, enhancing overall machine reliability.

| Component | Function |

|---|---|

| Brake Pedal | Activates the stopping mechanism when engaged. |

| Safety Switches | Ensures the machine halts under unsafe conditions. |

| Brake Linkage | Transfers force from the pedal to the brake system. |

| Parking Brake | Locks the machine in place to prevent unintended movement. |