In the realm of automated entry solutions, a comprehensive understanding of individual elements is crucial for effective maintenance and troubleshooting. Each system consists of various components that work in unison, and familiarity with their arrangement can significantly enhance one’s ability to address issues swiftly. This guide delves into the intricate relationships and positions of these essential parts.

Exploring the configuration of these mechanisms offers valuable insights into their functionality. Recognizing how each segment interacts with others allows users to pinpoint problems more accurately and execute repairs with greater confidence. This knowledge not only streamlines the process of upkeep but also contributes to the longevity of the entire system.

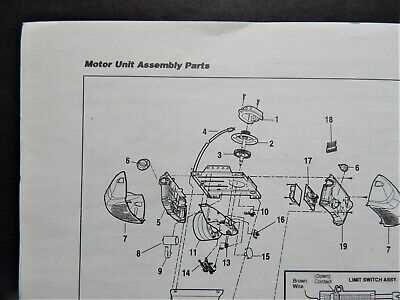

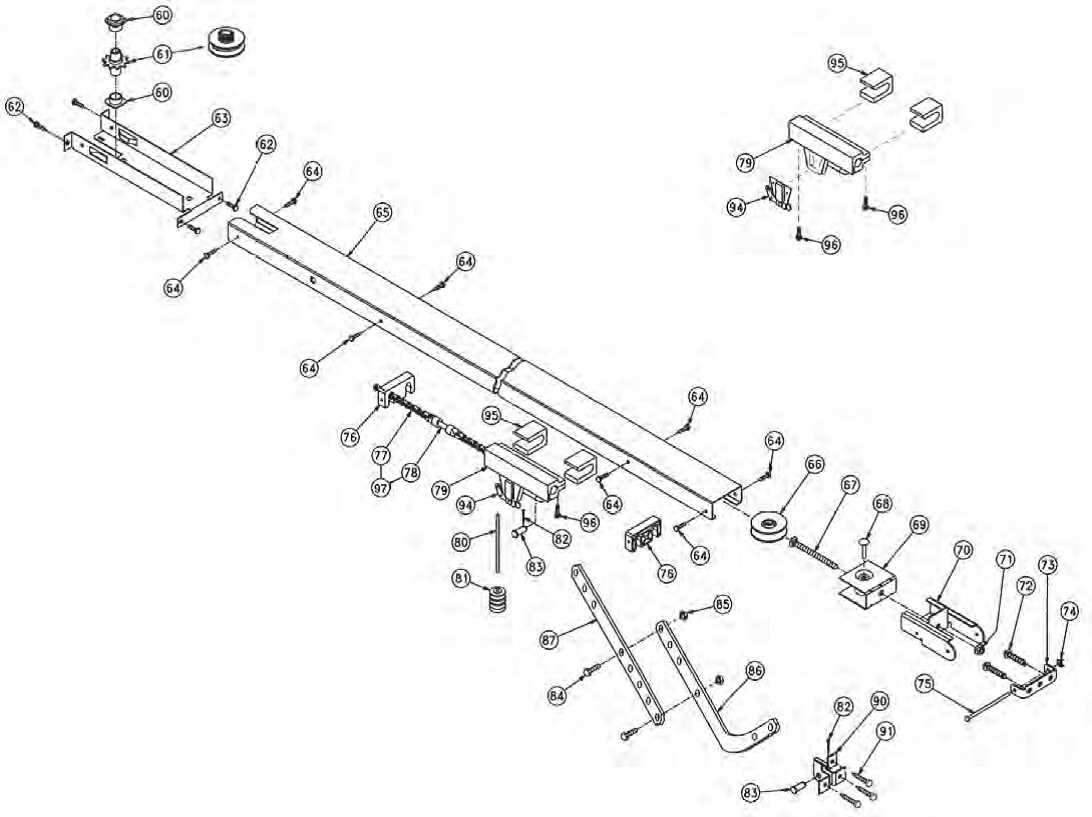

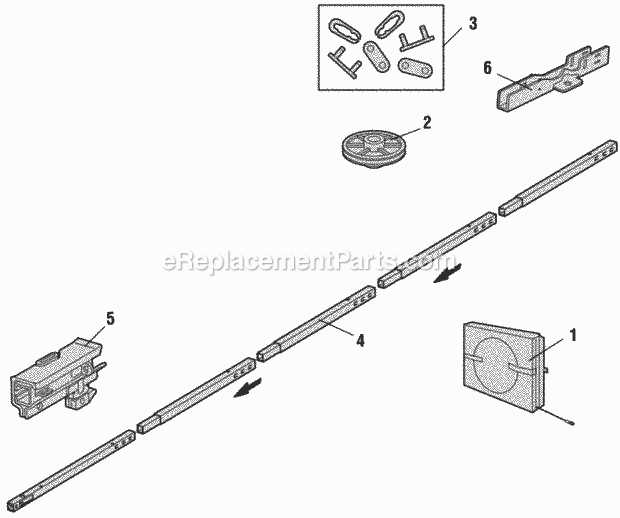

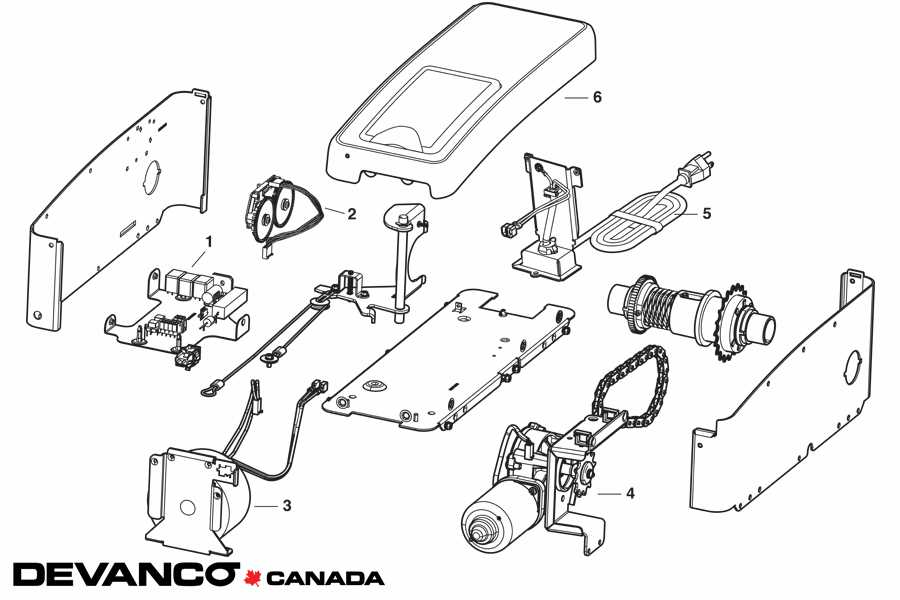

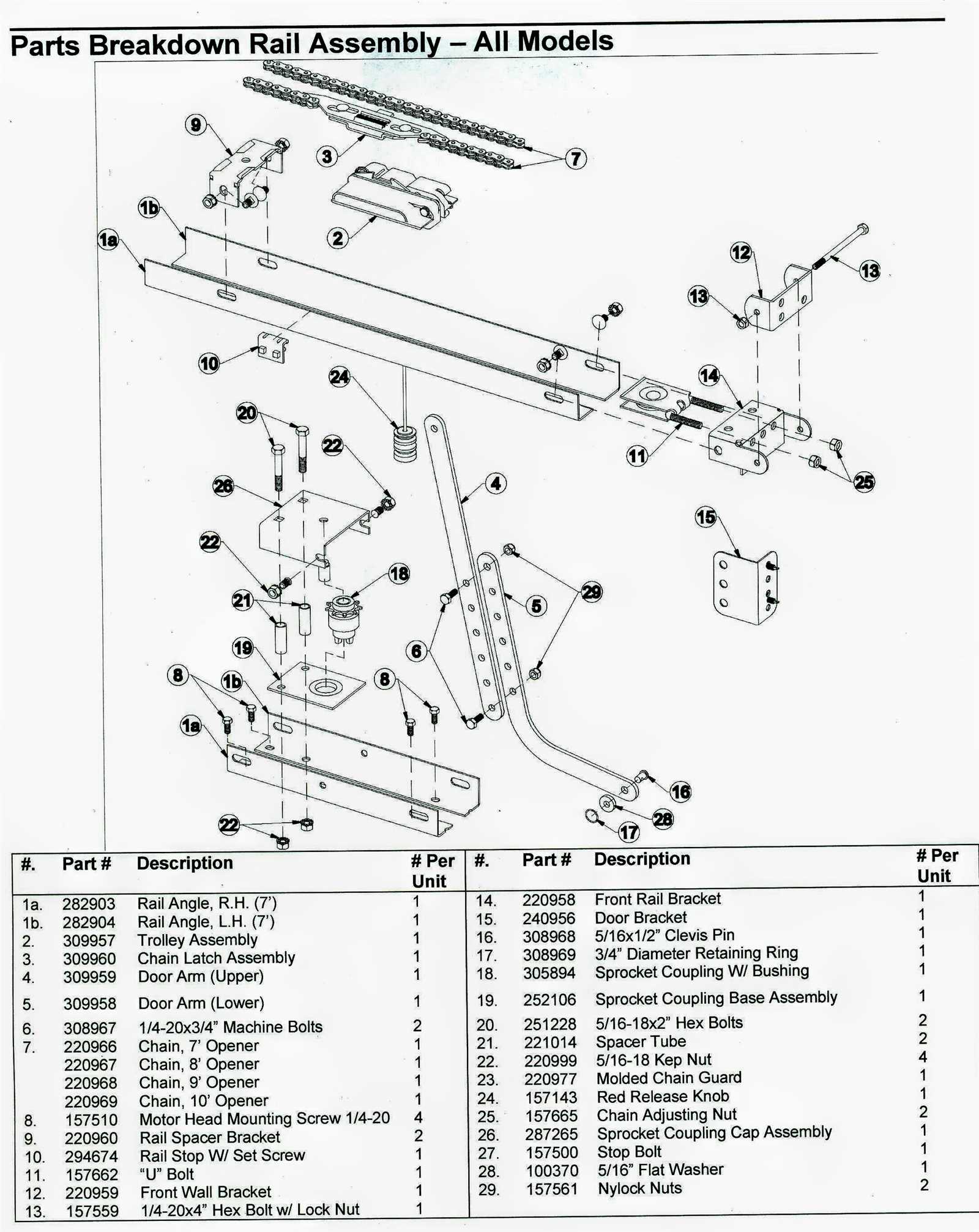

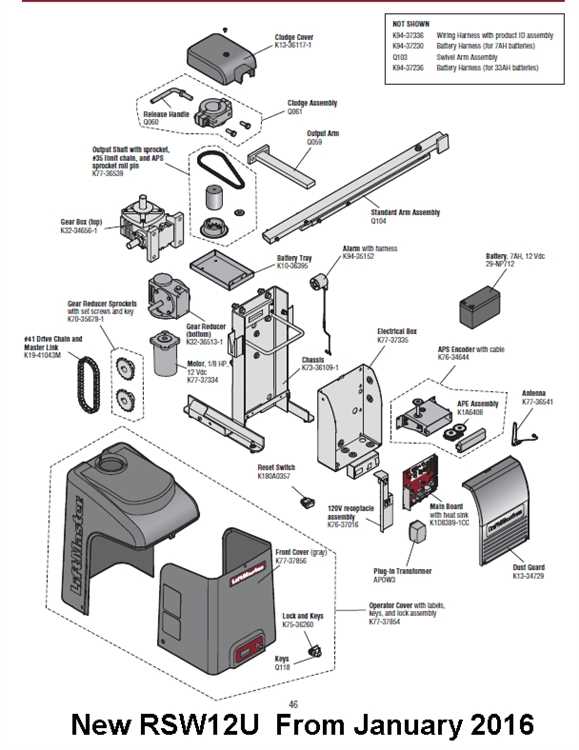

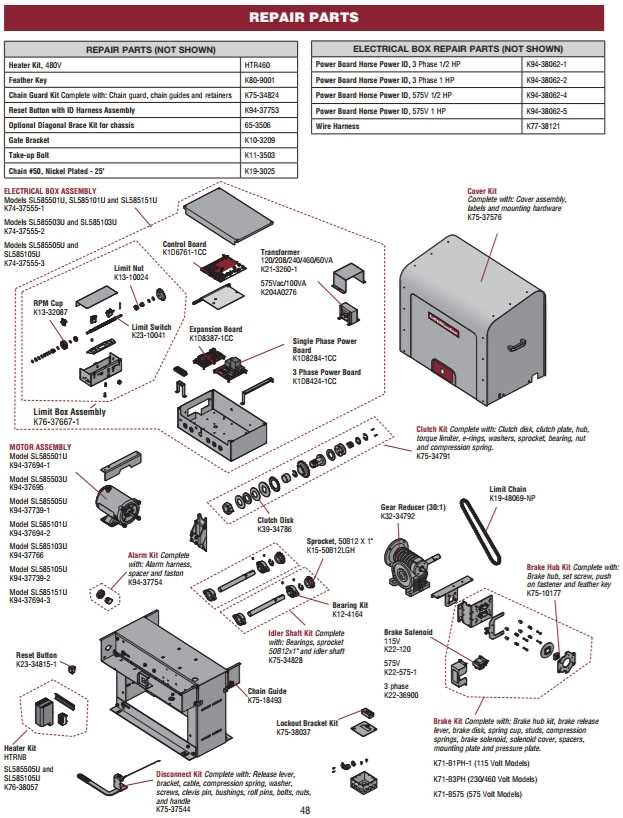

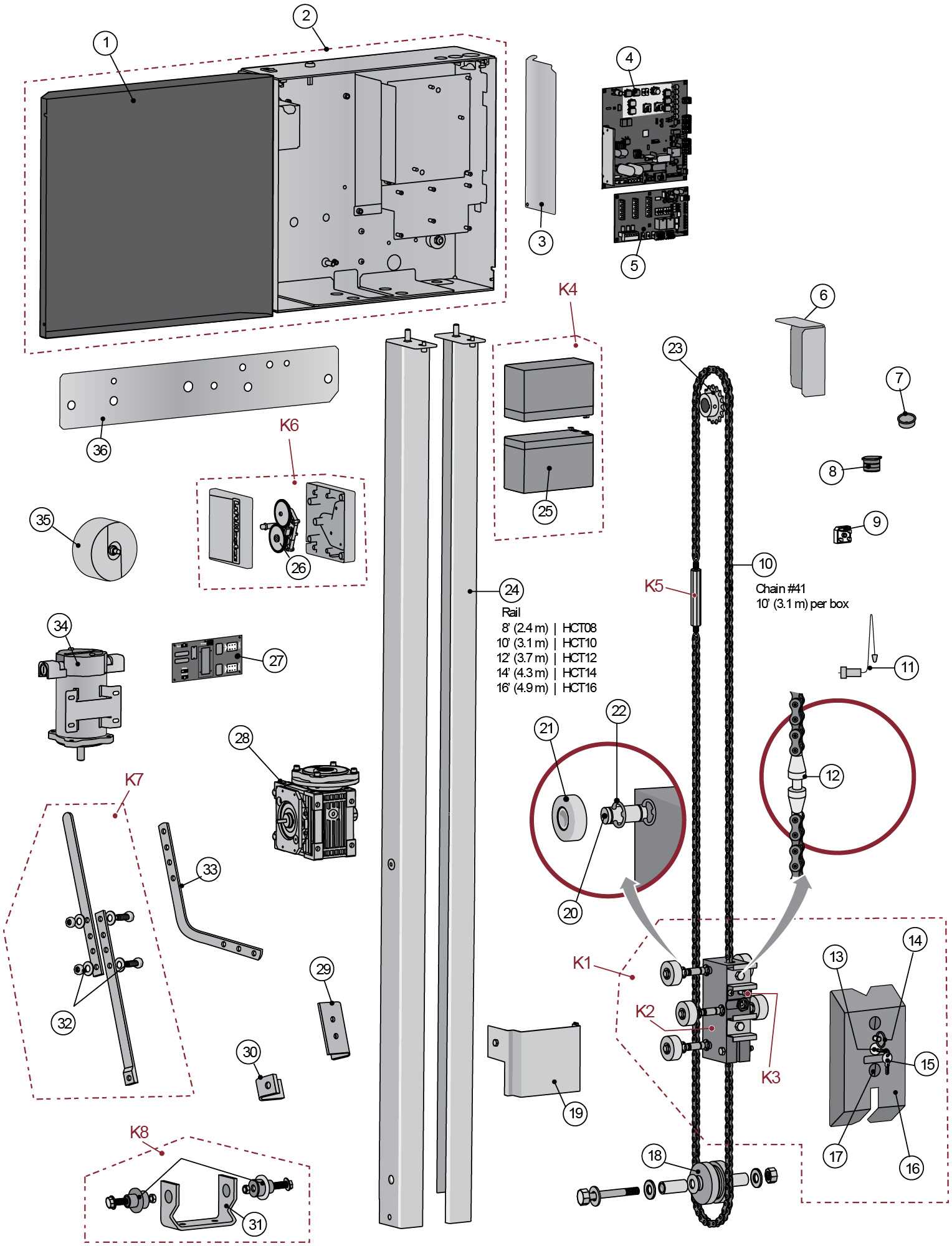

Furthermore, having access to a visual representation of these components serves as a vital reference. Such illustrations provide clarity, making it easier to identify specific areas that may require attention. By enhancing one’s comprehension of the layout, users can ensure optimal performance and prevent potential malfunctions.

Understanding Liftmaster Parts Functionality

In any automated entry system, each component plays a crucial role in ensuring smooth operation and security. A thorough grasp of how these elements function together is essential for effective maintenance and troubleshooting. This section will explore the key features and roles of various components in a typical setup.

Key Components and Their Roles

- Motor: Powers the opening and closing mechanism, providing the necessary force to operate the door.

- Control Board: Acts as the brain of the system, processing signals from remote controls and sensors.

- Safety Sensors: Detect obstacles in the path of the door, ensuring safe operation and preventing accidents.

- Remote Control: Allows users to operate the system from a distance, enhancing convenience.

- Gear Assembly: Transfers power from the motor to the door, facilitating movement.

Importance of Regular Maintenance

Regular upkeep of these components can prolong their lifespan and ensure reliability. Key maintenance practices include:

- Inspecting and cleaning safety sensors to ensure they function correctly.

- Checking the motor for signs of wear or damage.

- Testing remote controls for battery life and signal strength.

- Lubricating moving parts to reduce friction and wear.

Understanding the functionality of these components not only aids in troubleshooting but also enhances the overall performance of the entire system.

Common Components of Liftmaster Systems

Understanding the various elements of these automatic opening mechanisms is essential for proper maintenance and efficient operation. Each system is composed of several key components that work in harmony to ensure smooth functionality and security. Below is an overview of the most common parts found in such systems.

| Component | Description |

|---|---|

| Motor | The driving force that powers the system, enabling the movement of doors or gates. |

| Control Board | The central hub that manages signals and operations between the components, ensuring coordinated action. |

| Remote Control | A handheld device that allows users to operate the system from a distance, providing convenience and accessibility. |

| Safety Sensors | Devices that detect obstacles in the path of the door or gate, preventing accidents by stopping the operation if an obstruction is found. |

| Drive Belt or Chain | A mechanical element that transmits power from the motor to the door or gate, facilitating movement. |

| Power Supply | The source of energy required to operate the entire system, usually connected to a standard electrical outlet. |

Importance of Accurate Parts Diagrams

Precise representations of components are crucial for the effective maintenance and repair of various systems. They serve as vital tools that aid technicians and DIY enthusiasts alike in identifying, understanding, and assembling the elements necessary for optimal functionality. When these illustrations are accurate, they significantly reduce the chances of errors during installation or troubleshooting, ultimately enhancing the reliability of the overall system.

Enhancing Efficiency and Accuracy

Having a well-detailed visual reference streamlines the process of locating specific elements, thereby saving time and effort. It minimizes the risk of misplacement or incorrect assembly, which can lead to costly mistakes. Clear depictions help users to focus on the task at hand, allowing for a more efficient workflow and increasing the likelihood of a successful outcome.

Facilitating Communication

Accurate visuals also play a key role in communication between different parties involved in maintenance and repair processes. Whether it’s a technician discussing issues with a supplier or a homeowner seeking assistance from a professional, having a reliable reference allows for clearer dialogue. This clarity can lead to quicker resolutions and a better understanding of the necessary steps required to address any challenges that arise.

How to Read Liftmaster Diagrams

Understanding visual representations of mechanical components is essential for effective maintenance and troubleshooting. These illustrations provide valuable insights into the arrangement and function of various elements within a system. By grasping how to interpret these visuals, users can enhance their ability to identify issues and implement solutions efficiently.

Identifying Key Elements

Begin by familiarizing yourself with the symbols and notations used in the illustrations. Each component is usually represented by a specific shape or icon, and lines may indicate connections or relationships between them. Pay attention to any labels or legends that accompany the visuals, as they provide crucial information regarding the function and specifications of each part.

Understanding Relationships and Functions

Once you have identified the components, focus on their interconnections. Analyzing how parts interact with one another will help you comprehend the overall functionality of the system. Take note of any directional arrows or annotations that explain the flow of operation, as these details are vital for a comprehensive understanding.

Identifying Replacement Parts Easily

Understanding the components of your equipment is essential for effective maintenance and repair. Familiarity with various elements can significantly enhance your ability to recognize and obtain the necessary replacements. This section provides insights into streamlining the identification process, making it simpler to find the right components for your system.

Key Strategies for Identification

To accurately identify the necessary elements, consider the following approaches:

- Refer to the equipment’s manual for detailed descriptions.

- Utilize online resources, including forums and manufacturer websites, for additional guidance.

- Consult with professionals or experienced users who can offer insights and recommendations.

Helpful Resources

There are several tools and platforms available that can aid in your search for the right components. The following table lists some valuable resources:

| Resource Type | Description |

|---|---|

| Manufacturer Website | Official site often provides manuals and parts lists. |

| Online Retailers | Websites dedicated to selling components may have useful search functions. |

| User Forums | Communities where users share advice and experiences related to components. |

Maintenance Tips for Liftmaster Equipment

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By following a few straightforward recommendations, you can enhance the reliability of your equipment and prevent unnecessary breakdowns.

Routine Inspections

Conducting frequent inspections is vital to identify potential issues before they escalate. Check for any signs of wear or damage in mechanical components and ensure that all moving parts are adequately lubricated. Pay attention to the electrical connections as well, ensuring they are secure and free from corrosion.

Cleaning and Care

Keeping your equipment clean helps to maintain its efficiency. Remove any dirt, debris, or grease build-up that may hinder performance. Utilize a damp cloth for surfaces and a suitable cleaner for specific parts, following the manufacturer’s guidelines. Additionally, ensure that ventilation openings are unobstructed to promote proper airflow.

Where to Find Genuine Parts

When it comes to maintaining your automatic access systems, sourcing authentic components is essential for ensuring optimal performance and longevity. Quality elements not only enhance functionality but also provide peace of mind that your equipment will operate safely and effectively.

Authorized Dealers: One of the most reliable avenues for obtaining authentic elements is through authorized retailers. These distributors often have a comprehensive inventory and can guarantee the authenticity of their offerings.

Manufacturer Websites: Visiting the official website of the equipment manufacturer is another excellent option. Many manufacturers have dedicated sections for genuine components, complete with part numbers and detailed descriptions.

Online Marketplaces: Established online platforms may offer a variety of authentic options. It is crucial to verify the seller’s reputation and check customer reviews to ensure the reliability of the components.

Local Repair Shops: Local service providers can also be a valuable resource. They often have access to genuine elements and can provide guidance on the best options for your specific system.

By exploring these sources, you can confidently acquire the necessary items to keep your equipment functioning at its best.

DIY Repairs Using Diagrams

Understanding how to tackle home repairs can be significantly enhanced by utilizing visual aids. These illustrations provide a clear representation of components, making it easier for individuals to identify issues and follow step-by-step procedures. With the right resources, homeowners can efficiently address malfunctions without professional assistance.

When embarking on repair projects, having a comprehensive visual reference allows for better planning and organization. By analyzing the layout of various elements, one can quickly pinpoint areas that require attention. This method not only saves time but also reduces the likelihood of errors during the repair process.

Incorporating these visual resources into your toolkit fosters a more confident approach to home maintenance. Whether it involves simple fixes or more complex tasks, having a reference guide can significantly streamline efforts. Embracing this method can empower individuals to become more self-sufficient and knowledgeable about their home systems.