When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is essential. Whether you’re a seasoned user or a newcomer, familiarizing yourself with the intricate layout of the unit can enhance its performance and longevity. This section delves into the intricate relationships between different components, ensuring that you can navigate any maintenance task with confidence.

Every machine is composed of numerous parts that work in harmony to deliver optimal results. Grasping the function of each element not only aids in effective troubleshooting but also empowers users to perform repairs with ease. By visualizing how these pieces interconnect, you gain insight into the overall mechanics and can identify potential issues before they escalate.

In this guide, we provide a comprehensive breakdown of these essential components, highlighting their roles and how they contribute to the unit’s efficiency. Equipped with this knowledge, you will be better prepared to tackle any maintenance challenges, ensuring that your equipment remains in peak condition for years to come.

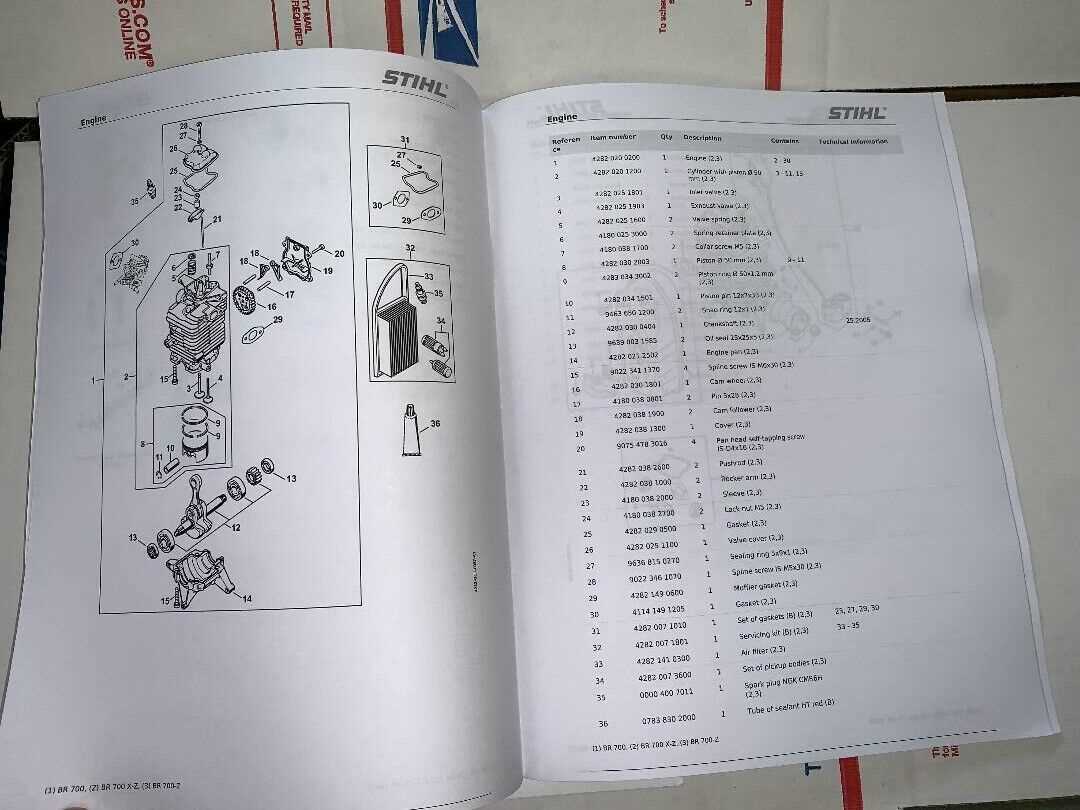

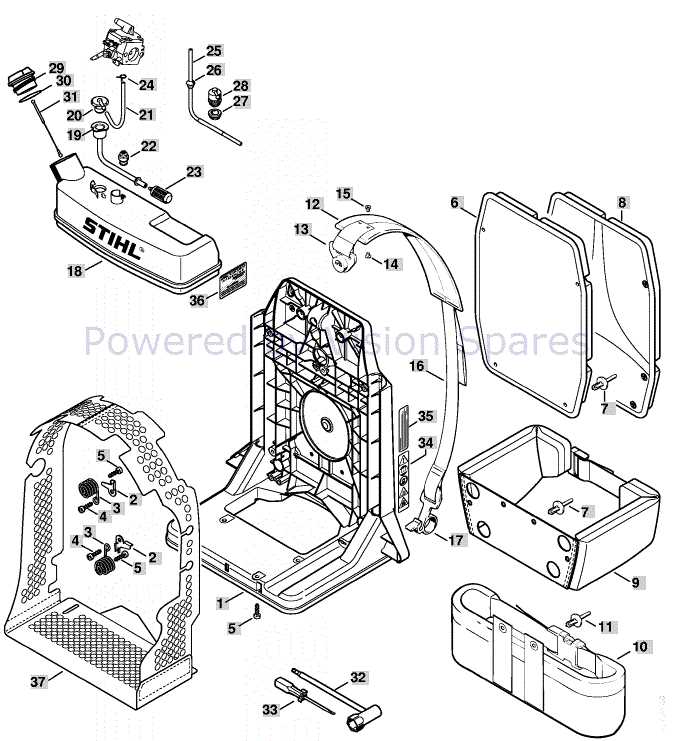

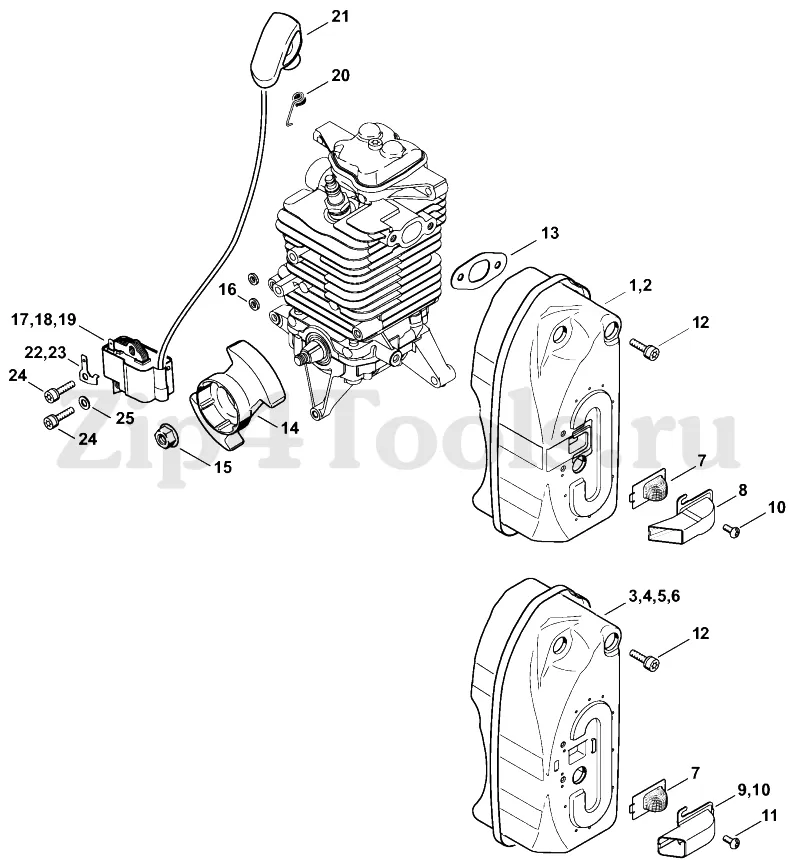

Understanding Stihl BR 450 Components

Grasping the essential elements of a high-performance blower is crucial for both maintenance and effective operation. Each component plays a significant role in the overall functionality, contributing to efficiency and durability. By familiarizing oneself with these parts, users can ensure optimal performance and longevity of their equipment.

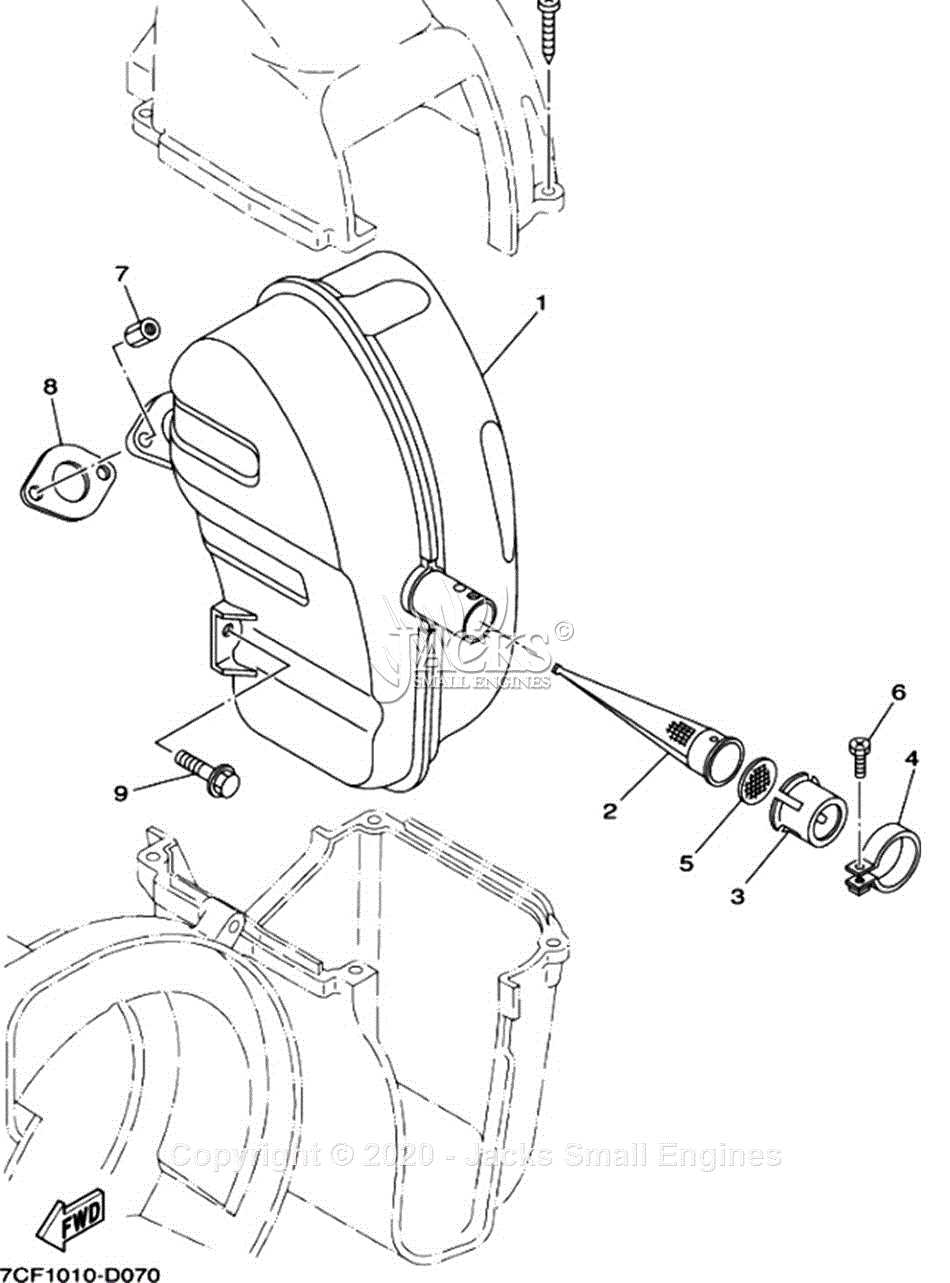

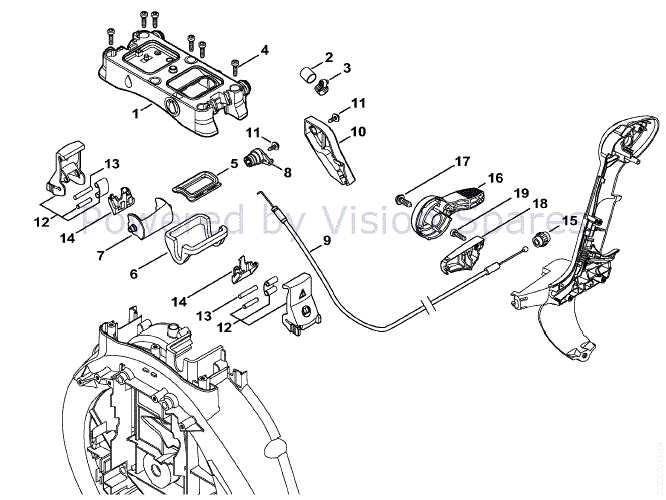

Main Components Overview

Key elements in a blower include the power unit, air intake system, and exhaust mechanisms. Each of these parts has a specific function that contributes to the machine’s effectiveness. Understanding these components aids in troubleshooting and repairs.

| Component | Function |

|---|---|

| Engine | Powers the blower and provides thrust for debris removal. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

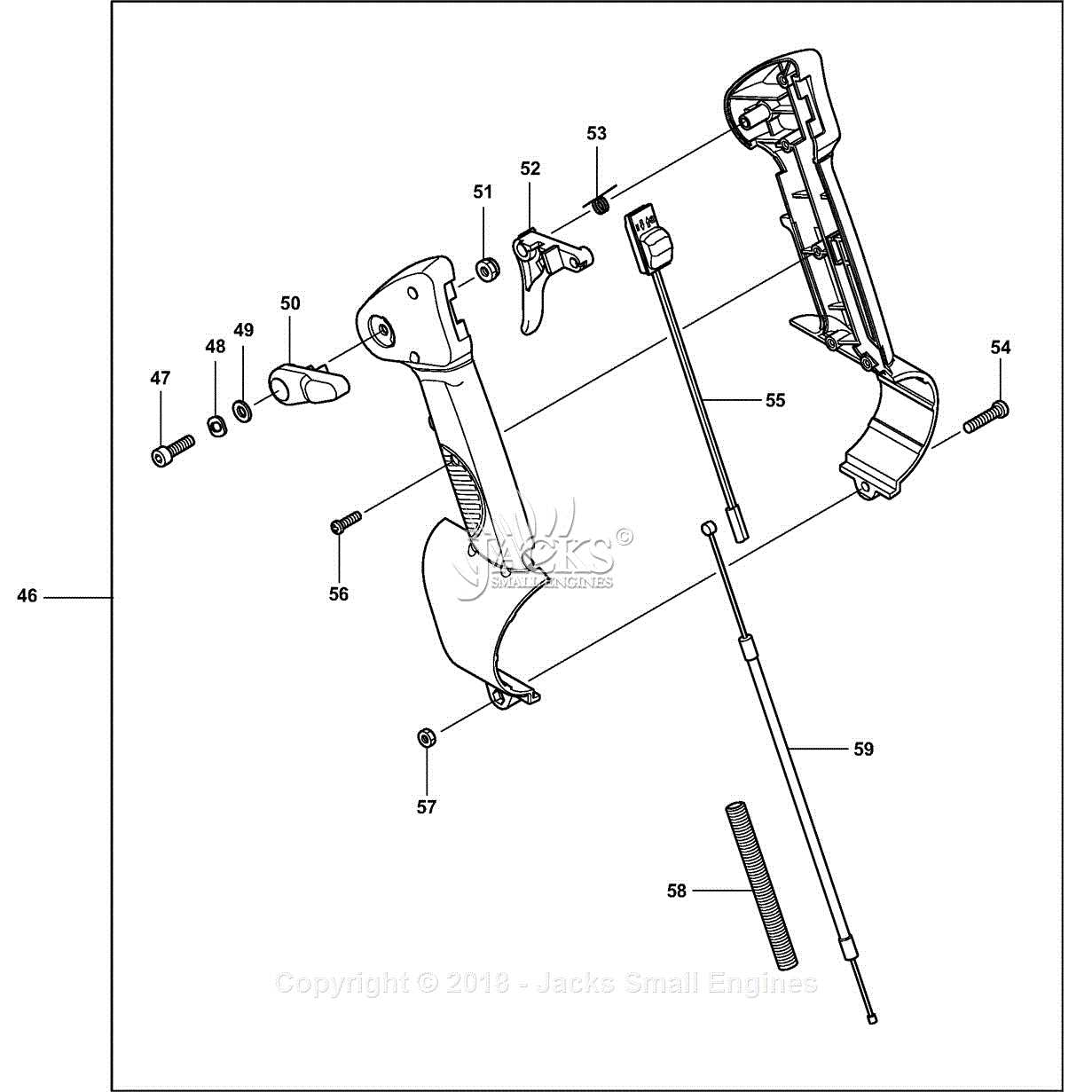

| Throttle Control | Regulates engine speed and airflow. |

| Fan Housing | Encases the fan and directs airflow effectively. |

Importance of Regular Maintenance

Regular upkeep of these components is vital for sustaining performance and preventing breakdowns. Users should frequently check and clean air filters, inspect fuel lines, and ensure all mechanical parts are functioning smoothly. Proper maintenance not only enhances efficiency but also extends the lifespan of the machine.

Importance of Parts Diagrams

Understanding the components of a machine is crucial for efficient maintenance and repair. Visual representations of these elements offer clarity and insight into how each part interacts within the system. This knowledge can significantly enhance the user’s ability to troubleshoot issues and perform necessary replacements.

Efficiency in Repairs is one of the primary benefits of having access to visual guides. When users can easily identify components, they save valuable time during repairs. Instead of guessing or relying on vague descriptions, technicians can follow a clear outline, ensuring that no crucial elements are overlooked.

Enhanced Learning also stems from utilizing these illustrations. New users or those unfamiliar with specific machinery can quickly familiarize themselves with different parts and their functions. This foundational knowledge empowers individuals to gain confidence in their skills and make informed decisions regarding upkeep.

Moreover, having a visual reference aids in preventive maintenance. By understanding where components are located and how they function together, users can spot potential issues before they escalate into major problems. This proactive approach not only prolongs the lifespan of the equipment but also reduces overall repair costs.

In conclusion, visual representations of machine components play a vital role in ensuring effective maintenance, facilitating learning, and promoting proactive care. Their importance cannot be overstated, as they serve as essential tools for both novice and experienced users alike.

Common Issues with BR 450 Parts

When it comes to outdoor power equipment, certain components can experience wear and tear over time, leading to performance issues. Understanding the frequent problems associated with these elements can help users maintain their equipment more effectively. Regular maintenance and prompt attention to these concerns are essential for optimal functionality.

1. Fuel System Troubles: One of the most common issues involves the fuel system. Clogged filters or damaged lines can restrict fuel flow, resulting in poor engine performance. It’s crucial to regularly inspect and replace these elements to ensure smooth operation.

2. Air Filter Blockage: A dirty or blocked air filter can hinder airflow, affecting engine efficiency. Cleaning or replacing the filter regularly can prevent this issue and prolong the lifespan of the equipment.

3. Ignition Failures: Problems with the ignition system, such as faulty spark plugs or ignition coils, can lead to starting difficulties. Regular checks and timely replacements can help avoid unexpected downtime.

4. Wear of Blades: Dull or damaged cutting blades can not only affect performance but also pose safety risks. Regular sharpening and replacement of blades are necessary to maintain effective cutting power.

5. Vibration Issues: Excessive vibration during operation can indicate loose or worn components. Identifying and tightening these parts can enhance comfort and improve overall performance.

By being aware of these common challenges and addressing them proactively, users can ensure their equipment remains reliable and efficient throughout its lifespan.

How to Identify Replacement Parts

Understanding how to find and select the appropriate components for your outdoor equipment is essential for maintaining its efficiency and longevity. Identifying the correct items can prevent potential issues and ensure optimal performance. This process involves recognizing key features and specifications of the equipment in question.

Begin by consulting the user manual, which often contains detailed information about the components, including model numbers and descriptions. If the manual is unavailable, look for labels or engravings on the machinery itself, as these may provide vital clues regarding the necessary items.

Another effective method is to utilize online resources or forums dedicated to equipment maintenance. Engaging with experienced users can yield valuable insights and recommendations for sourcing replacements. Additionally, many manufacturers offer online catalogs that allow for easy searching based on model specifications.

Once potential components have been identified, verify their compatibility by cross-referencing the model details. Always consider purchasing from reputable suppliers to ensure quality and reliability. Taking the time to accurately identify replacements can lead to improved functionality and extend the life of your equipment.

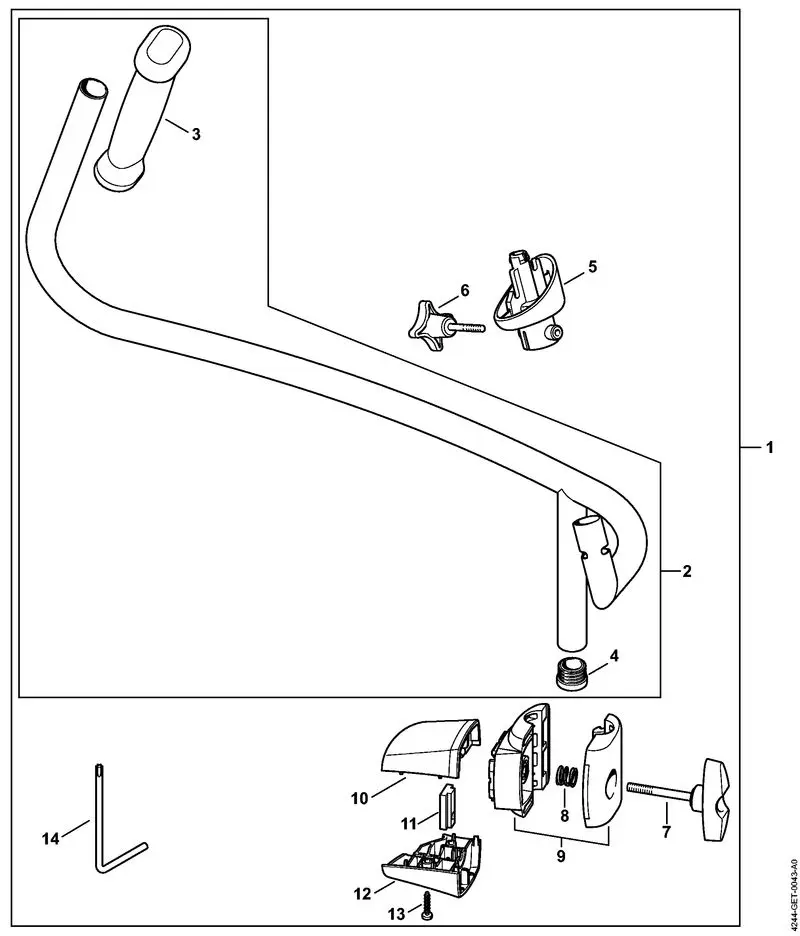

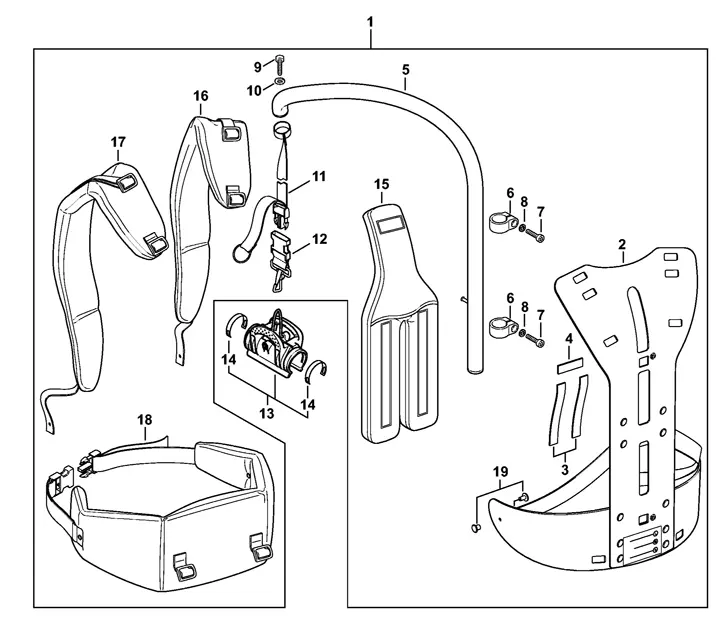

Step-by-Step Assembly Instructions

Assembling your equipment requires careful attention to detail and a methodical approach. This guide provides clear, concise instructions to help you piece together the various components efficiently, ensuring optimal performance and longevity.

Gathering Necessary Components

Before you begin, ensure you have all essential components within reach. Check that each part is in good condition and ready for assembly. Having tools at hand will streamline the process and prevent unnecessary interruptions.

Assembly Process

Start by aligning the base component with the main body, ensuring proper fitment. Use screws and fasteners to secure them, tightening adequately without over-torquing. Next, attach any additional components, such as the power unit and air filter, following the manufacturer’s guidelines. Finally, perform a thorough inspection to confirm everything is secured and in its correct position before testing.

Maintenance Tips for Longevity

Proper care and attention can significantly extend the lifespan of your equipment, ensuring it operates efficiently for years. Regular upkeep is crucial to avoid unexpected breakdowns and to maintain peak performance. By incorporating simple maintenance habits into your routine, you can reduce the likelihood of wear and tear, ultimately enhancing durability.

Clean after each use: Thoroughly remove any debris or residue that accumulates during operation. A clean surface prevents blockages and improves airflow, helping your machine function smoothly.

Check and replace filters: Filters play a vital role in keeping the internal components free from dust and dirt. Regular inspection and timely replacement can prevent damage to key elements, ensuring continued efficiency.

Inspect fuel and oil levels: Maintaining proper fuel and oil levels is essential for smooth operation. Regularly check these levels, and top them up as needed to avoid engine issues and prolong the machine’s lifespan.

Examine moving parts: Regularly inspect all moving components for signs of wear. Lubricating joints and replacing any worn-out parts will help avoid friction and ensure the machine runs at its best.

Adopting these maintenance practices will ensure your equipment remains reliable and effective over time, maximizing both performance and longevity.

Where to Find Genuine Parts

When it comes to maintaining your equipment, finding authentic replacements is essential for ensuring performance and longevity. Whether you are repairing or upgrading, sourcing original components will help keep your machine running smoothly and efficiently.

Authorized Dealers and Retailers

One of the best ways to secure high-quality replacements is through authorized sellers. These retailers offer a wide selection of official components specifically designed for your machinery. You can either visit physical stores or browse online platforms to find what you need.

Online Marketplaces and Resources

Various online platforms provide access to genuine components. Many websites feature easy-to-use search tools, allowing you to quickly identify the exact replacements required for your equipment. Make sure to verify that the sellers are reputable and that the items are certified as original products.

| Source | Availability | Additional Services |

|---|---|---|

| Authorized Retailers | High | Warranty, Customer Support |

| Online Marketplaces | Moderate | Delivery, Easy Returns |

Comparing Aftermarket vs. Original Parts

When maintaining or repairing equipment, users often face the choice between original components and those produced by third-party manufacturers. Each option has its benefits and drawbacks, making it essential to understand the key differences between them.

Quality and Durability: Original components are typically made to meet strict specifications, ensuring compatibility and longevity. Aftermarket alternatives, while often more affordable, may not always meet the same standards, potentially affecting performance and lifespan.

Cost Efficiency: One of the main attractions of aftermarket options is the lower price. However, this savings may come at the cost of durability or efficiency, which can lead to more frequent replacements over time.

Warranty and Support: Using original components usually guarantees the continuation of the manufacturer’s warranty, offering peace of mind. In contrast, aftermarket solutions may void warranties or lack the same level of customer support.

Ultimately, the decision depends on the balance between cost, quality, and reliability, all of which are crucial when choosing between original and aftermarket solutions for your equipment.