In the realm of gardening and agriculture, efficient machinery plays a crucial role in enhancing productivity. Grasping the intricate structure of these tools can significantly impact their functionality and longevity. Each element, from the smallest bolt to the larger assemblies, contributes to the overall performance of the machine.

Knowing the layout of these crucial elements allows users to troubleshoot issues effectively and carry out maintenance with ease. A comprehensive overview of the individual components fosters a deeper appreciation for the engineering behind these machines, enabling operators to make informed decisions about repairs and upgrades.

By exploring the various sections and their respective roles, one can ultimately improve the efficiency of the equipment. This understanding not only empowers users to handle repairs but also enhances their capability to operate the machinery with confidence and skill.

Understanding Maxim Tiller Components

Grasping the intricacies of essential machinery components is vital for efficient operation and maintenance. Each element plays a pivotal role in the overall functionality, contributing to seamless performance and user experience. By exploring these components, one can enhance their understanding and troubleshooting skills.

Core Elements of the system are designed to ensure stability and control, allowing for precise maneuvering. Understanding their arrangement and interaction is crucial for effective operation.

Maintenance practices can greatly benefit from a comprehensive grasp of these elements, enabling users to identify wear and potential issues before they escalate. Regular inspections and knowledge of component functions can lead to improved longevity and reliability.

In conclusion, an in-depth examination of these vital components not only aids in troubleshooting but also empowers users to optimize performance and enhance safety during operation.

Key Features of Tiller Mechanisms

Understanding the essential attributes of these agricultural implements is crucial for optimizing their functionality and performance. Their design integrates various components that work harmoniously to enhance efficiency and ease of use.

Robust Construction

The durability of these machines is one of their standout features. Crafted from high-quality materials, they are built to withstand rigorous use and various environmental conditions, ensuring longevity and reliability.

Adjustable Settings

Another important aspect is the flexibility in operation. Many models offer customizable settings, allowing users to adapt the tool’s performance to different soil types and cultivation needs. This adaptability is essential for achieving optimal results in diverse agricultural scenarios.

Importance of Proper Maintenance

Maintenance not only safeguards equipment but also boosts productivity. A well-maintained machine operates more smoothly, leading to improved outcomes in the field. Furthermore, it promotes safety for users, minimizing the risk of accidents due to mechanical malfunctions.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspecting Components | Monthly | Identifies wear and tear early |

| Lubricating Moving Parts | Every 50 Hours | Reduces friction and wear |

| Changing Filters | Every Season | Maintains efficiency and performance |

Common Issues with Tiller Parts

When operating soil cultivation equipment, users often encounter various challenges that can hinder performance. Understanding these common problems can lead to better maintenance and enhanced efficiency.

- Worn components can lead to reduced effectiveness.

- Improper alignment may cause excessive strain on machinery.

- Blocked mechanisms can prevent smooth operation.

- Corrosion may compromise durability and functionality.

Addressing these issues promptly can save time and resources.

- Regularly inspect for wear and tear.

- Ensure all elements are correctly aligned.

- Clear any obstructions from moving parts.

- Apply protective coatings to prevent rust.

By focusing on these aspects, users can prolong the life of their equipment and achieve optimal results.

How to Identify Replacement Needs

Understanding when components require substitution is crucial for maintaining optimal functionality and longevity of your equipment. Regular inspections and awareness of performance issues can help in pinpointing necessary replacements.

Signs of Wear and Tear

Look for obvious indicators of degradation, such as unusual noises, decreased efficiency, or visible damage. These symptoms often suggest that certain elements are nearing the end of their usable life and should be evaluated for replacement.

Regular Maintenance Checks

Conducting routine maintenance is vital. During these checks, assess each component thoroughly. Keep an eye on the condition of critical parts, as their health directly affects overall performance. Timely interventions can prevent larger issues and enhance durability.

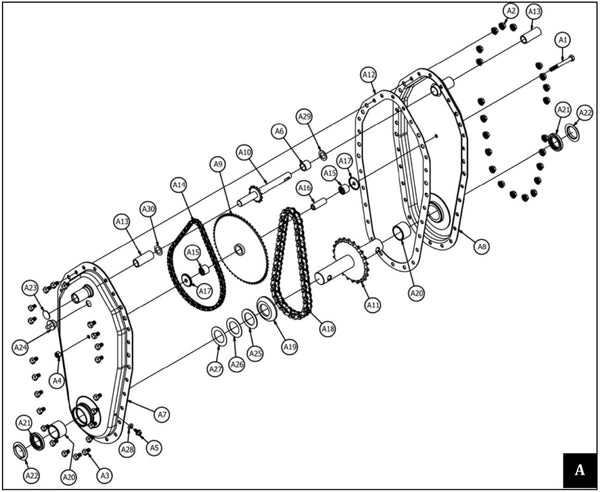

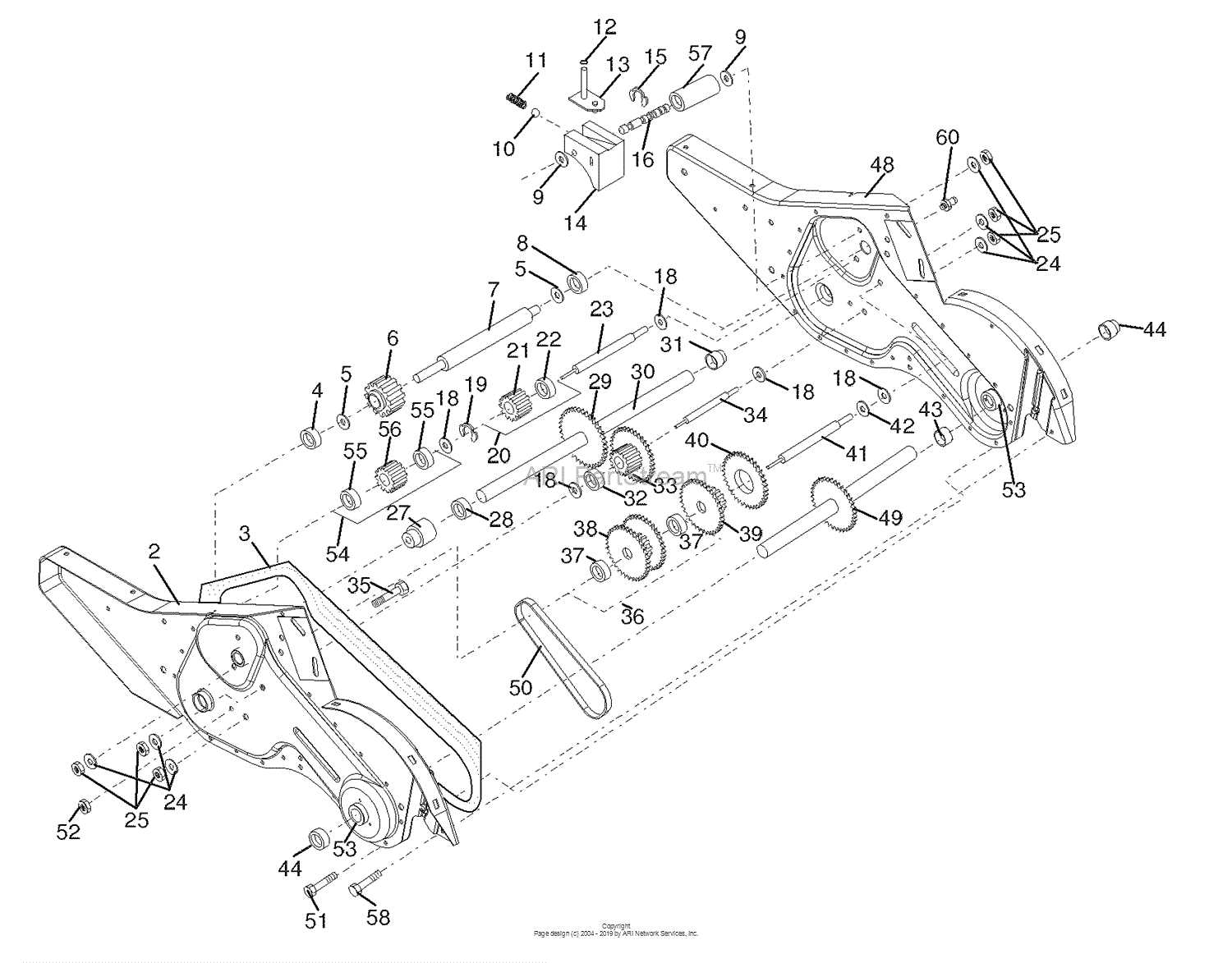

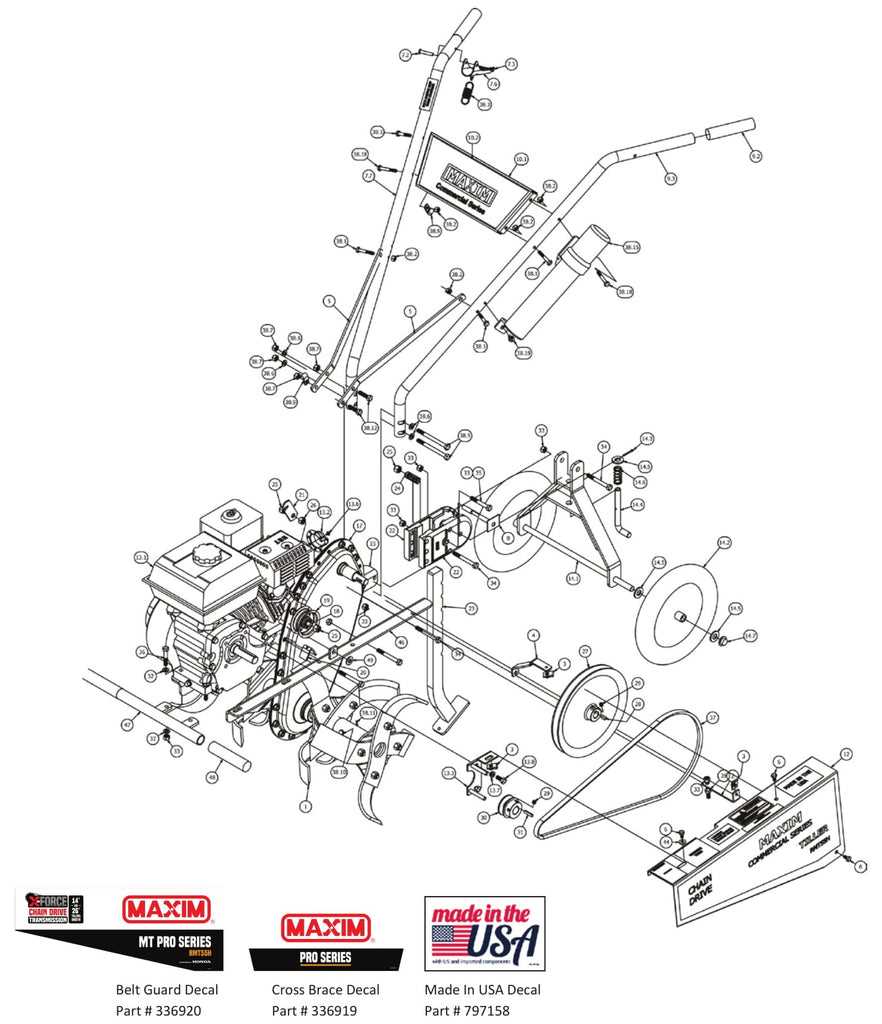

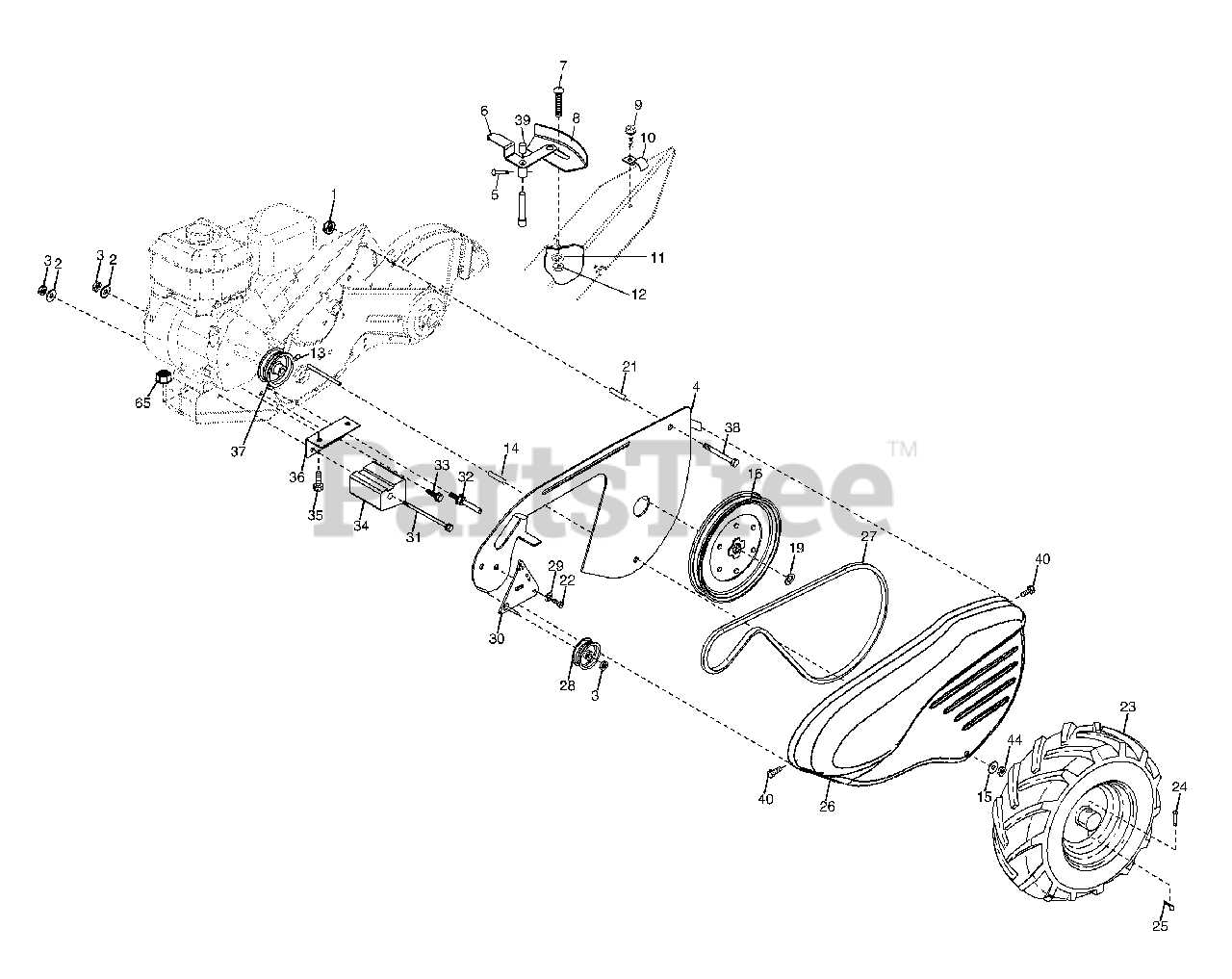

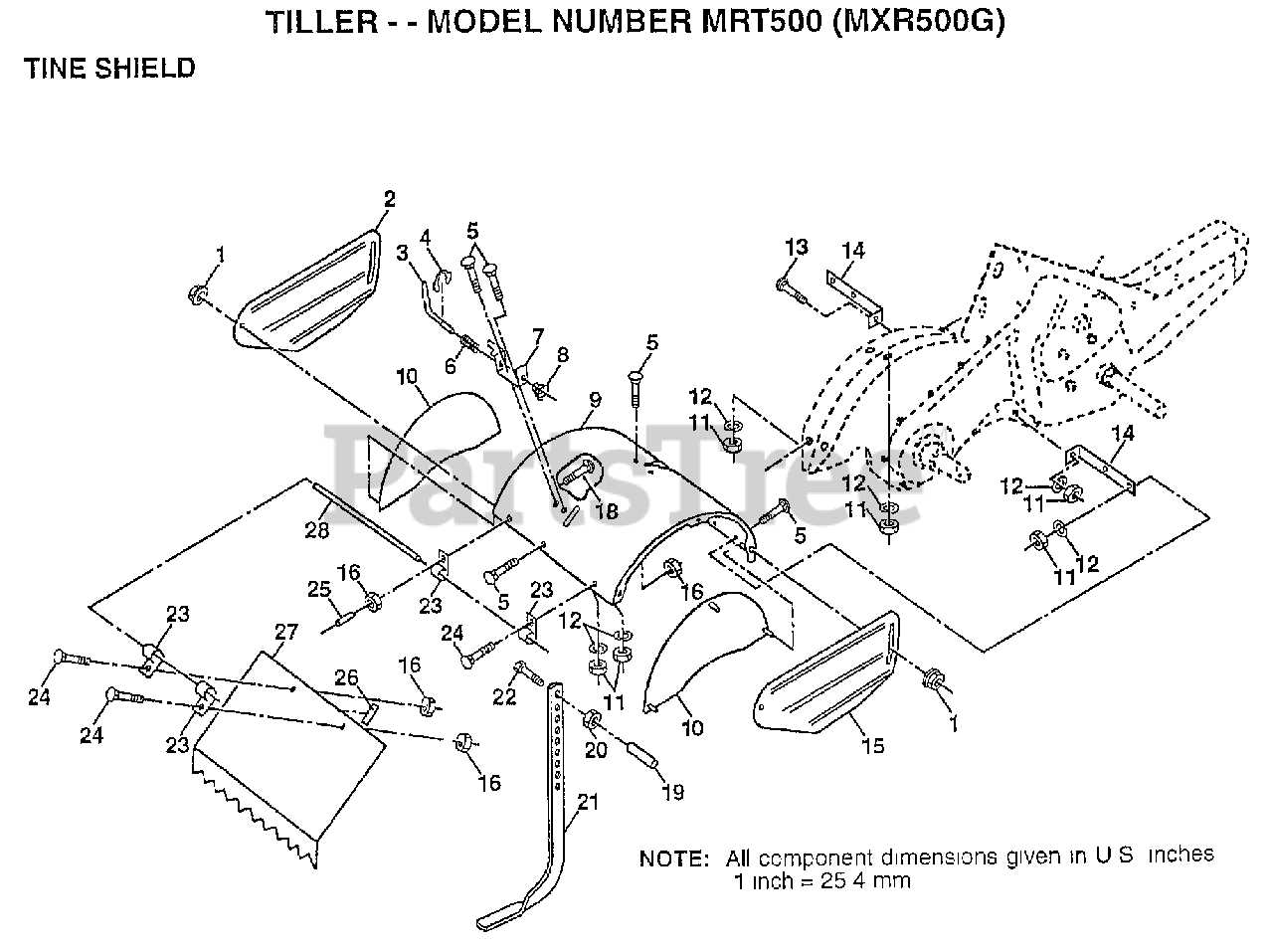

Overview of Tiller Diagrams

Understanding the layout and components of various agricultural implements is essential for efficient operation and maintenance. Visual representations of these assemblies provide users with a clear overview of the essential elements, their arrangement, and how they interact within the machine. This section delves into the significance of such illustrations in facilitating effective repairs and enhancements.

Importance of Visual Representations

Diagrams serve as crucial tools for operators, mechanics, and engineers alike. They simplify complex structures, allowing individuals to identify components quickly and comprehend their functions. Additionally, these illustrations assist in troubleshooting, ensuring that users can address issues with minimal downtime.

Common Elements Illustrated

Typically, these visual guides include various components, such as handles, blades, and drives, arranged systematically to depict their interconnections. Below is a table summarizing key features often highlighted in these visuals:

| Component | Description | Function |

|---|---|---|

| Handle | Control mechanism | Provides user guidance and maneuverability |

| Blade | Cutting element | Engages the soil for effective tilling |

| Drive System | Power transmission | Transfers energy from the engine to the working components |

Benefits of Using OEM Parts

Choosing original equipment manufacturer components offers numerous advantages that enhance the overall performance and longevity of your machinery. These high-quality pieces are designed specifically for compatibility and reliability, ensuring that your equipment operates at its best. Below are some key benefits associated with using these components.

Quality Assurance

OEM components are crafted to meet strict quality standards, providing assurance that they will function as intended. The benefits include:

- Consistent performance and durability.

- Enhanced safety due to rigorous testing protocols.

- Reduced likelihood of malfunctions or failures.

Perfect Fit and Compatibility

Using original parts guarantees a perfect fit, which is crucial for the overall functionality of your equipment. Key points include:

- Easy installation without the need for modifications.

- Improved efficiency in operation.

- Maintained warranty coverage, as using aftermarket alternatives may void guarantees.

In summary, opting for original components not only maximizes the operational efficiency of your machinery but also safeguards your investment for the long term.

Tips for Efficient Installation

Proper setup of your equipment can significantly enhance its performance and longevity. To ensure a smooth installation process, consider the following strategies that will help you achieve optimal results.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions to avoid common pitfalls.

- Gather Tools: Before starting, collect all necessary tools to minimize interruptions during the process.

- Check Components: Inspect all elements for damage or defects prior to assembly to ensure functionality.

- Follow a Systematic Approach: Work step-by-step according to the guidelines to maintain organization and clarity.

- Seek Assistance: If available, enlist a helper to manage heavier items or tricky angles.

Implementing these suggestions can make a notable difference in how effectively and quickly you can complete the installation.

- Plan the layout to ensure everything is easily accessible.

- Double-check alignment before securing components to prevent misalignment issues.

- Maintain a clean workspace to avoid losing small parts and enhance safety.

By adhering to these efficient practices, you can streamline the setup process and enjoy the benefits of your equipment sooner.

Resources for Tiller Repair Guides

When it comes to maintaining and fixing garden equipment, having access to reliable information is crucial. Various resources can help enthusiasts and professionals alike navigate through repairs and upkeep. Whether you prefer manuals, online tutorials, or community forums, the right guides can make the process much smoother.

| Resource Type | Description | Where to Find |

|---|---|---|

| Manuals | Official documentation that provides detailed instructions and specifications. | Manufacturer’s website, local retailers |

| Video Tutorials | Step-by-step visual guides that demonstrate repair techniques and best practices. | YouTube, DIY websites |

| Online Forums | Community-driven platforms where users share experiences, tips, and troubleshooting advice. | Reddit, specialized gardening forums |

| Repair Blogs | Blogs dedicated to equipment maintenance that offer insights, reviews, and repair tips. | Personal blogs, gardening websites |

| Workshops | Hands-on sessions that teach maintenance techniques and allow for direct interaction with experts. | Local garden centers, community colleges |

Utilizing these various resources can enhance your ability to perform repairs effectively, ensuring your equipment remains in optimal condition for years to come.