Effective upkeep of large farming machinery is crucial to ensuring long-term performance and efficiency in the field. Having a clear understanding of the individual components and their layout helps technicians and operators maintain smooth operations during critical seasons. This knowledge not only saves time but also reduces the likelihood of costly breakdowns.

In this section, we will explore the structural layout and functionality of key elements involved in common agricultural cutting equipment. By familiarizing yourself with the arrangement of these essential parts, you can simplify the repair and replacement process, making routine maintenance more efficient. Paying attention to the specifics of each component ensures a longer lifespan for your machinery.

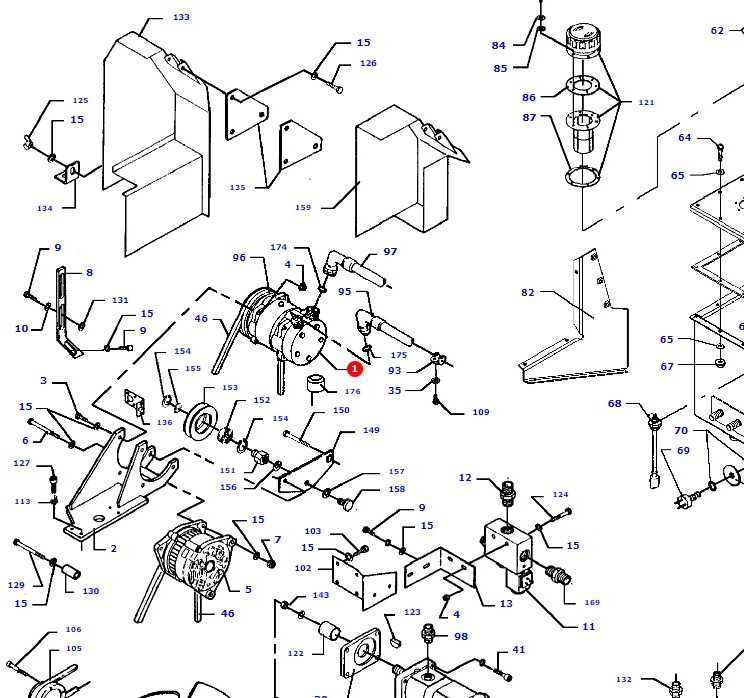

Understanding the Components of New Holland Mowers

Properly understanding the key elements of agricultural cutting equipment is essential for ensuring optimal performance and longevity. Each machine is built with a range of interconnected parts designed to perform specific functions, from cutting grass to ensuring smooth operation in the field. To maintain efficiency, it is crucial to recognize how these elements work together, enabling operators to troubleshoot potential issues and perform regular maintenance.

Frame and Structure

The core of any agricultural machine lies in its robust frame and structure, designed to support heavy-duty use. This section includes the main body, which serves as the foundation, holding all operational mechanisms in place. Durable construction materials are typically used to withstand the rigors of fieldwork and resist wear and tear.

Operational Mechanisms

Key operational mechanisms include various moving parts responsible for cutting, lifting, and driving. These components must be finely tuned and regularly maintained to ensure smooth functioning. Precision in these mechanisms helps achieve consistent and efficient cutting, reducing strain on the machine and improving the quality of work.

Blade System Design and Function

The efficiency and durability of any cutting mechanism rely heavily on how the blades are constructed and how they operate. A well-engineered blade setup ensures smooth performance across different terrains while minimizing wear and tear. Understanding the key design principles behind these systems can help optimize maintenance and operational longevity.

Blade Structure and Materials

Modern blade designs focus on combining strength with flexibility. Typically, they are forged from high-grade steel or alloy, making them resilient to both hard impacts and continuous use. The balance between sharpness and durability is crucial to maintain consistent cutting without frequent sharpening or replacement.

Operational Dynamics

Blades are configured to create a rotating motion that interacts efficiently with vegetation. Their positioning and angles are calculated to maximize cutting speed while reducing strain on the mechanism. This dynamic reduces energy consumption and ensures a cleaner cut, leaving less debris and requiring fewer passes.

Key Elements of the Cutting Mechanism

The efficiency of the cutting process relies on several interconnected components, each contributing to smooth and precise operations. These elements work together to ensure reliable and consistent performance, even under demanding conditions. Understanding their roles and interactions is crucial for optimizing functionality.

Blade Assembly

The sharp blades are the primary components responsible for trimming vegetation. They rotate at high speed, ensuring clean cuts. Proper maintenance of these components is essential for sustained efficiency.

Drive System

The power transmission mechanism plays a critical role in driving the blades. This system ensures that the necessary force is applied uniformly across the entire structure, guaranteeing smooth and even cutting performance.

- Gearbox: Transfers power to the cutting system efficiently.

- Belt and Pulleys: Essential for maintaining correct blade rotation speed.

- Safety Shields: Protects the operator and machinery from debris.

Drive and Transmission Overview

The mechanics of the drive and transmission system play a crucial role in ensuring the smooth operation of agricultural machinery. Understanding how the energy is transferred and the role each component plays is essential for efficient performance and maintenance.

Main Components

The drive system relies on several key parts that work together to transfer power effectively. Below is an overview of the main elements involved:

- Power Source: The initial energy generated for movement.

- Gearbox: Responsible for adjusting the speed and torque of the system.

- Belts and Pulleys: These components help in transferring motion from the engine to other parts of the machine.

Transmission Functionality

The transmission system is designed to manage power distribution efficiently. It adjusts the torque based on the terrain and load, ensuring smooth performance.

- Torque Adjustment: Automatically adapts to varying conditions.

- Speed Control: Regulates the machine’s operating speed for optimal results.

- Durability: Ensures longevity through robust components and precise engineering.

Gearbox Assembly and Maintenance Tips

The gearbox plays a critical role in ensuring the smooth operation of cutting machinery. A well-assembled and properly maintained unit can significantly extend the lifespan of equipment, reduce downtime, and improve efficiency. Regular inspection and upkeep are essential to prevent issues caused by wear, misalignment, or lack of lubrication.

Proper Lubrication: Ensure that all gears and bearings are adequately lubricated. Lack of lubrication is a common cause of overheating and premature wear. Use the manufacturer-recommended oil for optimal performance.

Component Alignment: Misaligned gears can lead to uneven wear and noise during operation. Check the alignment periodically to avoid costly repairs.

Inspection for Wear: Regularly inspect the gears, bearings, and seals for any signs of wear or damage. Early detection can prevent larger failures.

By following these simple tips, you can ensure a long-lasting and efficient gearbox performance.

Connecting the Disc Mower to the Tractor

Establishing a reliable connection between the cutting implement and the agricultural vehicle is essential for efficient operation. Proper alignment and secure attachment ensure that the equipment functions optimally, minimizing the risk of accidents and mechanical failures. This section outlines the necessary steps and considerations for effectively coupling the implement to the tractor.

Preparation Steps

- Ensure that both the tractor and the cutting implement are parked on a level surface.

- Verify that all safety features are functional and that the equipment is in good working condition.

- Gather necessary tools, such as wrenches and pins, to facilitate the connection process.

Connection Procedure

- Align the connection points of the tractor and the implement.

- Insert the hitch pin securely through the coupling mechanism.

- Check that all safety latches are engaged to prevent accidental disconnection.

- Perform a final inspection to ensure everything is correctly secured before operating.

Following these steps will facilitate a safe and effective attachment process, enabling smooth operation and enhancing productivity in the field.

Hydraulic System Parts and Role

The hydraulic mechanism in agricultural equipment plays a crucial role in ensuring smooth operation and efficiency. This system consists of various components that work in unison to facilitate movement and control, allowing the machine to perform its tasks effectively. Understanding these elements and their functions is essential for optimal performance and maintenance.

Key components of the hydraulic system include the pump, which generates fluid pressure, and the cylinders, which convert that pressure into mechanical force. Additionally, the valves control the flow of hydraulic fluid, directing it where needed for specific operations. Other elements, such as hoses and filters, ensure the system remains functional and free from contaminants, contributing to overall reliability.

Each part is integral to the system’s efficiency, with the proper functioning of one affecting the performance of others. Regular inspections and maintenance of these components are vital to prevent breakdowns and ensure the longevity of the equipment.

Safety Features and Protective Elements

Ensuring operator safety is a fundamental aspect of any agricultural machinery. This section outlines the essential safety measures and protective components designed to minimize risks during operation. Implementing these features not only enhances user confidence but also promotes a safer working environment.

- Shielding Guards: These components effectively cover moving parts, preventing accidental contact and potential injuries.

- Emergency Stop Mechanism: Easily accessible controls allow for quick shutdown in emergencies, ensuring immediate cessation of operation.

- Safety Interlocks: These systems prevent the machine from starting under unsafe conditions, such as when access panels are open.

- Visibility Enhancements: Mirrors and lights improve visibility, helping operators maintain awareness of their surroundings.

- Operator Protection Frames: Structures designed to shield the user from debris and other hazards during operation.

Incorporating these protective elements not only complies with safety regulations but also contributes to the overall efficiency of agricultural tasks. Proper maintenance and regular inspections of these features are vital to ensuring their effectiveness over time.

Common Wear Points and Replacement Parts

Maintaining optimal performance in agricultural equipment requires a keen understanding of the components that undergo frequent wear. Identifying these critical areas not only enhances efficiency but also prolongs the lifespan of the machinery. This section highlights common locations prone to wear and suggests suitable replacement options to ensure seamless operation.

Key Components to Monitor

Regular inspection of specific components is essential for early detection of wear. Focusing on high-impact areas can prevent unexpected breakdowns and costly repairs. Below are the primary components that should be regularly checked and maintained:

| Component | Common Issues | Recommended Replacement Parts |

|---|---|---|

| Blades | Dullness, chipping | High-quality replacement blades |

| Bearings | Excessive noise, heat | Durable bearings |

| Belts | Cracks, fraying | Premium replacement belts |

| Gearbox | Leaks, wear | OEM gearbox replacements |

Importance of Timely Replacement

Addressing wear promptly prevents further damage and maintains the effectiveness of the equipment. Regular maintenance schedules and keeping an eye on wear indicators can facilitate timely replacements, ensuring that the machinery operates smoothly and efficiently throughout the season.