The examination of machinery components and their configurations plays a crucial role in maintenance and repair processes. Understanding the relationships between various elements within a machine can significantly enhance its operational efficiency and longevity. This section provides a comprehensive overview of the essential components, allowing users to navigate the complexities of their equipment with ease.

By familiarizing oneself with the intricate connections and functionalities of individual parts, operators can troubleshoot issues effectively and perform necessary adjustments. This exploration not only aids in ensuring optimal performance but also empowers users to undertake informed decision-making regarding repairs and replacements.

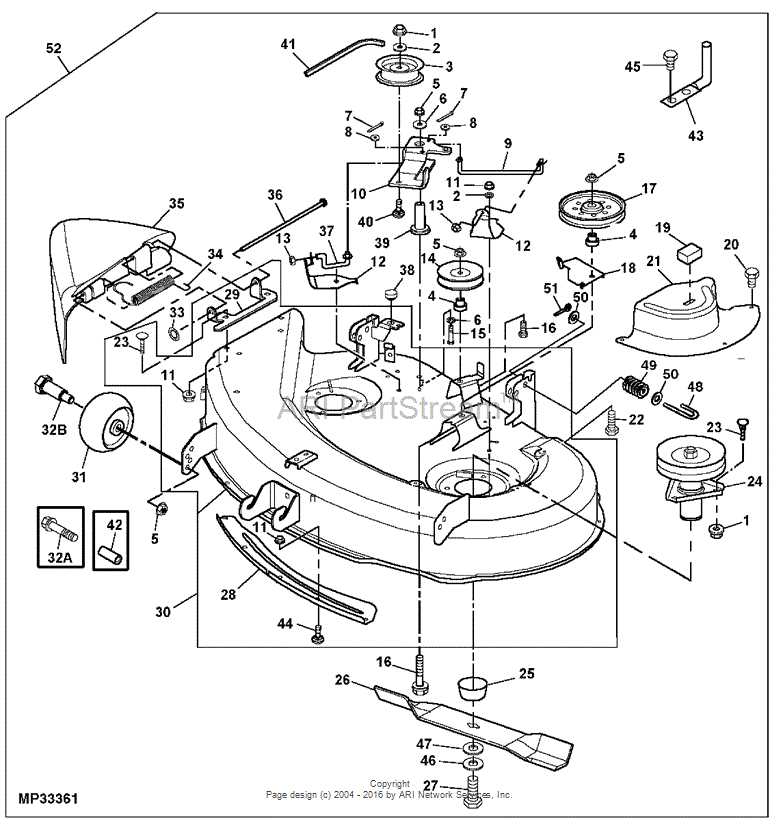

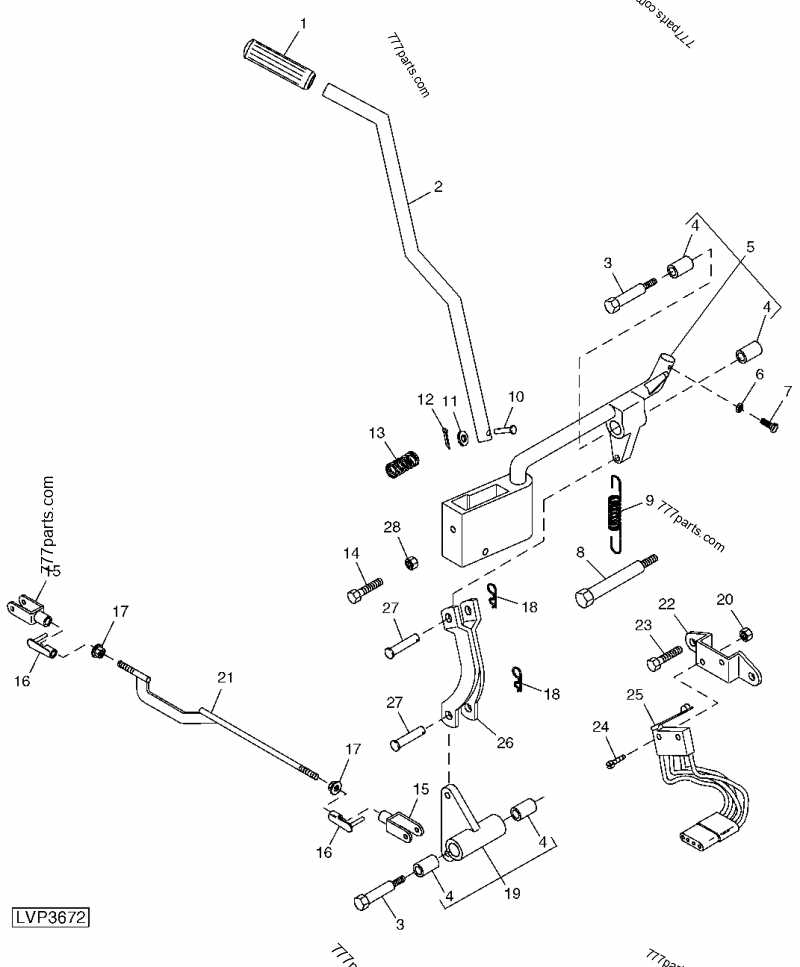

Moreover, a clear visual representation of the component layout can serve as a valuable reference, making it easier for users to identify specific parts during inspections or maintenance tasks. The insights gained from this analysis ultimately contribute to the overall reliability and performance of the machinery.

This section aims to provide a comprehensive understanding of a well-known riding machine, focusing on its design features, functionality, and essential components. By examining various aspects of this model, readers can gain insights into its operational efficiency and maintenance requirements, ensuring longevity and optimal performance.

Design Features and Specifications

The riding machine boasts a robust construction with a user-friendly interface, designed for ease of use and comfort. Its engine delivers reliable performance, making it suitable for various outdoor tasks. Additionally, the cutting system offers precision, ensuring a well-manicured lawn or garden.

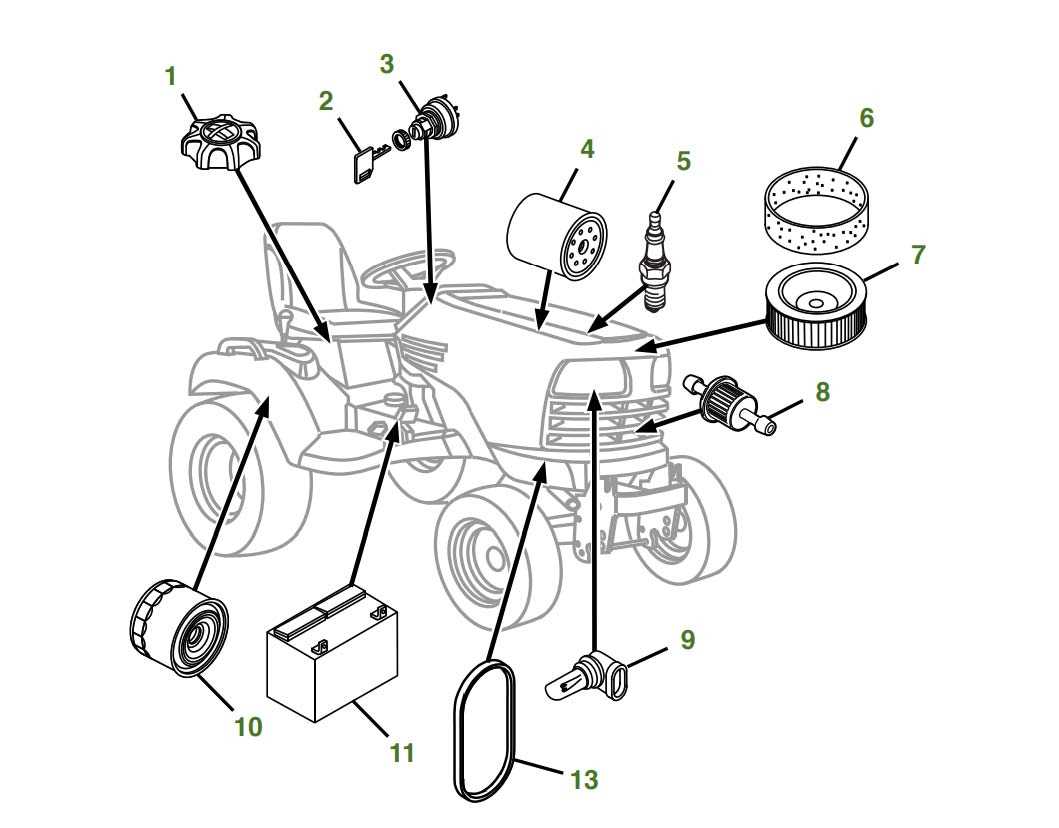

Essential Components for Maintenance

Regular upkeep is vital for maintaining the functionality of this machine. Familiarity with the main components allows users to perform timely replacements and repairs, enhancing the machine’s lifespan. Below is a table listing key elements that require periodic attention:

| Component | Description | Maintenance Frequency |

|---|---|---|

| Engine Oil | Ensures smooth engine operation. | Every 50 hours of use |

| Air Filter | Prevents debris from entering the engine. | Every 25 hours of use |

| Blades | Provides clean cuts for grass and plants. | Check after every use |

| Belt | Transmits power from the engine to the blades. | Inspect every season |

Key Components of L110 Tractor

The functionality of any agricultural vehicle relies heavily on its essential elements. Understanding these core components is vital for maintenance and optimal performance. This section delves into the significant parts that make up this particular machine, highlighting their roles and importance in overall operation.

Engine and Transmission

The heart of the tractor is its engine, which provides the necessary power for various tasks. Paired with a reliable transmission system, it ensures smooth operation across different terrains.

- Engine: This component converts fuel into mechanical energy, driving the entire system.

- Transmission: Transmits power from the engine to the wheels, enabling the vehicle to move efficiently.

Chassis and Steering Mechanism

The structural framework and steering system are crucial for stability and maneuverability. They allow the operator to navigate effectively in diverse environments.

- Chassis: Supports the entire structure and components of the vehicle, ensuring durability.

- Steering Mechanism: Provides control for directional changes, enhancing ease of operation.

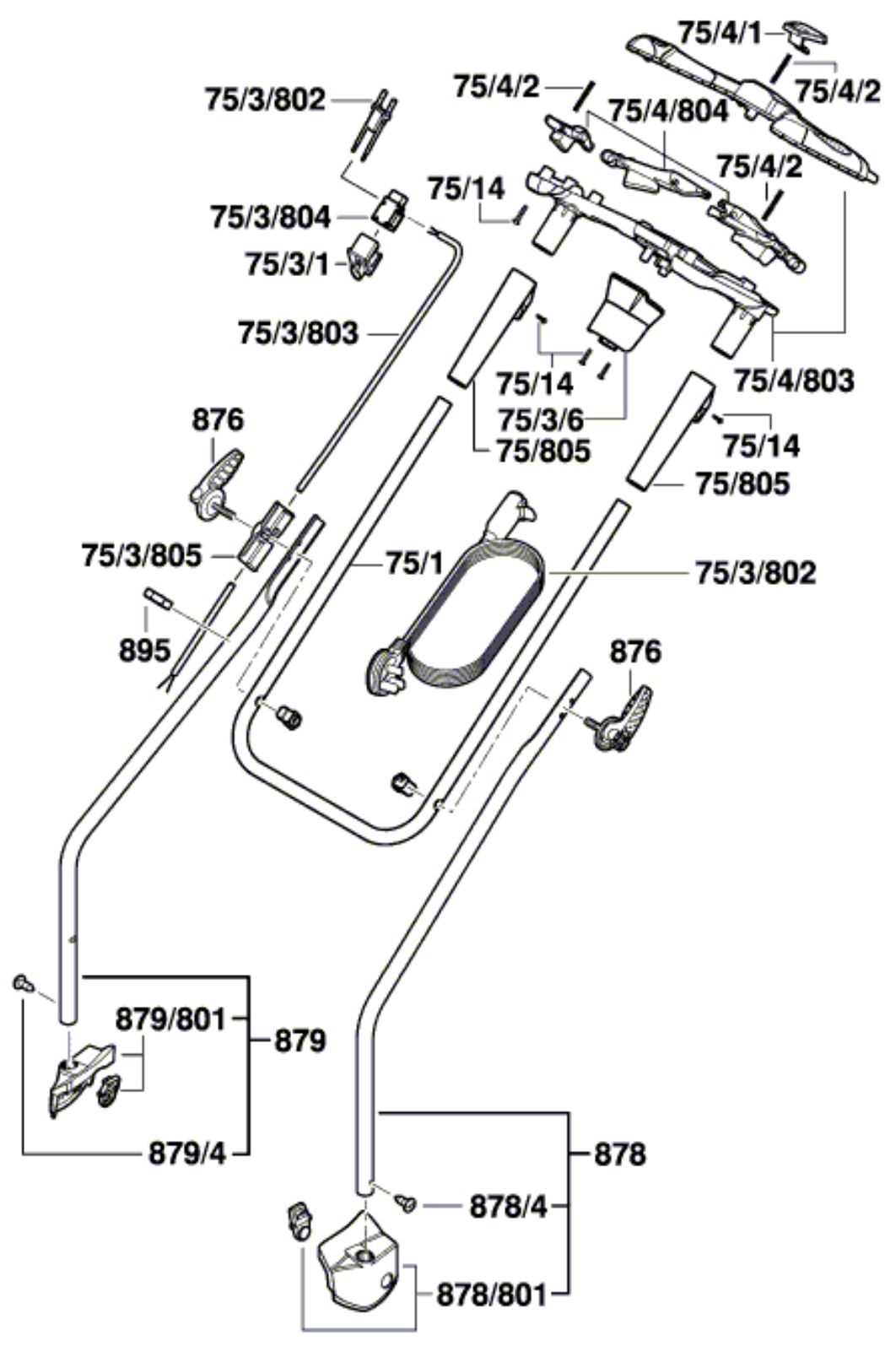

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate details of machinery. They facilitate effective maintenance and repair by providing clear references that enhance comprehension of how various elements fit together. Such illustrations are essential for both professionals and enthusiasts, allowing them to navigate complex systems with greater confidence.

Enhancing Understanding

Illustrative guides enable users to grasp the relationships and functions of different elements within a machine. By visually mapping out the connections and layouts, these tools help users identify components easily, ensuring they have the necessary information to make informed decisions during maintenance or assembly.

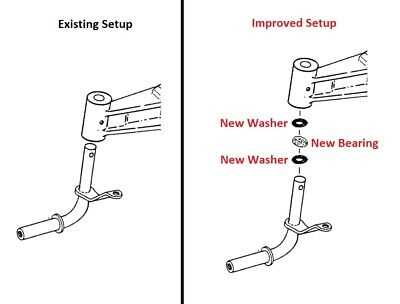

Streamlining Repairs

When issues arise, having access to visual references simplifies the troubleshooting process. Users can quickly locate faulty components and understand their role in the overall functionality of the machine. This efficiency not only saves time but also reduces the risk of errors during repairs, ultimately leading to enhanced performance and longevity of the equipment.

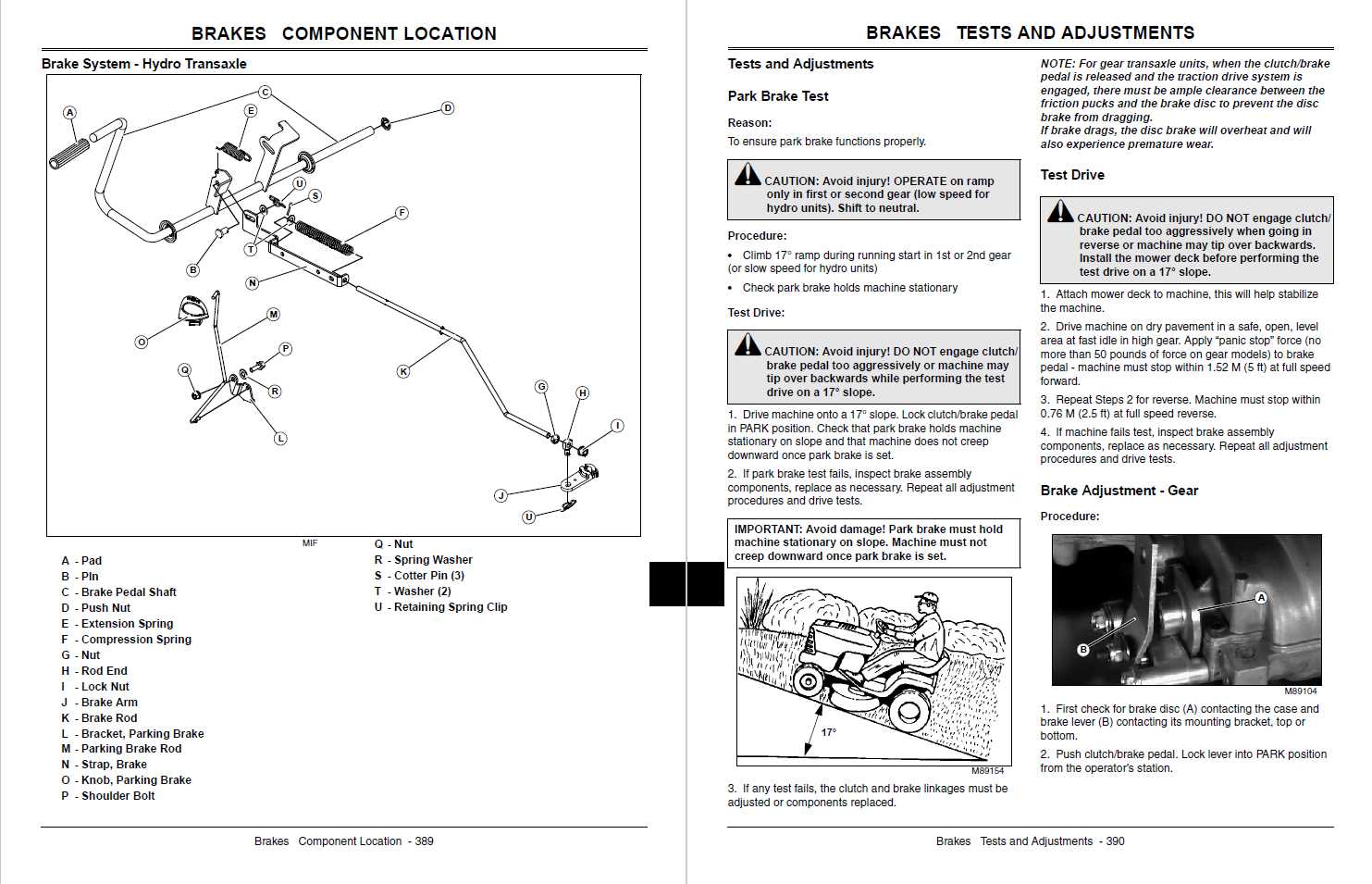

Common Issues with L110 Parts

When maintaining a garden tractor, various components may experience wear and tear, leading to performance issues. Understanding these common problems can help ensure smooth operation and prolong the lifespan of the equipment.

- Engine Performance: Over time, the engine may exhibit decreased power or efficiency due to fuel delivery problems, clogged air filters, or worn spark plugs.

- Transmission Issues: Difficulties in shifting gears or unusual noises can indicate problems with the transmission system, often resulting from low fluid levels or damaged components.

- Steering Difficulties: If steering feels stiff or unresponsive, it may be due to worn tie rods or issues with the steering gear assembly.

- Electrical Failures: Battery drain or failure to start can often be traced back to faulty wiring, corroded connections, or a malfunctioning ignition switch.

Regular inspections and timely replacements of these components can help mitigate issues and maintain optimal functionality.

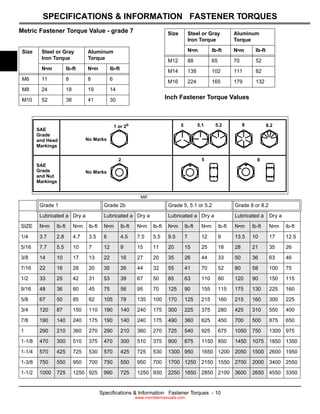

How to Interpret Parts Diagrams

Understanding technical illustrations is crucial for anyone involved in machinery maintenance or repair. These visual representations provide detailed insights into components and their relationships within a system. By effectively interpreting these visuals, users can identify necessary elements for repairs, facilitating efficient assembly and disassembly processes.

Key Elements to Consider

When examining these illustrations, pay attention to symbols, numbers, and color codes. Each of these features offers valuable information about the respective components and their specific functions. Additionally, familiarizing yourself with the legend or key can greatly enhance comprehension.

Steps for Effective Interpretation

Begin by identifying the main assembly and its subcomponents. Trace the connections between parts, noting how they interact. Highlight any special notes regarding installation or maintenance, which are often indicated in the margins or as annotations. This systematic approach will enable a clearer understanding of the entire mechanism.

Replacement Parts for L110 Models

When maintaining and repairing outdoor machinery, having access to quality components is essential for optimal performance and longevity. This section outlines the essential replacements available for a specific model, ensuring users can easily find what they need for effective upkeep.

Essential Components for Maintenance

Every machine requires specific items to function effectively. Key elements include engine filters, belts, and blades that contribute to seamless operation. Utilizing quality replacements ensures that the equipment remains reliable and efficient over time.

Choosing Quality Over Cost

While cost-effective options may seem appealing, investing in superior quality components often leads to better performance and durability. By selecting reliable suppliers and authentic replacements, users can prevent frequent breakdowns and reduce long-term expenses associated with repairs.

Maintenance Tips for L110 Tractor

Regular upkeep is essential for ensuring the longevity and optimal performance of your agricultural machinery. Implementing a few simple practices can prevent potential issues and enhance efficiency, ultimately saving time and resources.

Routine Inspection

Conducting frequent examinations of your equipment is crucial. Check for signs of wear or damage, especially in critical areas such as the engine, transmission, and hydraulic systems. Addressing minor concerns promptly can prevent costly repairs in the future.

Lubrication and Fluid Levels

Ensure that all moving parts are adequately lubricated to minimize friction and wear. Regularly check and top off fluid levels, including engine oil, coolant, and hydraulic fluids, as maintaining proper levels is vital for smooth operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect filters | Every 50 hours | Replace if dirty or clogged |

| Change engine oil | Every 100 hours | Use recommended oil type |

| Check tire pressure | Before each use | Ensure proper inflation for stability |

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Reliable sources provide assurance of quality and compatibility, allowing your machinery to function smoothly.

Authorized Dealers

One of the best options for acquiring authentic components is through authorized retailers. These establishments often have extensive inventories of high-quality items and can offer guidance on selecting the right components for your specific model. Additionally, purchasing from these outlets guarantees that you receive original products, backed by manufacturer warranties.

Online Platforms

The internet has revolutionized the way consumers shop, offering numerous platforms dedicated to equipment supplies. Reputable websites often feature sections specifically for genuine items, complete with detailed descriptions and compatibility information. Always ensure the site is trustworthy by checking customer reviews and ratings before making a purchase.