In this section, we will delve into the intricate structure of a mechanical system that generates and maintains high-pressure output. Such equipment is essential for various tasks in both industrial and domestic environments, offering the power to handle a range of operations efficiently. To fully grasp its capabilities, it is crucial to explore how its different elements interact and function together.

Each part within this system plays a vital role in ensuring smooth and reliable performance. From the central unit that drives the entire mechanism to the smaller yet equally important elements that regulate pressure, every component contributes to the overall efficiency. By understanding how these elements are interconnected, you can not only optimize its use but also ensure better maintenance and longer-lasting functionality.

Additionally, we will examine how periodic inspection and replacement of specific elements can prevent system failures and enhance its longevity. By keeping track of the most critical sections, you ensure uninterrupted operation and minimize the need for costly repairs.

Understanding Air Compressor Components

Grasping the intricacies of a pressure-generating system is essential for both optimal performance and maintenance. These mechanisms consist of various elements, each playing a crucial role in the overall functionality. By familiarizing oneself with these components, users can ensure longevity and efficiency in their operation.

Main Elements of a Pressure System

The primary components include a motor that provides energy, a tank for storing the compressed substance, and a series of valves that regulate flow. Each element interacts with the others, creating a seamless process that allows for the desired output.

Regular upkeep of these components is vital for sustained efficiency. Neglecting any part can lead to performance issues or system failures. Routine checks and prompt repairs can significantly enhance the lifespan and reliability of the entire setup.

Overview of Porter Cable Compressors

This section provides a comprehensive look at a popular brand known for its efficient and reliable machinery. These devices are designed to deliver powerful performance for a variety of applications, making them a preferred choice among both professionals and DIY enthusiasts. With a focus on durability and ease of use, these machines cater to different needs and tasks.

Key Features

These machines are equipped with several essential characteristics that enhance their functionality. They offer robust construction, user-friendly controls, and efficient energy consumption. The versatility of these models allows them to handle diverse tasks, from light-duty to heavy-duty operations.

Maintenance Tips

Proper upkeep is crucial for ensuring longevity and optimal performance. Regular inspections and timely replacements of worn components can prevent potential issues. Keeping the unit clean and storing it in a dry place can also significantly extend its lifespan.

| Feature | Description |

|---|---|

| Durability | Constructed to withstand rigorous use |

| Efficiency | Designed for low energy consumption |

| Versatility | Suitable for a wide range of applications |

Key Parts of Air Compressors

Understanding the essential components of these machines is crucial for effective maintenance and operation. Each element plays a vital role in the overall functionality, contributing to the efficiency and performance of the equipment. Familiarity with these features can enhance troubleshooting skills and extend the lifespan of the device.

Core Elements

The main components include a powerful motor that drives the unit, a robust tank that stores the pressurized substance, and a series of valves that regulate the flow. Each of these features works in harmony to ensure optimal operation and reliability.

Supporting Features

Additional elements such as gauges and filters are crucial for monitoring performance and maintaining cleanliness. Regular checks of these features can prevent malfunctions and ensure consistent operation. Understanding their roles helps users to make informed decisions about care and upgrades.

Importance of Each Component

Understanding the significance of each element in a mechanical system is essential for effective operation and maintenance. Every component plays a unique role, contributing to the overall functionality and efficiency of the machinery. Recognizing these roles not only aids in troubleshooting but also enhances the longevity of the equipment.

Critical Functions

Each individual piece has specific responsibilities that are crucial for optimal performance. For instance, the motor generates the necessary power, while the reservoir stores the pressurized fluid. The regulation mechanisms ensure stable output, allowing for controlled operations. Without these elements functioning correctly, the entire system could fail, leading to potential downtime and costly repairs.

Maintenance and Longevity

Regular inspection and maintenance of each element are vital for ensuring long-term reliability. By addressing wear and tear early, users can prevent more significant issues from developing. Moreover, understanding the importance of these components encourages proactive care, ultimately resulting in better performance and extended lifespan of the machinery.

Common Issues with Air Compressors

In various settings, machinery that generates pressurized gas can encounter a range of typical challenges. Understanding these issues is essential for ensuring optimal functionality and longevity. Regular maintenance and troubleshooting can significantly mitigate problems, enhancing performance and reliability.

One prevalent concern is inadequate pressure levels, which may result from leaks in the system or malfunctioning components. Identifying and sealing any gaps can often restore the expected output. Additionally, excessive noise during operation might indicate wear or misalignment within the machinery. Routine checks can help in early detection and timely repairs.

Another frequent issue involves overheating, which can occur due to prolonged use or insufficient cooling mechanisms. Monitoring operating temperatures and allowing adequate cool-down periods are vital to prevent potential damage. Moreover, the accumulation of moisture in the gas can lead to corrosion and other complications. Implementing proper drainage and using filters can effectively address this concern.

Lastly, frequent cycling on and off can signify an imbalance in the system. Ensuring the correct sizing of components and addressing any underlying malfunctions can stabilize operation and enhance efficiency.

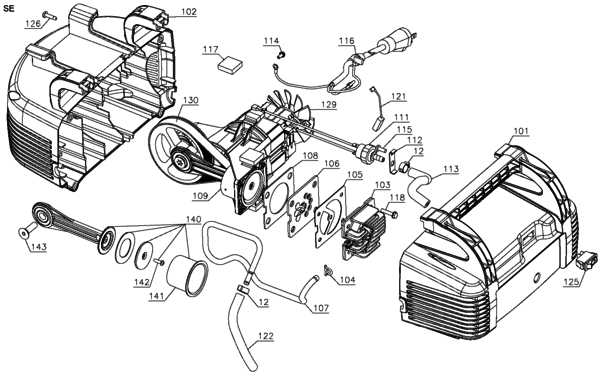

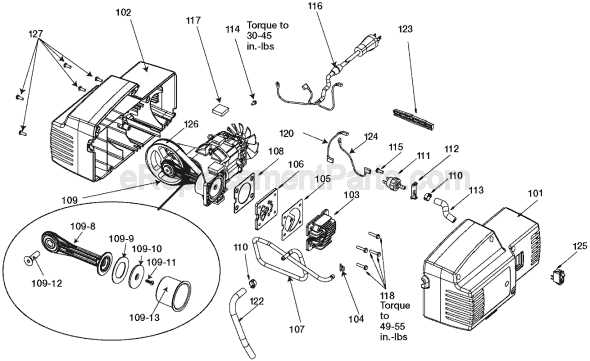

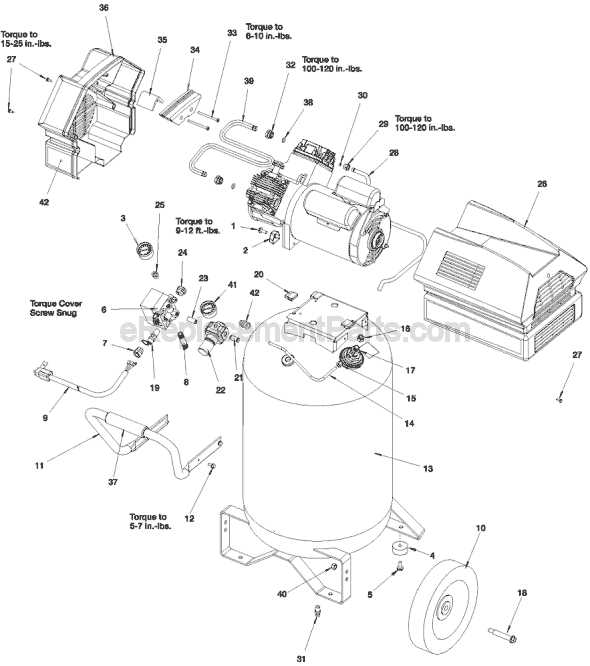

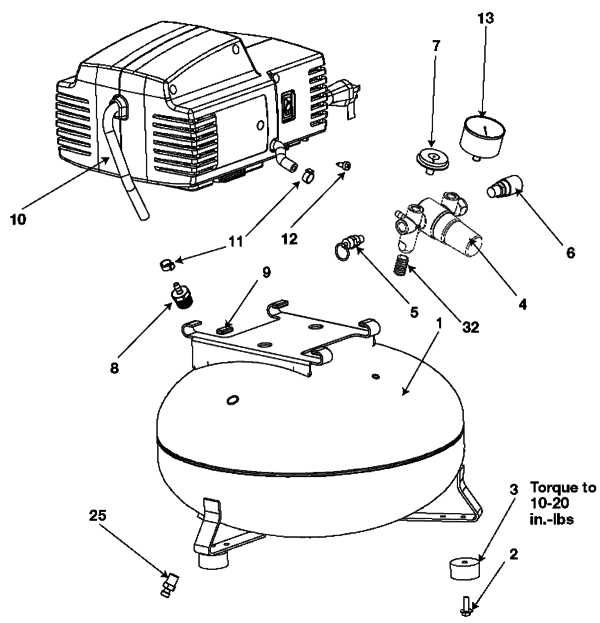

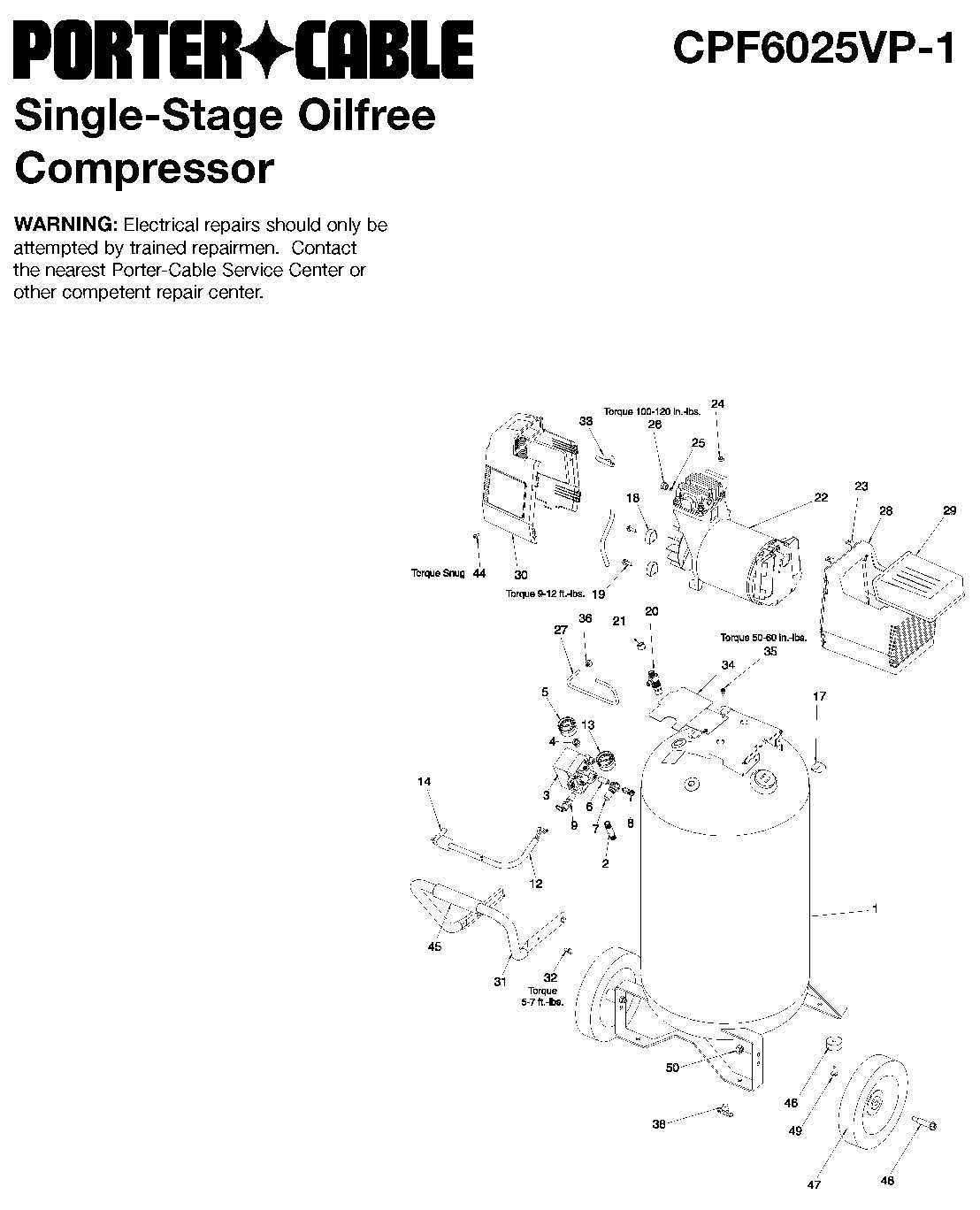

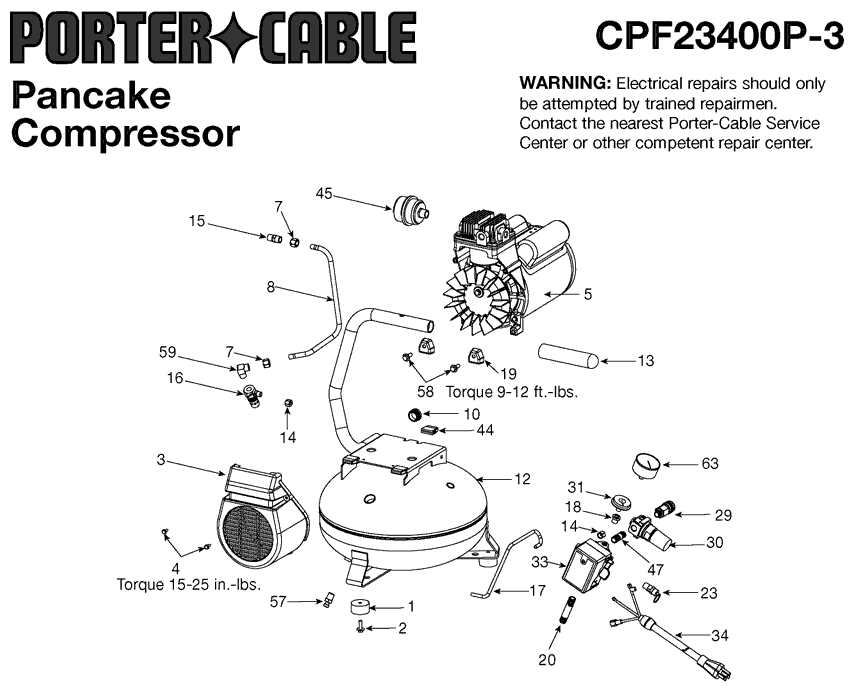

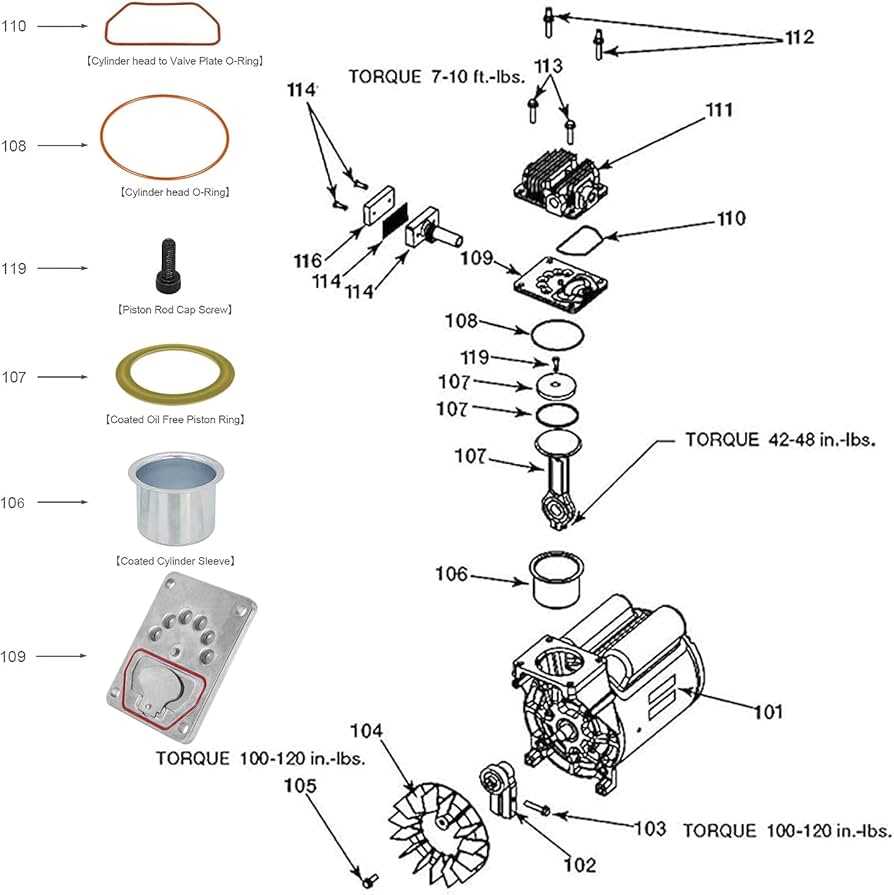

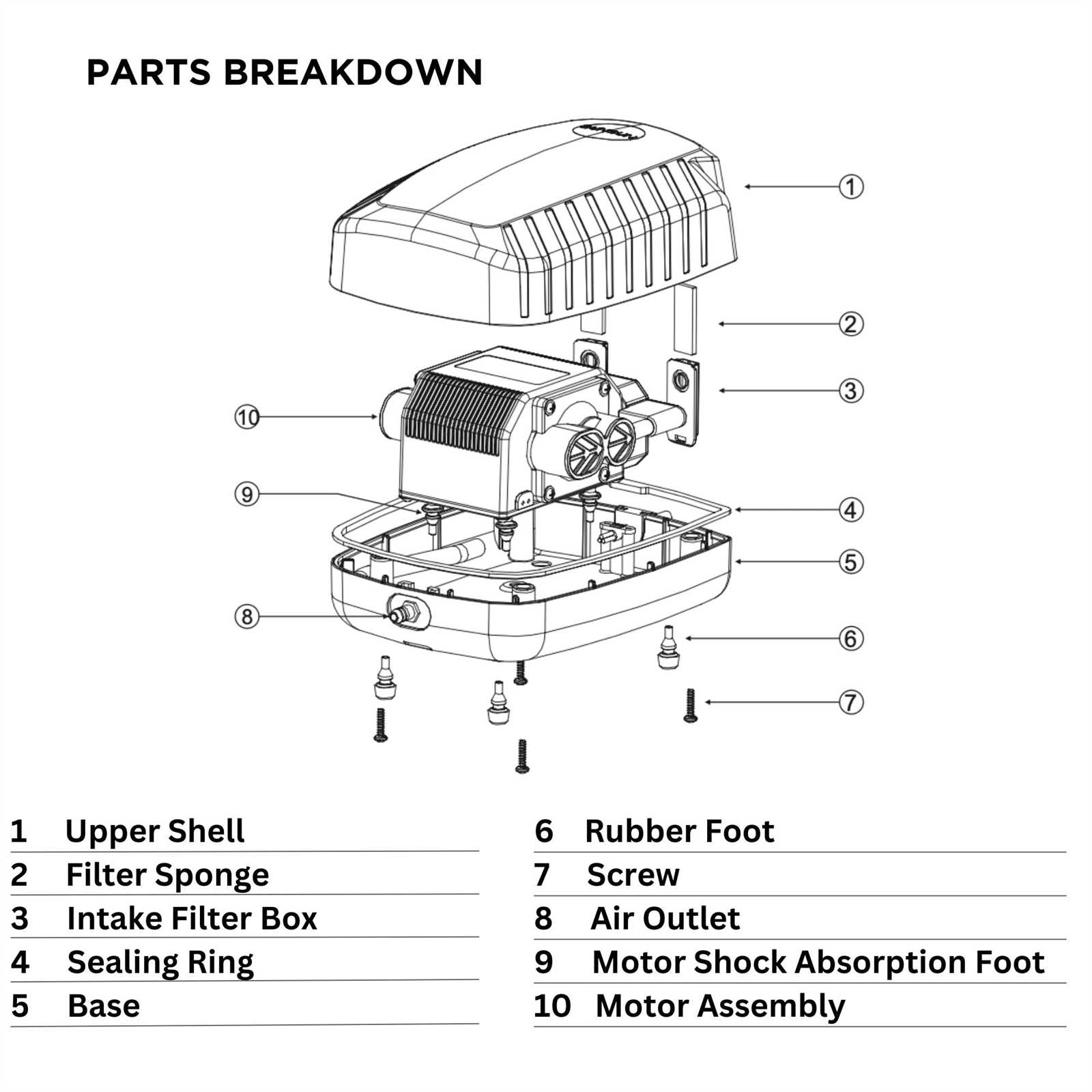

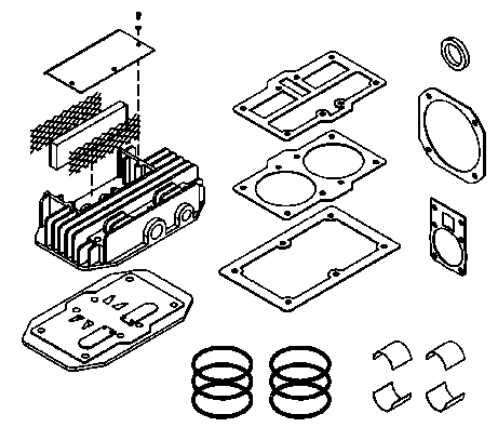

How to Read Parts Diagrams

Understanding component illustrations is essential for anyone seeking to maintain or repair equipment effectively. These visual representations provide a detailed overview of the various elements involved, making it easier to identify, organize, and replace items when necessary. By grasping the structure and notations used in these visuals, one can streamline the repair process and ensure optimal functionality.

Familiarizing with Symbols and Notations

Each illustration includes specific symbols and notations that signify various components and their relationships. Take time to familiarize yourself with these markers to interpret the representation accurately. Key indicators often include arrows, numbers, or letters that point to specific elements, helping you navigate the layout with ease.

Following the Sequence of Assembly

These visuals often illustrate the sequence in which components are assembled. By following the provided order, you can better understand how each element interacts within the system. This knowledge not only aids in efficient assembly but also assists in troubleshooting issues that may arise during operation.

In conclusion, mastering the skill of interpreting component illustrations is invaluable. It empowers individuals to tackle maintenance tasks confidently and enhances their understanding of the equipment’s functionality.

Finding Replacement Parts Easily

Locating suitable components for your equipment can sometimes feel daunting. However, understanding the right resources and methods can streamline the process significantly. With a few strategic steps, you can quickly identify the necessary elements to keep your machinery running smoothly.

Utilizing Online Resources

The internet offers a wealth of information for sourcing components. Various websites specialize in equipment accessories, providing detailed descriptions and images that help in making informed decisions. Search engines can direct you to forums and communities where users share their experiences and recommendations, creating a valuable knowledge base.

Consulting User Manuals

Often overlooked, user manuals are indispensable tools for identifying components. These documents typically contain diagrams and lists of specifications, ensuring you choose the correct items. If the manual is not readily available, many manufacturers provide digital versions on their websites, making it easier to reference essential information.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention to various components ensures optimal performance and minimizes the risk of unexpected failures. By implementing a few simple practices, you can significantly enhance the durability and efficiency of your machinery.

Regular Inspections

Conducting frequent checks is crucial for identifying potential issues before they escalate. Consider the following:

- Inspect seals and gaskets for wear and tear.

- Check hoses for cracks and leaks.

- Examine the overall condition of the unit for signs of corrosion or damage.

Routine Cleaning

Keeping your device clean is vital for preventing debris buildup and ensuring efficient operation. Follow these steps:

- Remove dirt and grime from external surfaces with a damp cloth.

- Clear out any dust or particles from intake filters regularly.

- Ensure that ventilation openings are free of obstructions.

Resources for DIY Repairs

When tackling home maintenance projects, having the right resources at your disposal can make all the difference. Whether you are looking to fix or enhance your equipment, a variety of tools, guides, and online communities can help you navigate the repair process effectively. By leveraging these resources, you can gain valuable insights and develop the confidence needed to address issues on your own.

Online Guides and Tutorials

Numerous websites and platforms offer comprehensive tutorials that guide users through various repair tasks. These resources often include step-by-step instructions, videos, and troubleshooting tips, making it easier to understand the intricacies of your equipment. Exploring these guides can equip you with the knowledge necessary for successful repairs.

Community Forums and Support Groups

Engaging with online communities dedicated to DIY repairs can provide additional support and encouragement. Forums and social media groups allow you to connect with other enthusiasts, share experiences, and seek advice on specific challenges. This collaborative approach can help you discover innovative solutions and gain insights from others who have tackled similar projects.