When maintaining expansive green areas, understanding the intricate systems that facilitate maneuverability is essential. This section explores the various components that contribute to the control mechanisms of such machinery, providing insights into their functionality and arrangement.

In this overview, we will delve into the essential elements that govern the directional capabilities of these machines. By examining how these mechanisms interact, users can gain a clearer perspective on ensuring optimal performance and addressing potential issues that may arise during operation.

With a focus on the structure and role of each element involved, this guide aims to enhance comprehension for both novice and experienced operators alike. Mastering these aspects will not only improve efficiency but also extend the longevity of the equipment, resulting in a more fruitful gardening experience.

This section delves into the fundamental concepts related to the control systems that guide lawn care vehicles. By exploring various components, readers can gain insights into how these mechanisms function, enhancing their understanding of vehicle navigation and maneuverability.

1. Overview of Control Systems

Control systems play a crucial role in the operation of garden vehicles. They facilitate smooth movement and precise handling. This section will cover:

- The purpose of control systems in garden vehicles.

- Common types of control mechanisms.

- Importance of maintenance for optimal performance.

2. Key Components of Control Mechanisms

Understanding the main elements involved in control systems is essential for proper operation. This part will highlight:

- Linkages that connect the steering assembly.

- Bearings that ensure smooth movement.

- Adjustment features for personalized handling.

3. How Control Mechanisms Work

This section will explain the principles behind the functioning of control systems. Key points include:

- The interaction between various components.

- Mechanical advantages provided by the system.

- Impact of design on maneuverability.

4. Common Issues and Solutions

Like any mechanical system, control mechanisms can encounter problems. This segment will cover:

- Typical malfunctions and their symptoms.

- Recommended troubleshooting steps.

- Preventative measures to avoid issues.

5. Maintenance Tips for Longevity

Regular maintenance is vital for extending the lifespan of control systems. This section will provide:

- Routine checks to perform.

- Cleaning and lubrication practices.

- Signs that indicate the need for professional servicing.

6. Upgrading Control Systems

Upgrading components can enhance performance significantly. This part will discuss:

- Benefits of modernizing control systems.

- Options available for upgrades.

- How to choose compatible components.

7. Resources for Further Learning

For those looking to deepen their knowledge, this section will list:

- Books and manuals focused on vehicle control systems.

- Online forums and communities for advice.

- Video tutorials on maintenance and repairs.

8. Conclusion

Summarizing the significance of understanding control systems, this closing section will reiterate:

- The benefits of proper knowledge and maintenance.

- Encouragement to apply learned skills.

- Invitation to explore additional resources.

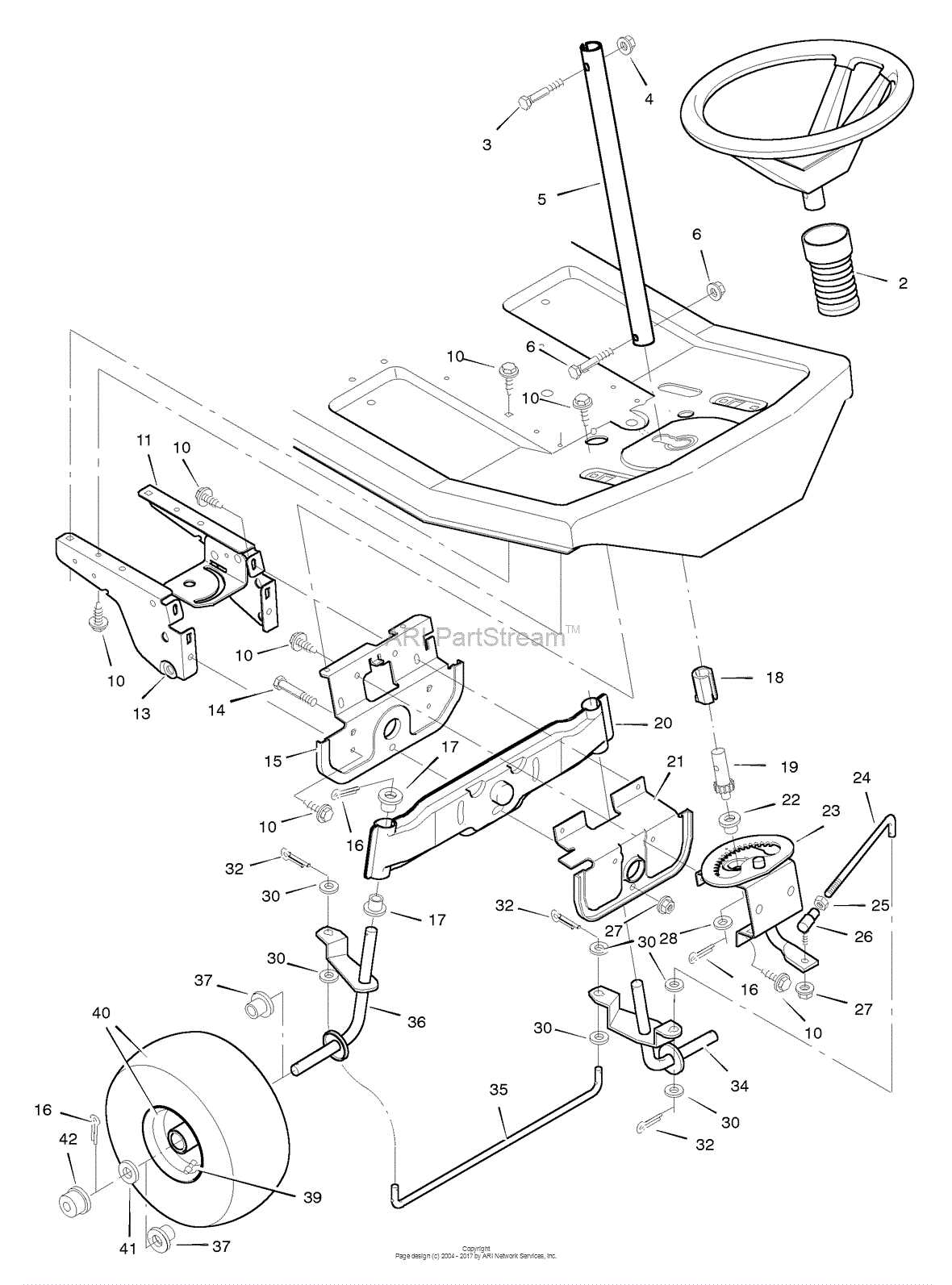

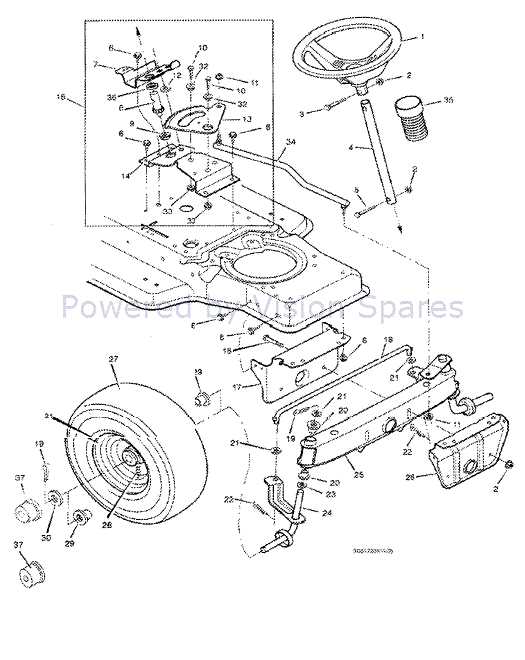

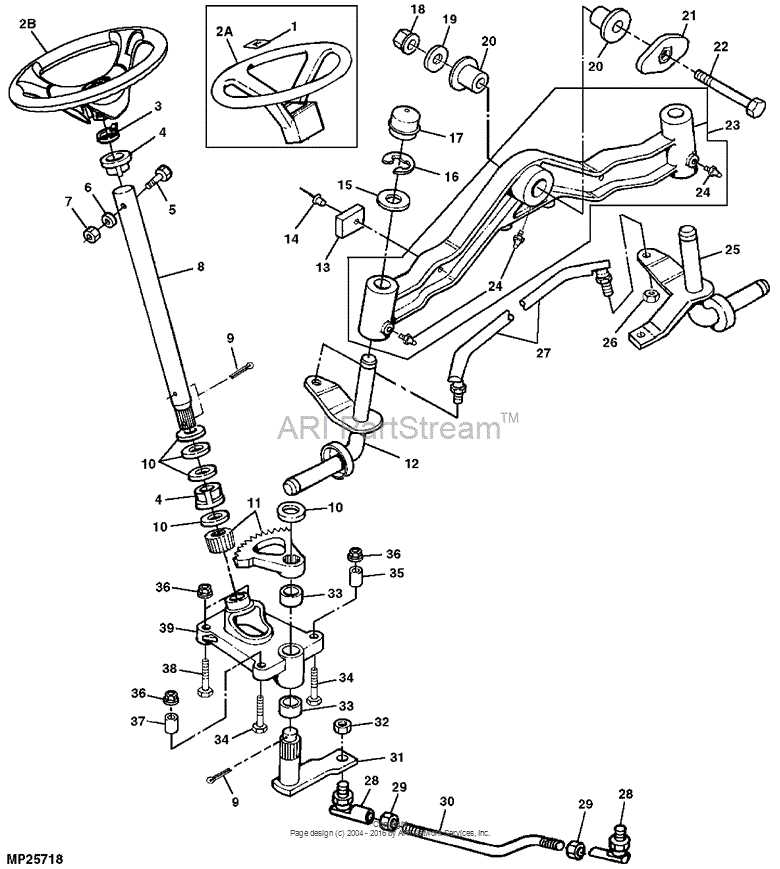

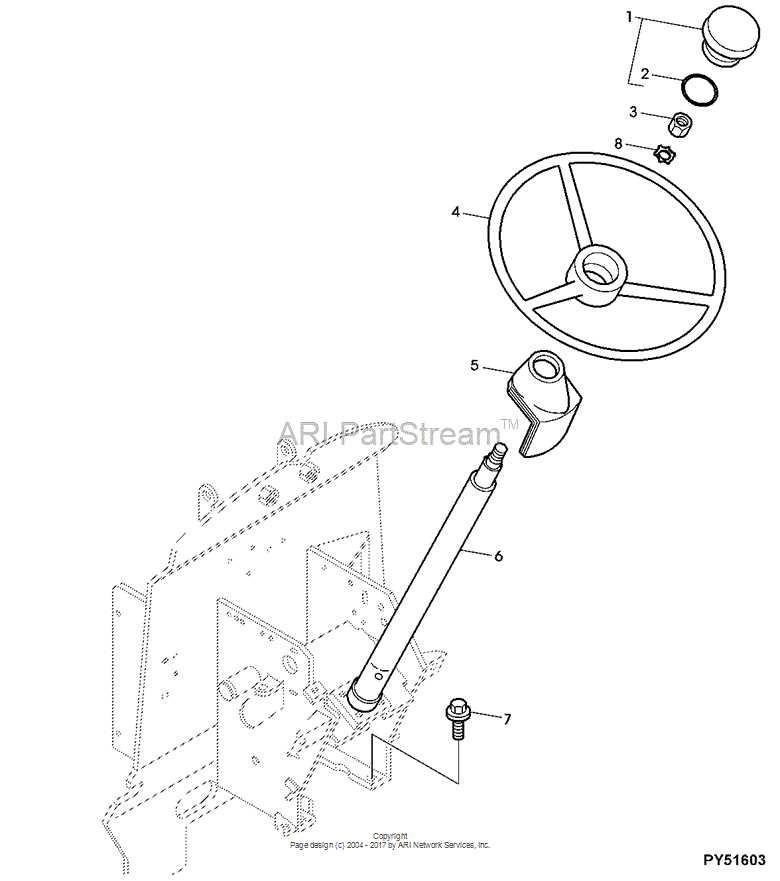

Key Components of Steering Systems

Understanding the fundamental elements that contribute to directional control is essential for effective vehicle operation. These components work together to ensure smooth navigation and stability, enhancing the overall driving experience. A well-designed system is crucial for both performance and safety.

One of the primary elements is the control mechanism, which allows the operator to influence the direction of movement. This component is typically linked to the wheels, facilitating responsiveness to the driver’s inputs. Another significant element is the linkage assembly, which connects the control mechanism to the steering unit, transmitting movements efficiently.

Additionally, the pivot points play a vital role in allowing articulation and flexibility, enabling the vehicle to maneuver with ease. The wheel assembly also contributes to this system by providing the necessary traction and support for turning. Each of these components is designed to work in harmony, ensuring reliable operation and enhancing the vehicle’s maneuverability.

Common Issues with Steering Parts

When operating a vehicle, the control system plays a crucial role in ensuring a smooth and safe ride. Various components within this system can encounter problems, leading to reduced performance and handling difficulties. Understanding these issues can help users maintain their machinery effectively.

Frequent Problems Encountered

- Worn Bearings: Over time, bearings can wear down, causing a lack of responsiveness in the control mechanism.

- Loose Connections: Fasteners and links may become loose, leading to instability and excessive play in the controls.

- Corroded Components: Exposure to moisture can cause rust and corrosion, impairing the functionality of essential parts.

Signs of Malfunction

- Difficulty in maneuvering the vehicle, especially during sharp turns.

- Unusual noises coming from the control assembly, indicating possible damage.

- Excessive vibration felt through the control system, signaling underlying issues.

How to Identify Steering Problems

Recognizing issues with directional control in your equipment is essential for ensuring safe operation and optimal performance. Several signs can indicate that adjustments or repairs are necessary. By being observant and proactive, you can prevent more serious complications down the line.

- Unusual Noises: Listen for grinding or clicking sounds when attempting to change direction. These may signal worn components or misalignment.

- Resistance in Movement: If you notice increased effort required to maneuver, it may indicate binding or friction in the system.

- Inconsistent Tracking: If the vehicle does not follow a straight path or veers off course, it may suggest problems with alignment or balancing.

- Vibration: Excessive shaking during movement can be a sign of loose or damaged components within the control system.

- Fluid Leaks: Check for any leaks under the equipment, as they may indicate issues with hydraulic systems or connections.

Regular inspection and maintenance can help identify these concerns early, allowing for timely interventions that enhance safety and extend the lifespan of your equipment.

Maintenance Tips for Steering Components

Ensuring the longevity and optimal functionality of your vehicle’s guidance system is crucial for a smooth and safe operation. Regular attention to various elements within this system can prevent wear and tear, enhancing the overall performance. Here are some essential tips to maintain these components effectively.

Regular Inspections

Perform routine examinations of the various components involved in the guidance mechanism. Look for signs of wear, such as cracks, corrosion, or unusual noises during operation. Early detection of issues can save time and costs associated with more significant repairs.

Lubrication Practices

Apply appropriate lubricants to moving parts to reduce friction and wear. Regularly check the manufacturer’s recommendations for suitable products and application intervals. Proper lubrication not only extends the life of the components but also ensures smoother functionality during use.

Tools Required for Steering Repairs

Proper maintenance and repair of the directional control system in garden machinery necessitate a set of specific tools. Having the right equipment not only facilitates the repair process but also ensures safety and efficiency. Below is a comprehensive list of essential tools needed for these tasks.

Essential Tools

- Wrench set

- Screwdriver set

- Pliers

- Socket set

- Torque wrench

- Hammer

Additional Equipment

- Grease gun

- Measuring tape

- Flashlight

- Safety goggles

- Gloves

Utilizing the right tools is crucial for achieving optimal results during repair and maintenance tasks, ensuring longevity and smooth operation of the equipment.

Upgrading Your Mower’s Steering System

Enhancing the control and handling of your equipment can significantly improve your mowing experience. A well-designed mechanism allows for better maneuverability and comfort during operation. This section explores various methods to upgrade the control system of your lawn care machine, ensuring a more efficient and enjoyable gardening process.

When considering an upgrade, there are several factors to keep in mind:

- Comfort: Evaluate the ergonomics of your current setup. Improved grips and controls can reduce fatigue during long sessions.

- Responsiveness: Check for any slack or play in the control mechanism. Tightening connections or replacing worn components can enhance responsiveness.

- Durability: Look for high-quality materials and designs that can withstand regular use and environmental exposure.

Here are some popular upgrades to consider:

- Replacing the existing control mechanism with a more advanced version that offers precision and ease of use.

- Installing new, ergonomic grips to provide a better feel and reduce hand strain.

- Upgrading any worn or damaged components to improve overall performance and longevity.

By investing in these enhancements, you can transform your equipment into a more efficient and user-friendly machine. The benefits extend beyond comfort, contributing to a more enjoyable and productive lawn maintenance experience.

Exploring Aftermarket Steering Options

When seeking alternatives for enhancing maneuverability in lawn care equipment, aftermarket solutions can offer a range of enhancements tailored to individual preferences. These options often provide improved control and comfort, allowing users to optimize their experience during operation. Evaluating the available aftermarket enhancements is essential for those looking to upgrade their machinery.

Aftermarket solutions often include components designed for increased durability and performance. Users may discover a variety of features such as ergonomic grips, precision adjustments, and enhanced responsiveness. By exploring these alternatives, operators can significantly elevate their equipment’s functionality and personal satisfaction.

| Option | Description | Benefits |

|---|---|---|

| Ergonomic Handles | Redesigned grips for improved comfort | Reduced fatigue during extended use |

| Adjustable Features | Customizable settings for user preference | Enhanced control for diverse terrains |

| Performance Kits | Upgraded components for better response | Improved efficiency and precision |

Ultimately, the choice to invest in alternative components can lead to a more enjoyable and efficient experience. Exploring the various aftermarket options allows users to tailor their machinery to meet specific needs, ensuring optimal performance and satisfaction.