Maintaining an efficient and functional hydration system requires a clear understanding of its key elements. These systems are designed to provide reliable access to liquids in a variety of settings, ensuring that they meet the demands of different environments. Knowing how each element contributes to the overall operation is crucial for both upkeep and optimization.

When working with such systems, it’s important to familiarize yourself with the various sections that ensure smooth functionality. Each element plays a specific role in the structure, whether it controls flow, maintains levels, or supports overall operation. A detailed look at these structures helps in identifying potential issues and making necessary adjustments.

This guide will provide a thorough overview of the key components involved, highlighting their purpose and interactions within the system. By gaining insight into these essential structures, you’ll be better equipped to maintain and troubleshoot any hydration solution.

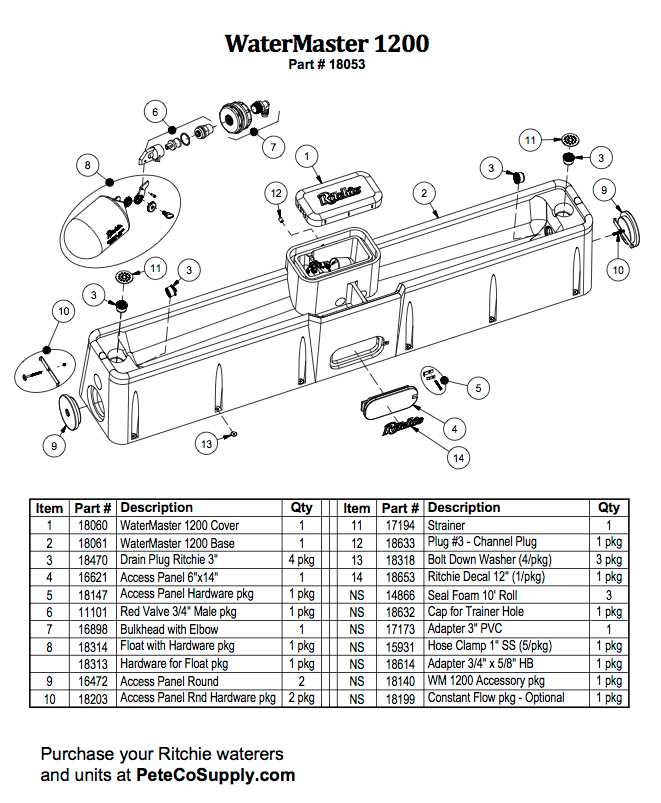

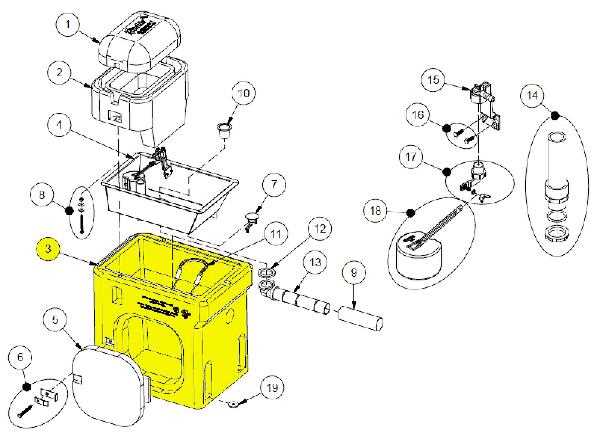

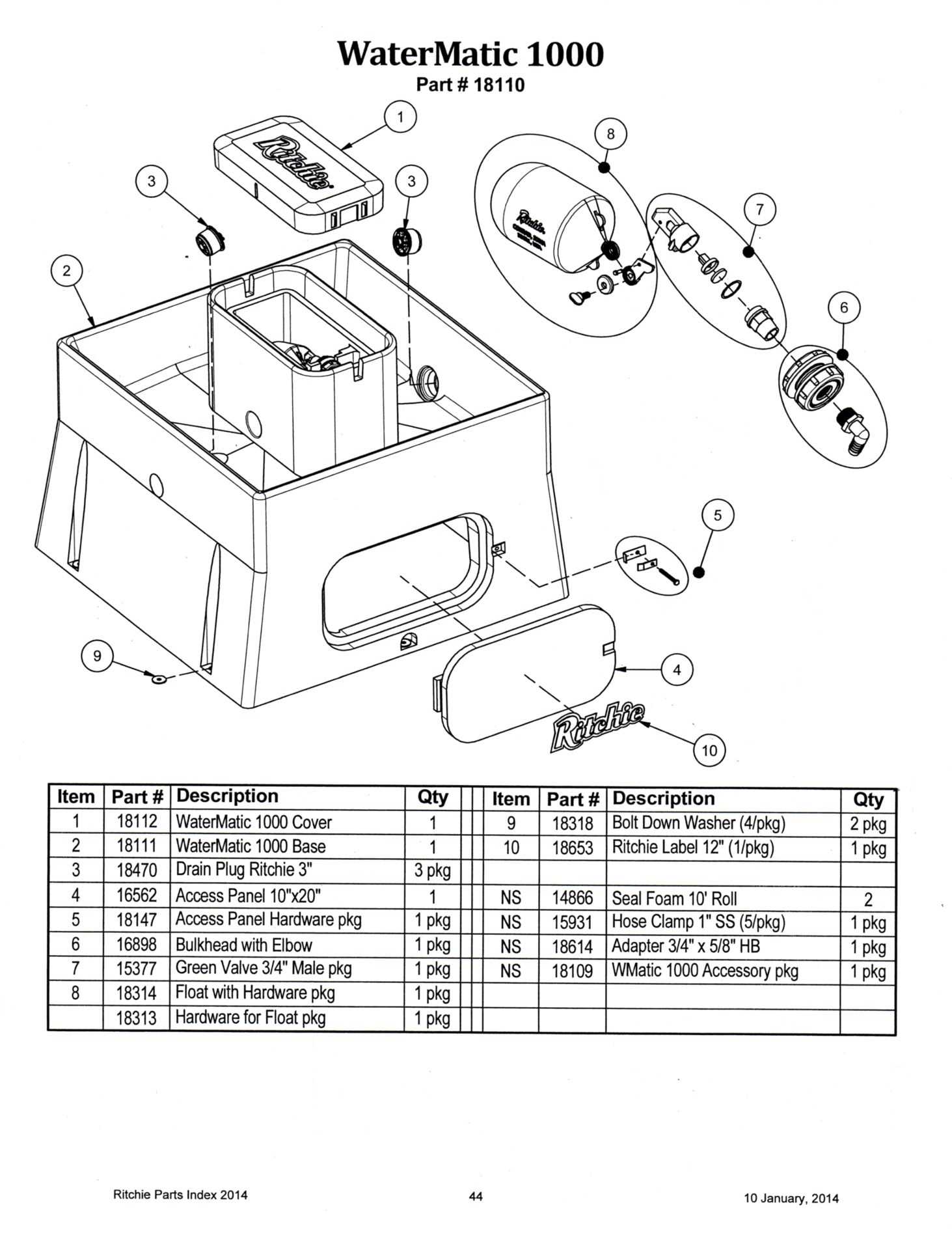

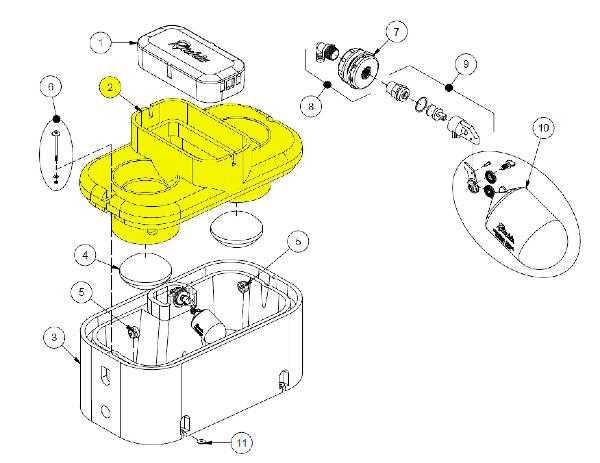

Overview of Ritchie Waterer Components

This section provides an in-depth look at the essential elements that make up an automatic hydration system. Each of these components plays a vital role in ensuring the system functions efficiently, delivering fresh water consistently and maintaining optimal conditions for livestock.

- Float Assembly: Regulates water levels by controlling the flow, ensuring a steady supply without overflow.

- Valve Mechanism: Works in conjunction with the float to open and close the water supply as needed, allowing precise water regulation.

- Heating Element: Prevents freezing during colder months by keeping the water at a suitable temperature, ensuring year-round functionality.

- Insulation Layer: Helps retain heat, making the system more energy-efficient and reducing the risk of water temperature fluctuations.

- Basin or Bowl: The primary reservoir where water is stored, designed to be durable and easy to clean.

- Drain Plug: Allows for easy cleaning an

Identifying Key Parts of the Waterer

Understanding the essential components of this equipment is crucial for its maintenance and efficient operation. Recognizing each element allows for quick troubleshooting and ensures that the system functions smoothly over time. This section will guide you through the main features, helping you pinpoint areas that may require attention or upkeep.

Main Functional Elements

At the core of the system are several critical mechanisms responsible for regulating the flow and distribution. These include the control valve, which manages the flow, and the basin that holds the necessary amount of liquid. Another essential feature is the float system, designed to automatically adjust levels to prevent overflow or shortages.

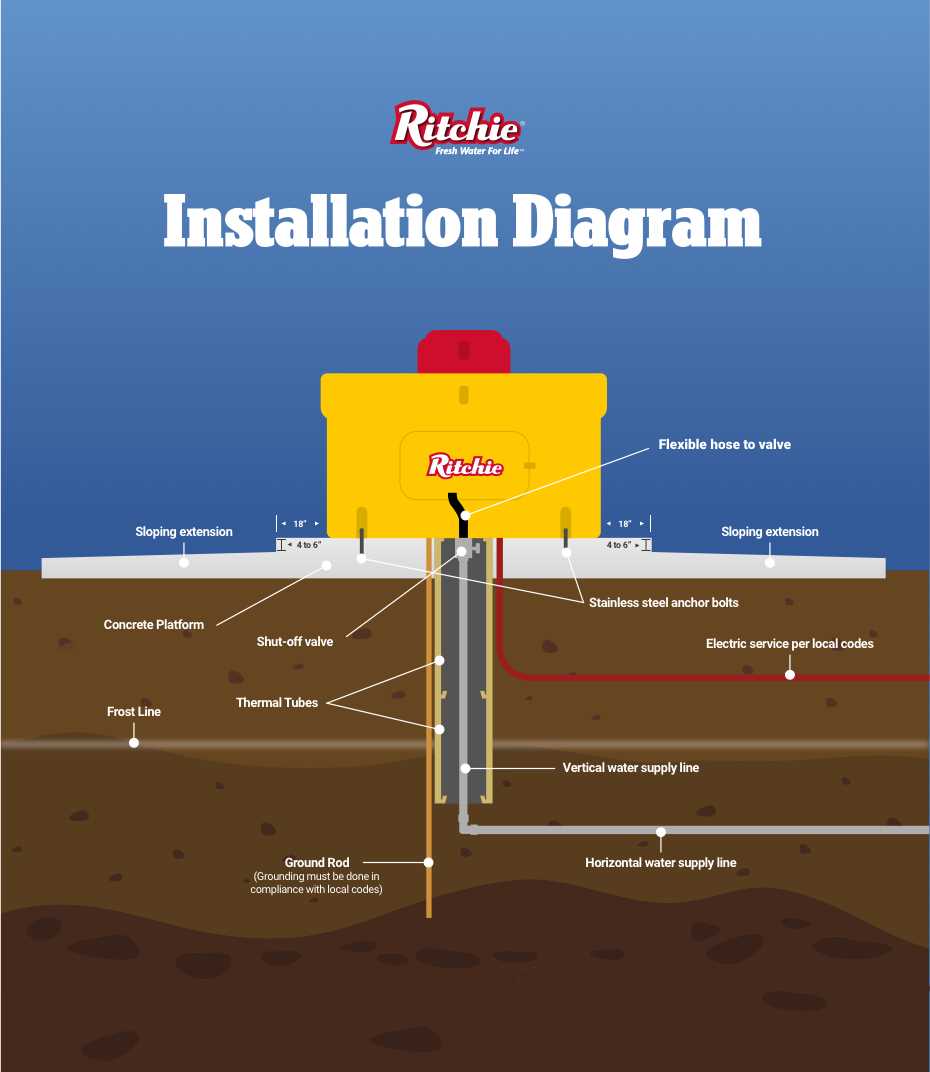

Supportive Structures

Along with the primary mechanisms, several supportive structures ensure stability and durability. These include the casing that protects internal components from external damage and weather conditions. The base and mounting hardware provide a secure foundation, preventing unwanted movement or displacement during operation.

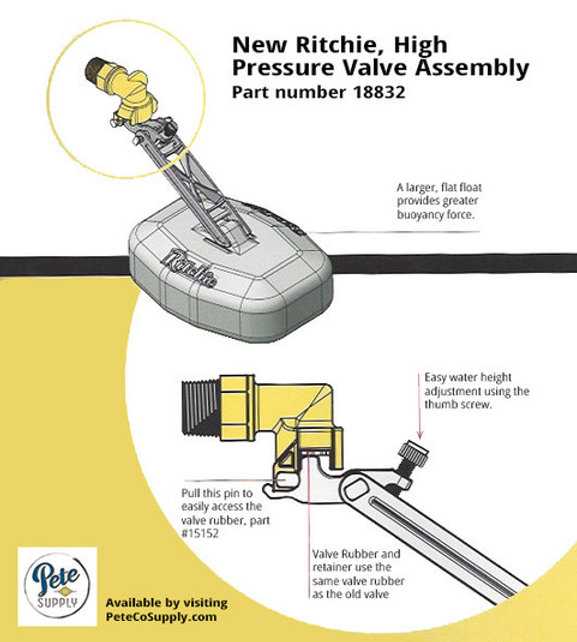

Understanding the Function of Valves and Seals

Valves and seals are critical components in managing the flow and containment of liquids within various systems. Their primary purpose is to regulate movement and ensure that the system operates efficiently without leaks or interruptions. By controlling the direction and pressure, these elements contribute to the smooth operation of the entire mechanism.

Key Role of Valves

Valves are designed to control the passage of fluid by opening, closing, or partially obstructing various pathways. They are essential for maintaining pressure balance and allowing the user to manage flow rates precisely. The integrity and performance of the valve affect the overall functionality, making it crucial to choose the right type for specific conditions.

Importance of Seals

Seals, on the other hand, are used to prevent unwanted leakage by creating a tight barrier between different components. Whether facing high pressure or constant wear, seals ensure that the internal environment remains stable, protecting both the liquid and the machinery. Durable and well-maint

Exploring Heating Elements and Their Role

Heating components play a vital function in maintaining a consistent temperature, especially in systems designed for temperature regulation. These elements ensure optimal thermal performance by providing consistent warmth, which is crucial for preventing freezing and maintaining functionality in colder environments. Understanding how these components work can help in ensuring the longevity and efficiency of the entire system.

The heating mechanism consists of various elements designed to distribute heat evenly. This uniform distribution prevents uneven temperatures, helping the system maintain its integrity. Below is an overview of the typical types of heating components and their roles:

Type of Heating Element Main Function Immersion Heaters Directly heats liquid, maintaining a constant temperature. Electric Resistance Heaters How to Replace a Float Replacing the float is an essential maintenance task that ensures the proper functioning of your equipment. Over time, the float may wear out or become damaged, leading to water level issues. Timely replacement helps maintain efficient operation and prevents potential malfunctions.

Step 1: Prepare the Necessary Tools

Before starting, gather the tools required for the job. You will need a wrench, pliers, and a new float. Having everything on hand will make the process smoother and quicker.

Step 2: Remove the Old Float

Begin by turning off the water supply to avoid any leaks. Use the wrench to loosen the bolts securing the old float. Carefully detach it, ensuring not to damage the surrounding components. Once removed, inspect the area for any debris or wear and clean as necessary.

Tip: Make sure the replacement part is the correct size to fit the system, ensuring optimal performance.

Installing the new float is the reverse of the removal process. Position the new float where the old one was, and secure it with the bolts. Tighten them just enough to hold it in place, but a

Common Issues with Ritchie Waterer Parts

Maintaining optimal performance of animal hydration systems can sometimes be challenging. Various components may experience wear and tear or functionality issues, leading to decreased efficiency. Understanding these common challenges is essential for ensuring proper operation and longevity of the system.

Below is a table highlighting frequent problems encountered with various elements of hydration systems, along with potential solutions to address them:

Component Issue Solution Float Valve Insufficient water flow Check for blockages and ensure the valve moves freely. Insulation Heat loss in cold weather Inspect for damage and replace or add insulation where needed. Heating Element Inadequate heating Test for electrical issues and replace the element if necessary. Drainage System Clogging Clear debris and ensure proper slope for drainage. Structure Cracks or leaks Repair with appropriate sealants or replace damaged sections. By regularly inspecting and maintaining these critical components, one can minimize disruptions and ensure a reliable hydration source for livestock.

Proper Maintenance of Ritchie Waterers

Ensuring the longevity and optimal performance of animal hydration systems is crucial for any livestock operation. Regular upkeep not only enhances efficiency but also prevents costly repairs and replacements. A well-maintained hydration unit contributes to the health and productivity of animals by providing clean and reliable access to water.

Regular Inspection

Frequent examination of the equipment is essential. Look for signs of wear, leaks, or blockages. Early detection of issues can prevent further damage. Key areas to focus on include:

- Checking for cracks or damage to the structure

- Inspecting seals and gaskets for proper sealing

- Examining fittings and connections for leaks

Cleaning Procedures

Regular cleaning is vital to ensure hygiene and functionality. Accumulated debris and mineral deposits can hinder performance. Recommended cleaning steps include:

- Drain the system and remove any debris.

- Use a non-toxic cleaner to scrub surfaces.

- Rinse thoroughly to remove all cleaning agents.

- Check and clean any filters or strainers.

By following these maintenance guidelines, you can ensure that your hydration systems remain in optimal condition, providing reliable service to your livestock.

Troubleshooting Diagrams for Waterer Repairs

When it comes to maintaining hydration systems, identifying and resolving issues effectively is crucial. This section provides visual aids and flowcharts that simplify the repair process. By understanding the various components and their functions, users can quickly pinpoint problems and implement solutions, ensuring optimal performance.

Common Issues and Solutions

Regular maintenance is essential for preventing malfunctions. The following table outlines typical problems, potential causes, and suggested remedies.

Issue Possible Cause Recommended Action No water flow Clogged inlet Check and clear any blockages Leaking from base Worn seals Replace seals or gaskets Incorrect temperature Faulty heater Inspect and replace heating element if necessary Visual Flowcharts for Quick Reference

Utilizing flowcharts can enhance understanding of troubleshooting steps. These visuals guide users through a systematic approach to diagnosing and fixing common issues. A clear, step-by-step format helps to streamline the repair process and minimizes downtime.

Ordering and Sourcing Replacement Parts

When it comes to maintaining equipment, acquiring the necessary components is crucial for optimal functionality. Identifying reliable sources for these essential items can ensure longevity and efficiency. Here are some strategies for obtaining the required components effectively.

Consider the following options for sourcing your needed components:

- Manufacturer’s Website: Visit the official site of the equipment manufacturer. They often provide a catalog of available components along with pricing and availability.

- Authorized Dealers: Locate authorized dealers in your area. These businesses specialize in the manufacturer’s products and usually have a wide selection of items in stock.

- Online Retailers: Utilize reputable online marketplaces that offer a variety of components. Make sure to read reviews to ensure the seller’s reliability.

- Local Hardware Stores: Check with local hardware stores for generic options that may be compatible with your equipment.

- Second-Hand Suppliers: Explore second-hand suppliers or platforms where you can find used components at a lower price, but verify their condition before purchasing.

Before placing an order, ensure you have the correct specifications and any relevant identification numbers. This practice will help prevent compatibility issues and ensure that the items you receive will meet your needs.

Additionally, consider establishing a relationship with your suppliers. This can lead to better customer service, potential discounts, and access to exclusive products. Keeping an open line of communication can be beneficial for future sourcing needs.