Proper upkeep and maintenance of agricultural machinery play a crucial role in ensuring efficient performance and prolonged usage. For those involved in the farming industry, being familiar with the individual components of essential machinery can significantly reduce downtime and prevent unexpected repairs. Knowing the layout and function of these elements aids in both routine inspections and more complex servicing tasks.

In this guide, we will explore how the different mechanisms within harvesting equipment interact and how they contribute to the overall functionality of the machine. By delving into these aspects, you will gain a clearer understanding of how to maintain and troubleshoot machinery effectively. This approach will ultimately help you keep the equipment in optimal working condition, leading to improved productivity in the field.

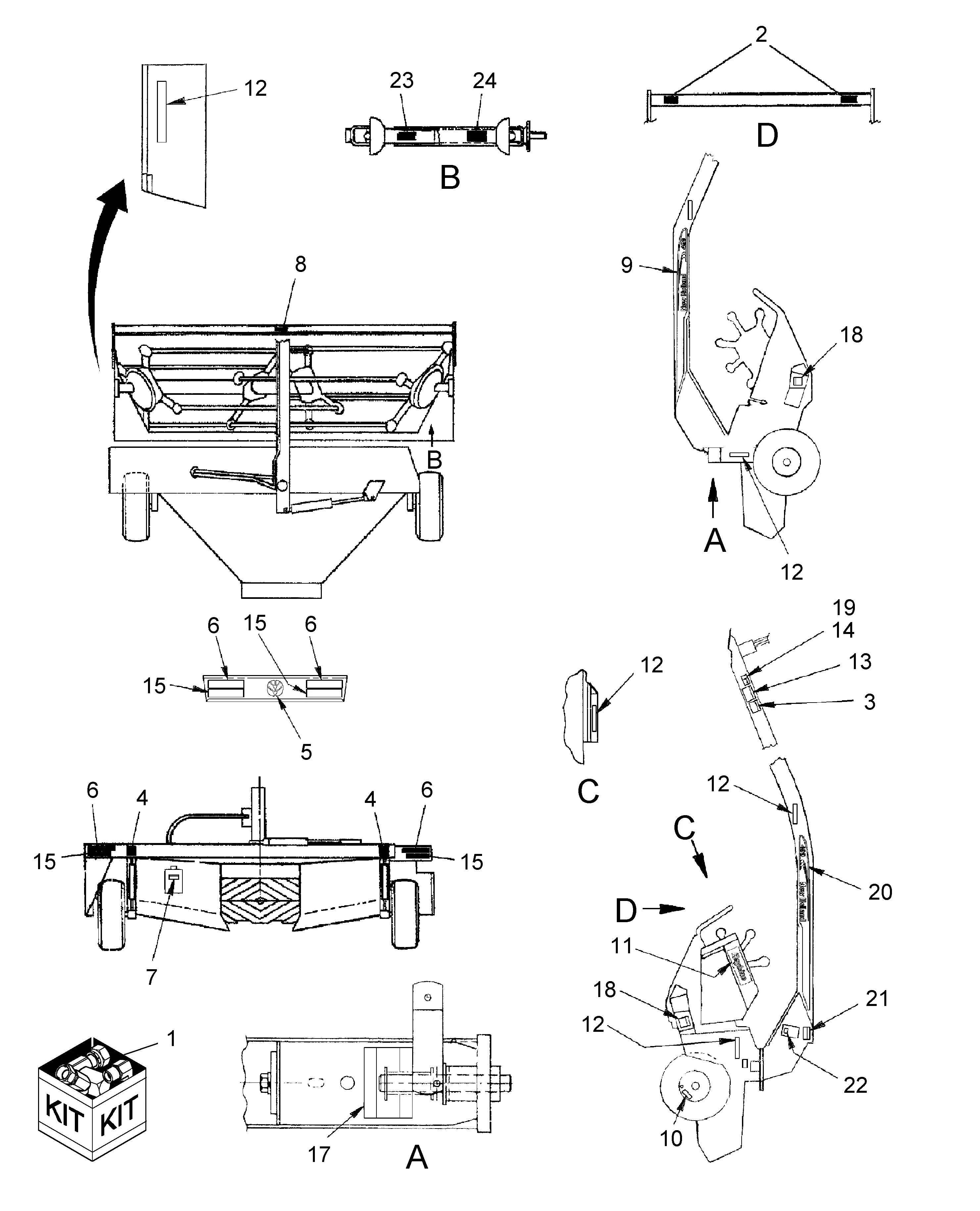

Overview of Equipment Components

The functioning and efficiency of this agricultural machine depend on its numerous elements, each serving a crucial role in the overall operation. Understanding the key assemblies involved ensures optimal performance and longevity of the equipment. This section will guide you through the most significant aspects of the machine’s composition, highlighting essential elements without diving into overly specific technical details.

Key Mechanical Sections

The machine is divided into several fundamental areas, each designed to perform specific functions. From the cutting mechanism to the drive system, each section plays a vital role in ensuring smooth operation in the field. Proper maintenance of these areas is essential for the longevity and reliability of the equipment during harvest.

Table of Essential Components

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

| Cutting Bar | Responsible for cleanly slicing crops at the base. | |||||||

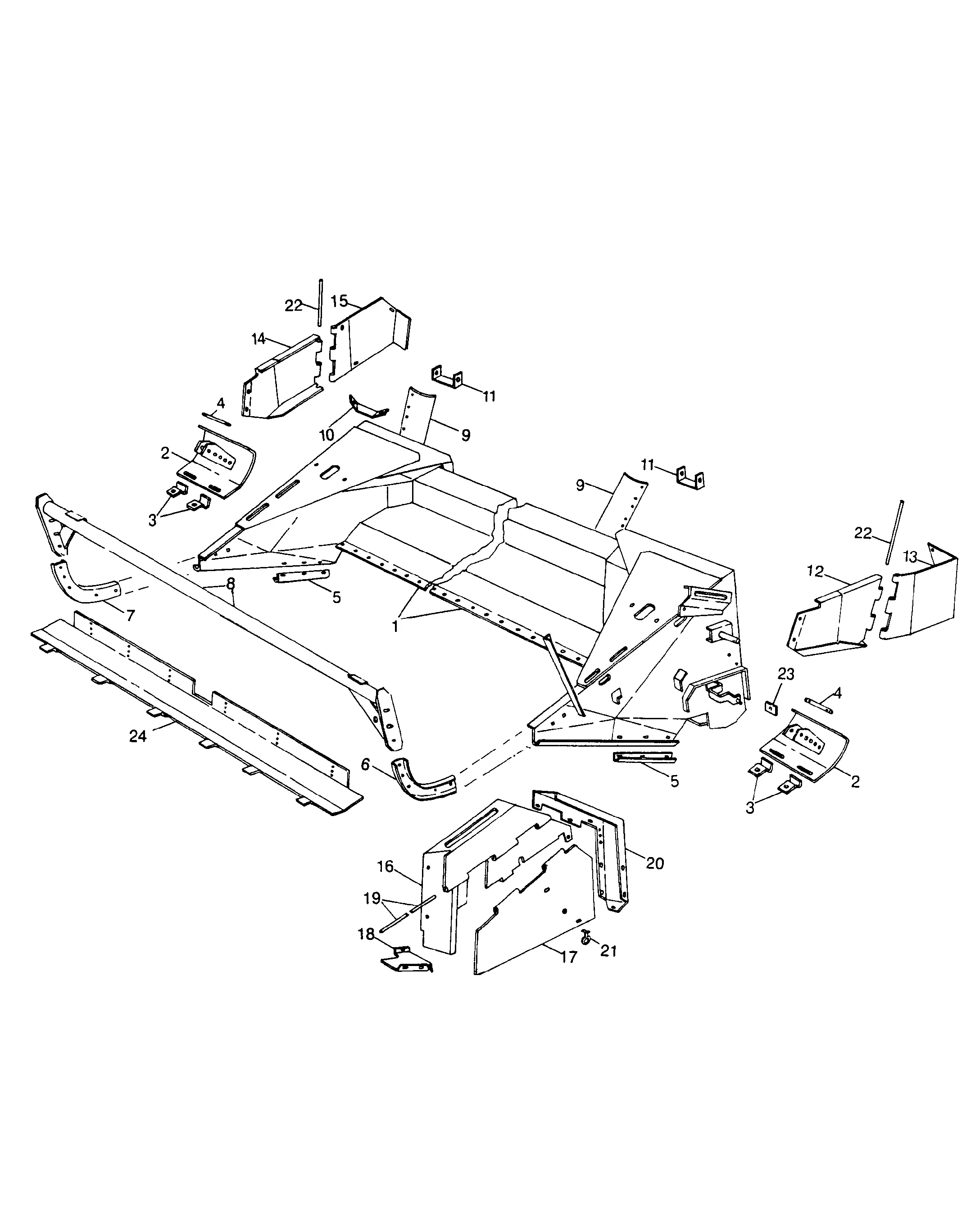

| Main Components of the Haybine

The machine responsible for cutting and conditioning crops consists of several essential parts that work together to ensure effective and efficient operation. Each element plays a crucial role in the overall performance, contributing to the process of harvesting while optimizing time and energy use in the field. Cutter Bar

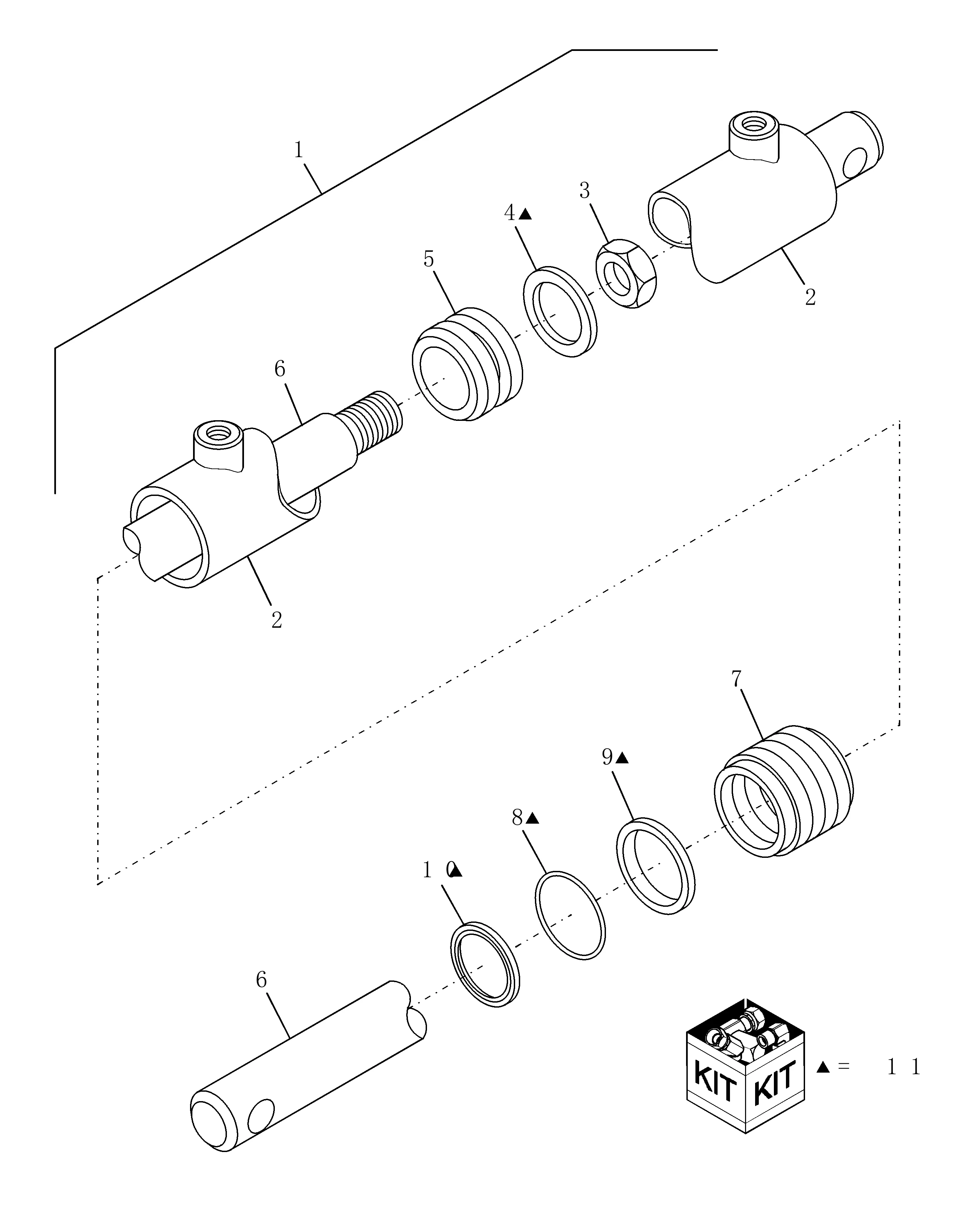

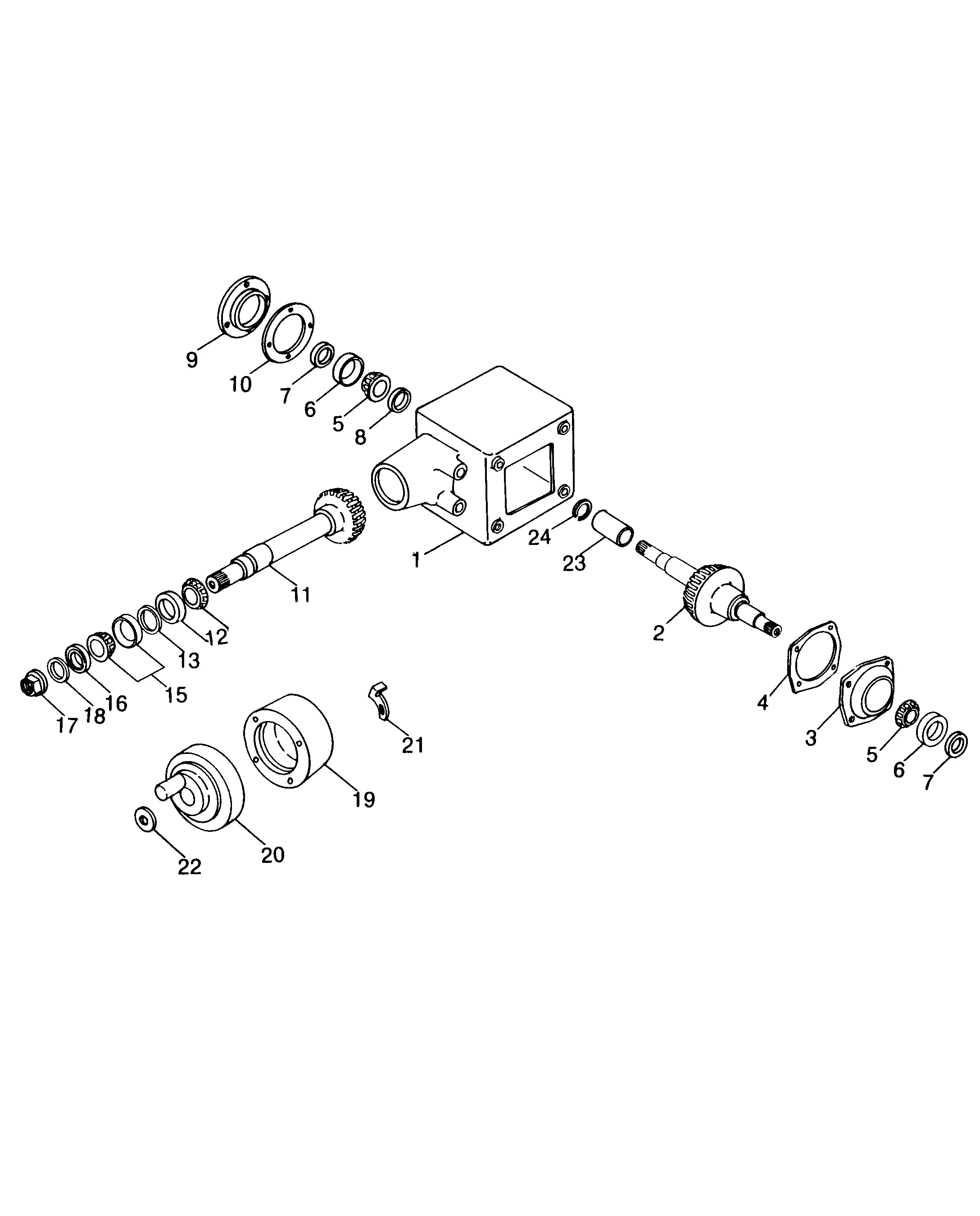

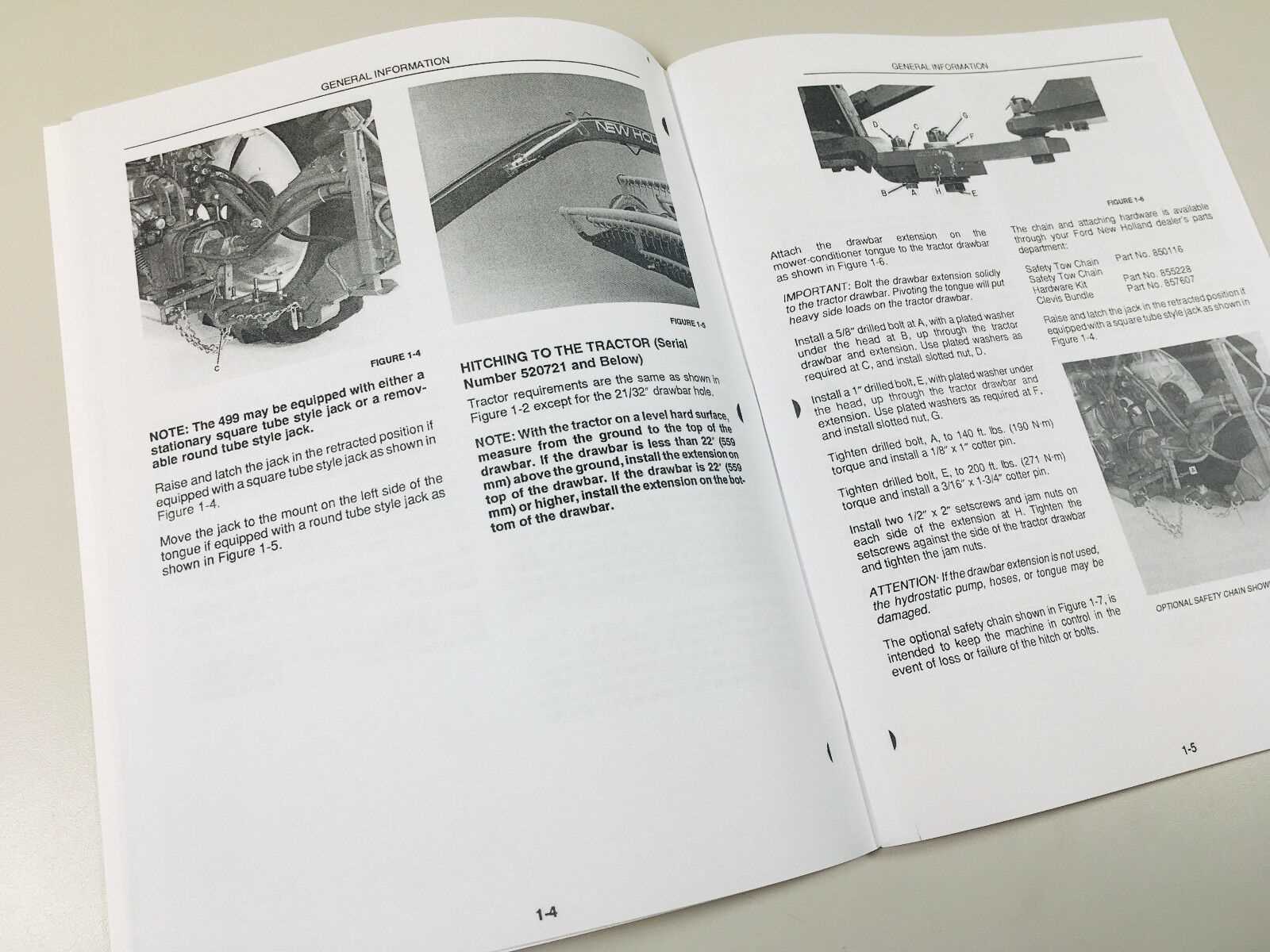

The cutter bar is the key component that performs the initial cut of the crops. Its sharp blades move in a rapid, reciprocating motion, enabling a clean cut through dense vegetation. Regular maintenance of this part ensures consistent cutting quality and reduces wear over time. Conditioner RollersThe conditioner rollers help speed up the drying process of the crops by breaking the stems, allowing moisture to escape more efficiently. These rollers compress the plants as they pass through, preparing them for easier drying and later collection. Understanding the Drive SystemThe drive system is an essential component that transfers power to various parts of the equipment, ensuring smooth and efficient operation. It is responsible for delivering motion and enabling the machinery to perform its functions effectively. By managing how energy flows, the drive mechanism plays a crucial role in optimizing performance. To better understand the drive system, it’s helpful to explore its core elements:

Each part of the system works together to ensure that power is efficiently transmitted, contributing to the overall reliability and functionality of the machine. Key Elements of the Cutting Mechanism

The cutting mechanism of agricultural equipment is designed to efficiently manage and process crops during harvest. It plays a crucial role in ensuring precise and consistent cutting performance. This section will focus on the main components that allow the cutting system to function effectively, providing reliable results across a range of conditions.

|