When it comes to maintaining small engines, having a clear visual representation of their components can make a significant difference. Such illustrations serve as essential guides for enthusiasts and professionals alike, helping them navigate through the complexities of engine assembly and disassembly. They not only enhance comprehension but also streamline the repair process, ensuring that each piece is correctly identified and understood.

In this section, we delve into the intricacies of a particular engine model, providing a comprehensive overview of its key components. These visuals play a vital role in identifying various elements, from the fuel system to the ignition components. Understanding these parts is crucial for effective maintenance and repair, allowing for more informed decisions when it comes to troubleshooting or upgrading.

Whether you are a seasoned mechanic or a DIY hobbyist, utilizing component illustrations can elevate your engine care experience. They transform what might seem like a daunting task into a manageable and straightforward process. By familiarizing yourself with these diagrams, you empower yourself to tackle any engine-related challenge with confidence and precision.

Understanding the Briggs and Stratton 500E Series

This section explores the essential aspects of a specific line of small engines, focusing on their components, functionalities, and applications. These power units are widely recognized for their reliability and performance in various equipment, making them a favorite among users worldwide.

Key Features

One of the standout characteristics of these engines is their user-friendly design. They often include features aimed at simplifying maintenance and enhancing efficiency. Moreover, the compact nature of these units allows for easy integration into numerous machines, from lawnmowers to pressure washers.

Maintenance Tips

Regular upkeep is crucial for prolonging the life of these power units. Users should routinely check fuel levels, replace filters, and inspect spark plugs. Understanding the assembly of components can significantly aid in diagnosing issues and ensuring optimal performance.

In summary, familiarity with the structure and operation of these engines contributes to effective use and maintenance, ultimately leading to better performance and longevity.

Components of the 500E Engine

The engine in question is a finely tuned assembly of various elements that work together to deliver optimal performance. Each component plays a crucial role in ensuring smooth operation and longevity, contributing to the overall efficiency and reliability of the machine.

Powerhead serves as the core unit, housing the combustion chamber and facilitating the conversion of fuel into energy. This part is vital for generating the force necessary to drive the equipment.

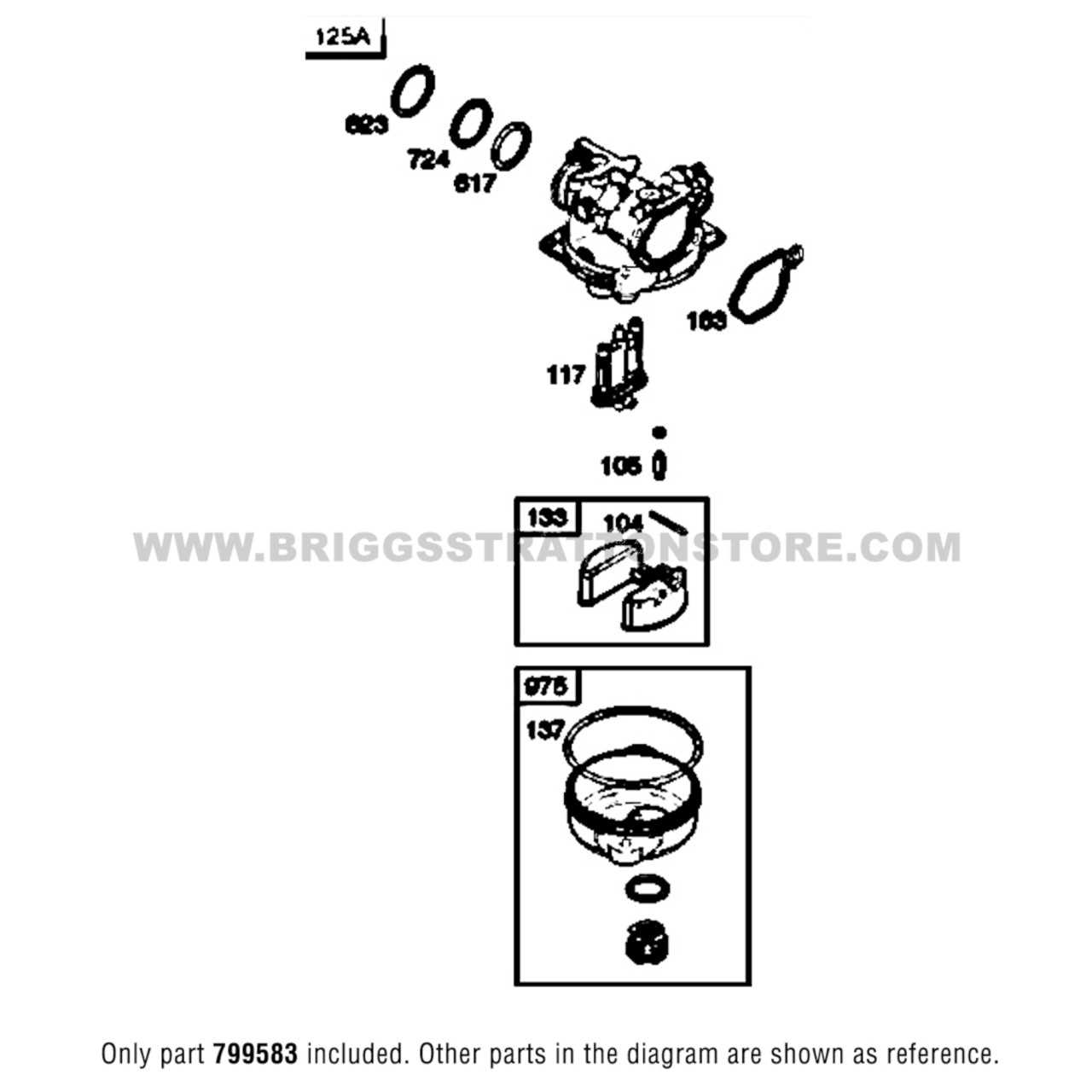

Fuel System includes the carburetor and fuel lines, responsible for delivering the right mixture of air and fuel to the engine. Proper functioning of this system is essential for achieving maximum power output and efficiency.

Ignition System consists of components like the spark plug and ignition coil, which are critical for initiating combustion. A reliable ignition system ensures that the engine starts easily and runs smoothly.

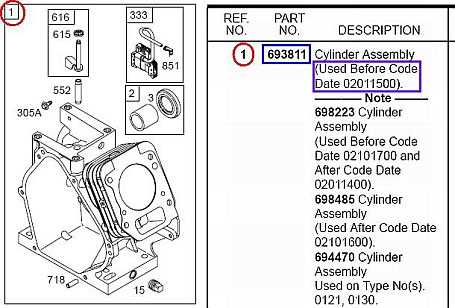

Cylinder is where the actual combustion takes place. This part withstands high temperatures and pressures, making its design and material quality crucial for durability.

Cooling System features fins or a fan that help dissipate heat generated during operation. Effective cooling prevents overheating, which can lead to severe damage and reduced performance.

Lubrication System ensures that all moving parts are adequately oiled, minimizing friction and wear. This system is key to extending the engine’s lifespan and maintaining its functionality.

Each of these components plays a pivotal role in the overall operation of the engine, making understanding their functions important for maintenance and troubleshooting.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visuals provide a clear representation of components, making it easier to identify what is needed for replacement or assembly. By familiarizing yourself with these illustrations, you can save time and avoid potential errors during the repair process.

Deciphering Symbols and Labels

Most technical visuals include a variety of symbols and labels that denote different elements. Familiarize yourself with these indicators as they guide you in recognizing the specific items depicted. Look for reference numbers that correspond to a list, which often details part names and specifications. This connection is vital for ordering the correct components.

Understanding Layout and Groupings

Components are typically arranged in logical groupings, illustrating how they interact with each other. Observe how parts are clustered; this often indicates their functional relationships. Pay attention to any annotations that might clarify the assembly order or highlight crucial connections. Recognizing these relationships will aid in comprehending the overall assembly or disassembly process.

Common Issues with 500E Parts

Understanding frequent complications associated with small engine components can enhance maintenance and improve performance. These challenges often stem from wear and tear, environmental factors, or improper usage, leading to decreased efficiency and reliability. Identifying these issues early can save time and prevent more significant repairs down the line.

Wear and Tear

Over time, components may degrade due to constant operation. Common signs include unusual noises, difficulty starting, and reduced power output. Regular inspections can help catch these problems before they escalate.

Fuel System Problems

Issues related to fuel delivery are prevalent, often caused by clogs or stale fuel. Symptoms may include erratic performance or stalling. Ensuring clean fuel and regular maintenance of the fuel system is essential for optimal function.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any engine. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Following a structured routine can significantly improve reliability and efficiency.

Begin with routine oil changes, as clean lubricant is vital for smooth operation. Replace the air filter periodically to maintain optimal airflow and reduce engine strain. Additionally, inspect the spark plug; a well-functioning spark plug promotes efficient combustion and fuel economy.

Cleaning or replacing the fuel filter is crucial for preventing contaminants from entering the fuel system. Regularly check for loose bolts and components to ensure everything is securely fastened. Lastly, store the equipment in a dry, sheltered location to protect it from environmental elements when not in use.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing high-quality components is crucial for optimal performance. Whether you are repairing a lawn mower or another machine, knowing where to look for reliable replacements can save both time and money. This guide will highlight various options available for locating the necessary items.

There are several avenues to explore when seeking out replacements. Here are some popular options:

| Source | Description |

|---|---|

| Official Retailers | Authorized dealers often carry a comprehensive selection of items and can provide expert advice. |

| Online Marketplaces | Websites like Amazon and eBay offer a vast array of options, often with competitive pricing. |

| Local Hardware Stores | Many community hardware shops stock essential components or can order them for you. |

| Manufacturer’s Website | Checking the official website can provide direct access to specific components and manuals. |

| Salvage Yards | Used parts from salvaged equipment can be a cost-effective solution if you’re comfortable with second-hand options. |

By exploring these resources, you can ensure your equipment remains in peak condition with the right replacements at your fingertips.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These original elements are specifically designed to fit and function optimally within the equipment, ensuring seamless operation and reliability.

One significant benefit of using certified replacements is the assurance of quality. Genuine items are manufactured to meet stringent standards, which means they are less likely to fail compared to generic alternatives. This quality translates to fewer repairs and lower long-term costs.

Moreover, employing original components helps maintain warranty coverage. Many manufacturers require the use of authentic pieces to uphold warranty claims, safeguarding your investment. Additionally, genuine products often come with better customer support and resources, providing users with confidence in their purchase.

Finally, choosing authentic replacements promotes safety. These components undergo rigorous testing to ensure they meet safety regulations, reducing the risk of accidents and enhancing user protection during operation. Overall, investing in original parts leads to a more efficient, reliable, and safe experience.

Tools Needed for Repairs

When tackling maintenance tasks on outdoor equipment, having the right instruments at your disposal is crucial for efficient and effective repairs. This section outlines the essential tools that will facilitate the troubleshooting and fixing processes, ensuring you are well-prepared to handle any issues that may arise.

Wrenches: A good set of wrenches is fundamental for loosening and tightening bolts. Both standard and metric sizes may be required, depending on the specifications of the equipment.

Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are essential for accessing components and securing parts. Ensure you have different sizes to accommodate various screws.

Socket Set: A socket set provides versatility for reaching fasteners in tight spaces. Ratchet handles and an array of socket sizes will streamline the process of removing stubborn bolts.

Pliers: Pliers can be invaluable for gripping, twisting, and cutting wires or small components. Needle-nose pliers are particularly useful for intricate work.

Torque Wrench: To ensure that bolts are tightened to the manufacturer’s specifications, a torque wrench is necessary. This tool helps prevent damage from over-tightening.

Cleaning Tools: Brushes and cloths are important for maintaining cleanliness during repairs. Keeping parts free of debris can significantly enhance performance and longevity.

Safety Gear: Don’t forget personal protective equipment. Safety glasses and gloves will help protect you while you work, ensuring a safe repair experience.

Equipped with these tools, you’ll be well-prepared to address any challenges that come your way, making the repair process smoother and more efficient.

FAQs about the 500E Series

This section aims to address common inquiries regarding a specific line of engines known for their reliability and performance. Whether you are a seasoned user or a newcomer, understanding the essential features and maintenance needs can enhance your experience and ensure optimal functionality.

What are the key features of this engine line?

This engine collection is recognized for its user-friendly design and robust performance. It typically includes easy-start mechanisms, efficient fuel consumption, and a compact structure suitable for various applications.