In the realm of marine propulsion systems, comprehending the layout and functionality of various elements is crucial for effective maintenance and repair. A thorough grasp of the intricate relationships between components can significantly enhance performance and reliability.

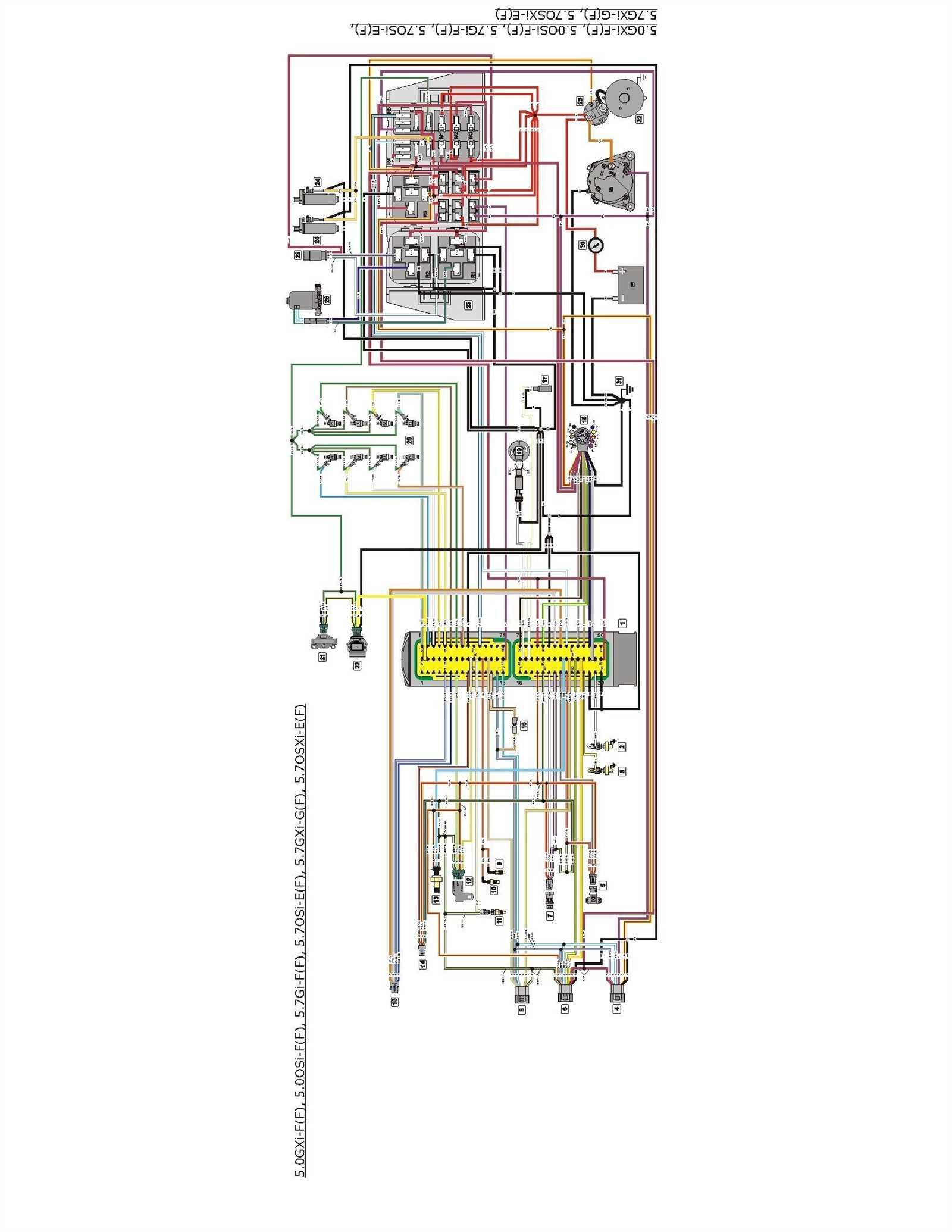

Each engine assembly comprises multiple parts that work in unison, creating a harmonious system. By familiarizing oneself with these intricate schematics, one can identify issues, streamline repairs, and optimize overall efficiency.

This guide aims to provide a detailed overview of component arrangements, offering valuable insights for enthusiasts and professionals alike. With the right knowledge, navigating the complexities of marine engines becomes a more manageable endeavor.

Understanding Volvo Penta 5.0 GXi Components

Familiarity with the essential elements of marine propulsion systems is crucial for maintenance and performance optimization. Each component plays a vital role in ensuring smooth operation, and understanding their functions can help troubleshoot issues effectively.

Here are the primary elements to consider:

- Engine Block: The core structure that houses internal components and facilitates combustion.

- Intake Manifold: Directs air-fuel mixture into the combustion chamber.

- Exhaust System: Responsible for expelling gases produced during combustion, preventing back pressure.

- Fuel System: Ensures the right mixture of fuel and air reaches the engine, including the pump and injectors.

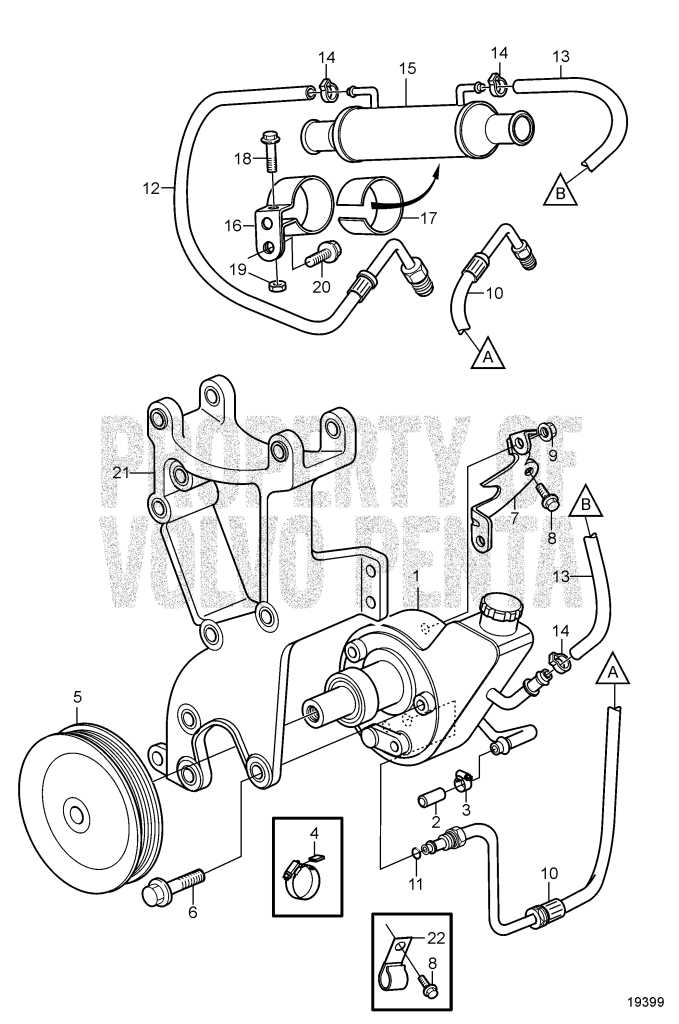

- Cooling System: Regulates engine temperature to prevent overheating, incorporating water pumps and heat exchangers.

- Ignition System: Initiates the combustion process, comprising spark plugs and ignition coils.

Understanding these components allows boat owners to perform routine checks and identify potential issues before they escalate. Proper maintenance of each part ensures longevity and reliability of the entire system.

Key Features of the 5.0 GXi Engine

The marine engine in question is renowned for its combination of power, efficiency, and reliability, making it a popular choice among boating enthusiasts. Designed to perform well under various conditions, it offers an impressive balance of speed and fuel economy, ensuring an exhilarating experience on the water.

Power and Performance

This engine is engineered to deliver robust horsepower, providing swift acceleration and impressive towing capacity. Its advanced design allows for quick response times, ensuring that vessels can navigate through challenging waters with ease. The innovative engineering also contributes to smoother operation, reducing vibrations and enhancing overall comfort.

Fuel Efficiency and Environmental Considerations

One of the standout attributes of this marine powerhouse is its fuel efficiency. By optimizing combustion processes, it minimizes fuel consumption without sacrificing performance. Additionally, this engine meets modern environmental standards, reducing emissions and promoting a greener boating experience. This commitment to sustainability is increasingly important for today’s eco-conscious consumers.

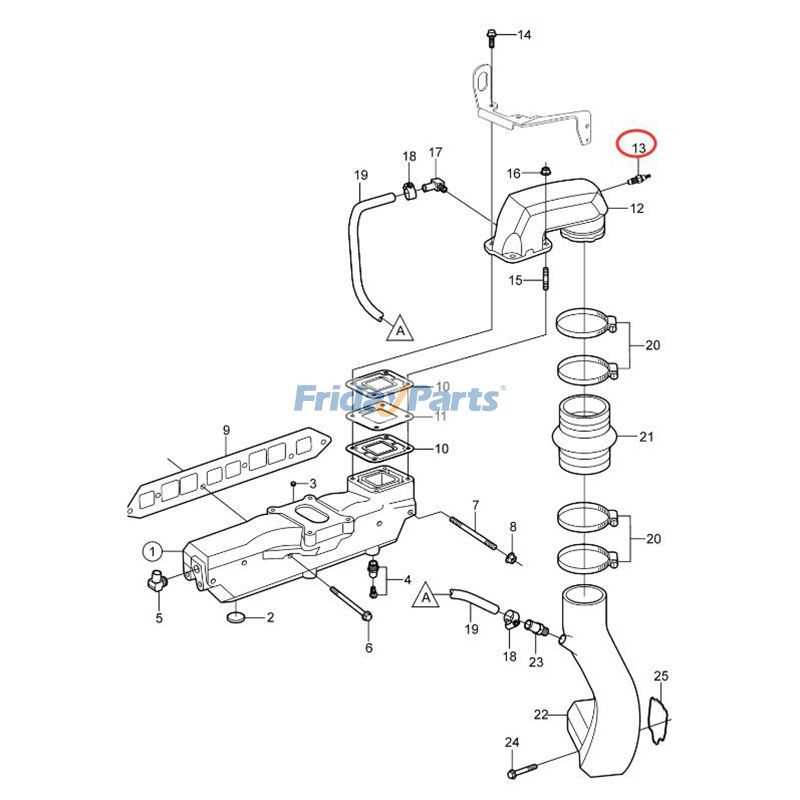

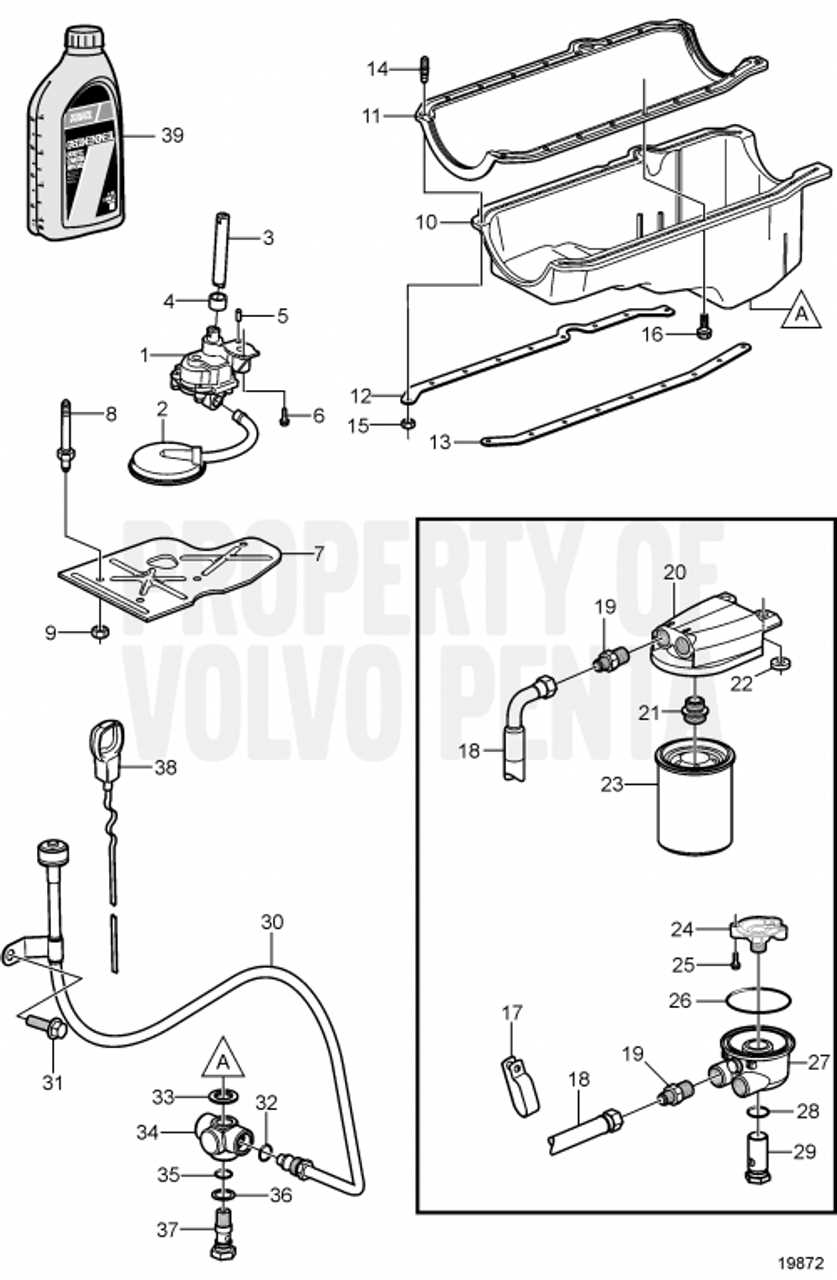

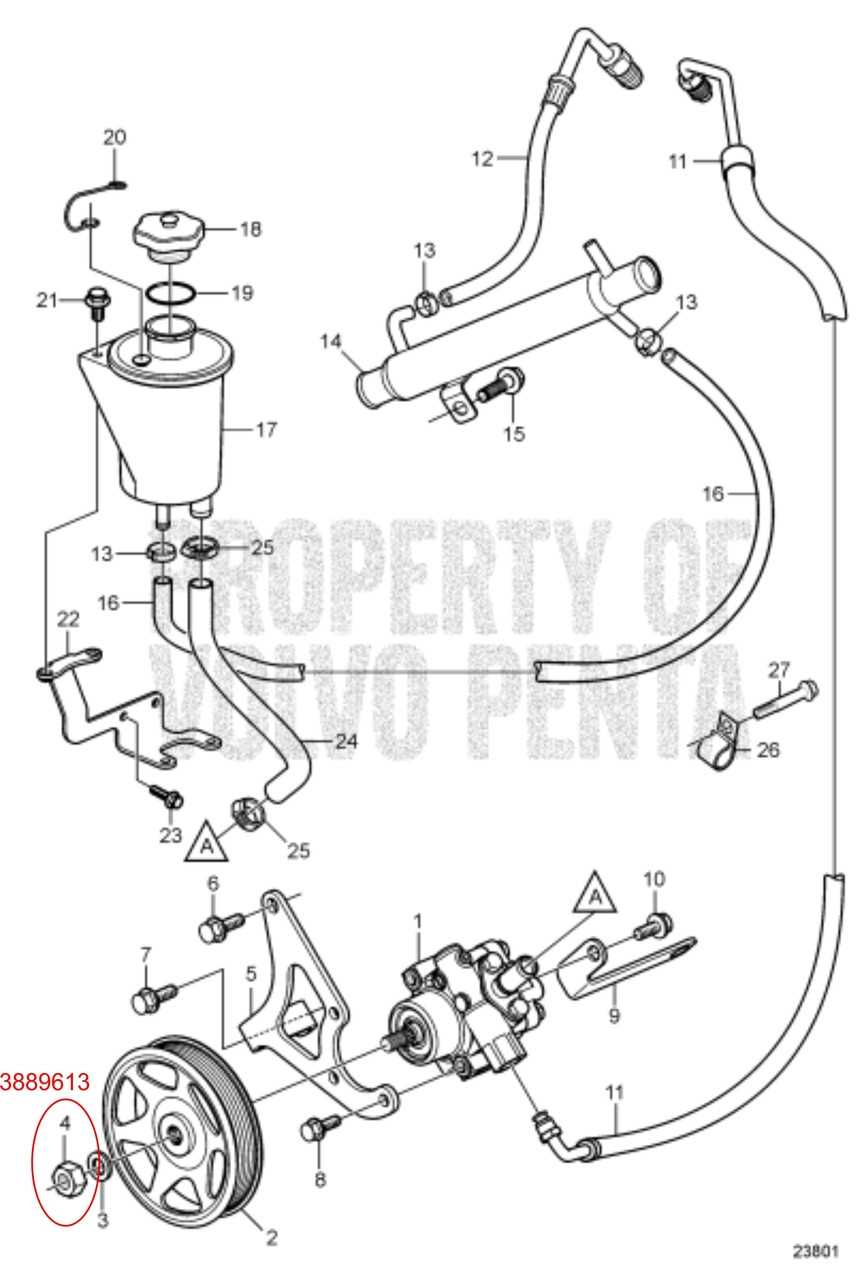

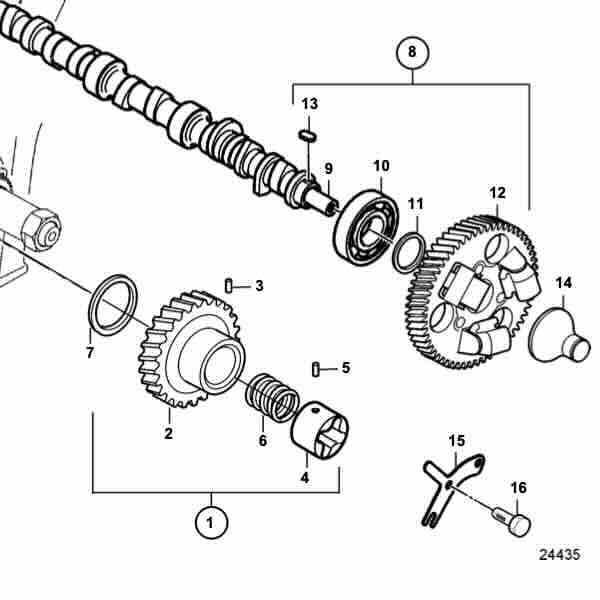

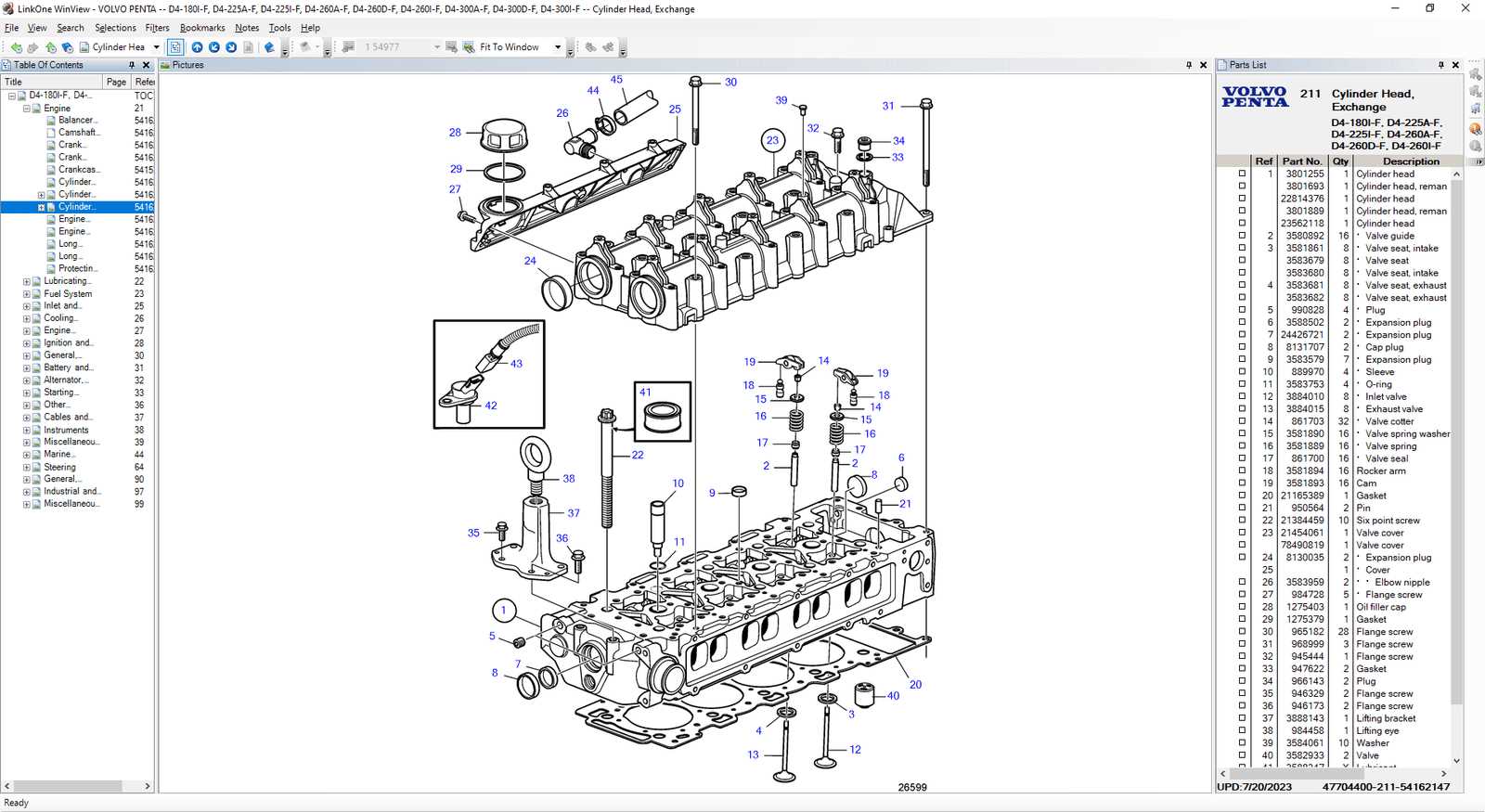

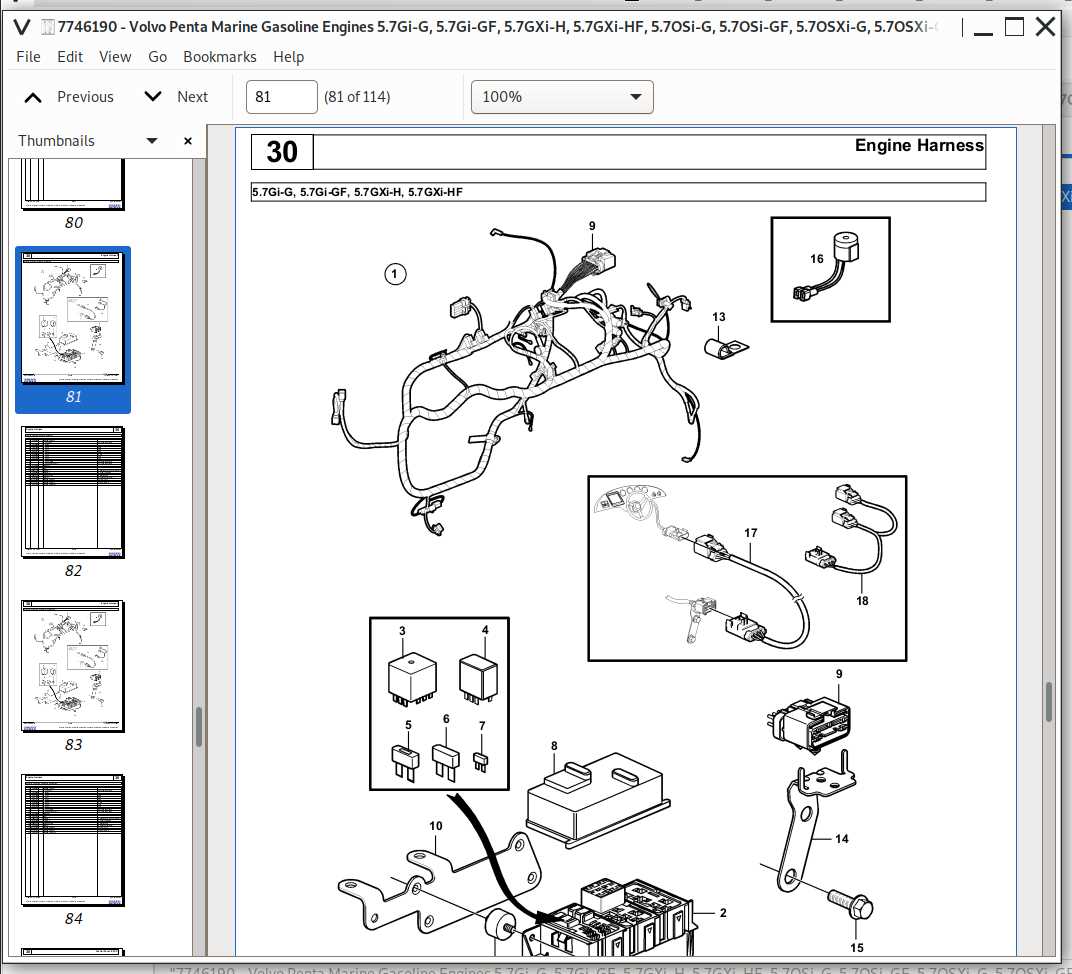

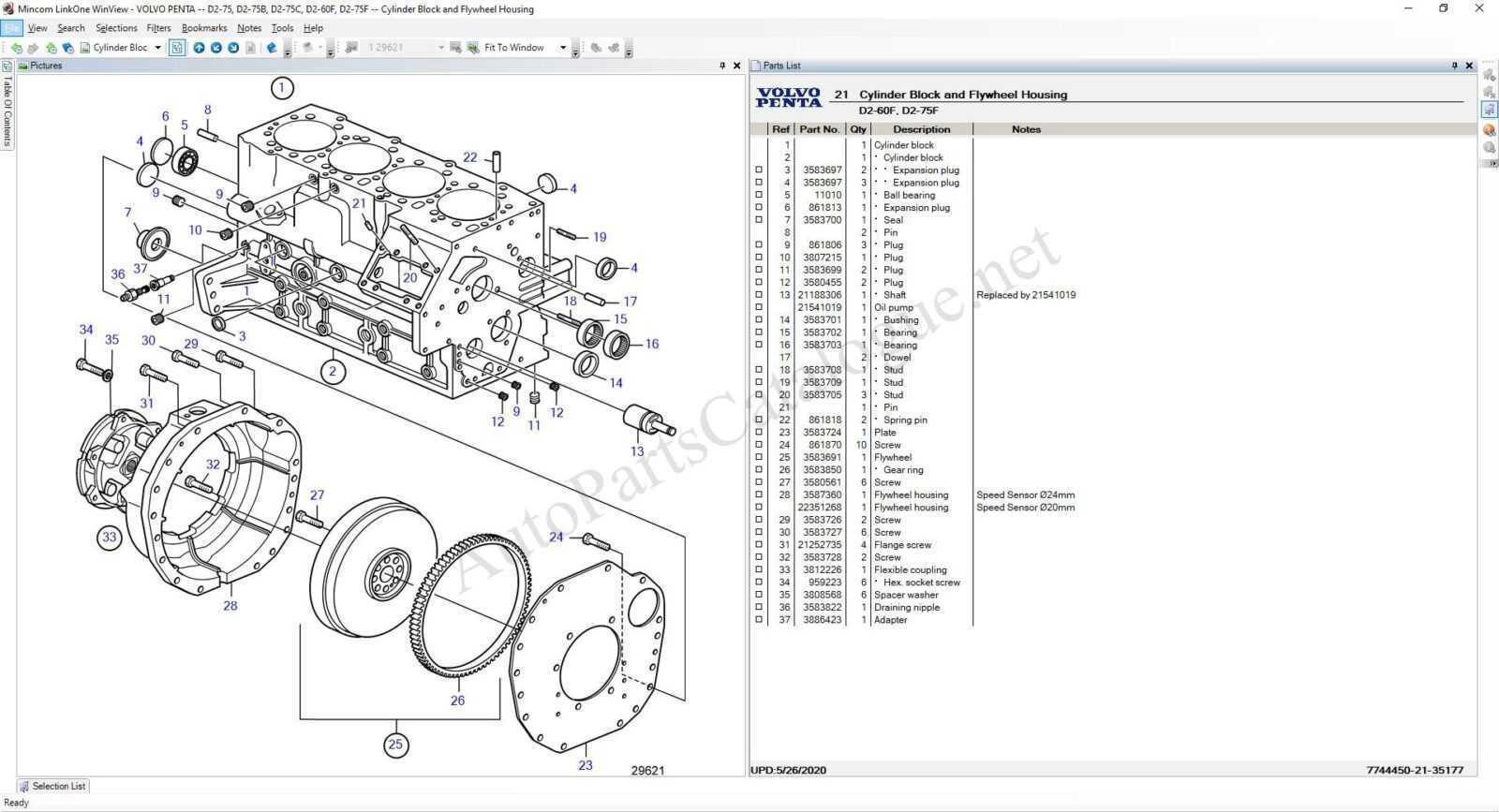

Importance of Parts Diagrams for Maintenance

Understanding the components and their interrelations within machinery is crucial for effective upkeep and repair. Visual representations of these elements provide clarity, allowing technicians to identify and locate specific pieces quickly. This facilitates a more organized approach to maintenance tasks, reducing downtime and enhancing overall efficiency.

Enhanced Troubleshooting

Visual aids assist in diagnosing issues by offering a clear view of how different elements interact. When a problem arises, having a schematic can lead to faster identification of faults and more efficient resolution, minimizing the risk of further complications.

Streamlined Ordering Process

Access to clear visual representations simplifies the process of sourcing replacement components. By referencing detailed illustrations, one can ensure the correct items are ordered, preventing costly delays and ensuring that repairs are completed without unnecessary interruptions.

Common Issues with 5.0 GXi Parts

When dealing with marine engines, several challenges may arise that affect performance and reliability. Understanding these common concerns can help in maintaining the machinery and ensuring smooth operation during voyages.

Frequent Problems

- Overheating: This is often caused by insufficient coolant flow or blockages in the cooling system.

- Fuel delivery issues: Clogs in fuel lines or problems with the fuel pump can lead to poor engine performance.

- Electrical failures: Corrosion or wear in wiring can result in faulty connections, leading to ignition problems.

- Wear and tear: Components such as gaskets and seals can degrade over time, causing leaks and requiring replacement.

Preventive Measures

- Regularly inspect and clean the cooling system to prevent blockages.

- Change fuel filters periodically to ensure clean fuel delivery.

- Check electrical connections for signs of wear and corrosion, and replace as necessary.

- Perform routine maintenance to identify signs of wear on critical components.

Addressing these common issues proactively can enhance the longevity and efficiency of your marine engine, ensuring safe and enjoyable experiences on the water.

Where to Find Replacement Parts

When it comes to maintaining and repairing marine engines, sourcing quality components is crucial for optimal performance and longevity. Whether you’re looking for essential machinery or specific accessories, knowing where to search can save you time and money.

Online Retailers

Many online platforms specialize in marine engine components. Websites dedicated to boating enthusiasts often provide a wide range of options, from OEM to aftermarket selections. Be sure to compare prices and read reviews to ensure you are getting quality items.

Local Distributors

Checking with nearby distributors can also be beneficial. They typically offer personalized service and might have the specific items you need in stock. Establishing a relationship with local suppliers can lead to valuable advice and potential discounts.

Networking with fellow boat owners can also uncover hidden gems, as they may recommend reliable sources or even sell spare parts directly.

Consider utilizing forums and social media groups dedicated to marine crafts, as these platforms often feature discussions on where to find the best components for your needs.

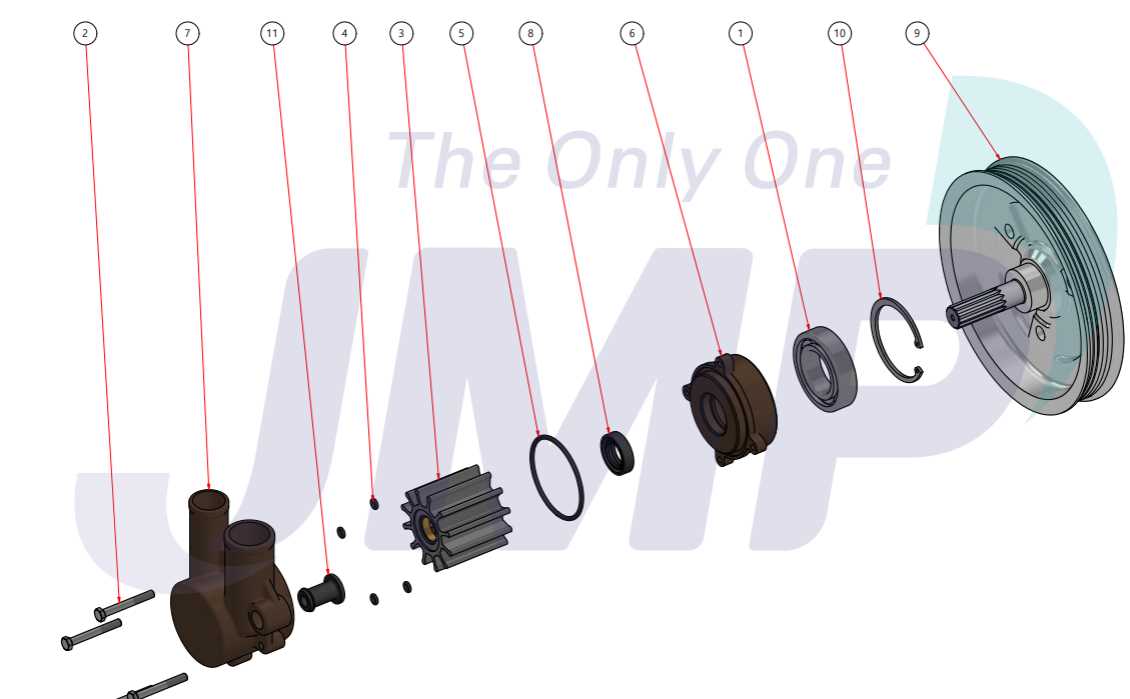

Step-by-Step Assembly Guide

This guide provides a comprehensive overview of the assembly process for a marine engine, ensuring that every component is correctly fitted for optimal performance. Following these instructions will help you navigate through the intricate steps involved in the setup, making the task manageable and straightforward.

Before starting the assembly, gather all necessary tools and components. A clean workspace will enhance efficiency and prevent the misplacement of parts. Below is a detailed table outlining the sequence of assembly tasks.

| Step | Description |

|---|---|

| 1 | Prepare the engine block by cleaning all surfaces to ensure a proper seal during assembly. |

| 2 | Install the crankshaft, ensuring it is properly aligned and secured within the block. |

| 3 | Attach the connecting rods to the crankshaft, making sure they are torqued to the manufacturer’s specifications. |

| 4 | Fit the pistons into the cylinders, applying assembly lube for smooth operation. |

| 5 | Seal the cylinder head onto the block, using a new gasket to prevent leaks. |

| 6 | Install the intake and exhaust manifolds, ensuring all connections are tight. |

| 7 | Connect the ignition system, verifying all wiring is correctly routed and secured. |

| 8 | Fill the engine with oil and coolant, checking for any leaks or irregularities. |

| 9 | Finally, perform a comprehensive inspection of all connections and components before starting the engine. |

By following this guide step-by-step, you will ensure a successful assembly and enhance the longevity of your engine. Pay attention to details at each stage, as they are crucial for a smooth operation.

Benefits of Genuine Volvo Penta Parts

Choosing authentic components for your marine engine is crucial for ensuring optimal performance and longevity. High-quality parts are designed specifically to fit and function perfectly within the system, providing a range of advantages that contribute to the overall reliability of your vessel.

Enhanced Performance

Using genuine components significantly enhances the efficiency of your engine. These products undergo rigorous testing to meet strict quality standards, ensuring they operate at peak performance. With authentic pieces, you can expect improved fuel efficiency and a smoother operation, allowing you to enjoy your time on the water without interruptions.

Long-Term Savings

Investing in high-quality replacements may seem more expensive initially, but it pays off in the long run. Genuine components tend to have a longer lifespan and are less prone to failure, reducing the frequency of repairs and replacements. This longevity translates to lower maintenance costs and greater peace of mind while navigating.

Overall, opting for authentic marine engine components ensures your vessel remains reliable, efficient, and ready for any adventure on the water.

Tips for DIY Repairs and Maintenance

Engaging in hands-on repairs and upkeep can be rewarding and cost-effective. Understanding the fundamental aspects of your equipment not only extends its lifespan but also enhances performance. With the right approach and tools, you can tackle various tasks with confidence.

Before starting any project, it’s essential to gather the necessary tools and materials. This preparation minimizes downtime and ensures a smooth workflow. Here’s a basic checklist to help you get organized:

| Tools | Description |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | Essential for assembling and disassembling components. |

| Multimeter | To test electrical connections and diagnose issues. |

| Oil Filter Wrench | Facilitates the removal of oil filters during maintenance. |

| Safety Gear | Includes gloves and goggles to protect yourself while working. |

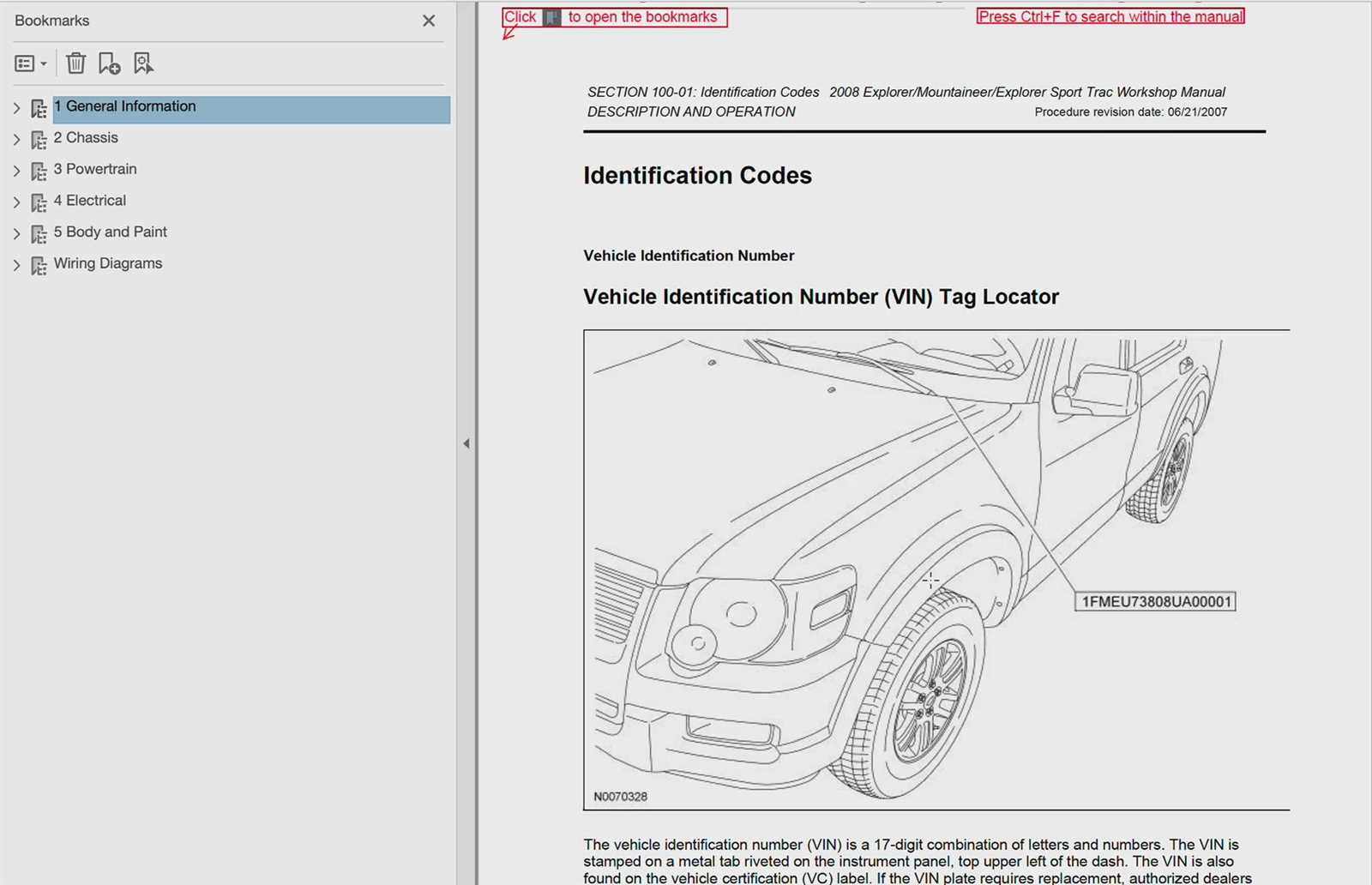

Next, familiarize yourself with the service manual. This document contains vital information regarding specifications and procedures that are specific to your model. Following the guidelines ensures that repairs are performed correctly, reducing the risk of further issues.

Finally, don’t hesitate to document your work. Keeping a log of repairs and maintenance activities can be invaluable for future reference. It helps track what has been done and when, allowing you to plan upcoming tasks more effectively.

Resources for Technical Support and Advice

Accessing reliable support and guidance is crucial when dealing with marine engines and their components. Enthusiasts and professionals alike can benefit from various resources that provide technical insights, troubleshooting tips, and community support. Whether you are looking for manuals, forums, or professional services, a wealth of information is available to ensure optimal performance and maintenance of your equipment.

Here are some valuable resources to consider:

| Resource Type | Description | Link/Contact |

|---|---|---|

| Manufacturer Manuals | Official documentation offering detailed information on installation, operation, and maintenance. | Visit the official website for downloads |

| Online Forums | Community-driven platforms where users share experiences, advice, and solutions. | Search for dedicated marine engine forums |

| Technical Support Hotlines | Direct access to experts for immediate assistance with technical issues. | Check the manufacturer’s contact section |

| YouTube Tutorials | Video guides providing step-by-step instructions on various repairs and maintenance tasks. | Search for engine-related channels |

| Local Service Centers | Professional repair shops offering hands-on support and servicing for your equipment. | Look up authorized service centers in your area |

Utilizing these resources can greatly enhance your understanding and handling of marine engines, leading to improved performance and longevity of your equipment.