The complexity of modern heavy-duty vehicles necessitates a comprehensive understanding of their various elements. Each component plays a crucial role in ensuring optimal performance, reliability, and safety. By gaining insight into these intricate systems, operators can enhance maintenance practices and prolong the lifespan of their machines.

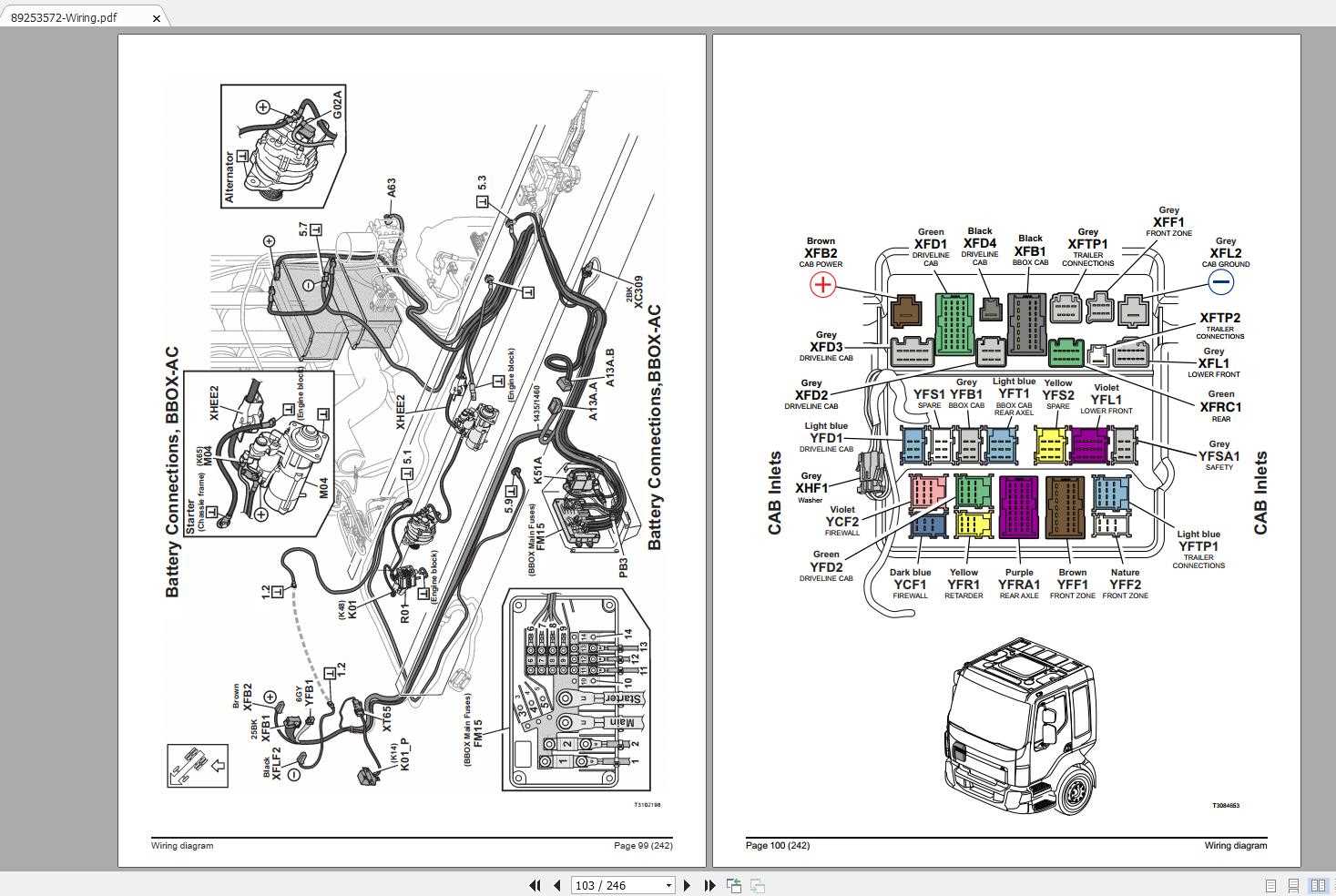

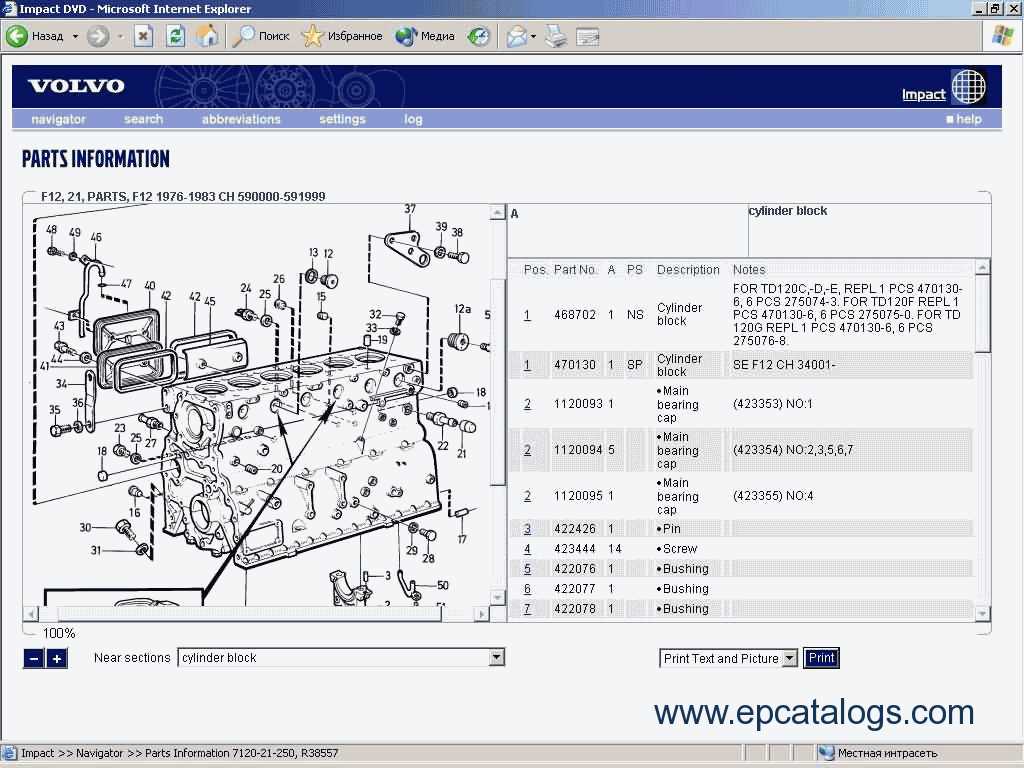

Illustrating the interconnections between individual pieces is vital for mechanics and enthusiasts alike. This visualization aids in identifying potential issues and facilitates timely interventions. Moreover, familiarity with the layout of these components empowers users to make informed decisions during repairs or upgrades.

Utilizing a detailed representation of the different sections allows for better comprehension of how each part interacts with others. By breaking down these intricate systems, individuals can tackle challenges more effectively and maintain the functionality of their vehicles with confidence.

Understanding Volvo Truck Parts Diagrams

Familiarizing oneself with the components of a heavy-duty vehicle is essential for effective maintenance and repair. A visual representation can provide valuable insights into the various elements that work in harmony to ensure optimal performance. These illustrations serve as a guide, allowing operators and mechanics to quickly identify and address issues that may arise.

The Importance of Visual Guides

Utilizing visual guides enhances comprehension of complex machinery. They offer a detailed view, making it easier to pinpoint specific components and understand their functions within the overall system. This clarity is crucial for troubleshooting and streamlining the repair process.

Key Features of Component Illustrations

These representations often highlight key features, such as connection points and assembly order. Understanding these aspects can significantly reduce the time spent on repairs. Additionally, familiarity with such resources empowers technicians to work more efficiently, ultimately leading to improved vehicle reliability and longevity.

Key Components of Volvo Trucks

Understanding the essential elements of heavy-duty vehicles is crucial for ensuring optimal performance and longevity. Each component plays a significant role in the overall functionality, safety, and efficiency of the machine. By familiarizing oneself with these vital structures, operators and technicians can enhance maintenance practices and address potential issues proactively.

Engine: The powerhouse of any vehicle, this component converts fuel into mechanical energy, driving the entire system. Its efficiency directly influences fuel consumption and overall performance.

Transmission: This element transfers power from the engine to the wheels, allowing for smooth acceleration and deceleration. A well-functioning system ensures that the vehicle operates seamlessly under varying loads and conditions.

Chassis: Serving as the foundation, this robust structure supports all other components and provides stability. It is designed to withstand significant stress and impacts during operation.

Braking System: A critical safety feature, this system enables effective stopping power and control. Advanced technologies often enhance responsiveness, ensuring safety during heavy loads and steep descents.

Suspension: This component absorbs shocks and maintains ride comfort, ensuring stability and control over various terrains. A well-designed suspension system is vital for both passenger comfort and vehicle longevity.

Electrical System: Responsible for powering lights, communication devices, and control systems, this network is essential for operational efficiency and safety. Regular checks are necessary to avoid potential electrical failures.

Cooling System: This mechanism prevents overheating by regulating the temperature of the engine. Proper maintenance ensures that the vehicle operates within optimal temperature ranges, enhancing performance and lifespan.

By understanding these key structures, individuals can make informed decisions regarding maintenance and repair, ultimately ensuring the vehicle operates at peak efficiency for years to come.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations offer a structured view of various elements, allowing users to identify and analyze the intricate relationships between them. Mastering the interpretation of these visuals enhances one’s ability to tackle technical challenges efficiently.

1. Familiarize Yourself with the Symbols: Each representation uses specific symbols to denote various items. Take time to study the legend to decode these meanings.

2. Follow the Layout: Most visual guides are organized systematically. Recognize the flow and arrangement to grasp how components fit together.

3. Pay Attention to Annotations: Additional notes and labels provide crucial information. Review these carefully for insights into installation and maintenance.

4. Use a Reference: Cross-referencing with manuals or guides can clarify any uncertainties you encounter while interpreting the visuals.

Ultimately, practice makes perfect. The more you engage with these visual tools, the more proficient you will become in navigating and utilizing them effectively.

Common Issues with Truck Parts

Maintenance of heavy vehicles often reveals a variety of challenges related to their components. Understanding these issues can enhance reliability and performance, ensuring a smoother operation and reducing unexpected downtime.

Frequent Component Failures

- Wear and tear due to prolonged use

- Corrosion from environmental factors

- Improper installation or alignment

Signs of Malfunction

- Unusual noises during operation

- Decreased efficiency or performance

- Visible leaks or fluid loss

Benefits of Using Official Diagrams

Utilizing authoritative illustrations offers numerous advantages for maintenance and repair tasks. These detailed visual aids ensure accuracy and enhance understanding, allowing technicians to work more efficiently and effectively.

Precision: Official representations provide exact specifications, reducing the risk of errors during assembly or disassembly.

Clarity: High-quality visuals clarify complex components, making it easier to identify and troubleshoot issues.

Consistency: Using standardized references ensures uniformity in repairs, which is vital for optimal performance and longevity.

In summary, relying on verified illustrations fosters greater efficiency, accuracy, and reliability in maintenance efforts.

Where to Find Reliable Diagrams

Locating trustworthy illustrations for heavy machinery can significantly enhance maintenance and repair processes. Accessing accurate visual guides ensures that users can effectively identify components and understand their relationships within the system.

Online Resources

- Manufacturer Websites: Many official sites provide comprehensive resources for machinery.

- Specialized Forums: Community-driven platforms often have shared diagrams and insights from experienced users.

- Technical Publications: Reputable publications often include detailed illustrations alongside descriptions.

Local Resources

- Authorized Dealers: Local dealerships may offer printed manuals or digital access to essential guides.

- Repair Shops: Professional mechanics often have valuable resources or can recommend reliable materials.

- Library Archives: Public or university libraries may house technical manuals that include necessary illustrations.

Tips for Accurate Parts Identification

Identifying components correctly is essential for effective maintenance and repair. Misidentification can lead to incorrect purchases, wasted time, and potential damage to machinery. Here are some strategies to ensure you pinpoint the right items every time.

Utilize Reference Materials

Consulting detailed reference materials, such as manuals and catalogs, is crucial. These resources often provide comprehensive information, including specifications and images, that can guide you in distinguishing between similar items. Pay attention to the part numbers, dimensions, and other specific attributes.

Cross-Reference with Online Databases

Leverage online platforms that offer databases for various components. Many websites feature search functionalities that allow you to input details and retrieve matching items. Always cross-reference multiple sources to verify accuracy. Additionally, engaging with community forums can provide insights from experienced users who may have faced similar identification challenges.

Comparing Diagrams Across Different Models

When analyzing technical illustrations of various vehicle models, it becomes evident that each design reflects unique engineering choices and operational functionalities. These visual representations serve as essential tools for understanding the intricate components and systems that make up each model. By examining these illustrations side by side, one can gain insights into the evolutionary trends in design and the specific adaptations made for different applications.

One of the most striking aspects of these comparisons is how certain features are standardized across models, while others are tailored for specific performance requirements. For instance, the placement of major assemblies can vary significantly, influencing maintenance procedures and accessibility. Such variations highlight the manufacturer’s approach to balancing efficiency and functionality in different contexts.

Additionally, color coding and labeling conventions often differ, providing clues about the priority placed on certain systems within each model. Understanding these nuances can be invaluable for technicians and enthusiasts alike, facilitating a deeper appreciation of the engineering behind each variant. Ultimately, comparing these illustrations not only enhances knowledge but also underscores the importance of customization in automotive design.

Maintenance and Repair Insights

Effective upkeep and restoration of heavy machinery are crucial for longevity and optimal performance. Understanding the intricacies of components and their interactions can significantly enhance reliability and efficiency. This section offers valuable guidance to ensure that your equipment remains in top condition.

Key Maintenance Practices

- Regular inspections to identify wear and tear.

- Consistent lubrication of moving parts to reduce friction.

- Timely replacement of filters to ensure clean operation.

- Monitoring fluid levels to prevent overheating and damage.

Common Repair Challenges

- Identifying the root cause of unexpected failures.

- Accessing hard-to-reach areas for repairs.

- Finding quality replacement components that meet specifications.

- Understanding technical manuals and repair guides for effective troubleshooting.