When it comes to power equipment, a thorough comprehension of its inner workings is essential for effective use and maintenance. Every tool is a complex assembly of elements that work in harmony to achieve optimal performance. By familiarizing oneself with these components, users can enhance their skills and ensure longevity in their devices.

Identifying individual sections not only aids in troubleshooting but also empowers operators to make informed decisions regarding repairs and upgrades. This knowledge transforms an operator into a more proficient craftsman, capable of maximizing their tool’s potential.

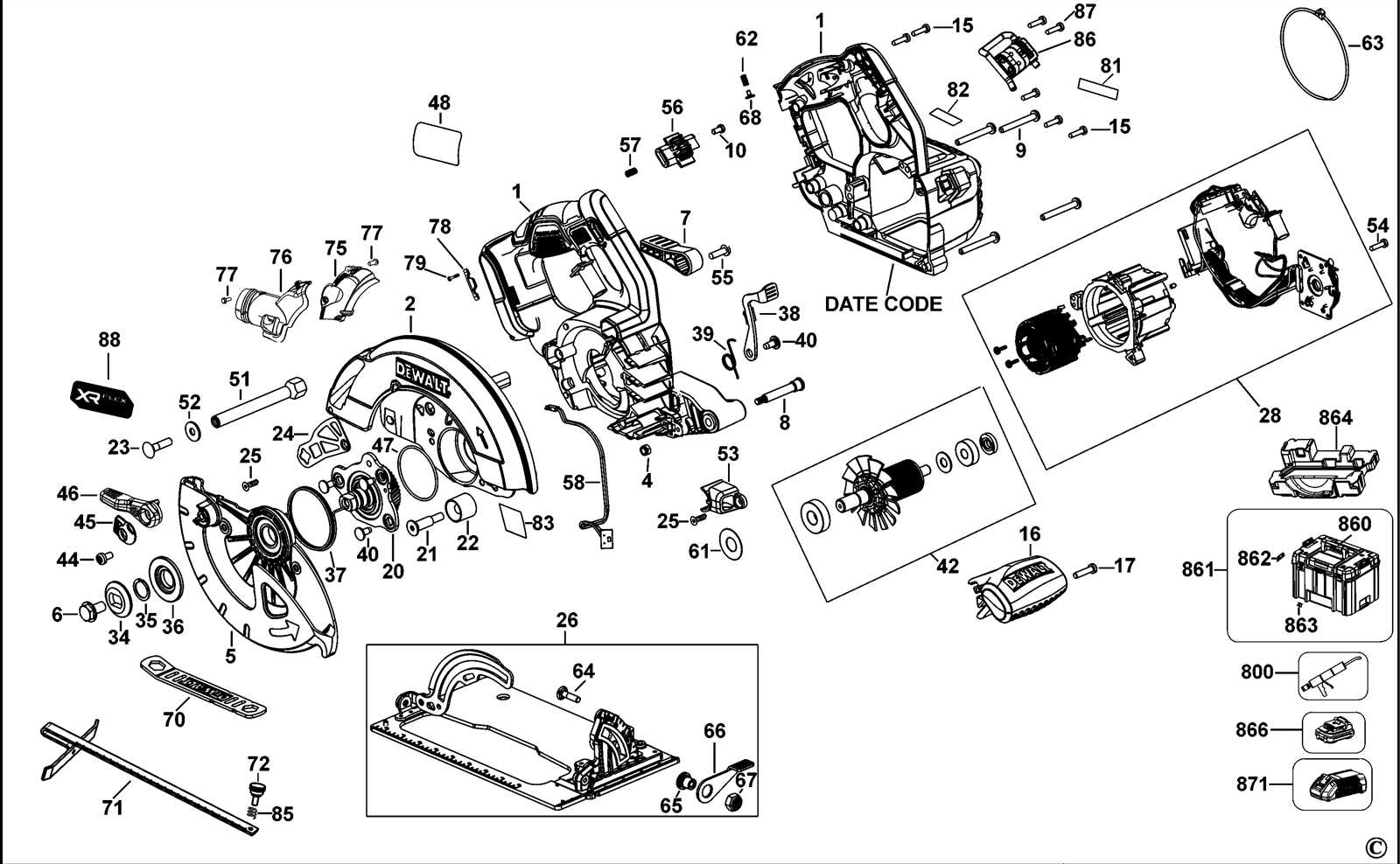

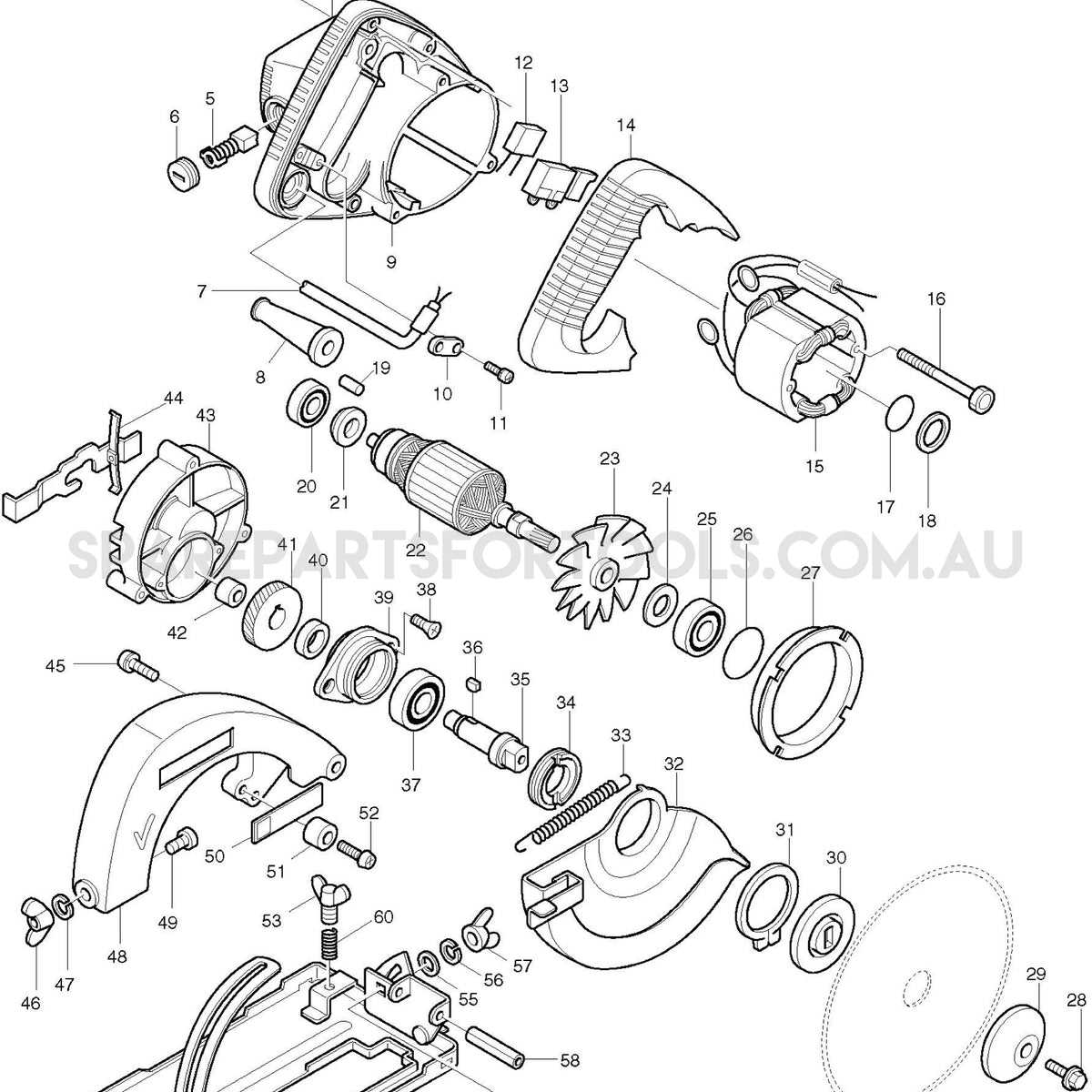

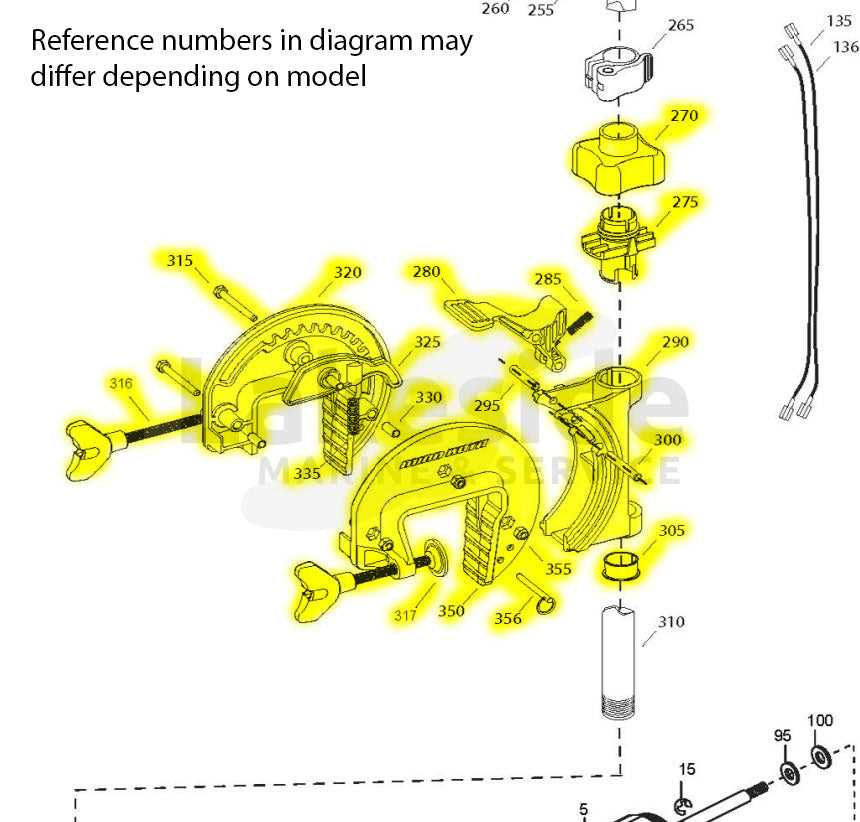

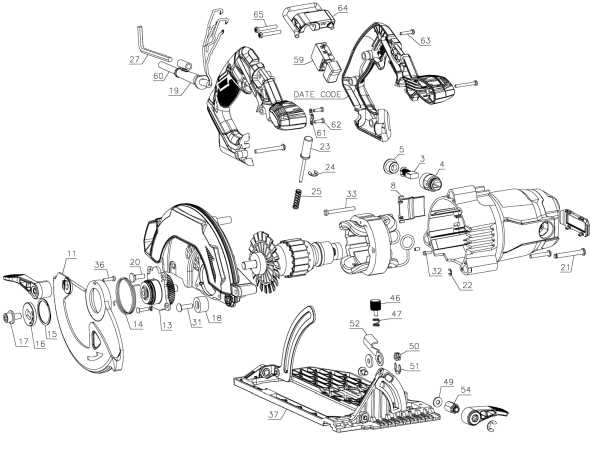

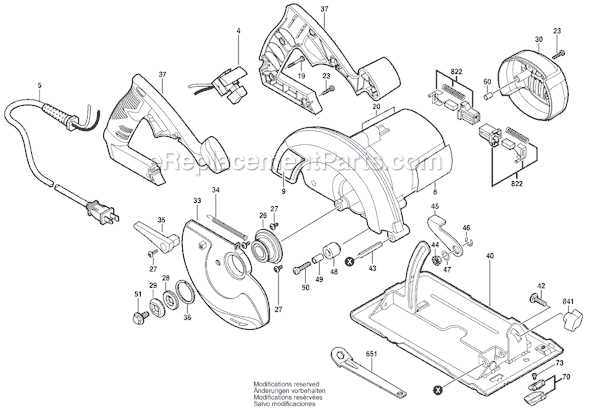

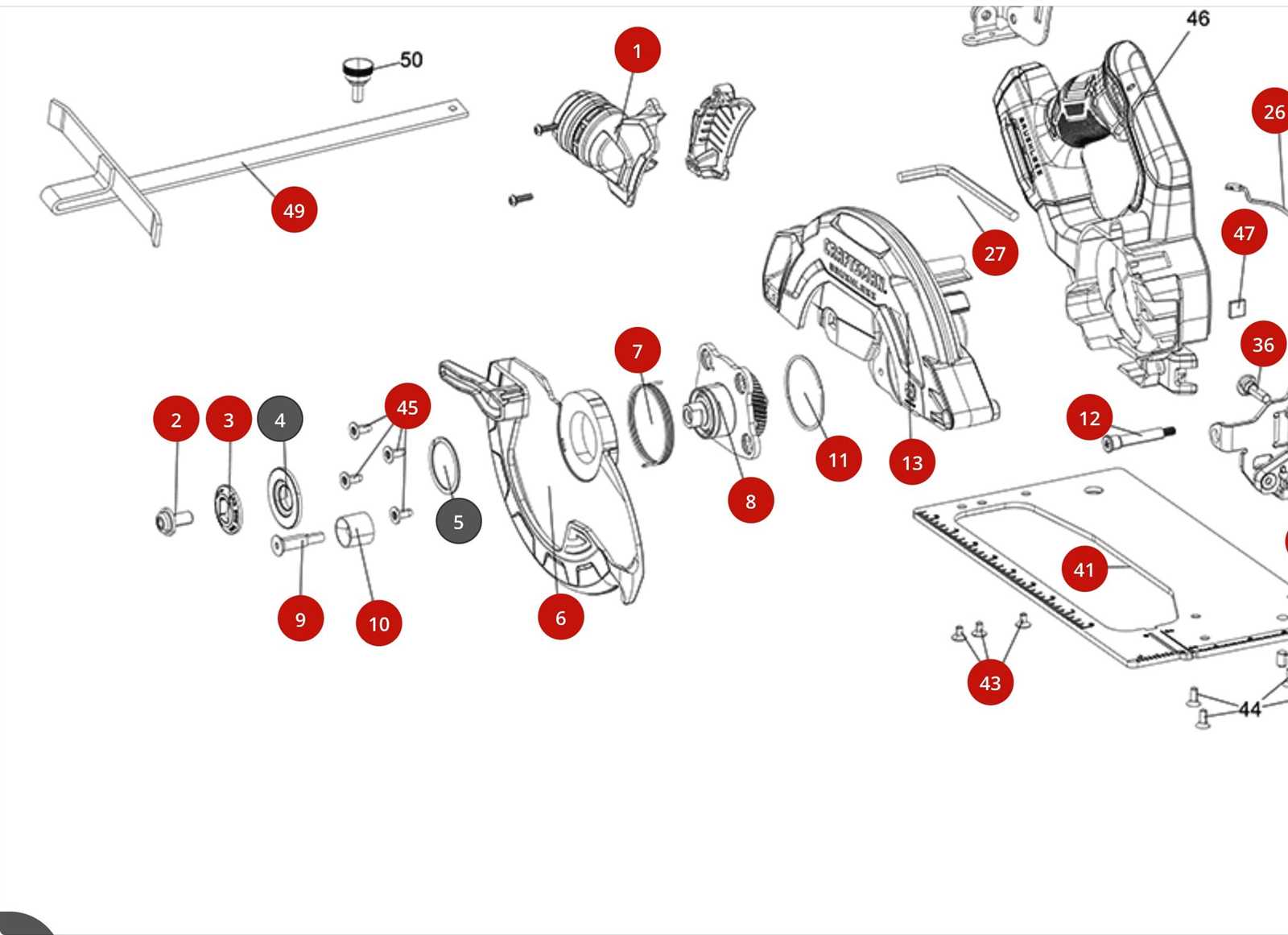

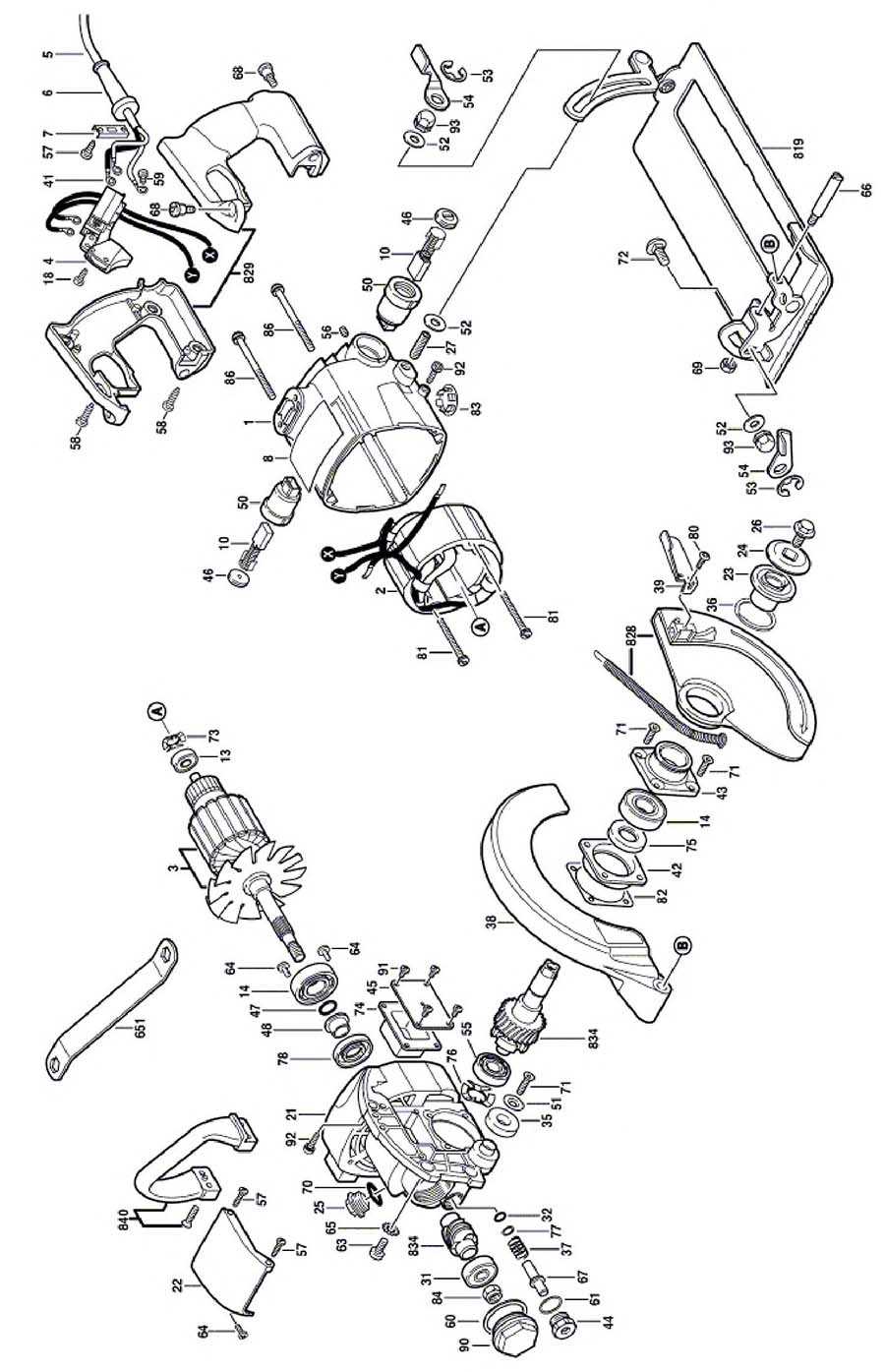

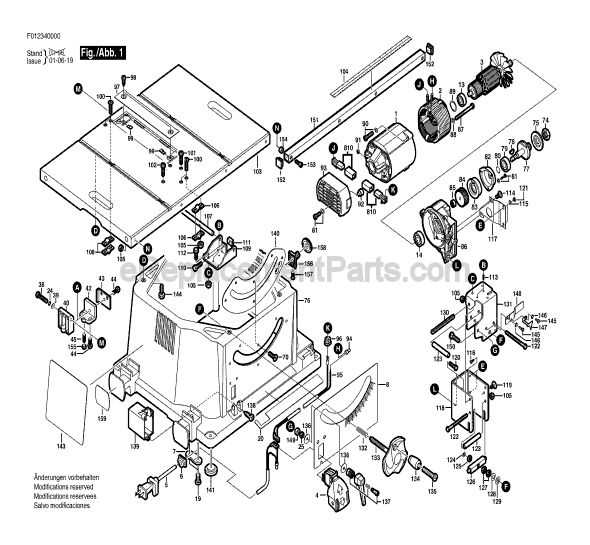

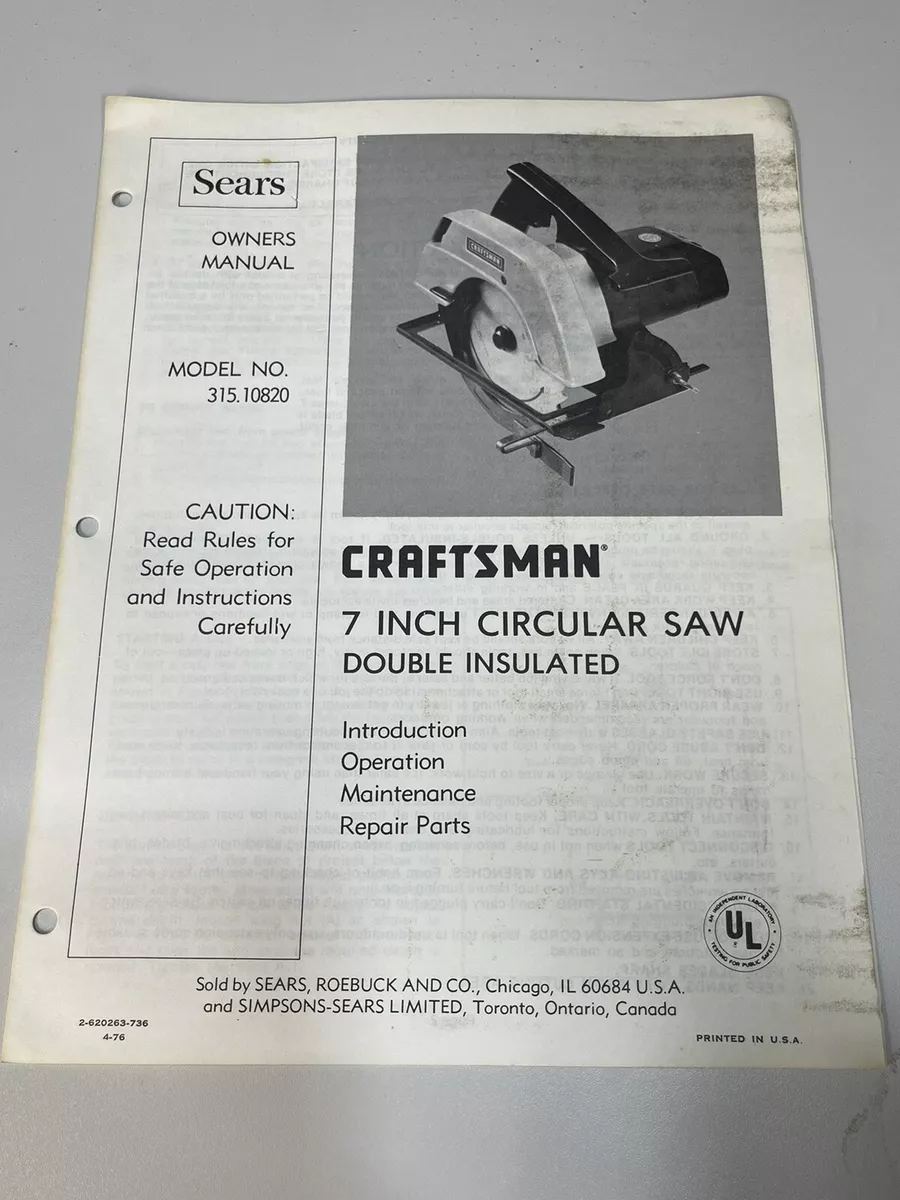

Furthermore, visual representations of these components provide clarity, enabling easier navigation through the intricate design. By delving into this subject, users can uncover the ultimate benefits of understanding their equipment, ultimately leading to a more efficient and enjoyable experience in their projects.

Understanding Skilsaw Parts Diagram

Familiarizing oneself with the components of a cutting tool can greatly enhance efficiency and maintenance. Recognizing each element’s function allows for better troubleshooting and repairs, ensuring optimal performance during usage. This guide will explore key aspects of these essential tools.

Key Components

- Motor: Powers the device and drives the blade.

- Blade: The cutting element that determines the tool’s effectiveness.

- Base Plate: Provides stability and guides the tool along the material.

- Trigger: Initiates operation and controls power flow.

- Guard: Ensures safety by covering the blade during non-use.

Benefits of Understanding Tool Components

- Enhanced troubleshooting skills for quick repairs.

- Improved safety practices while using the equipment.

- Ability to identify necessary replacements or upgrades.

- Increased familiarity with maintenance requirements.

Importance of Accurate Diagrams

Precision in illustrations is crucial for effective understanding and maintenance of complex machinery. Accurate visuals serve as essential references, guiding users through assembly, repair, and troubleshooting processes. They enhance clarity, reducing the risk of errors and ensuring that every component is correctly identified and utilized.

Clear representations foster efficiency, allowing technicians and hobbyists alike to swiftly locate necessary elements. When individuals can easily interpret these visuals, they can make informed decisions, ultimately leading to smoother operations and enhanced performance.

Moreover, well-crafted visuals play a vital role in training and education, providing new users with the foundational knowledge needed to engage with the equipment confidently. Investing in precise illustrations not only saves time but also minimizes potential frustrations in the long run.

Common Skilsaw Components Explained

Understanding the essential elements of a circular saw can enhance your ability to utilize this powerful tool effectively. Each component plays a crucial role in ensuring optimal performance and safety. Below, we delve into the most common parts that make up this versatile cutting device.

Key Components

- Blade: The heart of the tool, available in various sizes and types for different materials.

- Motor: Provides the necessary power to drive the blade through various substances.

- Base Plate: Offers stability and acts as a guide for straight cuts.

- Guard: A safety feature that protects users from accidental contact with the blade.

- Trigger: The mechanism that activates the motor and blade rotation.

Additional Features

- Bevel Adjustment: Allows for angled cuts by tilting the base plate.

- Depth Adjustment: Enables control over how deep the blade cuts into the material.

- Dust Port: Helps to minimize debris by connecting to a vacuum system.

- Power Cord: Supplies electricity to the motor, typically featuring a safety switch.

Familiarity with these components not only aids in effective operation but also facilitates maintenance and troubleshooting, ensuring longevity and reliability in your projects.

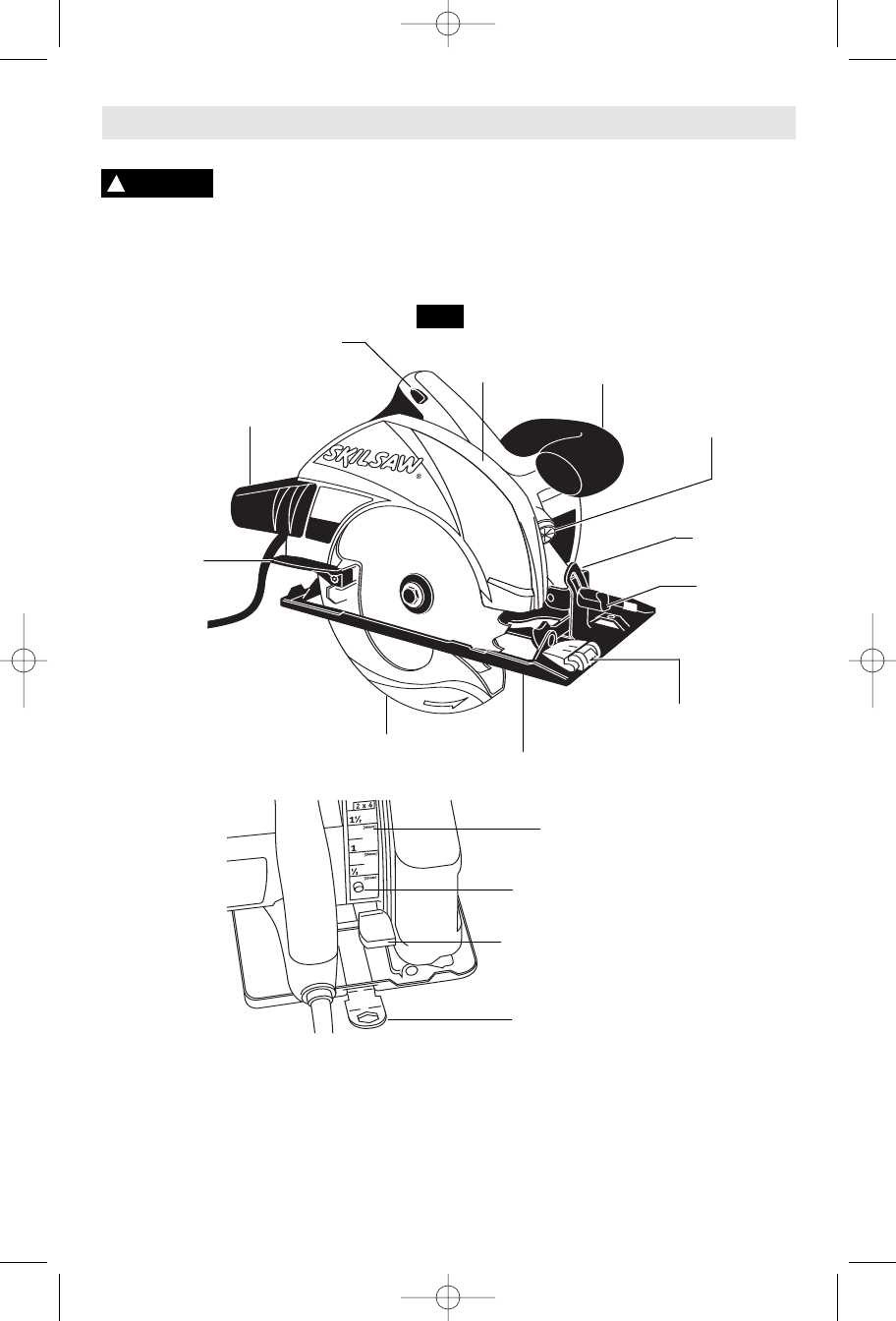

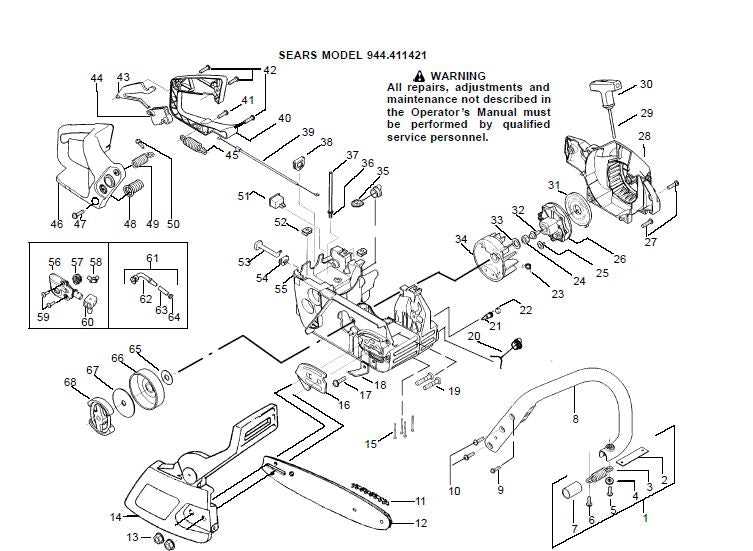

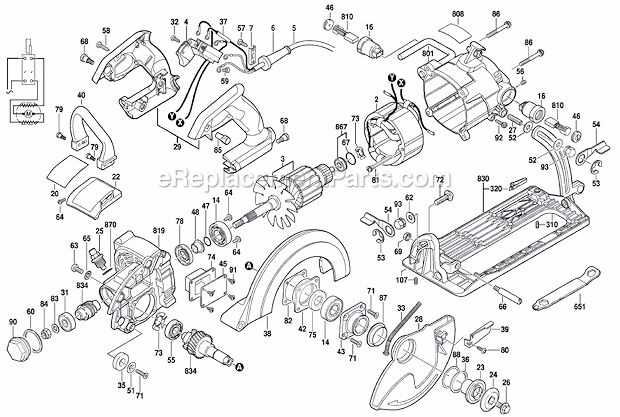

How to Read the Diagram

Understanding a technical illustration is crucial for effective maintenance and repair. This visual representation helps users identify various components and their relationships within a machine. By familiarizing yourself with this illustration, you can streamline your troubleshooting and enhance your overall efficiency.

Key Elements to Focus On

Start by identifying the main components highlighted in the illustration. These are often marked with labels or numbers, making it easier to correlate them with the written manual. Pay attention to the color coding or symbols, as they frequently indicate specific functionalities or categories, guiding you in recognizing parts quickly.

Understanding Connections and Functions

Next, observe how different elements interact. Arrows and lines often depict connections, showing how components work together. This is particularly important for understanding the flow of power or materials within the system. Recognizing these relationships will enable you to troubleshoot issues more effectively and ensure all elements are functioning as intended.

Identifying Replacement Parts Easily

Understanding how to locate the necessary components for your tools can significantly enhance your repair and maintenance efficiency. By familiarizing yourself with the structure and essential elements of your equipment, you can streamline the process of identifying what you need, ensuring you make informed choices.

Utilizing Visual Resources

One of the most effective methods for pinpointing the required components is to utilize visual aids. Clear illustrations or images can help you recognize specific sections and parts, allowing for quicker identification and comparison when searching for replacements.

Consulting Reliable Sources

Accessing trusted manuals or online resources can provide detailed information regarding various elements and their functions. This knowledge empowers you to make the ultimate decision when selecting replacements, ensuring compatibility and optimal performance.

Tools Needed for Maintenance

Regular upkeep of power tools ensures their longevity and optimal performance. Having the right instruments on hand can simplify this process, allowing for efficient adjustments and repairs. Below is a list of essential equipment that can aid in the maintenance of various machinery.

| Tool | Description |

|---|---|

| Wrench Set | Used for tightening or loosening nuts and bolts, essential for securing components. |

| Phillips and Flathead Screwdrivers | Critical for accessing screws during maintenance tasks, facilitating easy assembly and disassembly. |

| Allen Keys | Necessary for working with hexagonal screws, commonly found in various equipment. |

| Cleaning Brush | Helps remove dust and debris from intricate parts, preventing buildup that can affect performance. |

| Lubricant | Essential for reducing friction in moving parts, promoting smooth operation and preventing wear. |

| Safety Goggles | Protects eyes during maintenance activities, ensuring safety while working with tools. |

| Work Gloves | Provides hand protection against sharp edges and hot surfaces during upkeep tasks. |

Equipping yourself with these tools not only enhances the efficiency of maintenance procedures but also promotes a safer working environment.

Safety Tips When Disassembling

When taking apart machinery or tools, ensuring personal safety should be a top priority. Proper precautions help prevent accidents and injuries, allowing for a smooth disassembly process. Following a few essential guidelines can make this task safer and more efficient.

Preparation Before Disassembly

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and steel-toed boots.

- Ensure the tool is unplugged or disconnected from its power source to avoid accidental activation.

- Work in a well-lit area to clearly see all components and avoid mistakes.

- Keep a clean workspace to minimize the risk of tripping or losing small parts.

During the Disassembly Process

- Follow the manufacturer’s guidelines for taking apart the equipment.

- Use the correct tools to avoid damaging components or causing injury.

- Take your time and avoid rushing; being hasty can lead to mistakes.

- Label and organize parts as you remove them to facilitate reassembly.

By adhering to these safety tips, the disassembly process can be completed with minimal risk and maximum efficiency.

Frequently Asked Questions About Diagrams

This section addresses common inquiries related to visual representations of mechanical systems and their components. Understanding these illustrations can enhance efficiency in maintenance and repairs.

What are the benefits of using visual schematics? They provide a clear overview of complex assemblies, making it easier to identify parts and understand their relationships.

How do I read these illustrations effectively? Familiarize yourself with the symbols and notations commonly used, as they convey important information about dimensions and functionalities.

Where can I find accurate representations for my tools? Manufacturer websites and authorized retailers typically offer reliable visual guides that correspond to their products.

Can I create my own visual representations? Yes, you can design customized illustrations using software tools, allowing for specific modifications tailored to your needs.

Where to Find Official Resources

Accessing reliable information and resources is crucial for effective maintenance and repair. Whether you are seeking guidance on assembly, replacement, or troubleshooting, knowing where to look can save you time and ensure accuracy.

Manufacturer’s Website

The primary source for authentic materials is often the manufacturer’s official site. Here, you can find:

- Instruction manuals

- Maintenance guidelines

- Product specifications

- Contact information for customer support

Authorized Retailers and Distributors

Another excellent option is to consult authorized sellers. These platforms typically offer:

- Online catalogs with visual aids

- Expert advice and FAQs

- Access to genuine replacement items

- Promotions or discounts on tools and accessories

Utilizing these resources will enhance your understanding and ensure you have the right components for your needs.