When delving into the intricacies of robust machinery, one quickly realizes the importance of familiarizing oneself with the fundamental elements that drive performance. A comprehensive understanding of these essential components is crucial for both maintenance and enhancement of operational efficiency. Each part plays a vital role in the overall functionality, influencing durability and reliability.

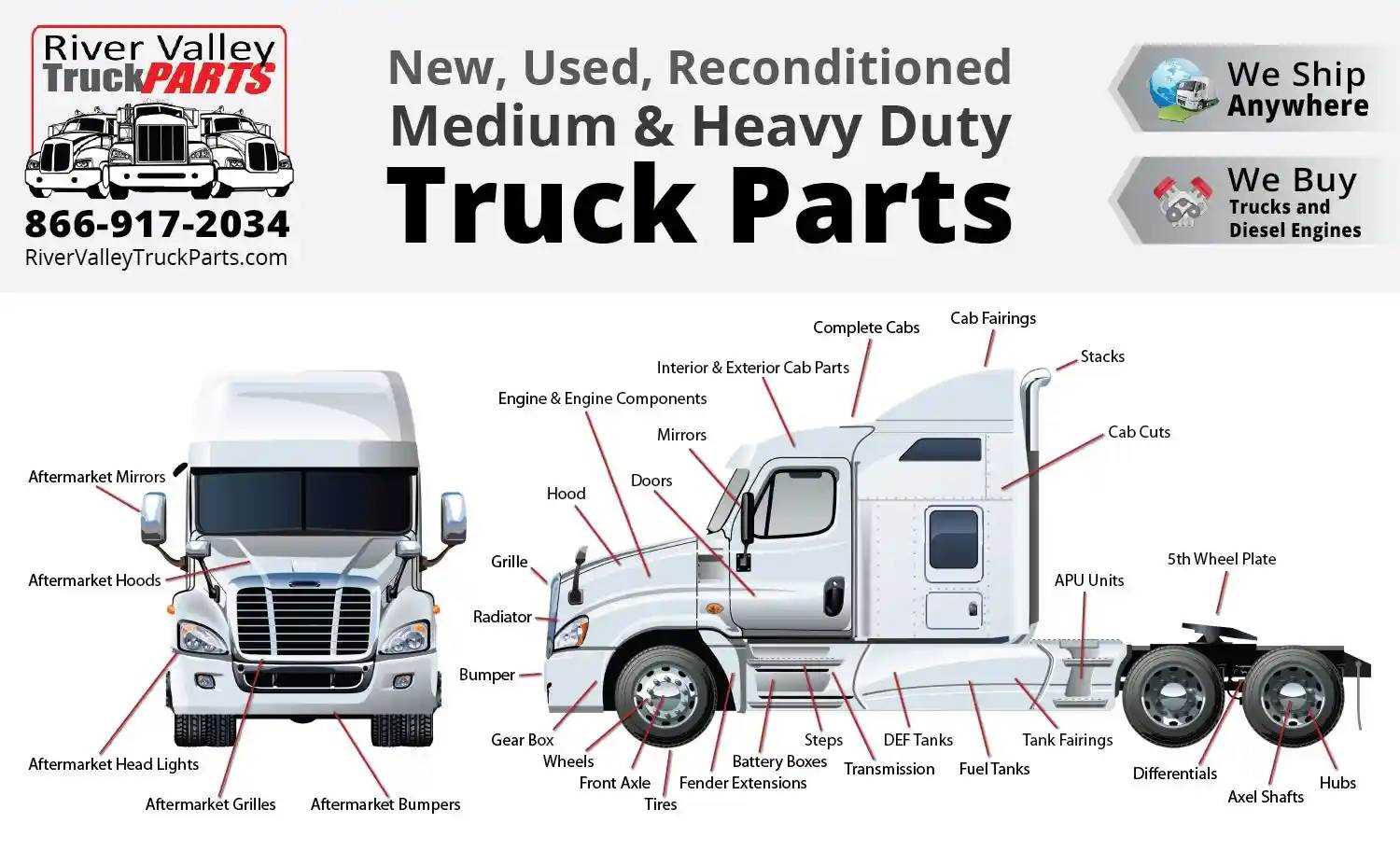

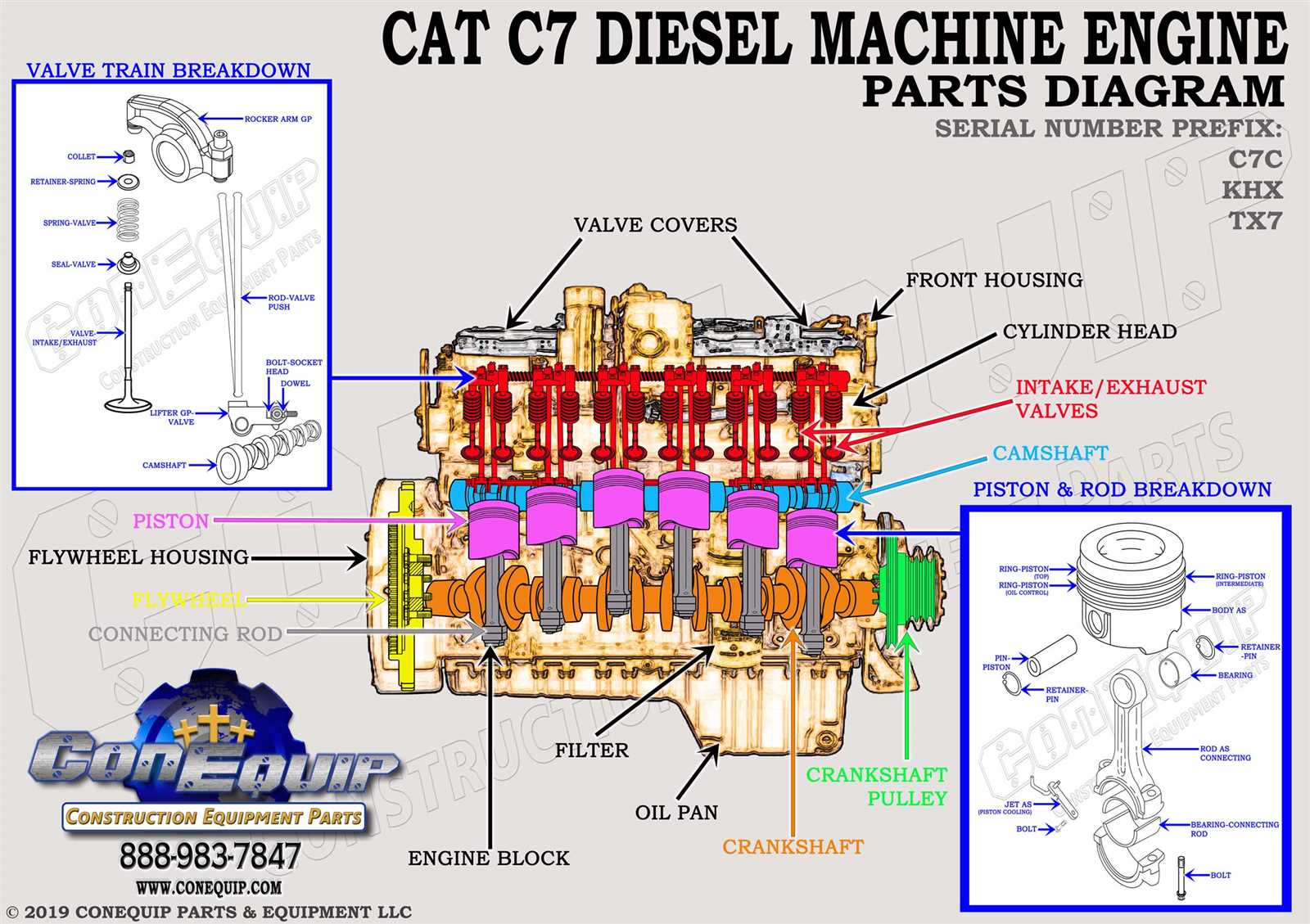

To aid in grasping these complexities, a visual representation can be invaluable. Such illustrations not only simplify the identification of various elements but also provide insights into how they interconnect and operate harmoniously. This knowledge is essential for technicians and enthusiasts alike, fostering a deeper appreciation for the mechanics at play.

In this exploration, we will uncover the specifics of various integral units, shedding light on their individual functions and interactions. By dissecting these components, one can develop a more nuanced perspective on how to optimize and troubleshoot these sophisticated machines, ensuring peak performance in demanding environments.

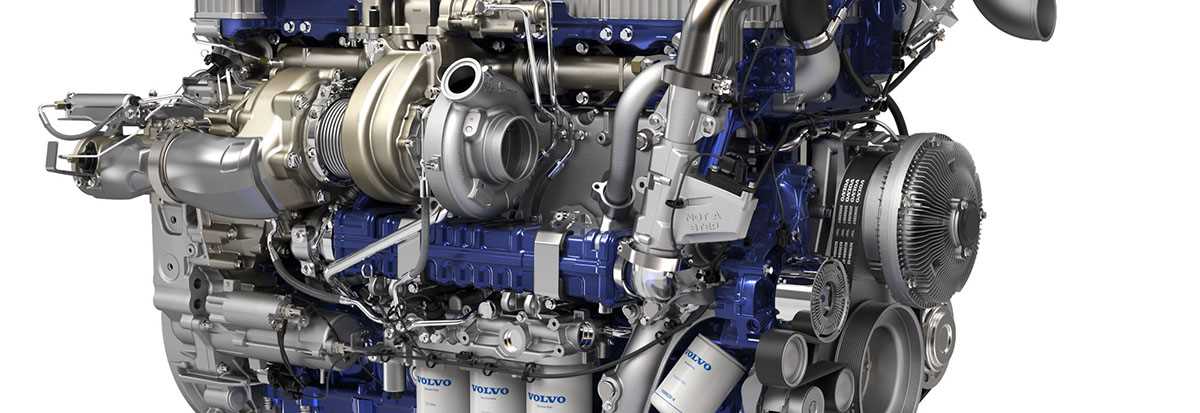

Understanding the Volvo D13 Engine

This section aims to provide insight into a particular type of power unit known for its reliability and efficiency. The focus will be on the components and their interactions that contribute to its overall performance. Familiarity with these elements is essential for anyone looking to maintain or repair this robust machine.

| Component | Description |

|---|---|

| Block | The main structure housing the internal components, providing support and alignment. |

| Cylinder Head | Houses valves and facilitates the combustion process, playing a crucial role in efficiency. |

| Pistons | Move up and down within the cylinders, converting fuel energy into mechanical power. |

| Crankshaft | Transforms linear motion of the pistons into rotational motion, driving the output. |

| Turbocharger | Enhances the air intake, allowing for better combustion and increased power output. |

Understanding each component’s role helps in diagnosing issues and optimizing the overall functionality of the unit. This knowledge is vital for technicians and enthusiasts alike, ensuring longevity and peak performance.

Key Components of the D13 Engine

The core structure of a high-performance power unit consists of several vital elements that work in harmony to ensure optimal functionality and efficiency. Each component plays a crucial role in the overall operation, contributing to the unit’s reliability and power output.

Fuel System: The fuel delivery mechanism is essential for maintaining the correct mixture and ensuring efficient combustion. It typically includes injectors and pumps designed to provide precision and reliability under varying conditions.

Cooling System: A robust cooling mechanism is vital for preventing overheating. It usually features a radiator, water pump, and thermostat that work together to regulate temperature and enhance performance.

Lubrication System: This system minimizes friction between moving parts, prolonging the lifespan of the unit. It includes an oil pump, filters, and passages that ensure a consistent flow of lubricant throughout the assembly.

Air Intake System: Proper airflow is crucial for efficient operation. This system comprises filters and ducts that facilitate the intake of clean air, which is necessary for effective combustion.

Exhaust System: The exhaust mechanism manages the removal of combustion byproducts. It often includes manifolds and pipes that direct emissions away from the unit, ensuring compliance with environmental standards.

Electrical System: A reliable electrical system powers various components, including the starter and sensors. This system is fundamental for monitoring performance and facilitating communication between different parts.

Importance of Engine Diagrams

Visual representations of mechanical assemblies play a crucial role in understanding complex machinery. They offer a clear overview of various components and their interconnections, making it easier to comprehend how each part functions within the whole system. This clarity is essential for both maintenance and repair tasks, enabling technicians to identify issues quickly and efficiently.

Benefits of Visual Representations

Utilizing visual guides can significantly enhance the workflow in mechanical environments. Some of the primary advantages include:

| Benefit | Description |

|---|---|

| Clarity | Helps in visualizing the layout and structure, reducing confusion during assembly or disassembly. |

| Efficiency | Streamlines troubleshooting processes by providing a reference for identifying components and their functions. |

| Training | Serves as a valuable educational tool for new technicians, enhancing their understanding of mechanical systems. |

| Documentation | Acts as a formal record of component relationships, useful for future maintenance and upgrades. |

Facilitating Maintenance and Repair

When addressing mechanical issues, having a comprehensive visual guide can save time and reduce errors. Technicians can quickly locate and assess problematic areas, leading to faster resolutions. Moreover, such illustrations ensure that all components are correctly reassembled, maintaining the integrity of the machinery.

How to Read Engine Parts Diagrams

Understanding technical illustrations related to machinery can enhance your ability to maintain and repair complex systems. These visuals serve as valuable tools, providing insights into component arrangement, functionality, and interconnections. By grasping the conventions used in these representations, one can streamline the troubleshooting and assembly processes.

Familiarize Yourself with Symbols

Each illustration employs specific symbols to denote various components. Take time to study the legend or key accompanying the graphic, as it will clarify the meaning of each symbol. Recognizing these icons is essential for accurately interpreting the layout and understanding the roles of individual elements.

Follow the Flow of Information

When examining the visual, focus on the directional flow of energy or fluid. Typically, these illustrations will indicate how different elements interact and influence each other. By tracing these connections, you can develop a comprehensive understanding of the overall operation, which is crucial for effective diagnostics and repairs.

Common Issues with D13 Parts

When dealing with components of heavy-duty vehicles, several recurring challenges can affect performance and longevity. Understanding these issues is crucial for maintaining efficiency and reliability.

Frequent Problems

- Wear and tear due to high mileage.

- Leakage from seals and gaskets.

- Overheating caused by coolant circulation issues.

Maintenance Tips

- Regular inspections to identify wear early.

- Replacing worn seals promptly to prevent leaks.

- Monitoring coolant levels to avoid overheating.

Maintenance Tips for D13 Components

Regular upkeep of vital systems is crucial for ensuring optimal performance and longevity. This section offers practical advice on maintaining various elements to enhance reliability and efficiency. Implementing these strategies can prevent potential issues and extend the service life of your machinery.

Routine Inspection

Conducting frequent inspections is essential for identifying wear and tear before they escalate into serious problems. Focus on critical areas where failure could lead to significant downtime.

| Component | Inspection Frequency | Key Checks |

|---|---|---|

| Cooling System | Monthly | Check coolant levels and inspect for leaks. |

| Fuel System | Every 500 hours | Examine filters and lines for clogs or damage. |

| Lubrication System | Weekly | Ensure oil levels are adequate and free of contaminants. |

Proper Cleaning

Maintaining cleanliness around various components can prevent build-up that may impede performance. Regular cleaning can also help identify potential problems early.

Utilize appropriate cleaning solutions and techniques to ensure that sensitive areas are not damaged. Establish a cleaning schedule based on operating conditions to maximize efficiency.

Upgrading Volvo D13 Parts Effectively

Enhancing the performance and longevity of heavy-duty machinery requires a strategic approach to component upgrades. By focusing on specific elements, operators can achieve significant improvements in efficiency and reliability. This section explores effective methods to upgrade essential components, ensuring optimal operation and reduced maintenance costs.

Identifying Key Components for Upgrade

When considering enhancements, it’s crucial to identify which components will yield the most benefit. Focus on:

- Fuel Delivery System

- Cooling Mechanisms

- Air Intake and Filtration

- Exhaust Management

- Electrical Systems

Choosing Quality Upgrades

Selecting high-quality replacements can make a significant difference in performance. Consider the following:

- Research manufacturers and reviews for reliability.

- Opt for components that offer improved efficiency and lower emissions.

- Consult with professionals or forums for expert recommendations.

- Check compatibility with existing systems to avoid future issues.

By thoughtfully upgrading components, operators can enhance the overall functionality and dependability of their machinery.

Sources for Quality Replacement Parts

Finding reliable sources for high-quality components is essential for maintaining the performance and longevity of your vehicle. Whether you’re looking for original equipment or aftermarket alternatives, knowing where to look can make a significant difference. This section outlines various avenues to explore when seeking durable replacements that meet your specific needs.

Authorized Dealers and Distributors

One of the most trustworthy options is to source components directly from authorized dealers and distributors. These vendors often carry genuine items that meet strict quality standards. By purchasing from them, you can ensure compatibility and reliability, as these parts are designed specifically for your vehicle model.

Reputable Online Retailers

Online shopping has transformed how consumers acquire components. Many established online retailers specialize in automotive supplies and offer a wide range of options. When selecting an online source, look for those with positive reviews and clear return policies. Comparing prices and checking for warranties can also enhance your purchasing experience.

In conclusion, whether you choose local dealerships or online platforms, prioritizing quality and reliability will contribute to the optimal functioning of your vehicle.

Future Developments in D13 Technology

The evolution of heavy-duty powertrains is set to embrace groundbreaking advancements that will enhance performance, efficiency, and environmental sustainability. As manufacturers continue to invest in innovative solutions, the next generation of propulsion systems is expected to integrate cutting-edge technologies that address the demands of modern transportation.

One significant area of focus will be the incorporation of alternative fuels and hybrid systems. These developments aim to reduce carbon emissions while maintaining the robustness required for demanding applications. Additionally, advancements in digital technology will enable more sophisticated monitoring and diagnostic capabilities, allowing for real-time data analysis to optimize performance and maintenance schedules.

Another promising direction involves the implementation of lightweight materials and advanced manufacturing techniques. By reducing overall weight, these innovations will not only improve fuel efficiency but also enhance the overall longevity and reliability of the systems. Furthermore, research into electrification will play a crucial role in shaping the future landscape of heavy-duty transportation, promising quieter and more efficient operations.

In summary, the trajectory of future advancements will be marked by a commitment to sustainability, performance enhancement, and the integration of new technologies, paving the way for a new era in heavy-duty powertrains.