Understanding the inner workings of agricultural machinery is crucial for ensuring its optimal performance and longevity. Each mechanical element plays a vital role in the overall functionality, making it important to have a clear understanding of the system’s structure. By familiarizing yourself with the layout and configuration of these elements, maintaining and servicing the equipment becomes more efficient and straightforward.

This guide provides a detailed look into the critical components that make up the core of the machine. With clear illustrations and descriptions, users can easily identify specific mechanical pieces and understand how they interconnect. Whether you’re performing routine maintenance or troubleshooting an issue, knowing the precise arrangement of these elements helps to ensure smooth operations.

By studying the equipment’s layout, owners and operators can take proactive steps in caring for their machinery. From understanding wear-prone areas to identifying key structural elements, this guide is designed to aid in preserving the machine’s efficiency and extending its lifespan.

Overview of Key Components

The machinery in question is composed of multiple crucial elements that work together to ensure efficient performance. Understanding these elements can help in maintaining the device’s functionality and prolonging its operational life.

- Frame Structure: The base of the equipment, designed to support other components and maintain stability during use.

- Drive Mechanism: This section powers the device, enabling motion and activity by transferring energy efficiently throughout the system.

- Cutting Blades: Sharp and durable, these parts handle the primary task of material processing, ensuring clean and precise results.

- Gearbox Assembly: Controls the speed and torque distribution, allowing for smooth operation under varying loads and conditions.

- Hydraulic System: Responsible for fluid movement and pressure regulation, this system helps in the movement and control of specific components.

Each component plays an essential role in the overall functionality, ensuring the machine operates at optimal capacity, while requiring regular checks and upkeep.

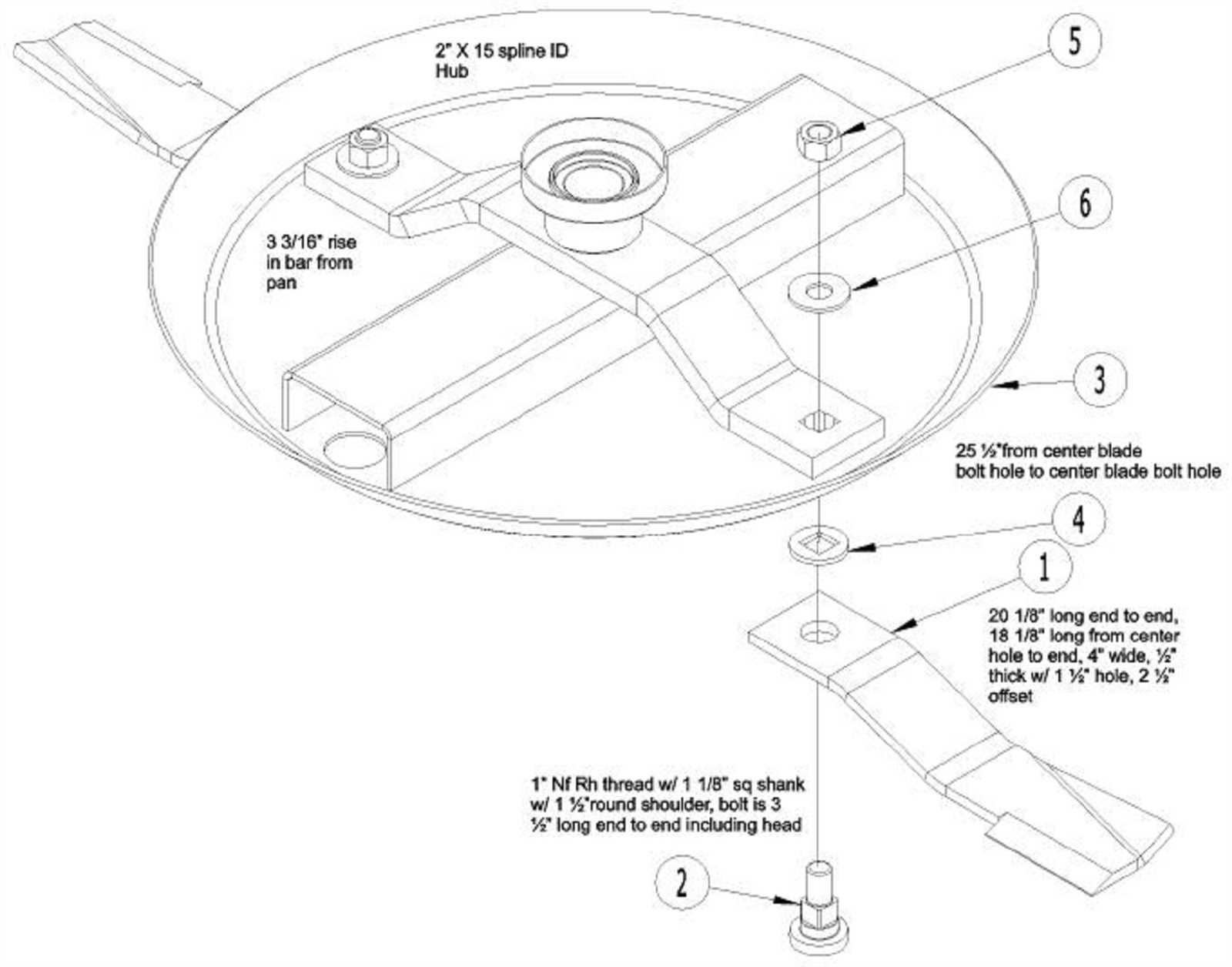

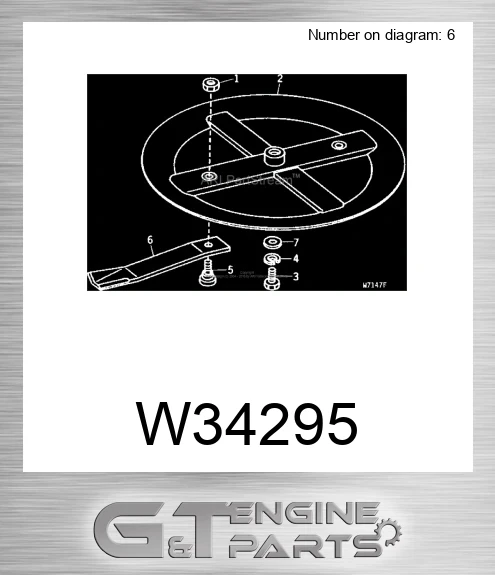

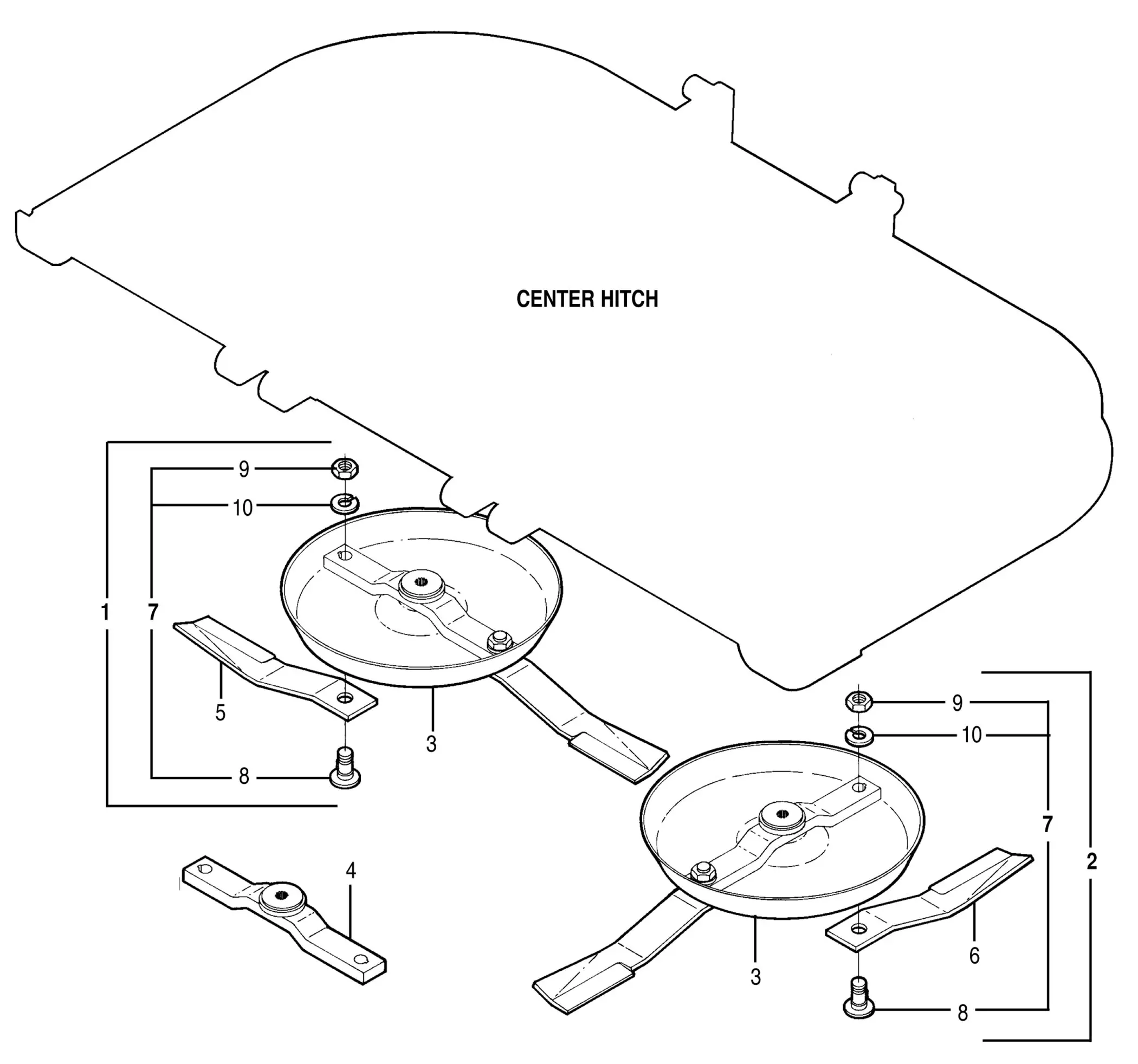

Blades and Cutting Mechanism

The cutting system plays a crucial role in ensuring efficient operation and clean cuts during use. At the heart of this system are the sharp edges, designed to handle various vegetation types with precision. Understanding the design and functionality of this mechanism can improve performance and durability over time.

Blade Design and Structure

The cutting edges are crafted from high-strength materials to endure tough conditions. Their shape and arrangement are optimized to provide maximum coverage while maintaining balance. This ensures smooth and consistent cutting, reducing strain on the machine and minimizing wear over time.

Maintenance and Longevity

Regular upkeep of the cutting edges is essential to maintain efficiency. Sharpening, balancing, and checking for damage will prolong the life of the cutting mechanism and ensure optimal performance. Proper care not only enhances the cutting process but also reduces downtime caused by potential issues.

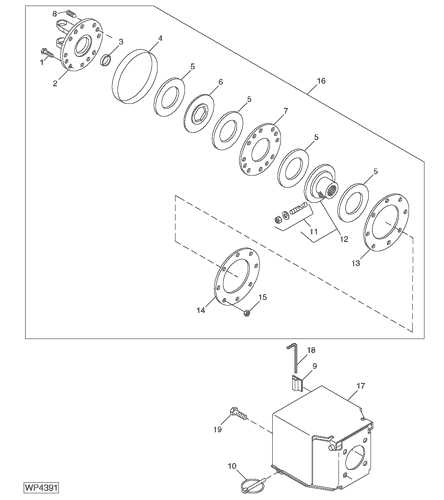

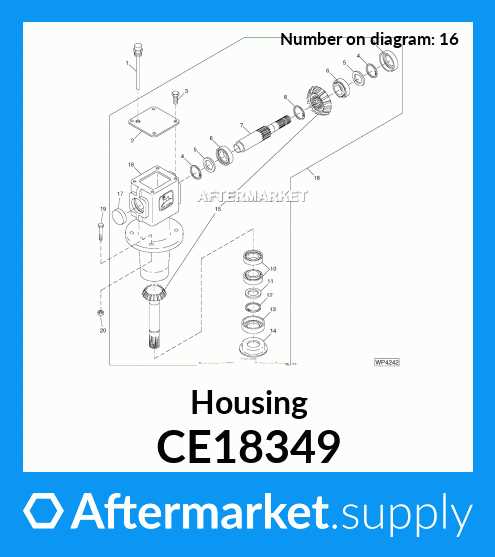

Drivetrain and Gearbox Assembly

The drivetrain and gearbox are essential components of any mechanical system, responsible for efficiently transmitting power from the engine to the working mechanisms. Properly assembled, they ensure smooth operation, handling heavy loads while minimizing energy loss. Understanding their layout and function is critical for maintaining optimal performance.

The drivetrain includes a series of interconnected shafts and joints, each designed to transfer rotational force. The gearbox, with its system of gears, adjusts torque and speed to match the required workload. Together, these elements form a robust foundation, enabling efficient power distribution throughout the equipment.

Regular inspection and proper alignment of these components are necessary for longevity and efficiency. A well-maintained drivetrain and gearbox can prevent breakdowns and extend the lifespan of the machinery, ensuring continuous, reliable operation even under demanding conditions.

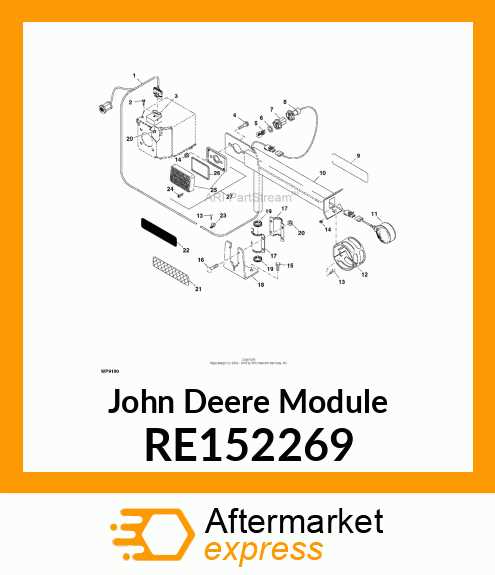

Hydraulic System Breakdown

The hydraulic mechanism plays a crucial role in the overall operation, ensuring that various components work smoothly and efficiently. It relies on fluid dynamics to transfer power, providing the necessary force to operate key functions. Understanding the breakdown of this system is essential for maintaining functionality and addressing potential issues.

At the core of this setup is the pump, which generates pressure to move the fluid through a series of valves and hoses. These elements work together to deliver the necessary power to the system’s working parts. Proper management of fluid flow is key to ensuring that the operation remains consistent and reliable.

In addition to the pump and valves, the system includes various connectors and seals that help to control the movement of hydraulic fluid. These components require regular inspection to prevent leaks and maintain performance. Over time, wear and tear can impact the system’s efficiency, making maintenance a top priority.

Frame Structure and Support Parts

The foundation and overall framework play a crucial role in the durability and reliability of the equipment. The structure must withstand constant stress, providing stability and balance during operation. The essential components of the frame and supportive elements are designed to distribute weight evenly, ensuring seamless performance across various tasks.

Primary Framework forms the backbone of the entire assembly, built to handle high loads while maintaining flexibility in movement. Reinforced materials are often used to ensure longevity, minimizing the risk of deformation under pressure.

Support elements work hand in hand with the main structure, providing additional strength where needed. These components often include crossbars, brackets, and stabilizers, which enhance the unit’s ability to operate under various conditions.

Safety Shields and Guards

Protective barriers and shields play a crucial role in ensuring the safety of operators and bystanders during machinery operation. These components are designed to prevent accidental contact with moving parts, reducing the risk of injury. Proper installation and maintenance are essential for their effectiveness in safeguarding users from potential hazards.

Made from durable materials, these safety elements are positioned strategically to cover potentially dangerous areas. Regular inspection and maintenance help to keep them in optimal condition, preventing wear or damage that could compromise safety. By adhering to safety standards, these protective devices provide peace of mind while operating heavy machinery.

Wheels and Axle Components

Understanding the essential elements that allow for efficient movement and stability is crucial for any machinery. These components play a key role in the overall performance, ensuring smooth operation and durability. The interaction between wheels and axles is integral to handling various terrains and maintaining balance under different loads.

The assembly includes various parts that connect the vehicle to its wheels, ensuring optimal performance across various applications. From the central axle to the wheel hubs, each component has a specific role in supporting movement and distributing forces evenly.

| Component | Description |

|---|---|

| Axle | The central shaft that supports the weight of the vehicle and transmits power to the wheels. |

| Wheel Hub | The part that connects the wheel to the axle and allows for rotation. |

| Wheel Bearing | A set of bearings that reduce friction and support the wheel hub’s rotation. |

| Spindle | A component that connects the wheel assembly to the axle, providing a pivot point for steering or stability. |

| Wheel Rim | The outer edge of the wheel, which holds the tire in place and provides surface contact. |

Attachment Points and Linkage

This section focuses on the key connection areas and mechanisms that enable the attachment of various implements to the machine. Proper understanding of these elements is essential for ensuring safe and efficient operation, as they provide the structural support for different attachments during use.

Key Connection Areas

- Front linkage: The primary location for attaching equipment designed for frontal tasks, ensuring stability during operation.

- Rear coupling: Located at the back, this area supports implements such as trailers and agricultural attachments.

- Side connectors: These points allow for the integration of side-mounted tools and machinery, often used in specialized applications.

Linkage Mechanisms

- Hydraulic systems: These provide the necessary force for engaging and disengaging attachments, allowing for smooth transitions between different tools.

- Manual adjustments: Some systems require manual configuration to ensure proper alignment and secure attachment.

- Pivot points: These allow for the rotation of attachments, facilitating movement and enhancing the machine’s versatility.

Maintenance Parts and Consumables

When it comes to keeping machinery in optimal working condition, certain components and consumables play a crucial role. These elements ensure the smooth operation of various systems, from the engine to the operational attachments. Regular attention to these items can help prevent breakdowns and enhance the overall efficiency of the equipment.

Essential Components for Routine Care

Among the most vital are components designed for regular replacement, such as filters, seals, and belts. These items need frequent checks and timely replacements to ensure that the machinery runs efficiently and without interruptions. Neglecting their condition could lead to performance issues or even damage to more complex systems.

Consumables for Optimal Functioning

In addition to the main components, consumables like lubricants, oils, and hydraulic fluids are essential for maintaining performance and preventing wear. These materials ensure that the moving parts remain properly lubricated and the system functions smoothly, even under heavy use.