When it comes to maintaining and repairing lawn care machinery, having a clear visual representation of its components is essential. This guide aims to provide an insightful overview of the intricate parts that make up these machines, facilitating a deeper comprehension of their functionality.

By exploring the various elements involved, users can gain valuable knowledge that aids in troubleshooting and replacement. A thorough understanding of these components is the ultimate key to ensuring optimal performance and longevity of the equipment.

Whether you are a seasoned technician or a novice owner, delving into this topic will equip you with the necessary tools to tackle maintenance tasks confidently. Knowing how each piece fits together will empower you to make informed decisions for your machinery.

Understanding John Deere LA120 Parts

Exploring the components of a particular lawn equipment model reveals the intricate design and functionality that make it effective for various tasks. Each element plays a crucial role in ensuring optimal performance and longevity.

- Engine: The powerhouse that drives the machine.

- Transmission: Facilitates movement and speed control.

- Chassis: Provides structural support and stability.

- Deck: Houses the cutting blades for efficient grass management.

- Wheels: Essential for mobility and terrain navigation.

Understanding these crucial elements allows for better maintenance, troubleshooting, and ultimately enhances the user experience.

Key Components of the LA120

This section explores the essential elements that contribute to the functionality and efficiency of a popular riding mower model. Understanding these components can enhance maintenance and improve overall performance, ensuring a reliable mowing experience.

Engine System

The heart of the machine, the engine system, powers all operations. With a robust design, it ensures smooth performance and reliable starting. Regular checks on this unit are crucial for optimal functionality.

Cutting Deck

The cutting deck plays a vital role in delivering a clean and even cut. Its sharp blades and adjustable height settings allow for customized mowing results, adapting to various lawn conditions and preferences.

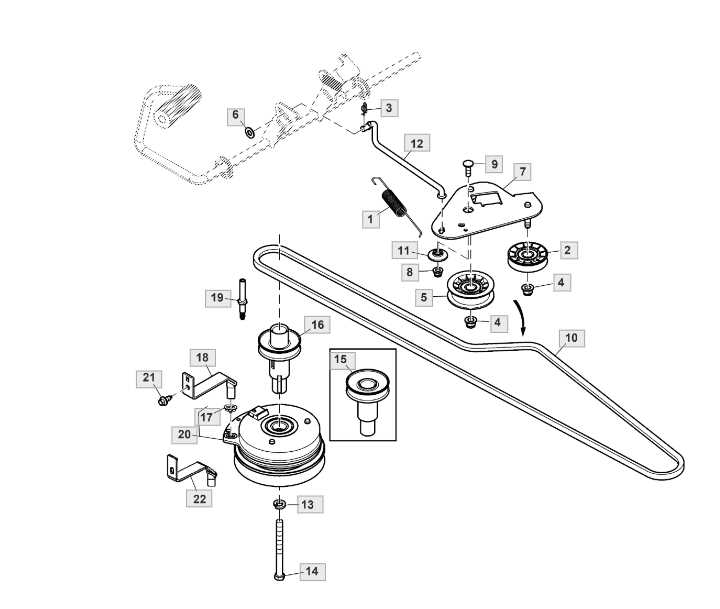

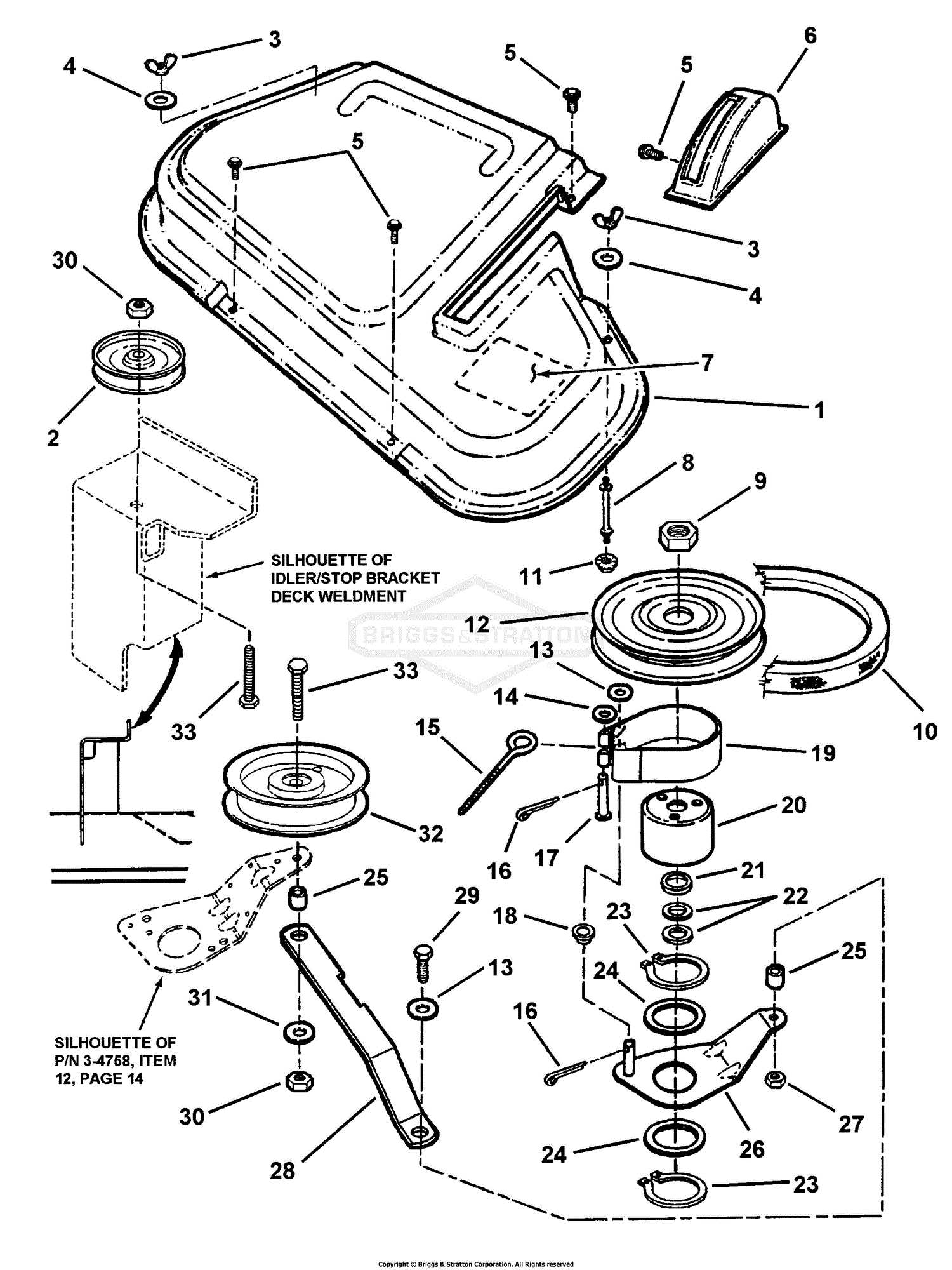

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying elements, ensuring proper assembly, and facilitating troubleshooting processes. By providing clarity, these illustrations enhance the overall efficiency of servicing tasks.

Benefits of Visual Representations

- Streamlined Maintenance: Clear visuals simplify the identification of specific components, making it easier to perform maintenance tasks.

- Efficient Repairs: Knowing the exact arrangement of elements helps technicians quickly locate and address issues.

- Reduced Errors: Accurate illustrations minimize the risk of misplacing parts or using incorrect replacements.

- Enhanced Training: Visual aids serve as valuable resources for training new technicians, allowing for quicker understanding of complex systems.

Impact on Longevity and Performance

- Improved Functionality: Regular upkeep informed by clear visuals contributes to the optimal performance of equipment.

- Increased Lifespan: Proper handling and timely repairs based on accurate representations can extend the durability of machinery.

- Cost Efficiency: Reducing the likelihood of mistakes and misdiagnoses ultimately leads to savings in both time and resources.

Incorporating these visual tools into maintenance practices is essential for anyone looking to ensure the reliability and longevity of their machinery.

How to Access the Diagram

Finding detailed illustrations of machinery components can be essential for effective maintenance and repair. These visuals serve as invaluable tools for understanding the assembly and function of various parts, making the repair process more efficient. This guide will walk you through the steps to access these essential resources with ease.

Online Resources

The internet is a rich source of information. Various official and third-party websites offer access to comprehensive visual guides. Start by visiting the manufacturer’s website, which often provides downloadable manuals and schematics. Additionally, online forums and community groups dedicated to machinery enthusiasts can be helpful. Many members share links and resources that may not be widely known.

Local Dealers and Service Centers

If online searches prove unfruitful, consider visiting a local dealership or service center. These establishments typically have access to the latest manuals and illustrations. They may even allow you to view the resources on-site or provide printed copies. Engaging with professionals in these locations can also offer insights into common issues and solutions related to specific models.

Common Issues with LA120 Parts

When it comes to maintaining a lawn care machine, various components can encounter challenges that may affect overall performance. Understanding these common troubles can aid in timely repairs and enhance longevity.

Wear and Tear: Over time, certain elements may degrade due to constant use, leading to inefficiencies. Regular inspection can help identify these issues early.

Incorrect Installation: Improperly fitted components can cause malfunctions. Ensuring that each piece is correctly installed is crucial for optimal operation.

Compatibility Problems: Using parts that are not designed for specific models can result in poor performance or damage. Always verify compatibility to avoid these pitfalls.

Fluid Leaks: Leaks can occur in various systems, affecting functionality. Regular checks can prevent significant issues from developing.

By being aware of these common challenges, users can take proactive measures to maintain their equipment effectively.

Replacing Worn Out Components

Maintaining the efficiency of your machinery requires regular inspection and timely replacement of aged parts. Over time, various components can degrade due to wear and tear, affecting overall performance and reliability. Recognizing when to replace these elements is crucial for ensuring optimal functionality and prolonging the lifespan of your equipment.

Identifying Signs of Wear

It is essential to monitor for indications that components may need replacement. Look for unusual noises, decreased performance, or visible damage. Regular maintenance checks can help in early detection, allowing you to address issues before they escalate.

Choosing Quality Replacements

When selecting new components, prioritize quality and compatibility. High-grade parts not only enhance performance but also contribute to the longevity of your machinery. Always refer to manufacturer recommendations to ensure you are choosing the right replacements for your specific model.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your outdoor equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your machinery. Implementing a few essential practices can lead to significant improvements in durability and efficiency.

Regular Cleaning: Accumulated dirt and debris can hinder performance. After each use, take the time to clean the exterior and remove any buildup around critical components. This simple step prevents corrosion and wear, keeping your equipment in optimal condition.

Check Fluid Levels: Proper lubrication is crucial for smooth operation. Routinely inspect and top off oil, coolant, and other necessary fluids. This practice minimizes friction and overheating, contributing to the overall health of your machinery.

Inspect Belts and Cables: Worn or frayed belts and cables can lead to operational failures. Regularly examine these components for signs of damage and replace them as needed. Doing so helps maintain efficient functionality and prevents unexpected breakdowns.

Sharpen Blades: If applicable, keep blades sharp for effective cutting. Dull blades can strain the engine and lead to uneven results. Schedule sharpening at regular intervals to ensure clean cuts and reduce energy consumption.

Store Properly: When not in use, store equipment in a dry, sheltered area. Protecting your machinery from harsh weather conditions can significantly reduce wear and tear, ensuring it remains ready for the next task.

By following these maintenance tips, you can ensure that your outdoor equipment remains reliable and performs at its best for years to come.

Where to Buy Genuine Parts

Finding authentic components for your machinery is essential for maintaining its performance and longevity. Opting for original replacements ensures compatibility and reliability, which are critical for seamless operation. Here are several avenues to consider when seeking these essential items.

Authorized Dealers

One of the most reliable sources for original components is through authorized dealerships. These locations specialize in a range of machinery and carry a comprehensive inventory of genuine items. Engaging with an authorized dealer not only guarantees the authenticity of the products but also provides access to knowledgeable staff who can assist with your specific needs.

Online Retailers

Another convenient option is to explore reputable online retailers. Numerous platforms offer a wide selection of original components, often with user-friendly search features. When purchasing online, it’s important to verify the credibility of the seller and ensure that the items are certified. Look for customer reviews and ratings to guide your decision.

Whether visiting a dealer or shopping online, securing authentic components is vital for optimal performance and durability.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures compatibility and performance that aftermarket alternatives often cannot match. These authentic items are crafted to meet specific standards, providing a range of advantages for machinery maintenance.

- Quality Assurance: Original components are rigorously tested for durability and reliability.

- Perfect Fit: Designed specifically for your equipment, ensuring seamless integration.

- Longevity: OEM products typically last longer, reducing the frequency of replacements.

- Warranty Protection: Many original parts come with a warranty, offering peace of mind.

- Enhanced Performance: Original parts help maintain the ultimate efficiency of your machinery.