Maintaining a lawn care machine requires a comprehensive understanding of its various components, particularly when it comes to navigation and control systems. Properly functioning mechanisms are crucial for achieving precise movement and ensuring an efficient mowing experience. Familiarity with these elements not only enhances performance but also extends the lifespan of the equipment.

In this section, we will explore the intricate network of elements that contribute to the directional functionality of your mower. By dissecting the assembly, users can gain insights into how each component interacts, allowing for informed maintenance and troubleshooting. A thorough grasp of these systems can significantly improve handling and overall user satisfaction.

Whether you are a seasoned operator or a newcomer to lawn care machinery, understanding these essentials will empower you to address potential issues proactively. This knowledge not only facilitates effective repairs but also promotes a safer, more enjoyable mowing experience. Let’s delve into the specifics of these crucial elements and uncover how they work together seamlessly.

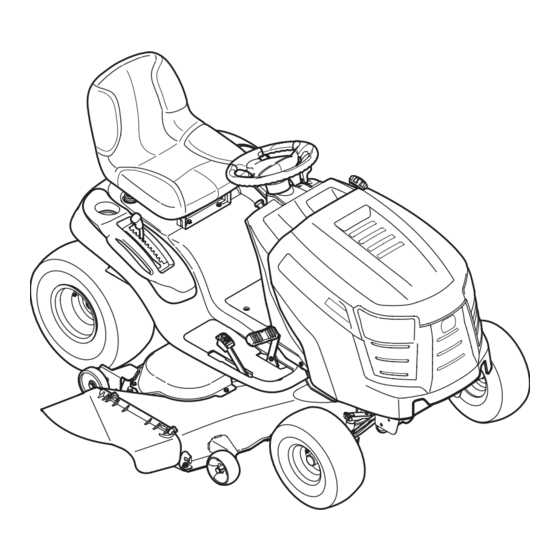

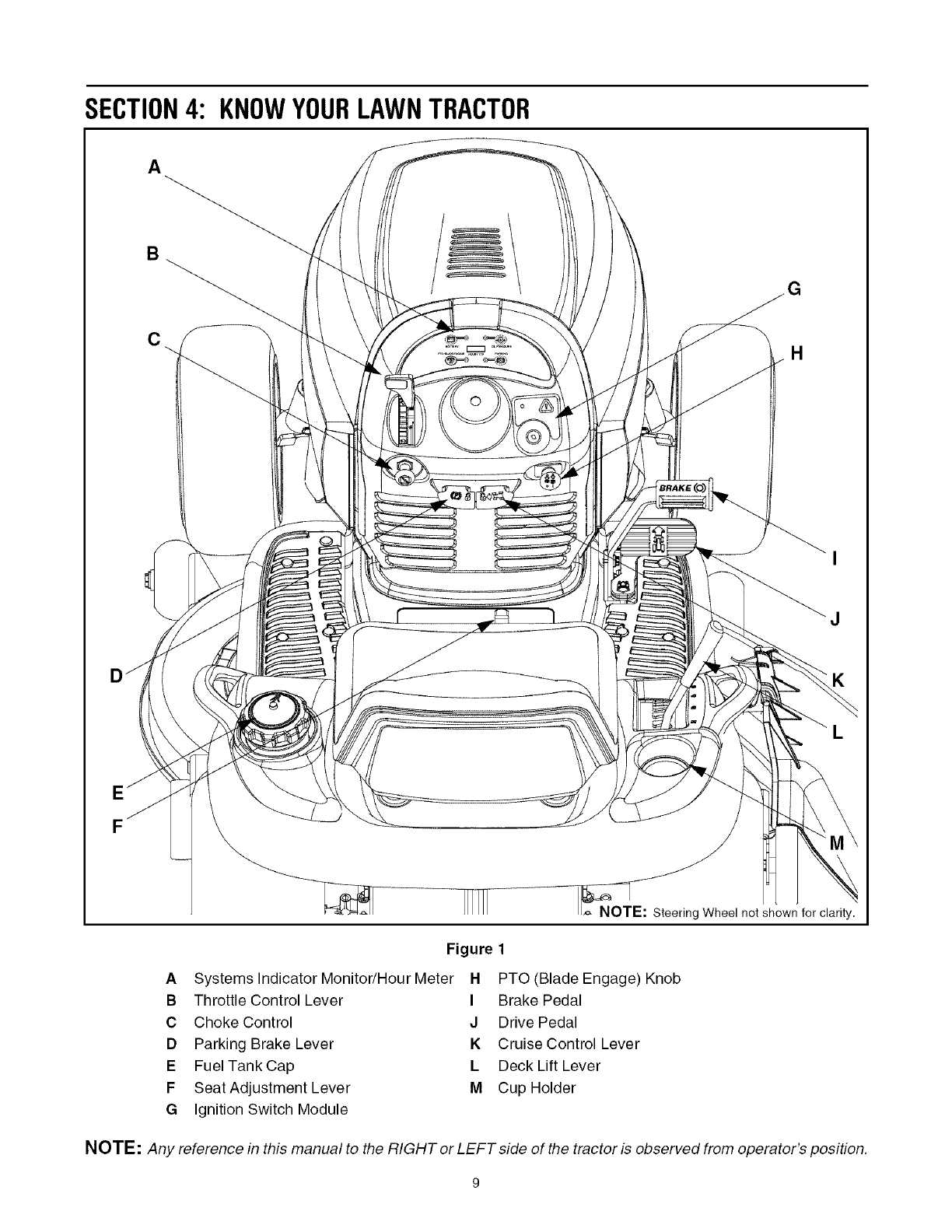

Overview of the Lawn Tractor

This section provides a comprehensive look at a specific model of lawn machinery, designed to simplify yard maintenance. With a focus on performance, comfort, and durability, this equipment stands out as a reliable choice for homeowners and landscaping professionals alike.

Key features include:

- Powerful engine for efficient cutting and mowing.

- User-friendly controls for effortless operation.

- Robust frame designed to withstand rigorous use.

- Comfortable seating arrangement for extended periods of work.

The design prioritizes both functionality and ease of use, making it suitable for various terrains. Regular maintenance ensures longevity, allowing users to enjoy its benefits for many seasons.

In addition, the availability of numerous accessories enhances versatility, catering to different gardening needs. Overall, this model represents a blend of innovation and practicality, aimed at improving the outdoor experience.

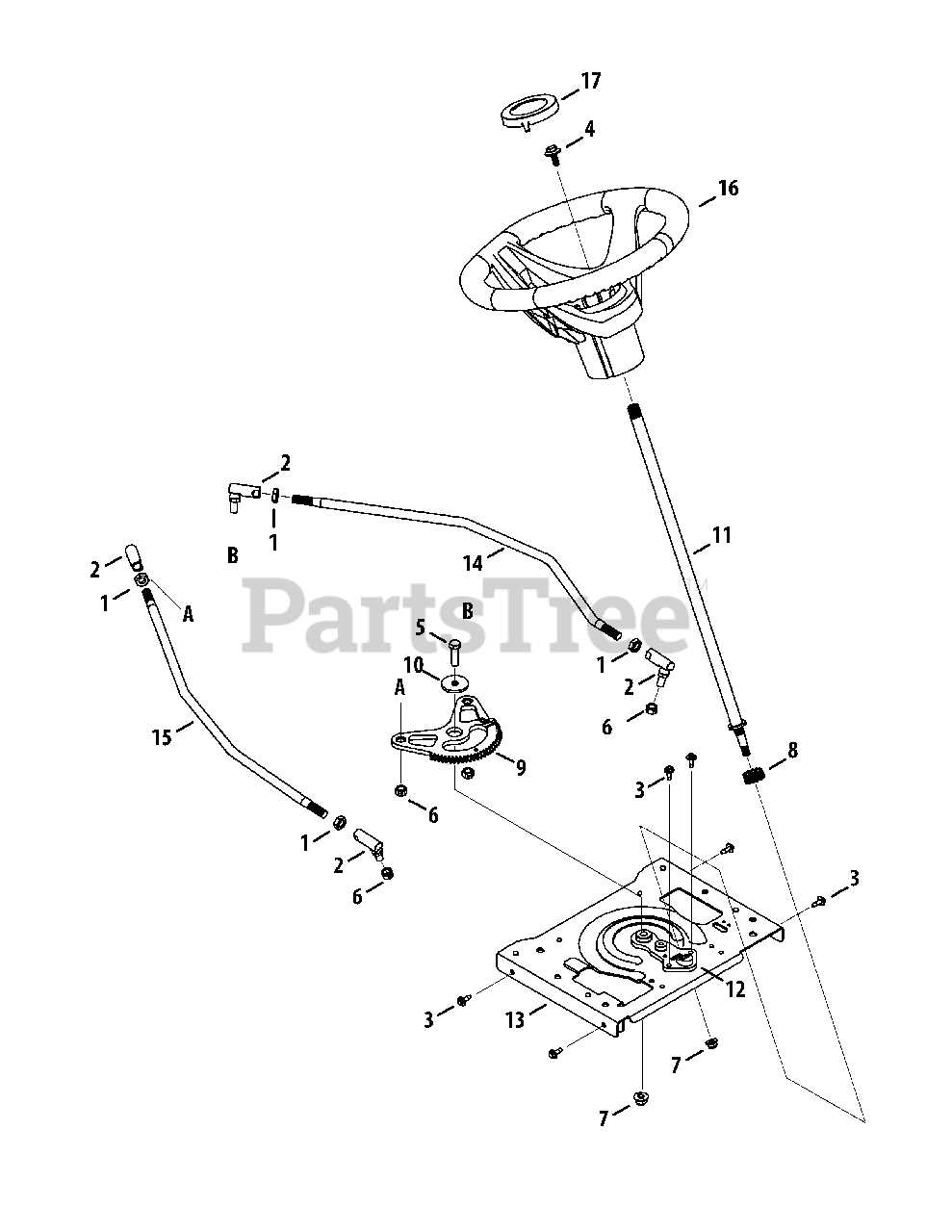

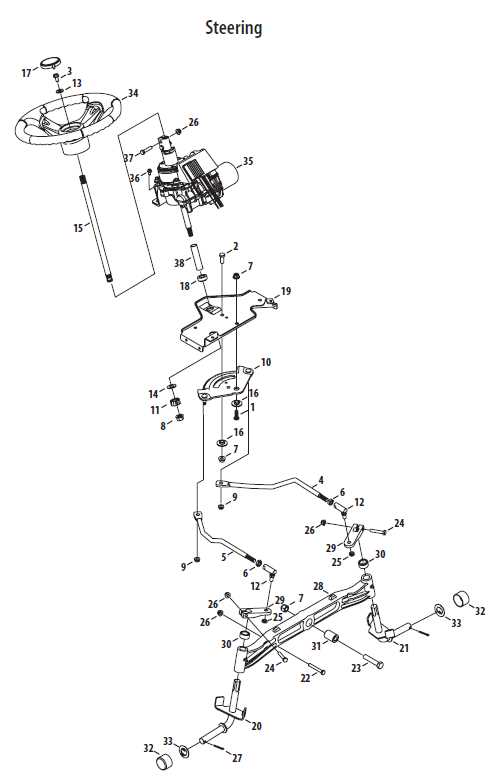

Understanding Steering Mechanism Basics

The function of a directional control system is essential for the maneuverability of various vehicles. It enables operators to navigate effectively, ensuring precision and stability while in motion. This mechanism consists of several interconnected components that work harmoniously to facilitate changes in direction, enhancing overall performance and safety.

Key Components of Directional Control

At the core of this system lies the wheel assembly, which interacts directly with the surface for movement. Coupled with this are linkages and joints, which transmit the operator’s inputs to the wheels. Each element plays a crucial role in ensuring that any adjustments in angle are translated into smooth, responsive movements.

Functionality and Importance

The effectiveness of a directional control system significantly impacts the overall driving experience. A well-designed assembly provides not only ease of use but also enhances the operator’s ability to handle the vehicle in various terrains. Understanding the underlying mechanisms contributes to better maintenance and longevity of the vehicle, ensuring reliability in performance.

Common Issues with Steering Parts

Proper control mechanisms are essential for the smooth operation of any vehicle. However, several complications can arise that may hinder performance. Understanding these frequent problems can help in timely diagnosis and maintenance.

One prevalent issue is the wear and tear of components due to constant use. Over time, friction can lead to degradation, affecting responsiveness. Additionally, misalignment can occur, resulting in difficulty in maneuvering. This misalignment can stem from improper installation or damage from impacts.

Another concern is the buildup of debris and grime within the control system. This accumulation can impede movement and create unnecessary resistance, ultimately leading to more severe malfunctions if not addressed promptly. Regular cleaning and inspections can mitigate this risk.

Moreover, hydraulic leaks can also present significant challenges. These leaks often lead to reduced fluid levels, which are critical for maintaining pressure within the system. Detecting and repairing these leaks promptly is vital for ensuring optimal functionality.

Lastly, the age of the vehicle plays a crucial role in the longevity of its components. Older systems may be more prone to issues, necessitating routine evaluations and potential replacements to ensure safe and efficient operation.

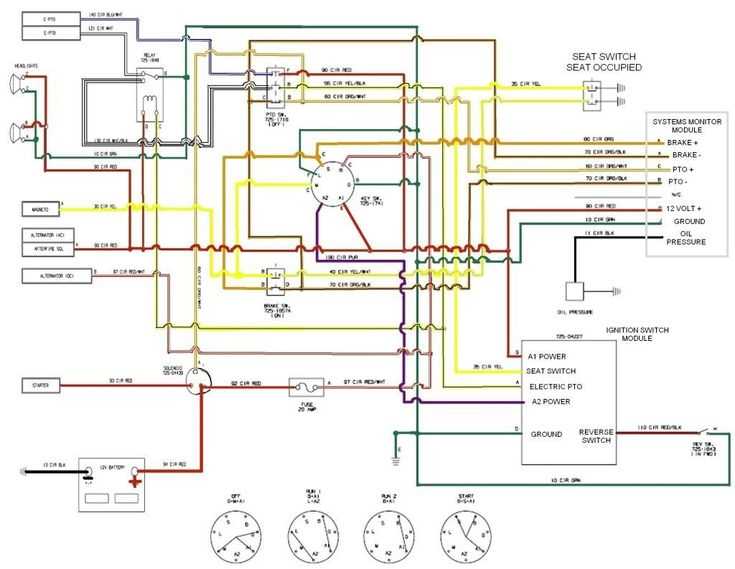

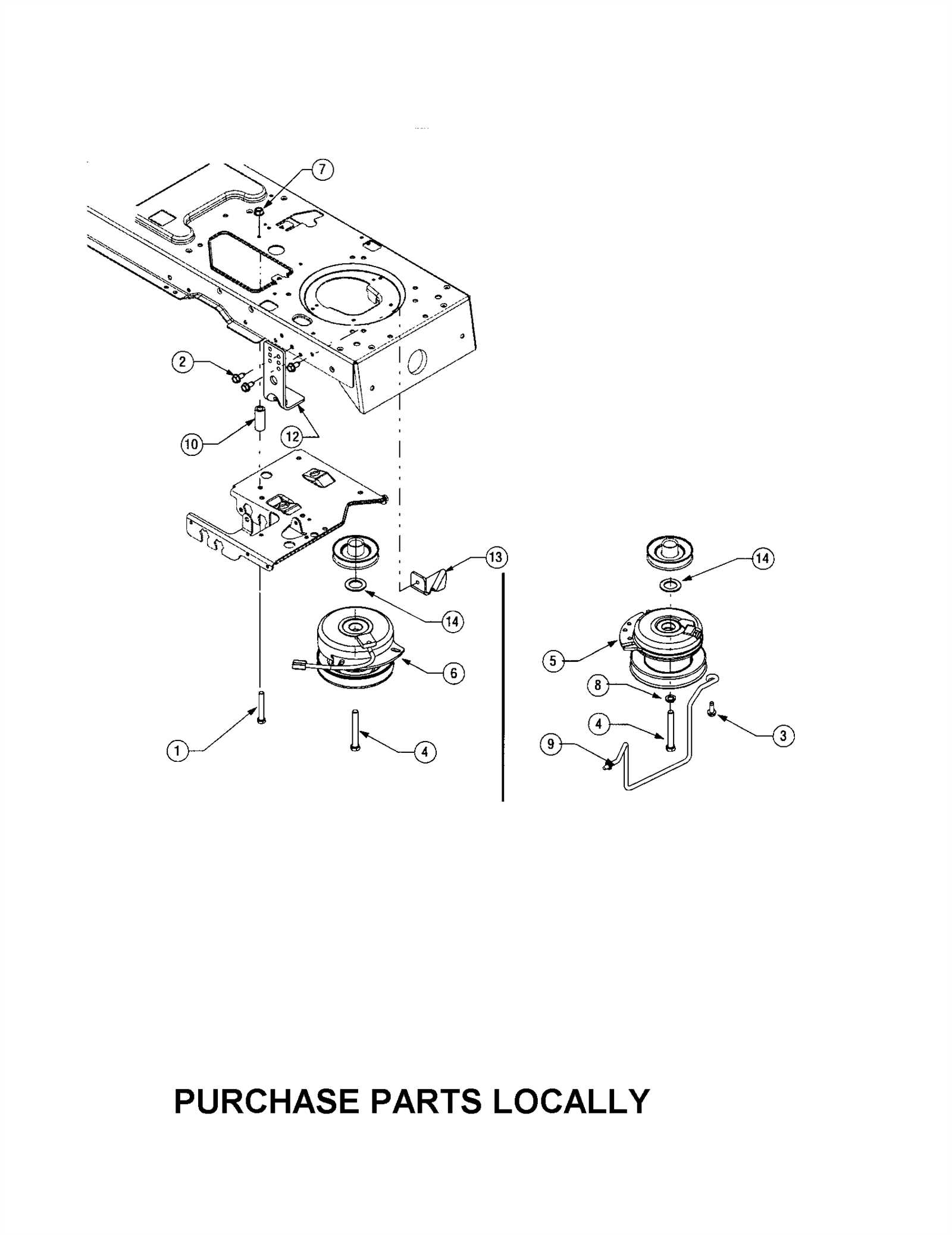

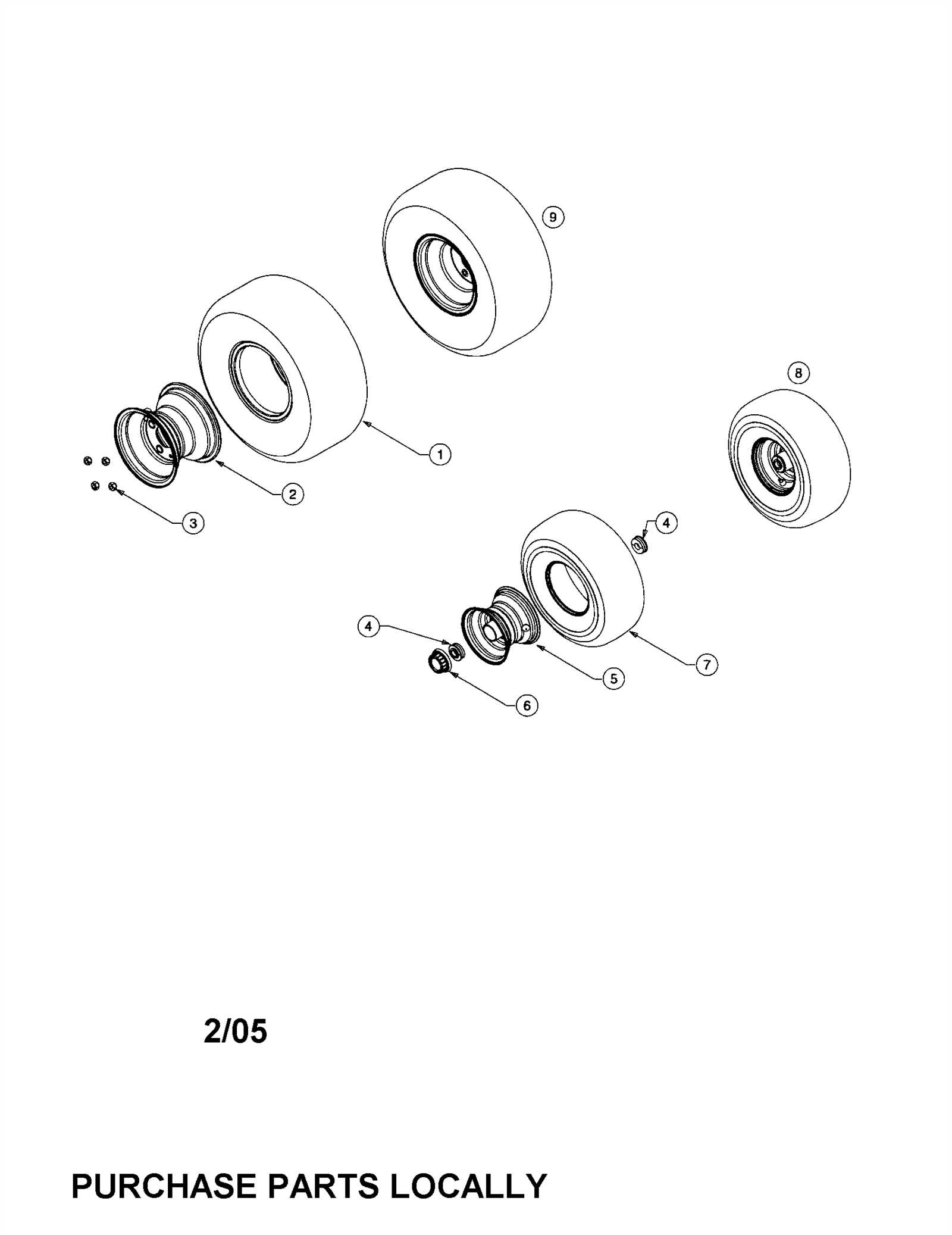

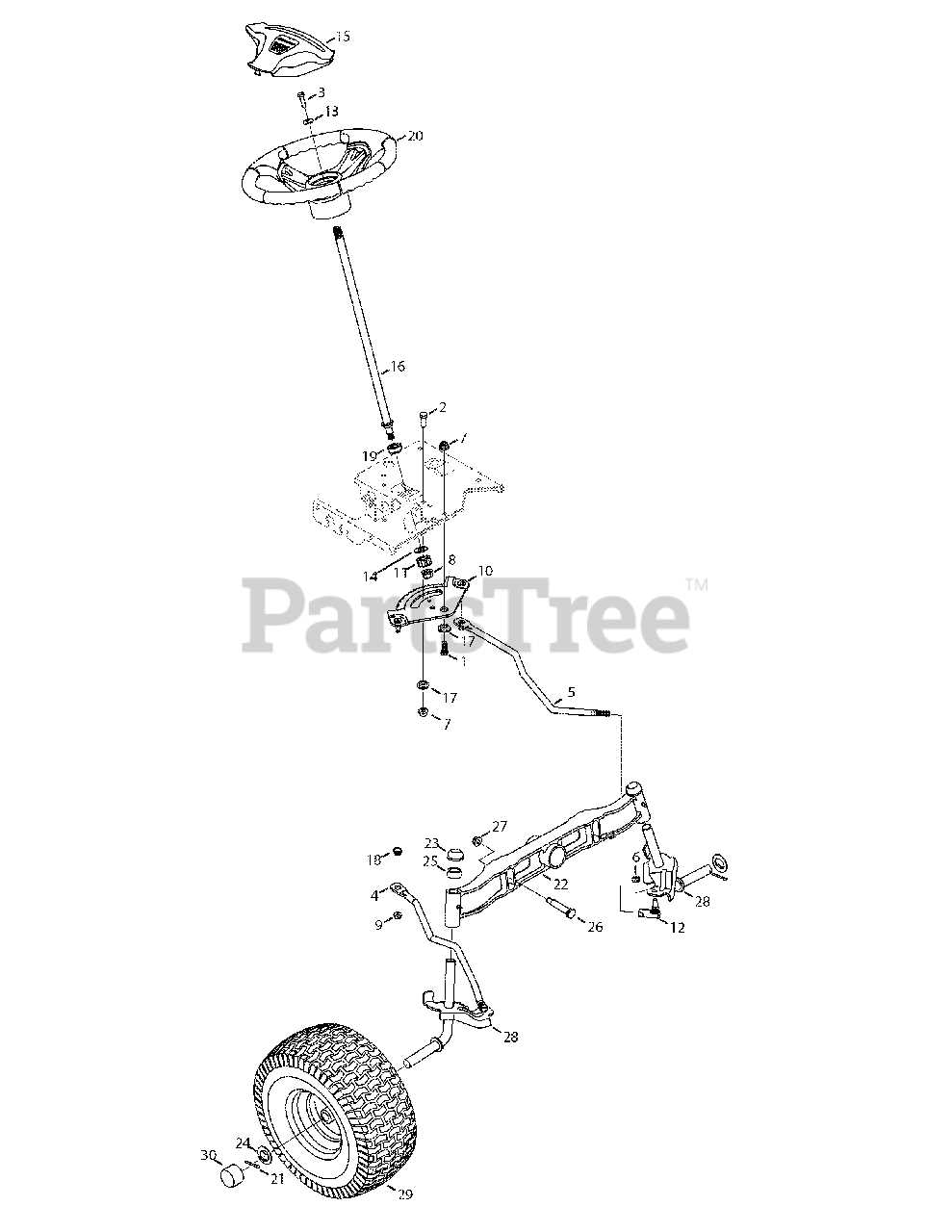

Identifying Essential Components in Diagram

Understanding the fundamental elements within a schematic is crucial for effective maintenance and repairs. By recognizing these components, users can troubleshoot issues more efficiently and ensure optimal functionality of their machinery.

When examining a schematic, it’s helpful to focus on the following key elements:

- Control Mechanisms: These are the levers and knobs that allow for direction and speed adjustments.

- Linkages: These components connect various parts, enabling smooth movement and response to user inputs.

- Mounting Brackets: Essential for securing parts in place, ensuring stability and durability during operation.

- Fasteners: Screws, bolts, and nuts that hold components together, crucial for maintaining structural integrity.

Each of these elements plays a significant role in the overall functionality, and recognizing their positions and relationships within the schematic can aid in troubleshooting and repairs.

To effectively interpret the diagram, consider the following steps:

- Familiarize yourself with the legend or key, which outlines symbols used in the schematic.

- Trace the flow of movement to understand how inputs translate into actions.

- Identify any potential points of failure by analyzing connections and stress points.

By following these guidelines, users can better navigate complex schematics and ensure their equipment operates smoothly and efficiently.

Maintenance Tips for Steering System

Regular upkeep of the guidance mechanism is essential for ensuring smooth operation and longevity of your equipment. A well-maintained system not only enhances performance but also contributes to safety and comfort during use. Here are some valuable suggestions to keep the directional controls in top condition.

1. Regular Inspection: Periodically examine the entire assembly for signs of wear or damage. Look for loose connections, frayed cables, or any unusual noises that may indicate a problem. Early detection can prevent more serious issues down the line.

2. Lubrication: Ensure all moving components are properly lubricated. Use an appropriate lubricant to reduce friction and wear. Check the manufacturer’s recommendations for specific products suitable for your machinery.

3. Tightening Fasteners: Over time, bolts and screws may become loose due to vibrations during operation. Regularly check and tighten these fasteners to maintain stability and performance.

4. Cleaning: Keep the area free from debris and dirt that can interfere with operation. Use a soft cloth or brush to clean the mechanism, ensuring no particles impede functionality.

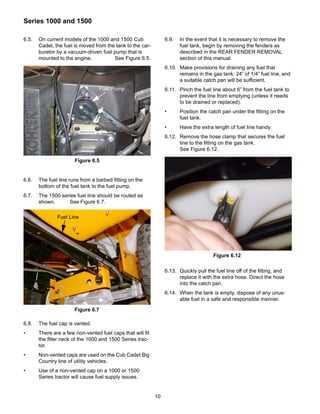

5. Fluid Levels: If applicable, regularly check and maintain fluid levels in the associated hydraulic systems. Low fluid levels can lead to diminished performance and potential damage.

6. Professional Service: Consider scheduling routine inspections with a qualified technician. Professional evaluations can uncover issues that may not be apparent during personal inspections, ensuring optimal operation.

By following these guidelines, you can enhance the reliability and efficiency of your equipment’s directional controls, ensuring a safe and enjoyable experience during use.

How to Replace Steering Parts

Replacing the control mechanism on your machine can enhance maneuverability and overall performance. This guide outlines the steps required to efficiently swap out worn components, ensuring a smoother operation.

Required Tools and Materials

| Tool/Material | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts. |

| Screwdriver | To remove screws and fasteners. |

| Replacement Components | New parts to be installed. |

| Grease | For lubricating moving elements. |

Steps to Replace Components

Begin by safely lifting the vehicle and securing it. Next, remove the old assembly by unscrewing the fasteners and disconnecting any linked items. Install the new pieces in reverse order, ensuring everything is tightened properly. Finally, lubricate the moving parts for optimal performance.

Tools Needed for Repair Process

When undertaking any maintenance or restoration project, having the right tools is crucial for efficiency and effectiveness. Proper equipment not only facilitates smoother operations but also ensures that repairs are performed safely and correctly. Below is a guide to essential tools that will aid in the repair process.

Essential Hand Tools

Basic hand tools are indispensable for most repair tasks. These include items that help with disassembly, adjustments, and assembly of various components.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws |

| Wrench Set | To adjust nuts and bolts |

| Pliers | For gripping and twisting |

| Socket Set | For turning fasteners |

Power Tools and Equipment

In addition to hand tools, power tools can significantly speed up the repair process and provide more precision. These tools are especially useful for larger projects or when working with tough materials.

| Tool | Purpose |

|---|---|

| Drill | For creating holes and driving screws |

| Impact Wrench | To loosen tight fasteners with ease |

| Saw | For cutting through various materials |

| Multimeter | To measure electrical parameters |

Where to Find Replacement Parts

Locating suitable components for your lawn care machinery can be a straightforward process when you know where to look. Various resources are available, catering to different needs and preferences. Whether you prefer shopping online or visiting a local store, there are numerous options to ensure your equipment is back in working order swiftly.

Online Retailers

The internet offers a wealth of choices for sourcing equipment components. Many dedicated websites specialize in outdoor machinery supplies, providing detailed catalogs and user-friendly interfaces. You can easily compare prices, read customer reviews, and find the exact items you need with just a few clicks.

Local Dealers and Service Centers

If you prefer a more hands-on approach, visiting local dealers or service centers is an excellent option. These establishments often carry a variety of components and can provide expert advice. Additionally, they may offer installation services, which can save you time and ensure the correct assembly of your machinery.