In today’s vehicles, the mechanisms responsible for managing directional movement play a critical role in ensuring safe and efficient operation. This section will explore the essential structures that contribute to the control and handling of the vehicle, providing a deeper understanding of their individual roles.

Each part of these systems works in harmony, ensuring that drivers can confidently navigate roads under varying conditions. By examining the connections and interactions between these elements, we can gain insight into the mechanical precision that supports modern driving experiences.

Whether you’re a technician or simply a car enthusiast, knowing how these components function together can enhance both maintenance and troubleshooting efforts. This guide will break down the internal arrangements, offering clarity on how they contribute to overall vehicle performance.

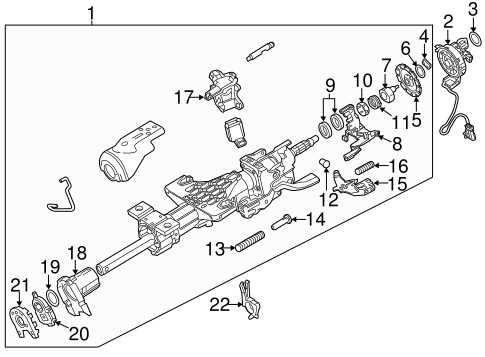

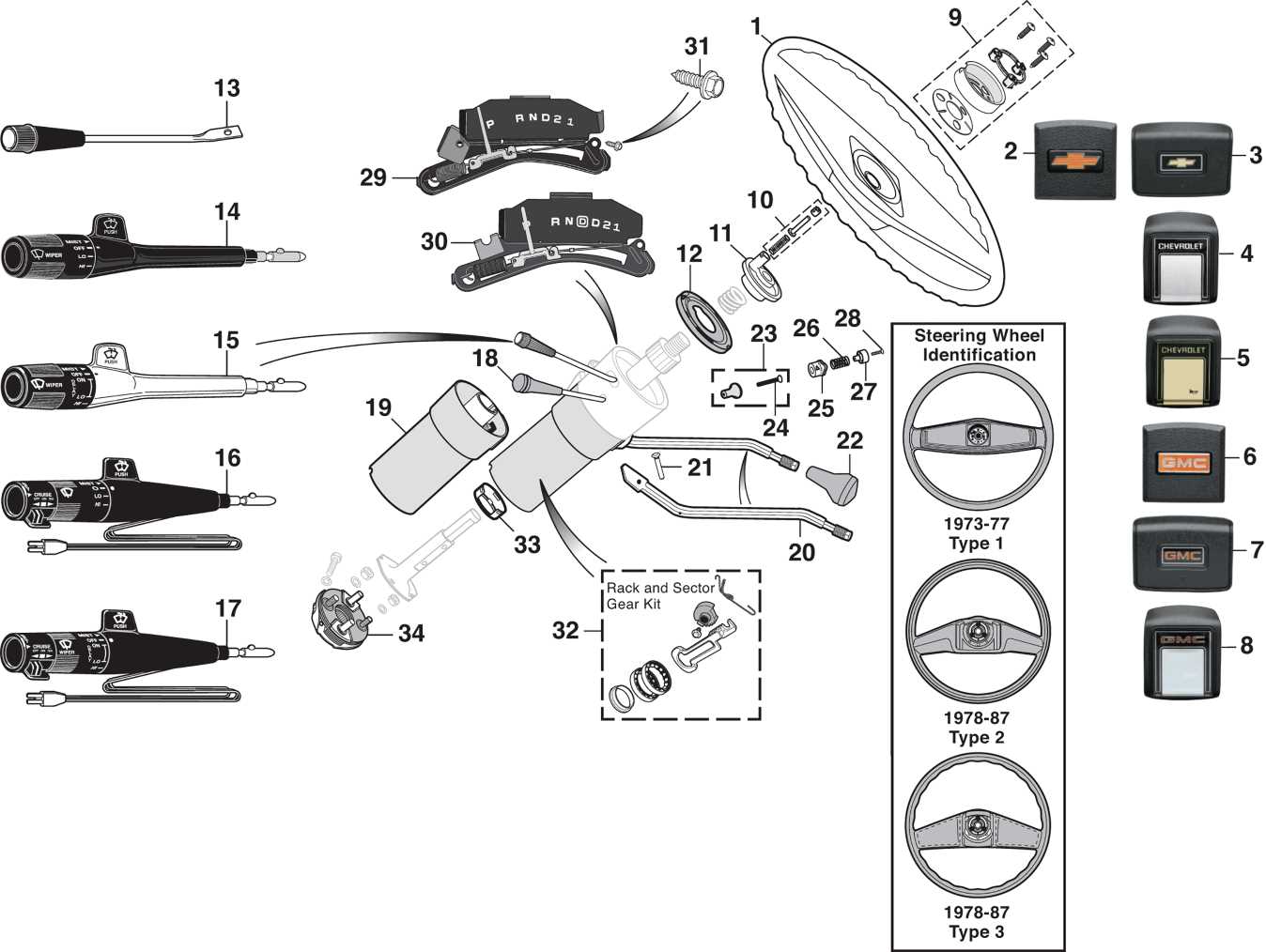

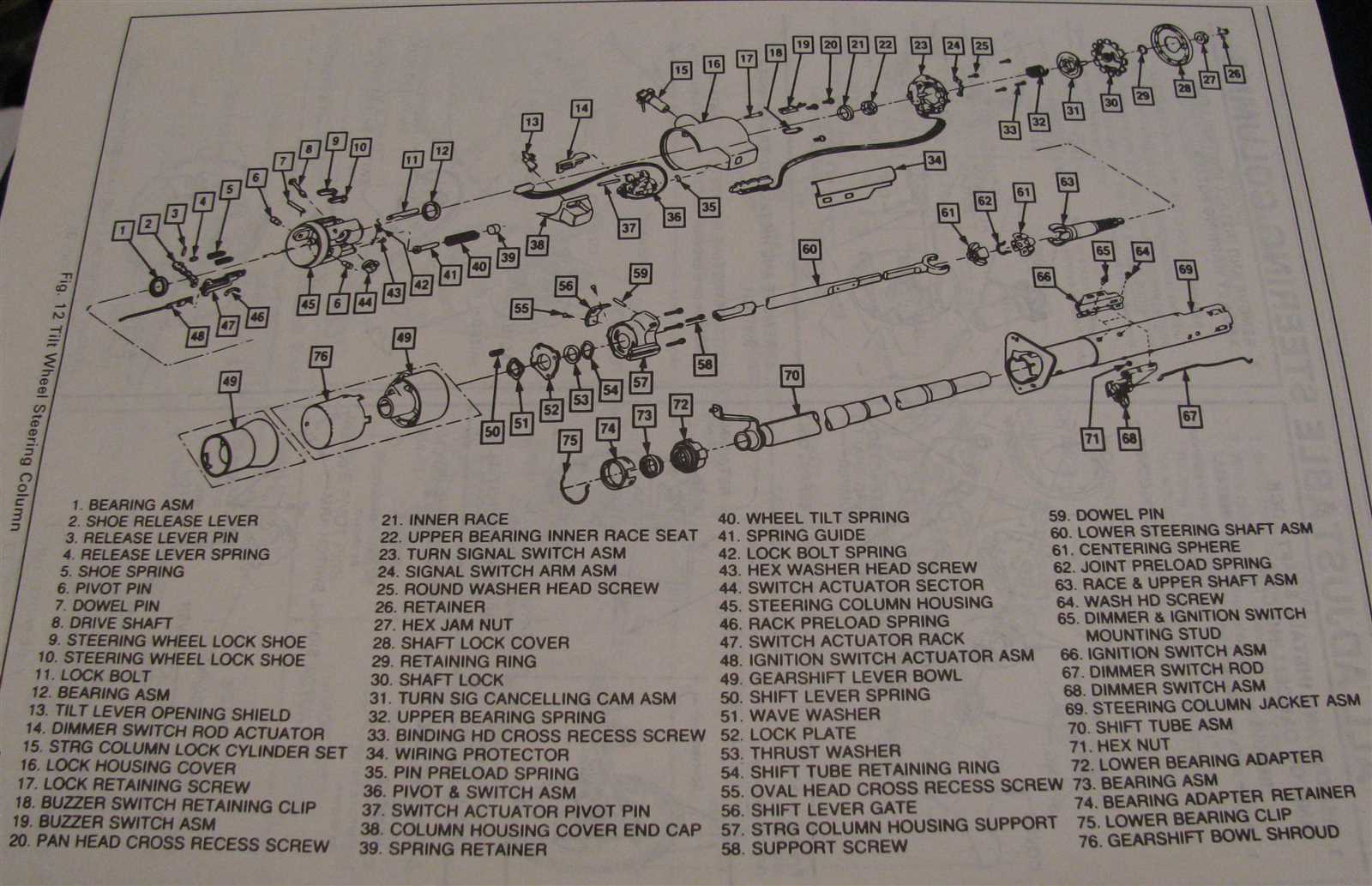

GM Steering Column Components Overview

Understanding the various elements that make up the control mechanism of a vehicle is essential for both maintenance and repair. In this section, we will break down the main elements that contribute to the proper functionality of the system responsible for managing vehicle direction and control. Each component plays a vital role in ensuring smooth operation, safety, and comfort.

Core Elements and Functions

Several key components work together to provide precise control and response. These include mechanisms responsible for adjusting position, ensuring stability, and enabling essential control features.

- Rotational Device: This allows for the smooth rotation necessary to direct the vehicle’s movement.

- Adjustment Mechanism: Provides the ability to fine-tune the positioning for different drivers.

- Linkage Components: Connects the control system to other vehicle mechanisms, ensuring a seamless flow of commands.

Additional Functionalities

Beyond the core mechanical elements, additional features enhance usability and comfort. These supplementary devices ensure that the system

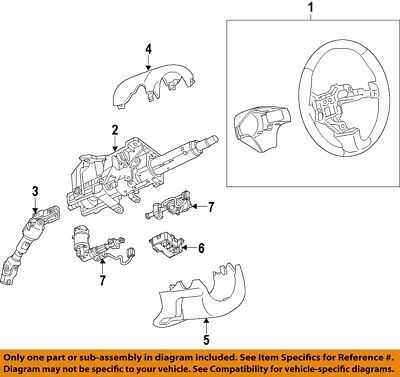

Key Structural Parts and Their Functions

The core of any mechanical system relies on various interconnected elements, each contributing to the overall operation. Understanding these essential components and how they work together is crucial for both maintenance and effective troubleshooting. In this section, we will explore the primary structures that form the framework and how they support the overall mechanism.

Support Mechanism

This critical structure ensures stability and alignment within the system, allowing other elements to function seamlessly. It serves as the backbone, maintaining balance and enabling the smooth motion of moving components.

Rotational Connectors

These connectors play a vital role in transferring motion between different parts of the system. By facilitating controlled movement, they ensure that inputs are accurately translated into the desired action, contributing to overall precision.

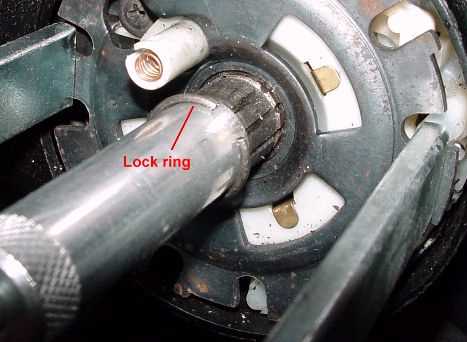

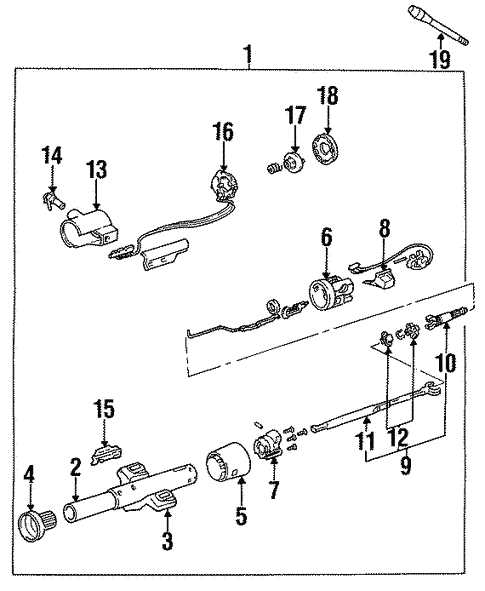

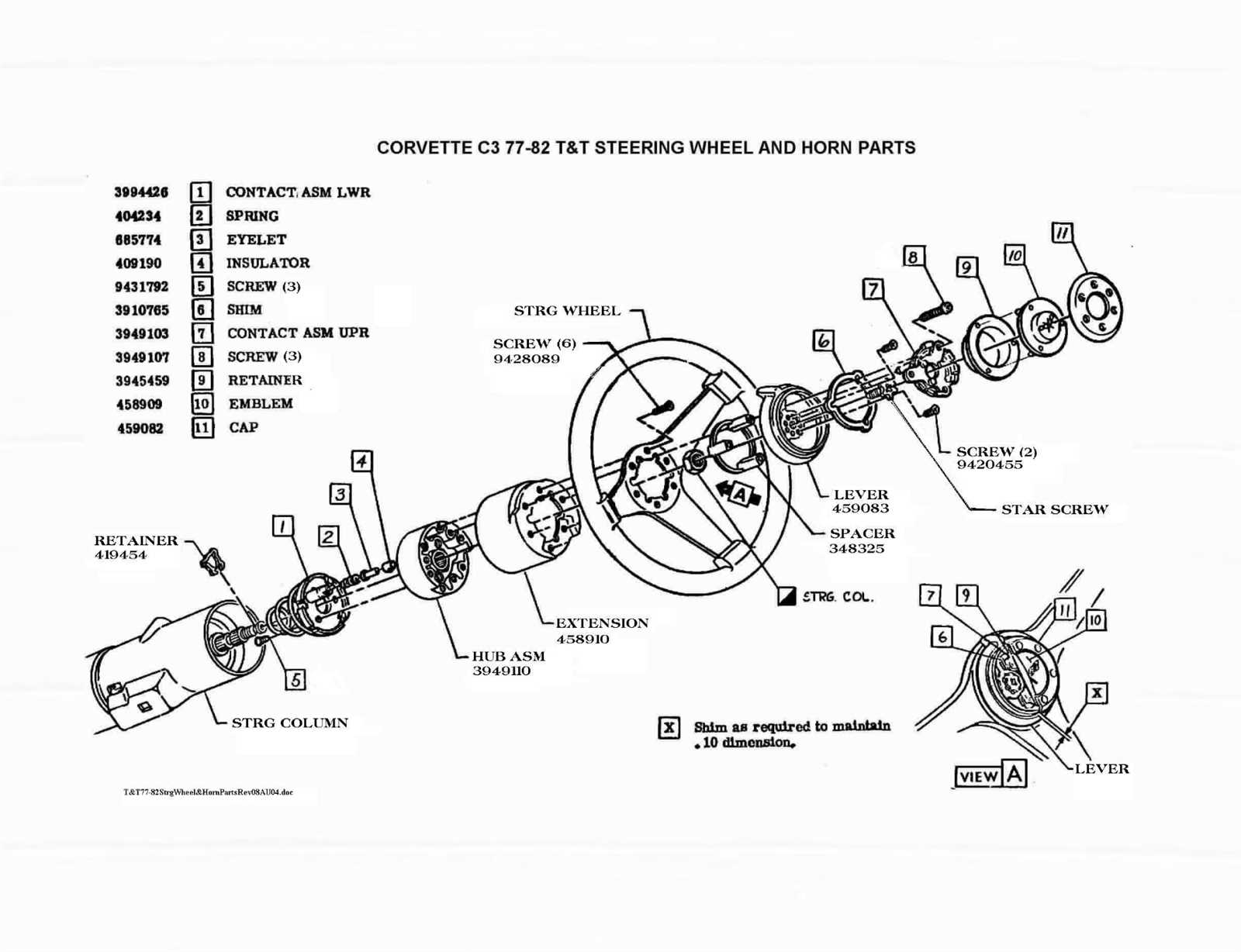

Understanding the Steering Wheel Attachment Mechanism

In modern vehicles, the method of connecting the central control wheel to the underlying framework is a crucial aspect of ensuring both safety and functionality. The attachment system involves multiple components that work together to provide a secure and responsive experience while driving. By examining how these elements interact, one can gain insight into maintaining or replacing key elements of this system.

Main Components Involved in the Connection

The assembly that links the central control to the rest of the vehicle typically includes a fastening device, spring mechanisms, and specialized bolts. These parts are designed to absorb shock, provide stability, and allow for easy adjustments or replacements when necessary. Understanding their roles helps in diagnosing potential issues and ensuring proper maintenance.

Key Considerations for Installation

When reattaching or replacing this essential component, it’s important to align the fasteners properly and ensure that all moving parts are well-lubricated. Proper tensioning of the bolts and correct placement of the safety mechanisms are vital to avoid looseness or improper function during operation.

Role of the Ignition Lock in Column Design

The ignition lock plays a critical role in vehicle safety and usability. It is responsible for allowing the driver to power the vehicle, while also ensuring security by preventing unauthorized operation. This component is designed to interact with several systems within the vehicle to provide both convenience and protection.

Below are some key functions of the ignition lock in the overall system:

- Engages power systems when the key is turned, activating the vehicle’s electronics and engine control.

- Locks the system in place when the key is removed, serving as a security measure to deter theft.

- Coordinates with other safety mechanisms, ensuring the system remains stable and functional during operation.

Understanding how the ignition lock integrates into the system highlights its importance in both functionality and security.

Exploring Tilt and Telescoping Features

Adjustable mechanisms that control the angle and extension are designed to improve user comfort and adaptability. These features allow for fine-tuning based on individual preferences, ensuring ease of use during operation.

The advantages of these mechanisms include:

- Customizable positioning for better control

- Enhanced ergonomic support to reduce strain

- Improved visibility for various seating positions

Understanding the interaction between different components is essential for proper functionality. These systems are carefully engineered to provide a smooth and responsive adjustment process, contributing to a more user-friendly experience.

- Adjustment mechanism allows for seamless vertical movement.

- Extension feature helps accommodate various user heights.

- Locking systems ensure stability and precision after adjustment.

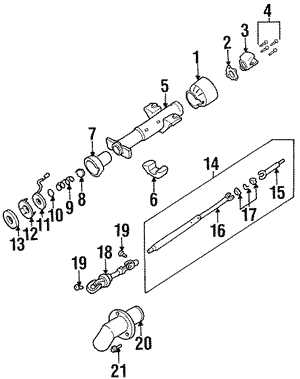

How the Steering Shaft Connects to the System

The connection of the shaft to the overall mechanism is a critical aspect that ensures proper maneuverability and control of the vehicle. This essential link allows for the transmission of motion from the driver’s input to the wheels, enabling efficient handling and responsiveness.

Understanding this connection involves several key components:

- Universal Joints: These flexible joints facilitate movement between different angles, accommodating the alignment of the shaft with the driving mechanism.

- Couplings: These elements serve to secure the shaft to the associated gear system, ensuring a stable and reliable connection.

- Bearings: Positioned strategically, bearings support the shaft and minimize friction, allowing for smoother operation.

- Column Housing: This encasement provides protection for the shaft and associated components while maintaining alignment and integrity during operation.

When the driver rotates the wheel, the shaft engages with these elements, converting rotational motion into the necessary directional change. This interaction is fundamental to achieving a seamless driving experience, reflecting the importance of each component in the assembly.

Common Issues with Column Bearings

Bearings that support the rotational mechanism in automotive assemblies often encounter various challenges. These issues can lead to impaired functionality and potential safety hazards if not addressed promptly. Understanding these common problems can help in diagnosing and maintaining proper operation.

Wear and Tear: Over time, frequent movement and load stress can cause bearings to wear down. This degradation can result in increased friction, leading to abnormal noise and compromised handling. Regular inspection can help identify early signs of wear.

Lubrication Failure: Insufficient lubrication is a significant contributor to bearing failure. Without proper lubrication, bearings may overheat and seize, resulting in operational malfunctions. Ensuring adequate lubricant levels is essential for optimal performance.

Misalignment: Incorrect alignment during installation can lead to uneven load distribution, causing premature bearing wear. It is crucial to ensure precise alignment to prevent unnecessary strain on the components.

Contamination: Debris and contaminants can infiltrate the bearing housing, leading to increased friction and wear. Keeping the assembly clean and ensuring proper sealing can help mitigate this risk.

Addressing these common issues proactively can enhance the longevity and reliability of rotational components, contributing to overall vehicle performance.

Wiring and Electrical Connections Explained

The intricate network of wires and electrical links plays a crucial role in the functionality of automotive systems. Understanding how these connections interact ensures that various components operate efficiently, enhancing overall vehicle performance. Properly configured circuits are essential for communication between different elements, facilitating seamless operation.

Importance of Accurate Wiring

Accurate wiring is fundamental in maintaining electrical integrity. Each connection must be properly established to prevent malfunctions. Faulty wiring can lead to issues such as intermittent failures or complete system breakdowns. Therefore, meticulous attention to detail during installation and maintenance is paramount for optimal functionality.

Common Electrical Components

Several electrical components are integral to the network. These include connectors, which link various sections, and relays, which help control electrical flow. Fuses also play a protective role, preventing damage due to overload. Familiarity with these elements aids in troubleshooting and ensures a robust electrical setup.

Maintenance Tips for Longevity of Steering Columns

Ensuring the durability and efficiency of essential vehicle components requires regular upkeep and preventive measures. Proper maintenance not only enhances functionality but also extends the lifespan of these critical elements, reducing the likelihood of costly repairs.

Regular Inspection

Conducting routine checks is vital for identifying potential issues early. Focus on the following:

- Examine for visible wear and tear.

- Check for unusual noises during operation.

- Ensure all connections are secure and free from rust.

Lubrication and Cleaning

Keeping components clean and well-lubricated is essential for smooth operation. Consider these practices:

- Use appropriate lubricants for all moving parts.

- Clean dust and debris to prevent buildup.

- Follow manufacturer guidelines for maintenance products.