The functionality of agricultural machinery relies heavily on the intricate systems that enable precise movement and control. Recognizing these components is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring optimal performance, contributing to the overall efficiency of farming tasks.

By examining the various mechanisms involved, one can gain insights into how they interact and function together. A clear representation of these elements not only aids in troubleshooting but also enhances one’s ability to perform necessary repairs and replacements. This knowledge ultimately empowers operators to maximize their equipment’s potential.

In this section, we will delve into the specific components that facilitate directional control. Understanding these intricacies will provide a foundation for better handling of machinery, leading to improved productivity and longevity of the equipment.

Overview of John Deere D130

This section provides a comprehensive insight into a popular model in the lawn care sector. Known for its reliability and efficiency, this machine is designed to simplify the maintenance of outdoor spaces. With its user-friendly features and robust construction, it caters to both novice and experienced operators alike.

Key Features

The model boasts a powerful engine that ensures optimal performance across various terrains. Its cutting system is engineered for precision, allowing for an even and clean finish. Additionally, the ergonomic controls enhance comfort during operation, making long tasks more manageable.

Maintenance and Durability

Regular upkeep is essential to extend the life of this equipment. Quality components are integral to its design, contributing to overall durability. Understanding the assembly and functionality of each segment helps users troubleshoot effectively and maintain peak performance over time.

Key Features of the D130 Model

The model in question is designed to offer exceptional performance and reliability for various outdoor tasks. Its construction emphasizes user comfort and efficiency, making it a popular choice among enthusiasts and professionals alike.

Some of the standout characteristics include a powerful engine, easy maneuverability, and a range of attachments that enhance versatility. These features work together to provide an optimal experience for the user.

| Feature | Description |

|---|---|

| Engine Power | Robust engine that delivers ample horsepower for heavy-duty tasks. |

| Maneuverability | Designed for easy navigation in tight spaces, ensuring efficiency. |

| Comfortable Seating | Ergonomically designed seat to reduce fatigue during prolonged use. |

| Versatile Attachments | A variety of compatible tools and accessories for enhanced functionality. |

| Durable Build | Constructed with high-quality materials for long-lasting use. |

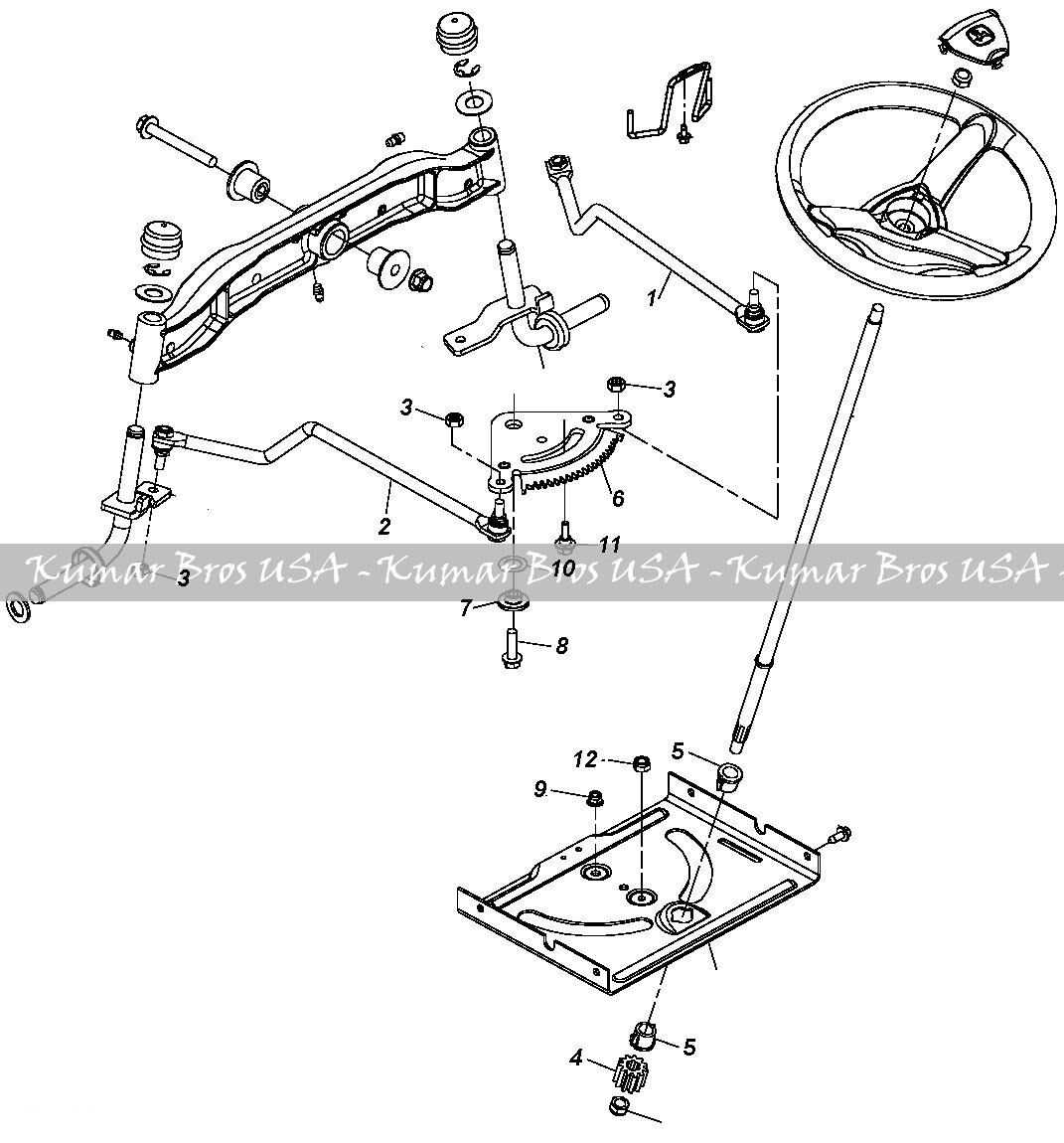

Understanding Steering Mechanism Basics

Grasping the fundamentals of directional control is essential for anyone involved in vehicle operation or maintenance. This system allows an operator to guide a machine effectively, ensuring both precision and safety during movement. Various components work together harmoniously, providing the necessary feedback and control to navigate diverse terrains and obstacles.

Key Components of Directional Control

At the heart of any directional control system lies a combination of levers, linkages, and pivot points. Each element plays a critical role in transferring the operator’s input into motion. The interaction between these components facilitates smooth turns and adjustments, allowing for responsive handling even in challenging conditions.

Importance of Maintenance

Regular upkeep of the directional control system is vital to ensure optimal performance and longevity. Neglecting maintenance can lead to wear and tear, potentially compromising safety and maneuverability. Therefore, understanding the underlying mechanics not only aids in effective operation but also in timely repairs and replacements, fostering a reliable and efficient experience.

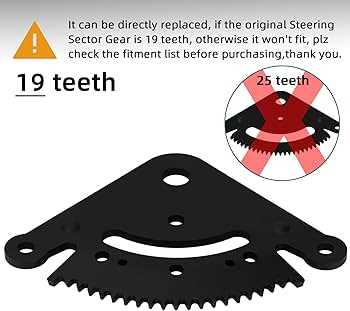

Common Steering Issues and Solutions

In any vehicle, managing directional control can sometimes lead to challenges that affect overall performance. Identifying and resolving these issues is crucial for ensuring a smooth and safe experience. This section explores frequent problems encountered with maneuverability and offers practical remedies to enhance functionality.

One common issue is a loose connection, which can result in erratic handling. Tightening bolts and checking alignment can often remedy this situation. Another frequent concern is the buildup of debris, which can hinder movement. Regular cleaning and maintenance of the system can help maintain optimal function.

Additionally, worn components may cause uneven response. Replacing these elements promptly is vital to restore balance. If noise accompanies the movement, it could indicate lubrication deficiencies. Applying the appropriate grease can alleviate this problem and extend the lifespan of the system.

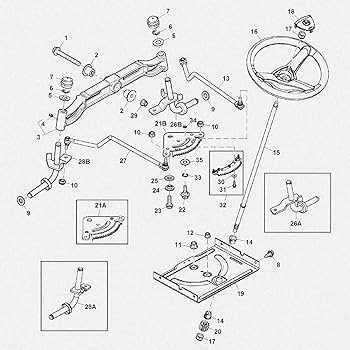

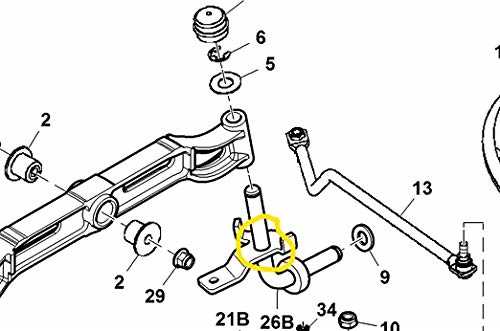

Parts List for Steering Components

This section provides a comprehensive overview of essential components required for the control system of a lawn tractor. Understanding the various elements involved is crucial for effective maintenance and repair, ensuring smooth operation and maneuverability of the machine.

Essential Elements

The primary components that contribute to the functionality of the control mechanism include:

- Wheel Assembly: The main structure that supports movement and provides a connection to the ground.

- Control Rod: A critical component that transmits motion and adjusts the direction of the vehicle.

- Pivot Point: This allows for rotation and helps in achieving precise directional changes.

- Mounting Brackets: These secure various elements in place, ensuring stability during operation.

- Linkage System: A network of rods and joints that connects the control elements to the wheels.

Additional Components

Alongside the main elements, several auxiliary parts play supportive roles:

- Bearings: Facilitate smooth movement and reduce friction within the system.

- Fasteners: Essential for holding components securely together, ensuring integrity during use.

- Seals: Protect against dirt and debris, prolonging the lifespan of the moving parts.

Familiarity with these components will aid in troubleshooting and replacement, promoting efficient functionality in your equipment.

How to Access the Steering Diagram

Gaining insights into the assembly of the control mechanism is essential for effective maintenance and troubleshooting. Understanding the layout allows users to identify components and ensure optimal performance.

Steps to Locate the Assembly Blueprint

Begin by consulting the user manual specific to your model. This document typically includes a section dedicated to the mechanical components, which provides invaluable information.

Online Resources

If the manual is unavailable, many manufacturers offer digital resources. Visit their official website or trusted forums where enthusiasts share useful files and links.

| Resource Type | Description |

|---|---|

| User Manual | Detailed instructions and illustrations related to assembly. |

| Manufacturer’s Website | Access to digital copies and additional resources. |

| Online Forums | A community-driven platform for sharing knowledge and diagrams. |

Maintenance Tips for Steering System

Proper upkeep of the control mechanism in your equipment is essential for ensuring smooth operation and longevity. Regular checks and maintenance can prevent issues and enhance performance, ultimately leading to a more efficient experience.

Regular Inspections

Conduct frequent examinations to identify wear or damage. Pay attention to components that are subject to friction and stress. Early detection can save time and money in repairs.

Lubrication

Keep all moving parts well-lubricated. Use quality lubricants to reduce friction and prevent rust. Regular application will ensure optimal functionality and extend the lifespan of the mechanism.

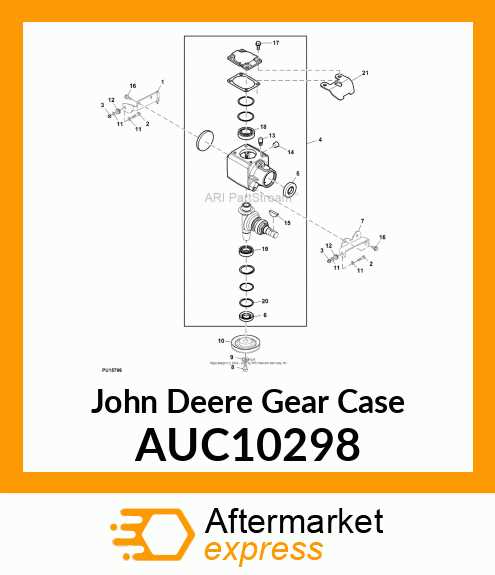

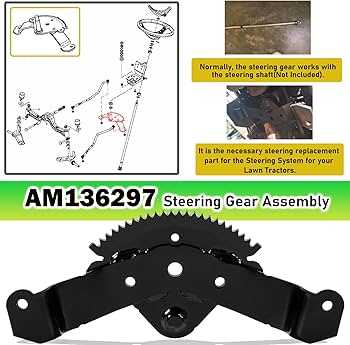

Upgrading Steering Parts Effectively

Enhancing the control mechanism of your equipment can significantly improve its performance and user experience. A well-planned upgrade not only increases efficiency but also extends the lifespan of your machinery. Understanding the components involved is crucial for a successful enhancement.

Benefits of Upgrading

- Improved maneuverability

- Increased safety

- Enhanced comfort during operation

- Longer operational lifespan

Steps to Consider

- Assess current condition and performance.

- Research compatible upgrades available in the market.

- Consult with experts for tailored recommendations.

- Gather necessary tools and replacement components.

- Implement upgrades carefully, following guidelines.

- Test the new setup for optimal functionality.