The intricate world of agricultural machinery necessitates a comprehensive understanding of its individual components. Each element plays a pivotal role in ensuring optimal performance and efficiency. By grasping how these parts interact, operators can maximize the effectiveness of their equipment.

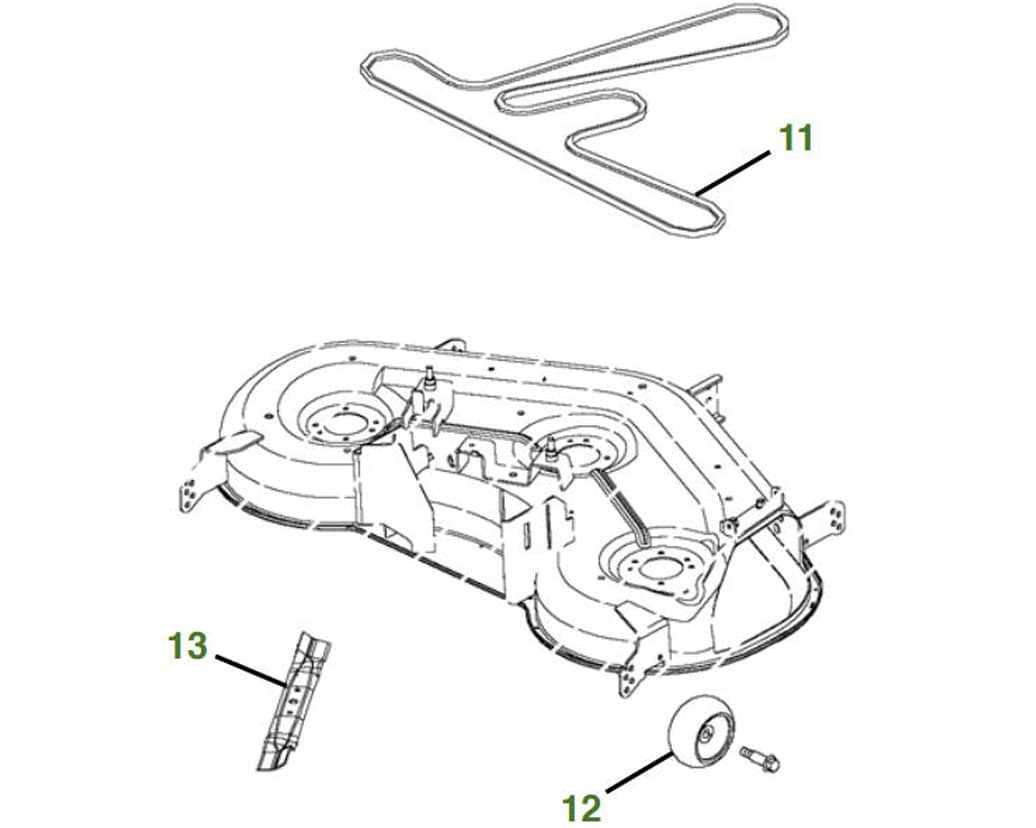

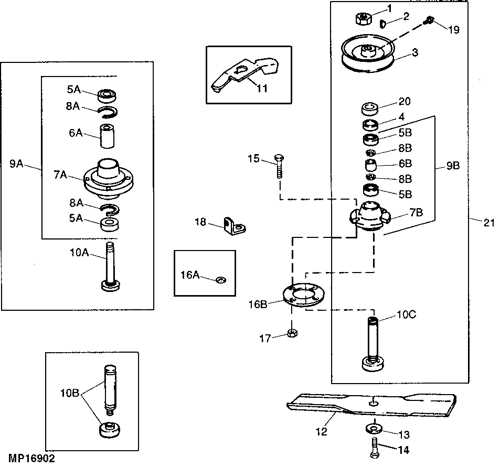

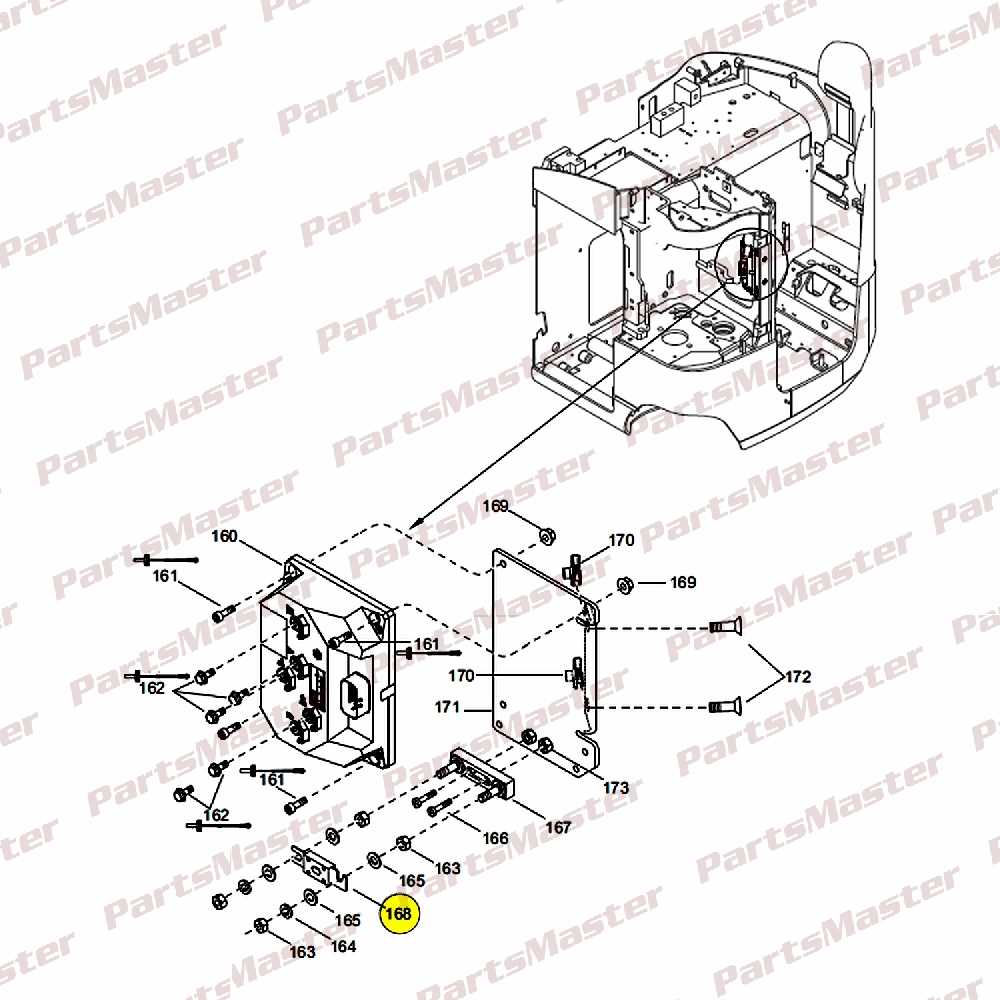

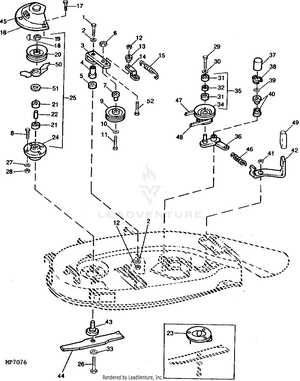

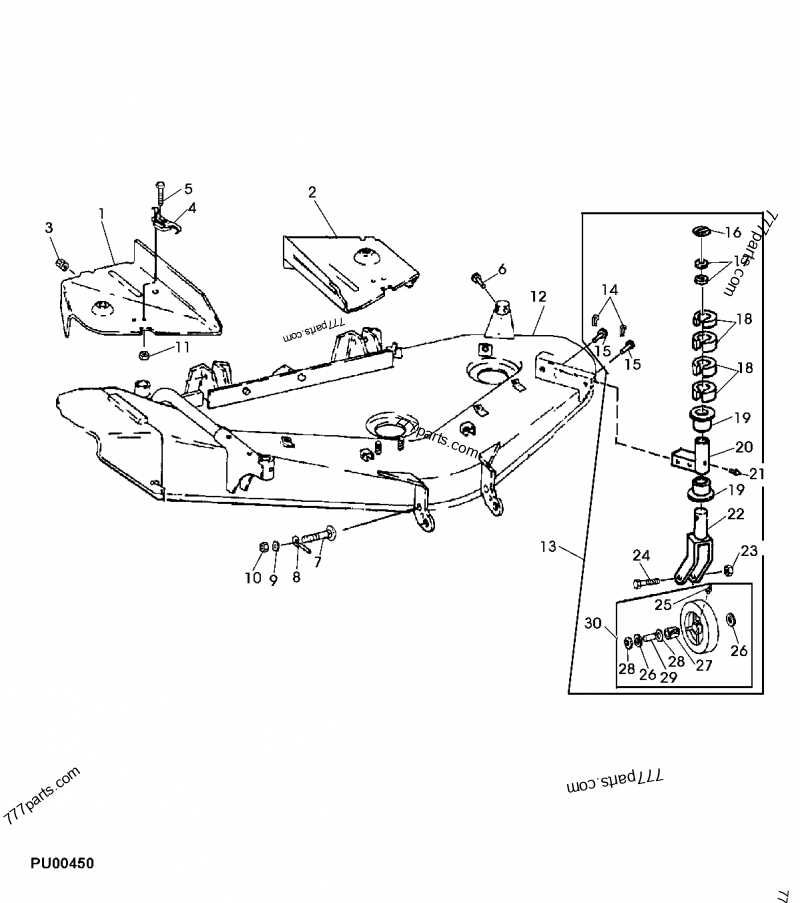

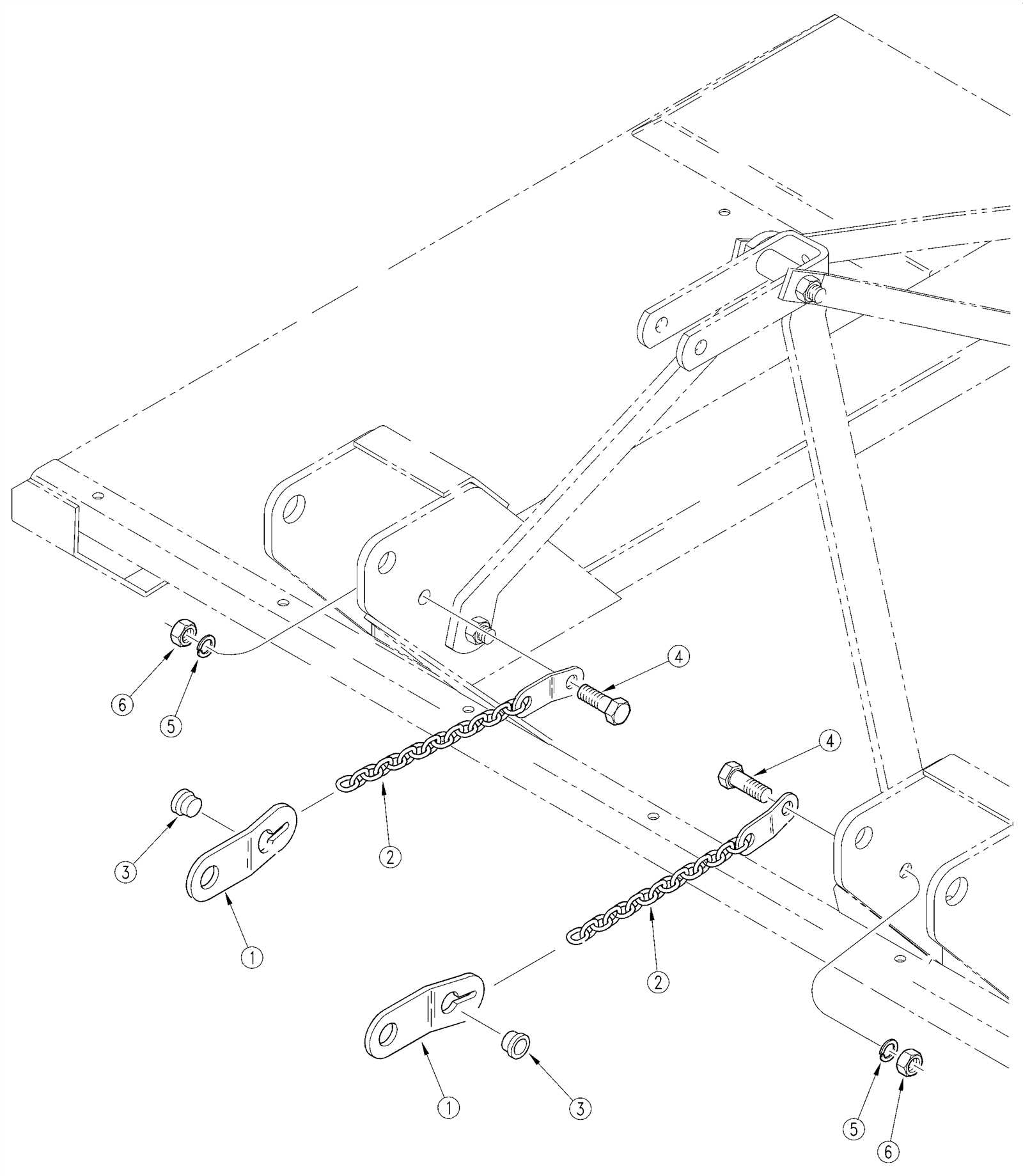

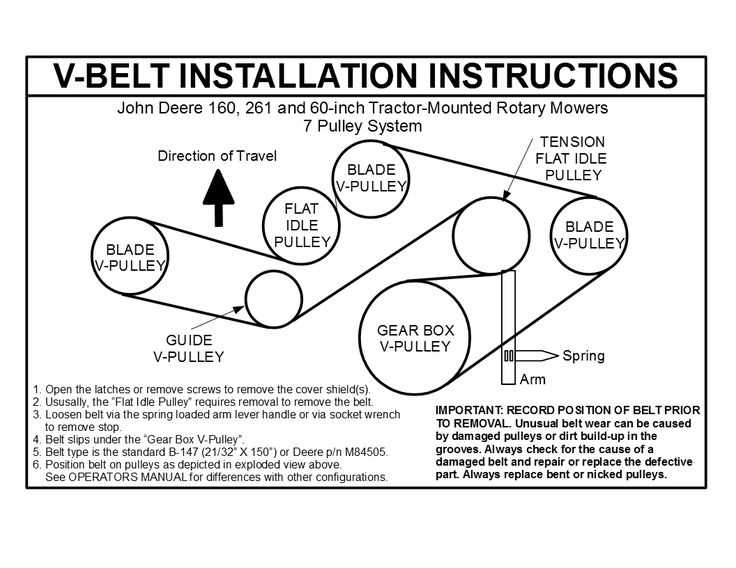

Within this context, visual representations serve as invaluable resources. They offer clarity and facilitate better comprehension of the assembly and functionality of various elements. This is particularly beneficial for maintenance and troubleshooting tasks.

Furthermore, having access to detailed illustrations enhances the ability to identify specific pieces that may require replacement or repair. Ultimately, this knowledge empowers users to make informed decisions, promoting longevity and reliability in their machinery.

Understanding the John Deere 160 Model

This section delves into the nuances of a well-regarded agricultural machine that has made a significant impact in the field of farming and landscaping. Recognized for its reliability and efficiency, this equipment serves a variety of functions, catering to both professional and casual users alike. By exploring its features and components, one can gain a comprehensive understanding of its capabilities and applications.

Key aspects of this model include its robust engine performance, user-friendly design, and adaptability to different terrains and tasks. Below is a table highlighting some essential specifications that define its operational strengths:

| Specification | Detail |

|---|---|

| Engine Type | Gasoline, air-cooled |

| Horsepower | Approximately 16 HP |

| Transmission | Manual with variable speeds |

| Cutting Width | 42 inches |

| Weight | Around 400 lbs |

Understanding these specifications helps users make informed decisions regarding maintenance and potential upgrades, ensuring optimal performance over time. The blend of engineering and functionality continues to make this model a preferred choice for many in the agricultural community.

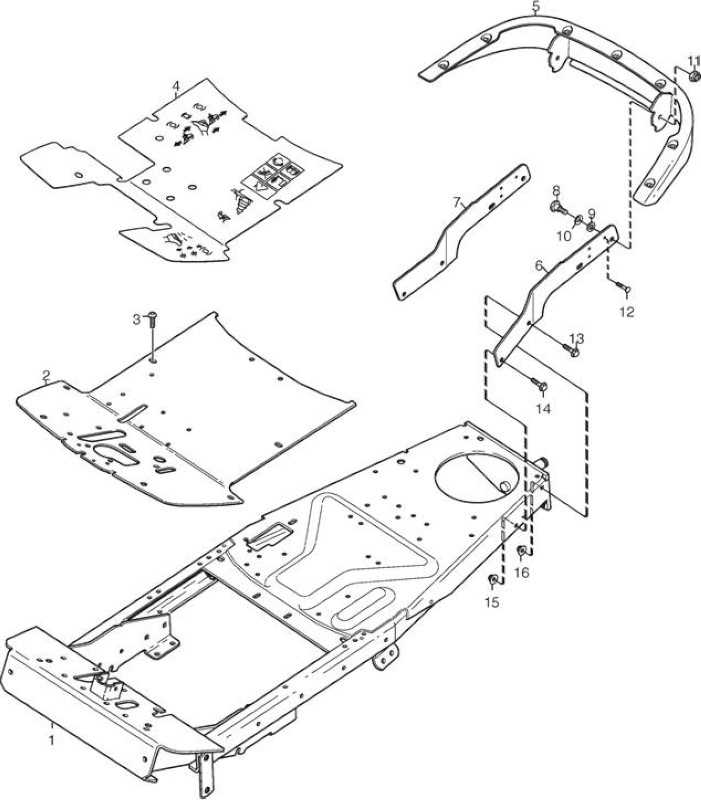

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. They provide users with a clear view of each element’s placement and function, facilitating efficient maintenance and repairs. By breaking down complex systems into understandable sections, these illustrations help users identify parts that require attention, ensuring the longevity and optimal performance of the equipment.

Enhanced Understanding

Having a visual reference allows technicians and operators to quickly grasp how different components interact within the system. This clarity is essential not only for troubleshooting issues but also for routine checks and upkeep. A well-structured illustration reduces the chances of misidentifying components, which can lead to costly mistakes or unnecessary repairs.

Efficient Repair Processes

When it comes to performing repairs or replacements, having a clear visual guide streamlines the process significantly. Technicians can easily locate the necessary elements and understand their relationships with adjacent components. This efficiency saves time and minimizes the risk of damaging parts during service. Ultimately, clear illustrations contribute to a more effective workflow and enhance overall productivity.

Common Issues with John Deere 160

Machines of this type often encounter a range of challenges that can affect their performance and efficiency. Understanding these frequent problems can help owners maintain their equipment better and avoid costly repairs.

Electrical Problems

One of the most common issues involves electrical components. Faulty wiring, corroded connections, and battery failures can lead to starting problems or intermittent power loss. Regular inspection of electrical systems is crucial for preventing these issues.

Engine Performance

Another frequent concern is related to engine functionality. Symptoms such as rough idling, reduced power, or difficulty starting can indicate underlying issues. Regular maintenance, including oil changes and air filter replacements, is essential to ensure optimal engine performance.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Electrical Failures | Starting problems, power loss | Inspect wiring, clean connections |

| Engine Problems | Rough idling, reduced power | Regular maintenance, replace filters |

| Hydraulic Issues | Poor lift performance | Check fluid levels, inspect hoses |

Where to Find Parts Diagrams

Locating accurate schematics is essential for effective maintenance and repair of machinery. Various resources are available to assist users in finding the necessary illustrations that detail component layouts and assembly instructions. These sources can range from official manufacturer websites to community forums and specialized retailers.

Here are some recommended platforms to explore for obtaining the required visual references:

| Source Type | Description |

|---|---|

| Manufacturer Website | Official sites often provide comprehensive resources, including downloadable schematics and repair manuals. |

| Online Retailers | Many retailers offer not only parts for sale but also associated diagrams to help customers identify the right components. |

| Forums and Community Sites | Online communities may share user-generated content, including schematics and tips from experienced users. |

| Service Manuals | Physical or digital manuals may contain detailed breakdowns of machinery, often available for purchase. |

Utilizing these resources will streamline the process of obtaining the necessary illustrations for effective equipment care and troubleshooting.

Key Components of the John Deere 160

This section focuses on essential elements that contribute to the functionality and efficiency of the machinery. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The powerhouse, responsible for driving all operations.

- Transmission: Facilitates gear changes and power distribution.

- Chassis: Provides structural integrity and support for all parts.

- Hydraulics: Enables lifting and moving capabilities through fluid power.

- Control System: Governs operations and allows user inputs for varied tasks.

Each of these elements plays a vital role in the overall performance, making knowledge about them indispensable for users.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a systematic approach to upkeep and care. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. By adopting a proactive strategy, you can significantly improve the reliability and efficiency of your equipment.

1. Regular Inspections: Conduct routine checks on key components to identify wear and tear early. Pay attention to belts, filters, and fluids. Addressing minor issues promptly can prevent costly repairs down the line.

2. Cleanliness is Key: Keep the exterior and interior of the machine clean. Debris buildup can lead to overheating and other operational issues. Regular cleaning will help maintain optimal performance.

3. Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and wear, which can prolong the lifespan of your equipment. Follow the manufacturer’s guidelines for the right type of lubricant.

4. Fluid Management: Regularly check and replace fluids as needed. This includes oil, hydraulic fluid, and coolant. Clean fluids are essential for effective operation and can prevent damage to internal components.

5. Seasonal Preparation: Before changing seasons, inspect your machinery for any necessary adjustments. Winterizing or preparing for high-use periods can help avoid performance issues when you need it most.

6. Operator Training: Ensure that all users are well-trained in operating the equipment. Proper handling reduces the risk of accidents and damages, promoting a longer service life.

By implementing these maintenance practices, you can enjoy improved performance and reliability from your machinery, ultimately extending its usable life and enhancing your investment.

Upgrading Parts for Better Performance

Enhancing machinery efficiency often involves selecting superior components that can significantly improve functionality. By replacing outdated or underperforming elements, users can experience increased power, reliability, and longevity. This process not only optimizes current capabilities but can also lead to reduced maintenance costs over time.

When considering enhancements, it’s essential to evaluate compatibility and the specific advantages each upgraded component can provide. Improved materials and advanced designs can lead to greater durability and efficiency. Moreover, investing in high-quality replacements can enhance overall operation, making tasks more manageable and effective.

Furthermore, upgrading specific assemblies can result in noticeable performance boosts, allowing for better handling of heavy workloads and challenging terrains. By focusing on quality and innovation, operators can ensure their machinery remains competitive and effective for years to come.

Comparing with Other John Deere Models

When examining agricultural machinery, it’s essential to evaluate the similarities and differences between various models within the same brand. This comparison not only highlights unique features but also aids in understanding how each machine fits specific operational needs.

In terms of performance, different models may offer varying horsepower and efficiency levels, impacting their suitability for diverse tasks. For instance, some might excel in maneuverability and compact design, making them ideal for small to medium-sized farms, while others are built for larger-scale operations, providing robust power and durability.

Another critical factor to consider is the range of attachments available for each model. Certain variations might have a wider array of compatible implements, enhancing versatility and making them more adaptable to changing agricultural requirements.

Additionally, maintenance and serviceability can differ significantly between models. Some designs may prioritize easy access to components for routine upkeep, whereas others might require specialized knowledge for repairs, affecting long-term ownership costs and convenience.

Ultimately, understanding these distinctions enables operators to make informed decisions tailored to their specific farming practices and preferences.

DIY Repairs Using Parts Diagrams

Engaging in repairs can be a fulfilling task, especially when you have access to detailed visual guides. These illustrations serve as invaluable resources, enabling individuals to understand the assembly and components of machinery. With the right visual aid, even complex repairs become manageable, empowering users to tackle projects confidently.

Understanding the Components

Before diving into repairs, it’s essential to familiarize yourself with the various elements involved. The visuals can clarify how each piece fits together, making it easier to identify what needs replacement or adjustment. This knowledge not only aids in the repair process but also enhances overall mechanical comprehension.

Step-by-Step Approach

Utilizing visual references allows for a systematic method to follow during repairs. Begin by reviewing the guide thoroughly, then proceed with disassembly and replacement in a logical order. This structured approach minimizes errors and ensures that all components are reinstalled correctly, leading to optimal functionality.