In the world of material handling, comprehending the intricate arrangement of machinery components is essential for optimal performance. This section delves into the various elements that make up these powerful machines, emphasizing their significance and functionality.

Each section of the machinery plays a critical role in ensuring smooth operations, from the drive system to the lifting mechanisms. Familiarizing oneself with these individual components enhances maintenance practices and can prevent operational issues. By exploring the specific arrangements and connections, operators and technicians can improve their understanding and efficiency in handling equipment.

Additionally, recognizing how each element interacts within the broader system can facilitate better troubleshooting and repairs. This knowledge empowers users to make informed decisions, ultimately contributing to enhanced productivity and safety in the workplace.

Understanding the fundamental elements of industrial lifting machines is crucial for optimal performance and longevity. These components work together to ensure that operations run smoothly and efficiently. By familiarizing oneself with these critical elements, operators and maintenance personnel can enhance functionality and safety.

- Power System: This includes the engine or electric motor that provides the necessary energy for operation.

- Lifting Mechanism: Comprising various elements that enable the vertical movement of loads, this system is vital for effective handling.

- Chassis: The base structure that supports all other components and contributes to stability during operation.

- Steering System: Essential for maneuverability, this system allows for precise control and navigation in tight spaces.

- Braking System: A critical safety feature that ensures effective stopping power and control while transporting heavy items.

- Hydraulic System: Responsible for facilitating the lifting and lowering actions, this system plays a key role in the overall functionality.

Each component plays a specific role in the effective operation of the machinery, contributing to the overall efficiency and safety of material handling tasks. Regular maintenance and understanding of these elements can significantly improve productivity and extend the lifespan of the equipment.

Understanding Forklift Functionality

The operation of industrial lifting vehicles involves a sophisticated interplay of various components that work harmoniously to facilitate efficient material handling. These machines are designed to elevate, transport, and stack heavy loads, making them essential in warehouses and manufacturing environments.

Key Elements include the lifting mechanism, which typically relies on hydraulic systems to raise and lower cargo smoothly. The stability of the vehicle is crucial; thus, a well-engineered chassis ensures balance while navigating uneven surfaces.

Moreover, ergonomic controls enhance the operator’s experience, allowing for precise maneuvering and minimizing fatigue during prolonged use. Understanding how these elements function together provides insight into the effectiveness and reliability of these machines in various operational contexts.

Common Issues with Forklift Parts

Equipment utilized in material handling often experiences a range of challenges that can impact its efficiency and safety. Understanding these frequent complications is essential for maintaining optimal functionality and ensuring longevity. This section delves into the typical problems encountered with these mechanisms and highlights the importance of addressing them promptly.

One prevalent issue is wear and tear on various components, which can lead to decreased performance. Regular usage may cause certain elements to degrade over time, resulting in malfunctions or reduced capacity. Additionally, environmental factors, such as exposure to moisture or extreme temperatures, can exacerbate these effects, necessitating routine inspections and timely replacements.

Another common challenge involves electrical malfunctions. Wiring and connection issues can disrupt the operation of key systems, causing intermittent failures or complete shutdowns. Identifying and rectifying these electrical problems is crucial to ensure seamless operation and prevent costly downtime.

Furthermore, fluid leaks are often observed in hydraulic systems, which can compromise lifting capabilities and overall efficiency. Regular monitoring of fluid levels and prompt repairs of any leaks can help mitigate this issue, ensuring the machine remains reliable and functional.

Lastly, alignment and calibration issues can arise, affecting the overall stability and control of the equipment. Regular maintenance and adjustments are vital to maintain proper alignment, enhancing safety during operation and preventing potential accidents.

Maintenance Tips for Forklift Owners

Proper upkeep is essential for ensuring the longevity and efficiency of material handling equipment. Regular maintenance not only enhances performance but also reduces the likelihood of unexpected breakdowns, ultimately saving time and money for operators. Below are some key practices to keep your machinery in optimal condition.

Regular Inspections

Conducting frequent evaluations of your machinery is crucial. This includes checking fluid levels, examining tires for wear, and inspecting safety features. By identifying potential issues early, you can prevent more significant problems from developing.

Routine Cleaning

Keeping your equipment clean is vital for both performance and safety. Dirt and debris can accumulate and hinder functionality. Regular cleaning of the chassis, engine compartment, and other critical areas will help maintain operational efficiency and extend the lifespan of your machinery.

Emphasizing preventative measures ensures that your equipment operates smoothly and safely. Incorporating these maintenance tips into your routine will lead to improved productivity and reliability.

How to Identify Forklift Parts

Understanding the components of a lifting machine is essential for effective maintenance and operation. Recognizing different elements can enhance the efficiency and safety of the equipment, allowing users to troubleshoot issues and perform necessary replacements. This section will provide guidance on how to discern various elements and ensure optimal performance.

Visual Inspection Techniques

Start by conducting a thorough visual examination. Look for identifying markings, labels, or color codes that may indicate specific components. Each element often has a unique design or shape, making it easier to differentiate between them. Familiarity with the common features of these components can aid in their recognition.

Utilizing Reference Guides

Reference materials can be invaluable when trying to pinpoint specific elements. Manuals and online resources often contain images and descriptions that can help users identify components accurately. Taking advantage of these guides not only streamlines the identification process but also ensures that users understand the functionality of each part, leading to more informed maintenance decisions.

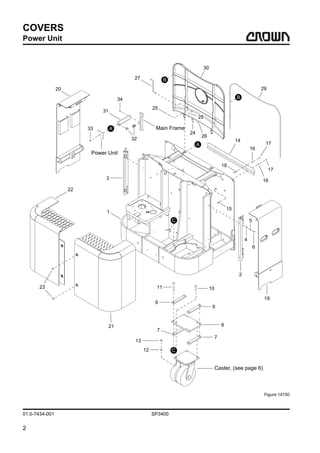

Diagram Interpretation for Users

Understanding visual representations is crucial for effective equipment management. This section aims to guide users in making sense of these illustrations, enhancing their ability to identify components and comprehend their functions within machinery. By grasping the layout and symbols used, users can optimize their interaction with technical documents.

Key Elements to Recognize

When examining visual guides, focus on various symbols and labels. These elements often indicate specific functions or locations of components. Recognizing color codes can also aid in distinguishing between different parts and their respective roles. Users should familiarize themselves with the legend or key provided in the document to facilitate understanding.

Practical Application and Benefits

Accurate interpretation of these visuals allows users to conduct maintenance and repairs with confidence. By mastering this skill, individuals can troubleshoot issues more effectively and ensure optimal performance of their machinery. This knowledge not only enhances operational efficiency but also promotes safety in handling equipment.

Ordering Replacement Parts Effectively

Efficient procurement of essential components is vital for maintaining optimal performance and minimizing downtime in any machinery. Understanding the nuances of the ordering process can significantly enhance the experience, ensuring that you receive the correct items promptly. This section outlines key strategies to streamline your approach to acquiring necessary replacements.

First, it is crucial to identify the specific components required. Utilizing a comprehensive reference guide can assist in determining the exact specifications and compatibility of the items needed. Gathering all relevant information, such as model numbers and descriptions, will facilitate accurate ordering and reduce the chances of errors.

Next, consider sourcing these items from reputable suppliers who specialize in industrial equipment. Researching and comparing various vendors can lead to better pricing, availability, and customer support. Establishing a relationship with a reliable distributor can also provide insights into product quality and lead times, which can be invaluable for future orders.

Additionally, utilizing online platforms can enhance convenience and efficiency. Many suppliers offer user-friendly websites where you can easily navigate through their inventory, check stock levels, and place orders. Keep track of previous purchases to streamline reordering processes and maintain adequate inventory levels for critical components.

Finally, staying informed about new developments and product innovations can enhance your ordering strategy. Engaging with industry publications, forums, and trade shows can provide insights into emerging technologies and better alternatives, ensuring that your machinery remains at the forefront of efficiency and reliability.

Benefits of Genuine Crown Parts

Utilizing authentic components ensures optimal performance and longevity for your machinery. These original elements are specifically engineered to meet the highest standards, which significantly enhances the reliability of your equipment. By choosing genuine alternatives, users can avoid complications associated with inferior substitutes, thus ensuring smooth operation.

Enhanced Durability

Original elements are crafted from superior materials, which translates to greater resilience under demanding conditions. This durability reduces the likelihood of breakdowns and maintenance issues, ultimately saving both time and money.

Improved Efficiency

By incorporating authentic components, users can experience enhanced operational efficiency. These elements are designed to work seamlessly with the machinery, leading to better fuel consumption and reduced energy expenditure. This results in a more eco-friendly approach to operation while maximizing productivity.