In the world of lawn maintenance, comprehending the layout of a mowing machine is essential for efficient operation and maintenance. Each model consists of a variety of elements that work together to ensure optimal performance. By familiarizing oneself with these components, users can enhance their understanding of how the equipment functions and troubleshoot any potential issues that may arise during usage.

Every mowing machine is designed with specific features tailored to various tasks. This involves numerous interconnected parts, each serving a unique purpose. Recognizing these elements is crucial for users who wish to maintain their machines in peak condition. With knowledge of the configuration and functionality of each component, owners can ensure longevity and reliability in their lawn care endeavors.

Additionally, grasping the arrangement of parts facilitates easier repairs and replacements when needed. Whether it’s the blades, belts, or other vital elements, knowing their locations and functions enables users to perform maintenance tasks more effectively. This understanding not only contributes to a smoother operation but also empowers owners to take proactive measures in preserving the lifespan of their equipment.

Toro TimeCutter 4235 Overview

This section provides a comprehensive overview of a popular riding mower model designed for efficiency and ease of use. With a robust design, this machine is tailored to meet the needs of homeowners looking for a reliable solution for lawn maintenance.

The mower boasts several features that enhance its performance, making it suitable for a variety of terrains. Key characteristics include:

- Powerful Engine: Equipped with a reliable engine that delivers exceptional power and torque.

- Efficient Cutting System: Features a cutting mechanism designed to ensure a clean and even cut.

- User-Friendly Controls: Intuitive controls that allow for easy operation, making it accessible for users of all experience levels.

- Comfortable Seating: Ergonomically designed seat to provide comfort during extended use.

Maintenance is simplified with easily accessible components, ensuring that users can perform routine checks and repairs with minimal effort. The model is engineered to handle various lawn sizes and types, making it a versatile choice for many homeowners.

In summary, this riding mower represents a blend of power, efficiency, and comfort, making it an excellent investment for anyone looking to enhance their lawn care routine.

Key Components of the Model

The success of any outdoor equipment lies in its essential elements, which work together to ensure efficient operation and durability. Understanding these critical components is vital for effective maintenance and optimal performance. This section delves into the primary parts that contribute to the functionality of this particular model.

| Component | Description |

|---|---|

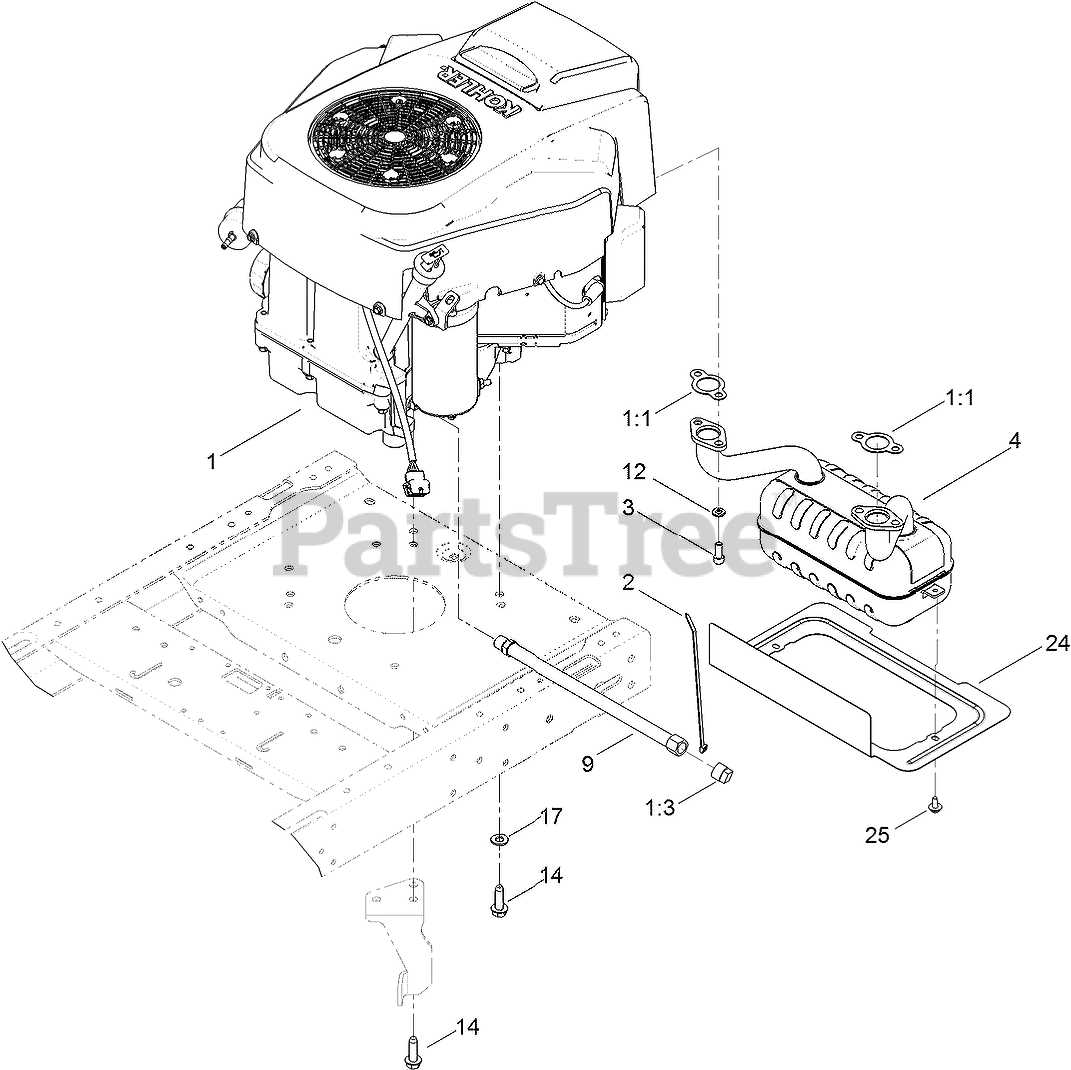

| Engine | Serves as the power source, providing the necessary energy for operation. |

| Deck | Houses the cutting blades, designed for precision and even grass trimming. |

| Transmission | Facilitates movement, enabling the machine to navigate various terrains smoothly. |

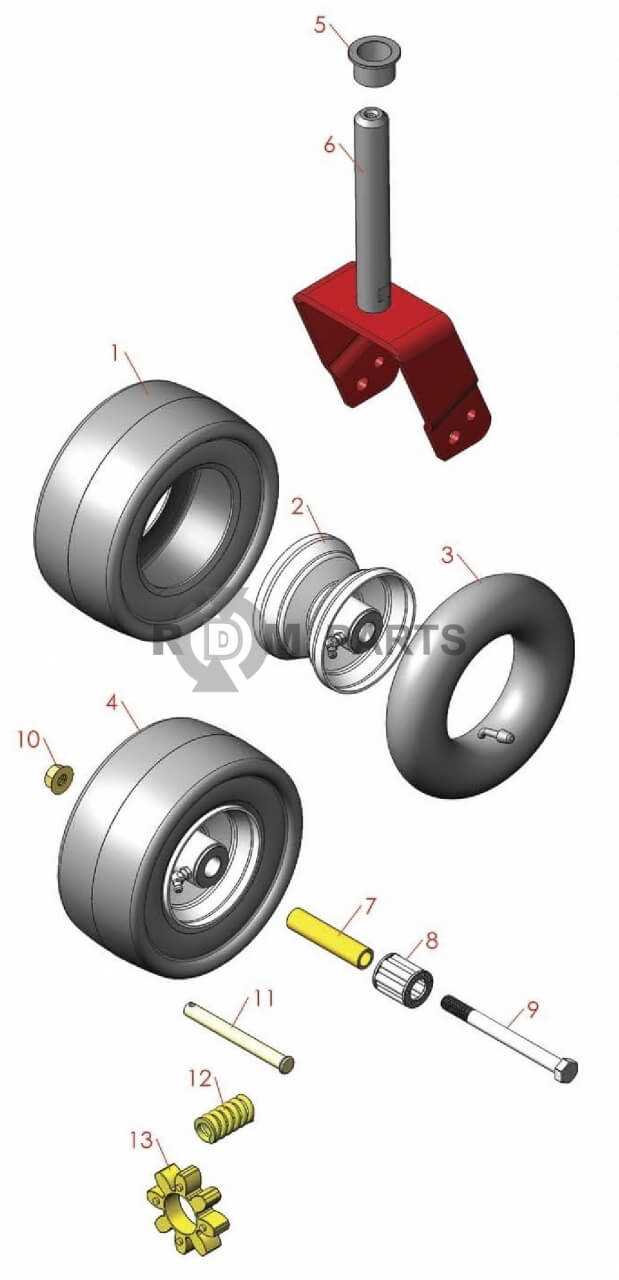

| Wheels | Provide stability and mobility, ensuring ease of maneuverability during use. |

| Control Panel | Offers user interface for adjusting settings and monitoring performance. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your equipment. Regular attention to maintenance tasks can significantly enhance the lifespan and efficiency of your machinery. By implementing a few straightforward practices, you can minimize wear and tear, reduce the need for repairs, and maximize productivity.

- Regular Cleaning: Keep the exterior and internal components free from dirt, debris, and grass clippings. This will prevent overheating and mechanical failures.

- Inspect Blades: Regularly check the cutting implements for sharpness and damage. Dull blades can lead to uneven cuts and additional strain on the engine.

- Change Fluids: Replace oil and filters at recommended intervals. Clean, fresh oil ensures smooth operation and reduces wear on engine parts.

- Tire Maintenance: Ensure that tires are properly inflated and check for signs of wear. This will improve traction and fuel efficiency.

- Battery Care: Keep battery connections clean and check the charge regularly. Proper battery maintenance can prevent starting issues.

Following these guidelines will not only extend the life of your equipment but also ensure it operates at peak performance. Make maintenance a regular part of your routine for the best results.

Common Repair Parts and Accessories

When it comes to maintaining outdoor equipment, having the right components and attachments can significantly enhance performance and longevity. Whether it’s routine upkeep or addressing specific issues, familiarizing oneself with frequently used elements is crucial for optimal functioning. This section highlights some of the most essential components and accessories that users should consider keeping on hand.

Engine Components

One of the most critical areas requiring attention involves engine elements. Regular maintenance or replacement of spark plugs, filters, and gaskets ensures efficient operation. These components are vital for maintaining power output and minimizing emissions. Having spare spark plugs and air filters can help prevent unexpected breakdowns during heavy usage.

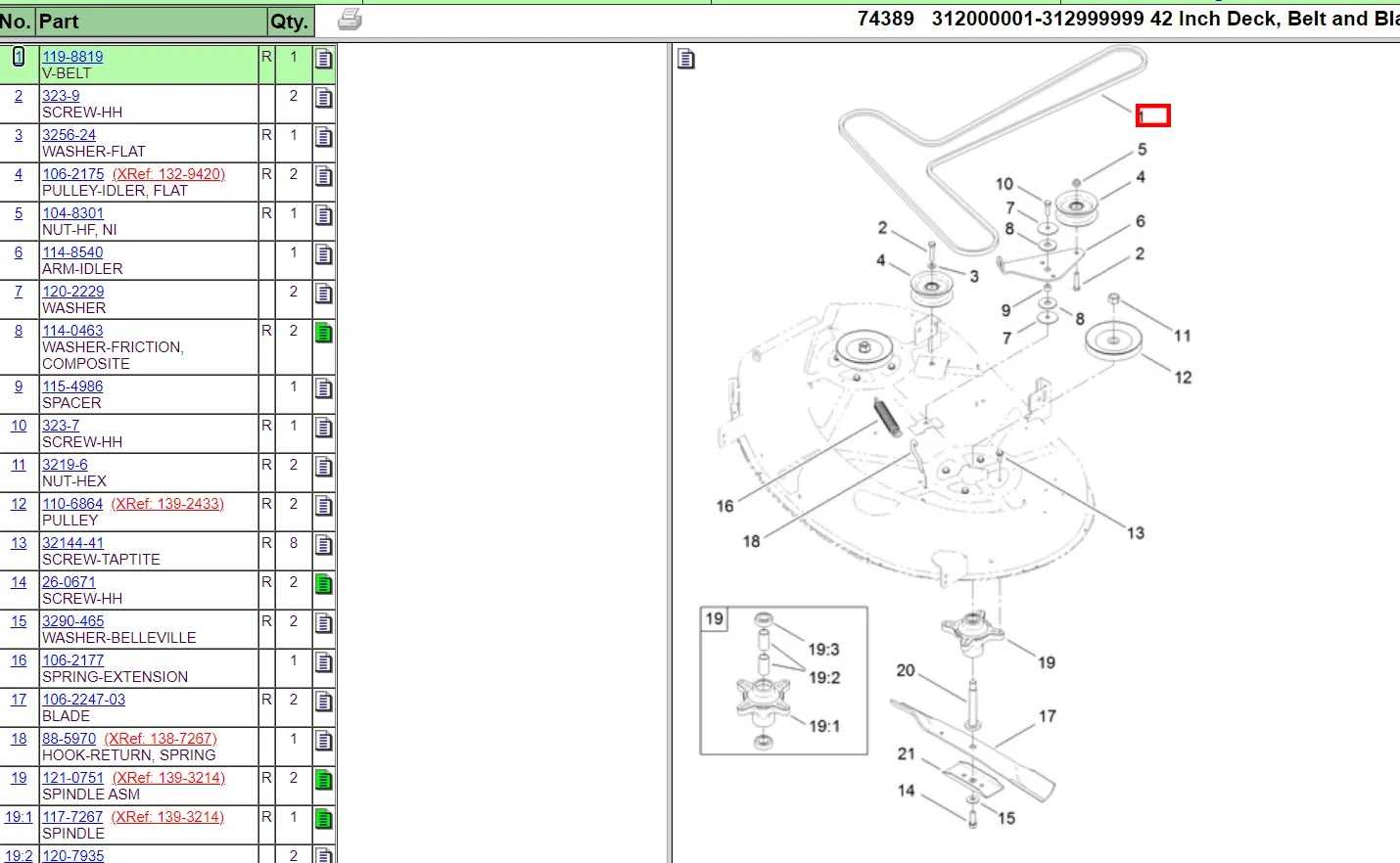

Cutting Deck Accessories

The cutting deck is another area that often needs replacement or repair items. Blades, belts, and roller wheels are essential for achieving a clean cut and maintaining maneuverability. Keeping a set of sharp blades and replacement belts readily available can enhance performance and reduce downtime, allowing for smoother operation during mowing sessions.

Understanding the Assembly Process

The assembly process of outdoor equipment involves a systematic approach to bringing together various components to ensure optimal functionality and performance. Each part plays a critical role in the overall operation, making it essential to understand how they fit together. This section will explore the key stages and considerations involved in assembling these machines effectively.

Key Stages of Assembly

- Preparation: Before starting the assembly, it’s crucial to gather all necessary tools and components. This stage ensures that everything is organized and ready for the assembly process.

- Sub-Assembly: Certain components may need to be assembled separately before being attached to the main unit. This includes items like the engine, chassis, and transmission.

- Main Assembly: This is where the individual components come together. Each part must be aligned and secured properly to prevent future malfunctions.

- Testing: Once assembled, the equipment should undergo thorough testing to ensure all systems are functioning as intended. This step helps identify any issues that may need addressing.

Considerations for Successful Assembly

- Attention to Detail: Pay close attention to specifications and instructions during the assembly process.

- Quality of Components: Use high-quality parts to ensure durability and reliability.

- Proper Tools: Employ the right tools for each task to avoid damaging components or compromising assembly integrity.

Safety Features of TimeCutter 4235

Ensuring user safety during operation is a critical aspect of modern machinery design. The model in focus incorporates various mechanisms aimed at minimizing risks and enhancing the overall experience for operators. These features not only protect the user but also contribute to the longevity and reliability of the equipment.

Operator Presence Control

One of the primary safety elements is the operator presence control system. This feature requires the user to be actively engaged while the machine is in operation. If the operator leaves the seat or is no longer in control, the system automatically disables the cutting blades, preventing accidental injuries.

Robust Frame Design

The machine’s robust frame design adds an additional layer of safety. Constructed to withstand various conditions, the sturdy build reduces the likelihood of tipping or loss of control. This solid construction ensures that the equipment remains stable even on uneven terrain, enhancing user confidence during operation.

Where to Purchase Replacement Parts

Finding the right components for your outdoor equipment can greatly enhance its performance and longevity. Several avenues exist for sourcing these essential items, whether you seek genuine manufacturer offerings or quality aftermarket alternatives.

Authorized Dealers are a reliable option, as they often provide original components that meet the manufacturer’s specifications. You can locate these vendors through the official website of the manufacturer, ensuring you obtain authentic items tailored for your equipment.

Online Retailers present a convenient alternative, with numerous platforms offering a vast selection of items. Websites specializing in outdoor equipment often have detailed listings, including customer reviews, which can guide your purchasing decisions. Popular e-commerce sites frequently feature both original and compatible options, allowing for a range of price points.

Local Repair Shops may also stock essential components or be able to order them for you. These establishments can provide personalized service, ensuring you find the exact item you need. Additionally, mechanics can offer valuable advice based on their experience with similar equipment.

Lastly, salvage yards and classified ads can yield affordable alternatives. Often, you can find used but functional items at a fraction of the new cost. Engaging with local community forums or online marketplaces can help connect you with sellers who have what you need.

Troubleshooting Common Issues

When operating any machinery, encountering difficulties is a common experience. Understanding the typical problems that may arise and their potential solutions can greatly enhance the efficiency of maintenance efforts. This section provides insights into common complications and their resolutions, ensuring smoother operation.

Engine Performance Problems

One of the most frequent issues relates to engine performance, which can manifest as a lack of power or stalling. Various factors contribute to this, and it is essential to diagnose the root cause accurately. Below is a table summarizing common causes and recommended actions:

| Symptoms | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine won’t start | Fuel blockage, faulty spark plug | Check fuel lines, replace spark plug |

| Engine sputters | Dirty air filter, low fuel | Clean or replace air filter, refill fuel tank |

| Poor acceleration | Clogged fuel filter, throttle issues | Inspect and replace fuel filter, adjust throttle |

Electrical System Failures

Another area that often requires attention is the electrical system. Issues here can lead to various operational problems. The following table outlines some common electrical malfunctions along with troubleshooting steps:

| Symptoms | Possible Causes | Suggested Solutions |

|---|---|---|

| Lights not functioning | Blown fuse, faulty wiring | Replace fuse, inspect wiring connections |

| Starter motor not engaging | Weak battery, corroded terminals | Charge or replace battery, clean terminals |

| Unexpected shutdowns | Overheating, loose connections | Check cooling system, secure connections |

Comparative Analysis with Similar Models

This section explores the key differences and similarities among comparable riding mowers within the same category. By examining various models, we can gain insights into their performance, features, and overall value, helping consumers make informed decisions.

When evaluating these mowers, several criteria stand out:

- Engine Power: The horsepower of each model is critical for assessing cutting efficiency and capability in different terrains.

- Cutting Width: A wider cutting deck can enhance productivity, making it essential to compare dimensions.

- Transmission Type: Variations between automatic and manual transmissions impact user experience and ease of operation.

- Durability: Build quality, including frame and deck materials, is vital for longevity and performance under challenging conditions.

- Comfort Features: User-friendly elements, such as seat design and controls, significantly affect the mowing experience.

For instance, when compared to similar riding mowers, the evaluated model often excels in:

- Engine efficiency, providing more power while maintaining fuel economy.

- Innovative design features that enhance maneuverability in tight spaces.

- Advanced safety features that offer added peace of mind during operation.

Ultimately, understanding these distinctions allows potential buyers to choose a mower that aligns closely with their specific needs and preferences, ensuring a satisfactory purchase experience.