A comprehensive exploration of machinery is essential for anyone involved in the agricultural sector. A thorough grasp of the various elements that constitute these machines allows operators and technicians to maintain, repair, and optimize equipment performance. In this section, we will delve into a specific model, examining its unique features and how they contribute to its overall functionality.

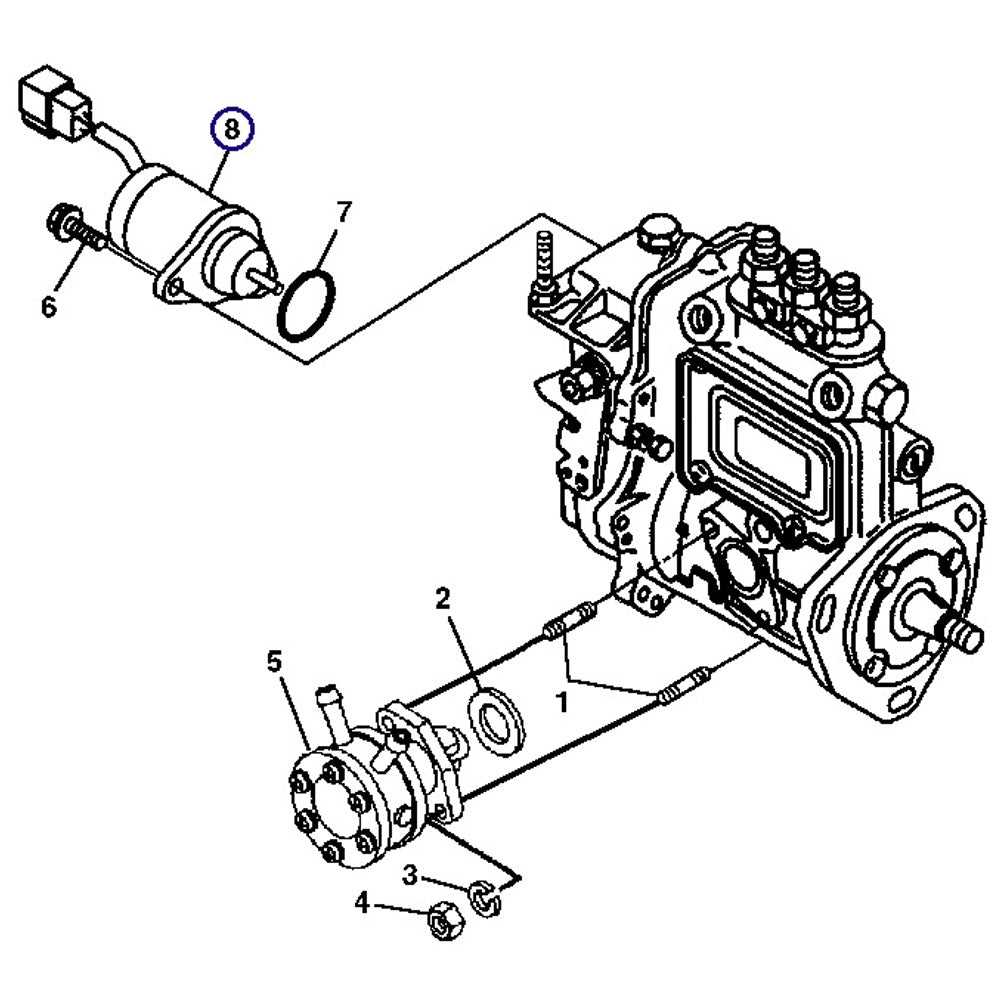

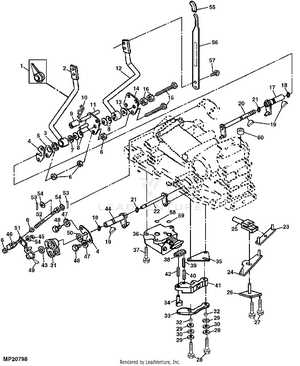

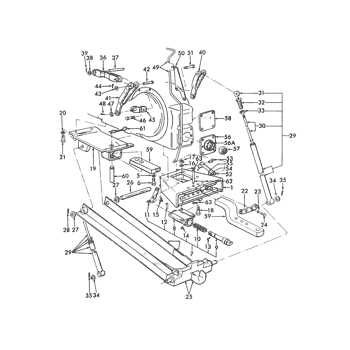

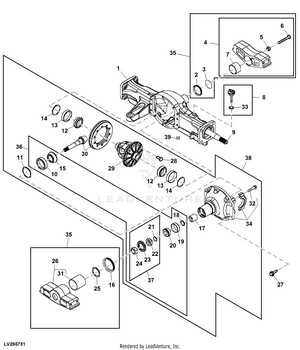

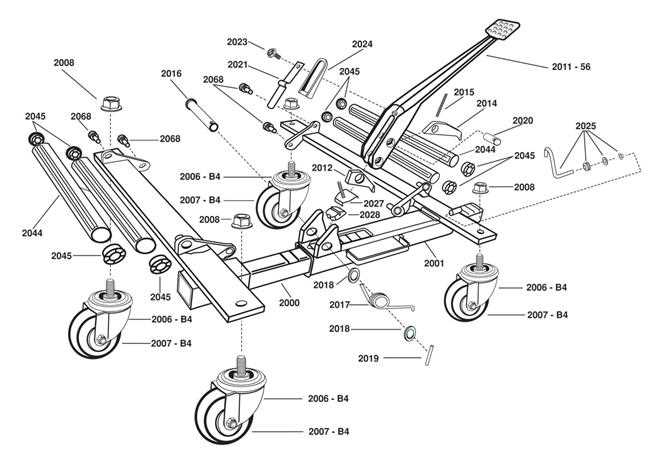

Visual representations play a crucial role in understanding complex systems. By breaking down the machinery into its individual components, one can easily identify and locate essential features, facilitating effective maintenance practices. Moreover, these illustrations serve as a valuable reference for both seasoned professionals and those new to the field.

In the upcoming discussion, we will outline the critical components of this particular agricultural machine. By focusing on the intricate details of its design, we aim to provide a clearer understanding of how each element contributes to the efficient operation of the equipment. This knowledge not only enhances troubleshooting skills but also aids in making informed decisions regarding upgrades and repairs.

Understanding John Deere 4500 Overview

This section aims to provide a comprehensive insight into a particular model of agricultural machinery, focusing on its essential features, functionalities, and overall significance within its category. By examining various aspects, one can appreciate the engineering and design choices that contribute to its efficiency and versatility in farming tasks.

The machinery is renowned for its reliability and performance, making it a preferred choice for many in the agricultural sector. Notably, its robust construction allows it to handle diverse tasks, from tilling to transporting materials, effectively meeting the demands of modern farming. With a user-friendly interface and advanced technology, operators can navigate and control the equipment with ease, enhancing productivity.

Moreover, understanding the intricacies of this model can aid in proper maintenance and operation, ensuring longevity and optimal performance. Familiarity with its components and their functions fosters a deeper connection between the operator and the machine, leading to more informed decisions regarding usage and care.

Importance of Parts Diagrams

Visual representations of component layouts play a crucial role in understanding and maintaining machinery. These illustrations provide detailed insights into the organization and relationships of various elements within a system, aiding users in efficient repairs and servicing.

Enhancing Understanding

Diagrams significantly enhance comprehension by offering a clear view of how different components interact. This clarity allows technicians and operators to:

- Identify individual components quickly.

- Understand the assembly and disassembly processes.

- Visualize the overall structure and functionality of the equipment.

Facilitating Maintenance and Repair

Utilizing these illustrations during maintenance can lead to more effective and timely repairs. They help in:

- Locating faults and issues more efficiently.

- Reducing the time spent on troubleshooting.

- Ensuring that all necessary components are available before commencing repairs.

Overall, these visual aids are essential for anyone involved in the upkeep and operation of complex machinery, making the maintenance process smoother and more efficient.

Key Components of John Deere 4500

This section focuses on the essential elements that contribute to the efficiency and functionality of a specific agricultural machine. Understanding these critical components can enhance maintenance practices and overall performance.

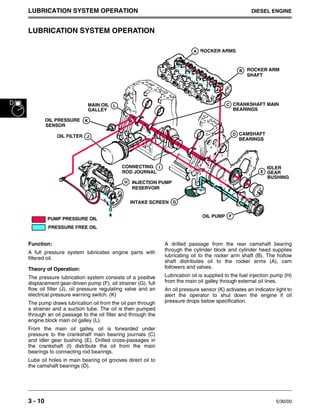

1. Engine Assembly

The engine serves as the powerhouse, providing the necessary energy for various operations. Key features include:

- Power output for heavy-duty tasks

- Cooling system to maintain optimal temperature

- Fuel injection for improved efficiency

2. Transmission System

The transmission is crucial for controlling speed and torque, allowing for smooth operation. Important aspects include:

- Gear ratios for different working conditions

- Hydraulic components for seamless gear shifting

- Drive shaft for transferring power to the wheels

By familiarizing oneself with these fundamental components, users can ensure better care and maximize the lifespan of their machinery.

How to Use the Parts Diagram

Understanding how to navigate the schematic can significantly enhance the efficiency of maintenance and repairs. A well-organized representation of components serves as a crucial tool for identifying and locating necessary elements within a machine. This guide will assist you in effectively utilizing this resource.

Follow these steps to maximize your understanding:

- Familiarize Yourself with the Layout: Start by reviewing the overall structure. Notice how the various segments are categorized and labeled.

- Identify Key Components: Focus on essential parts and their corresponding numbers. Make a list of those you might need to replace or repair.

- Refer to the Index: Use the index or legend, if available, to locate specific items quickly. This can save time during your search.

- Cross-Check with Manuals: Compare the information from the representation with your service manuals. This will provide additional context and ensure accuracy.

- Keep Notes: As you analyze, jot down any observations or queries. This can be beneficial for discussions with professionals or during future maintenance sessions.

By following these guidelines, you will enhance your ability to navigate the schematic and ensure efficient maintenance of your equipment.

Common Issues with John Deere 4500

When operating agricultural machinery, various challenges can arise that may affect performance and efficiency. Understanding these common complications is essential for timely maintenance and repairs. This section explores frequent problems encountered by users, providing insight into symptoms and potential solutions.

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Overheating | Excessive heat buildup can lead to engine failure, often caused by coolant leaks or faulty thermostats. | Regularly check coolant levels, inspect hoses for leaks, and replace the thermostat as needed. |

| Hydraulic System Failure | Malfunctions in the hydraulic system can result in loss of power steering and lift capabilities. | Check fluid levels, inspect for leaks, and replace damaged hoses or filters. |

| Electrical Problems | Faulty wiring or connections can lead to starting issues and electrical component failures. | Inspect wiring harnesses, clean connections, and replace worn-out components. |

| Transmission Issues | Difficulty in shifting gears or unusual noises may indicate transmission problems. | Check fluid levels, look for leaks, and consult a professional for complex repairs. |

Finding Replacement Parts Easily

Locating the right components for machinery can often be a daunting task, especially when faced with a wide range of models and specifications. However, with the right approach and resources, you can simplify the process significantly. This section provides useful insights on how to efficiently find suitable replacements for your equipment.

One effective method is to utilize online resources that offer comprehensive listings and detailed information about various components. Many manufacturers and retailers have websites featuring catalogs, allowing users to search by model number or category. Additionally, forums and communities dedicated to machinery enthusiasts can provide invaluable assistance through shared experiences and recommendations.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often have parts catalogs and ordering options for specific models. |

| Online Retailers | Many e-commerce platforms specialize in selling replacement components, often at competitive prices. |

| Forums and Communities | Online groups can be great for seeking advice and finding trusted suppliers. |

| Local Dealerships | Dealerships often have access to a wide range of components and can provide personalized assistance. |

| Parts Catalogs | Printed or digital catalogs can help you understand what is available for your specific model. |

By leveraging these resources, you can streamline your search for suitable replacements, ensuring that your machinery operates at its best without unnecessary delays.

Maintenance Tips for Longevity

Proper care and regular maintenance are key to ensuring that your machinery operates smoothly over the long term. By paying attention to wear and tear, performing timely inspections, and keeping the equipment in optimal condition, you can significantly extend its service life and avoid unexpected breakdowns.

Regular Inspection and Cleaning

Conduct routine checks to identify any potential issues early on. Focus on parts prone to dirt accumulation, corrosion, or damage. Clean these components frequently to prevent malfunctions caused by debris or grime.

- Inspect fluid levels, such as oil and coolant, and top them off as necessary.

- Check for loose bolts, leaks, or cracks that may compromise the machine’s function.

- Clean air filters to maintain efficient engine performance.

Lub

Resources for Parts and Manuals

Finding the right resources for machinery components and technical manuals is essential for maintenance and repairs. Whether you’re a seasoned mechanic or an equipment owner, having access to reliable documentation and supplies ensures smooth operations and prolongs the lifespan of your machine.

Below are some helpful sources where you can locate replacement components and comprehensive guides:

- Official manufacturer websites, offering detailed catalogs and downloadable manuals.

- Authorized dealers and service centers that provide both physical and digital copies of technical guides.

- Online forums and communities where users share advice and resources for locating hard-to-find items.

- Third-party vendors specializing in aftermarket components and maintenance guides.

- Local repair shops, often equipped with a wide selection of both original and compatible components.

By leveraging these resources, you can streamline the repair process, reduce downtime, and ensure your equipment runs efficiently.