Understanding the various elements and how they fit together is crucial for effective equipment maintenance. Knowing the arrangement and functionality of different components helps in identifying potential issues and performing repairs swiftly, ensuring the machinery operates smoothly and efficiently.

Regular upkeep and timely replacement of worn-out elements are essential to extend the lifespan of any equipment. A comprehensive overview of the internal structure allows for a more informed approach to maintenance, offering insights into how different mechanisms work together to achieve optimal performance.

Having a detailed layout of the mechanical structure aids in troubleshooting, making it easier to pinpoint areas that may need attention. This approach not only saves time during repairs but also enhances the overall reliability of the machinery, minimizing downtime and maximizing productivity.

Cub Cadet ST 100 Parts Diagram

This section provides a detailed overview of the components for a specific lawn care equipment model. Understanding the various elements that make up this machine is crucial for maintenance and repairs, ensuring optimal performance and longevity.

Key components include:

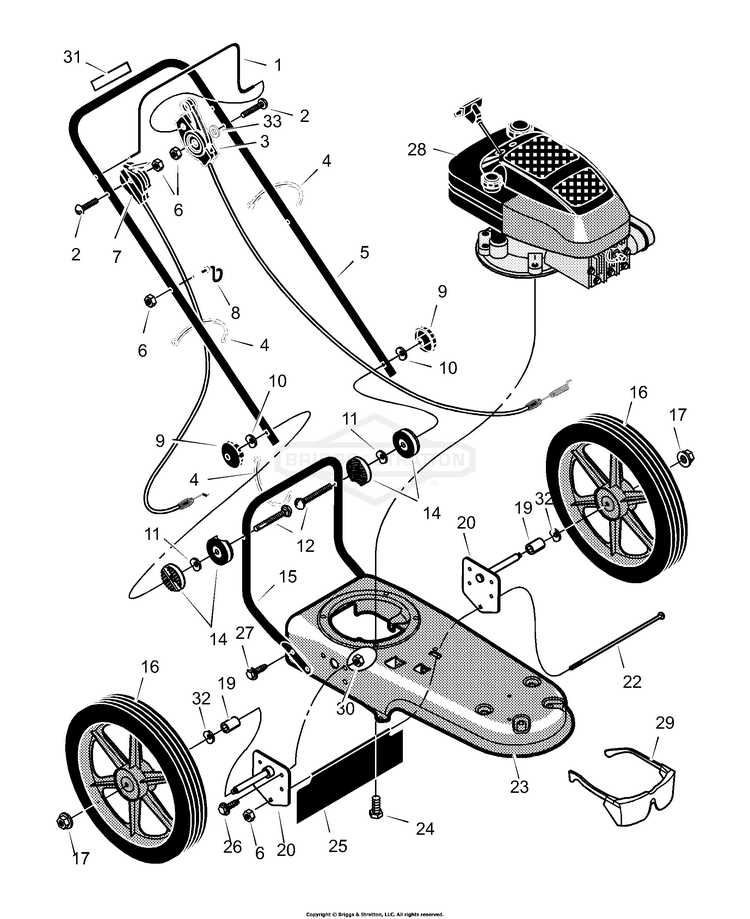

- Engine assembly

- Transmission system

- Cutting deck

- Wheels and tires

- Handle controls

Each of these parts plays an essential role in the functionality of the equipment. Familiarizing yourself with their locations and functions can simplify troubleshooting and enhance your overall maintenance experience.

Additionally, a comprehensive guide often includes:

- Identification of common wear items

- Tips for replacement and repair

- Resources for obtaining spare components

By being informed about the various components and their specific roles, users can better manage upkeep and ensure their lawn care device operates smoothly.

Understanding the Parts Layout

Grasping the arrangement of components is essential for effective maintenance and operation. A clear visualization of how each element fits into the overall mechanism can significantly enhance the user’s understanding of functionality and facilitate troubleshooting processes. This section delves into the key aspects of the configuration, highlighting the significance of each segment within the system.

Key Components Overview

Each element in the configuration plays a pivotal role, contributing to the overall performance. Familiarizing oneself with these components can simplify the process of repairs and replacements.

Importance of Layout Clarity

A well-structured layout allows for quick identification of parts that may need attention or replacement. Understanding the specific roles and locations of each component aids in efficient troubleshooting.

| Component Name | Function |

|---|---|

| Engine | Powers the entire system |

| Blade Assembly | Cuts grass and vegetation |

| Chassis | Provides structural support |

| Control Handles | Allows user operation |

How to Identify Key Components

Understanding the essential elements of your equipment is crucial for effective maintenance and repair. Recognizing these vital components ensures that you can troubleshoot issues efficiently and source the correct replacements when needed. Each part plays a significant role in the overall functionality, making it imperative to familiarize yourself with their appearances and functions.

To help you identify these components, consider the following table that outlines common parts, their descriptions, and their functions:

| Component Name | Description | Function |

|---|---|---|

| Engine | The core power unit | Provides the necessary power for operation |

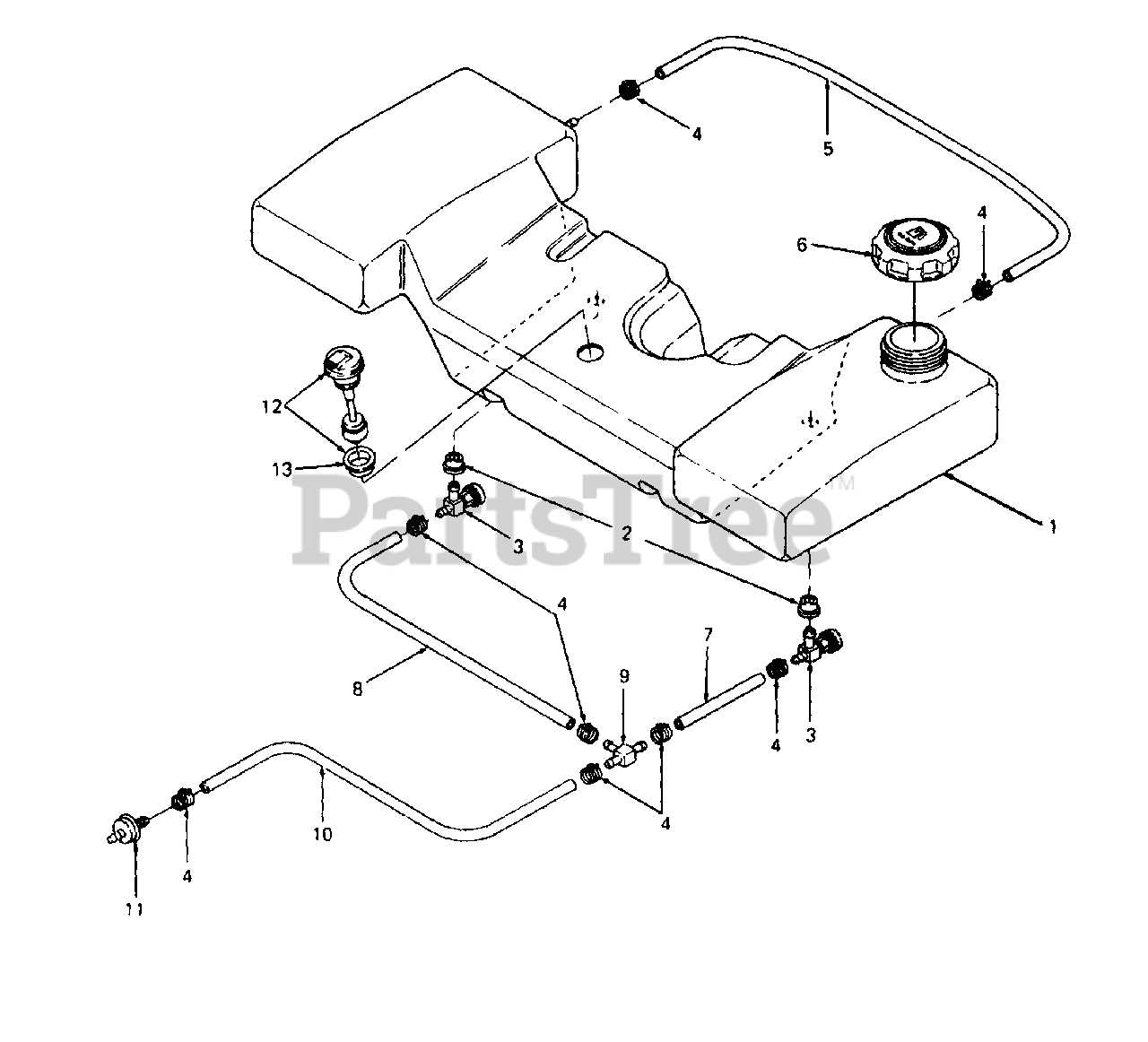

| Fuel Tank | Container for fuel storage | Supplies fuel to the engine for combustion |

| Cutting Deck | Base structure housing the blades | Enables efficient grass cutting |

| Blade Assembly | Rotating sharp edges | Performs the cutting action |

| Wheels | Round structures for mobility | Facilitates movement across various terrains |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of outdoor equipment involves a series of essential practices. Regular upkeep not only enhances efficiency but also extends the lifespan of the machine. Adhering to a maintenance routine can prevent unexpected breakdowns and reduce repair costs over time.

Regular Inspection

Frequent checks are vital for identifying potential issues early on. Consider the following aspects during inspections:

- Check for signs of wear and tear on belts and cables.

- Inspect the condition of filters and replace them if necessary.

- Examine the blades for sharpness and damage.

- Look for leaks or loose connections in fuel and oil systems.

Routine Cleaning

Maintaining a clean machine is crucial for optimal performance. Follow these cleaning practices:

- Remove debris and grass clippings from the body and undercarriage.

- Clean air filters to ensure proper airflow.

- Wipe down surfaces to prevent rust and corrosion.

- Regularly wash components to maintain their functionality.

Replacing Common Wear Items

Maintaining your equipment involves periodic replacement of various components that experience wear over time. These elements are crucial for ensuring optimal performance and longevity. Regular attention to these items can help prevent costly repairs and keep your machinery functioning smoothly.

Identifying Worn Components

Recognizing the signs of deterioration is essential. Common indicators include reduced efficiency, unusual noises, or difficulty in operation. Inspecting belts, blades, and filters regularly can help identify these issues early, allowing for timely replacement.

Replacement Process

When replacing worn components, always refer to the manufacturer’s guidelines for specific instructions. Start by gathering the necessary tools and parts. Ensure that the equipment is turned off and properly secured before proceeding with the replacement. Following the correct procedure will help maintain safety and ensure the best results.

Troubleshooting Mechanical Issues

When encountering mechanical problems with outdoor equipment, it is essential to adopt a systematic approach to identify and resolve the underlying issues. Understanding the common symptoms and their potential causes can significantly expedite the repair process. This section provides valuable insights into diagnosing typical mechanical failures and offers practical solutions to restore functionality.

Identifying Common Symptoms

Before diving into repairs, it is crucial to observe and document the specific symptoms exhibited by the equipment. Common indicators include unusual noises, vibrations, or failure to operate as expected. For instance, a persistent grinding sound may suggest issues with the drive mechanism, while excessive vibration might indicate loose components. Careful inspection of these symptoms can help pinpoint the root cause.

Practical Solutions for Repair

Once the symptoms are identified, the next step involves applying appropriate remedies. For instance, if the equipment is not starting, check the power supply and ensure all connections are secure. Routine maintenance, such as lubricating moving parts and tightening loose bolts, can prevent many common problems. Additionally, replacing worn-out components promptly will enhance performance and prolong the lifespan of the equipment.

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original items guarantees compatibility and reliability, allowing your machinery to function as intended.

To secure these essential components, begin by identifying authorized retailers or official distributors. These sources provide assurance that you are acquiring high-quality items that meet industry standards. Additionally, conducting thorough research online can yield valuable insights and reviews, helping you make informed decisions regarding your purchases.

Exploring various options may lead you to specialized websites dedicated to aftermarket solutions, which often offer a range of choices. However, always verify the credibility of these suppliers to avoid counterfeit alternatives. Investing in genuine components ultimately enhances your equipment’s performance, ensuring it remains reliable for years to come.

Exploring Aftermarket Alternatives

When considering enhancements or replacements for your outdoor machinery, exploring options beyond the original manufacturer can provide both cost-effective solutions and improved performance. Aftermarket alternatives often offer comparable quality and functionality, allowing users to maintain and upgrade their equipment without breaking the bank.

Benefits of Aftermarket Solutions

- Cost Savings: Often more affordable than OEM components, providing an economical choice for maintenance.

- Variety: A broader selection of options that may not be available from the original manufacturer.

- Performance Enhancements: Potential for improved functionality and durability with alternative products.

- Availability: Easier to find in local stores or online platforms, reducing wait times for replacements.

Factors to Consider

- Compatibility: Ensure that any replacement part matches the specifications of your equipment.

- Quality: Research the reputation of aftermarket brands to ensure reliable performance.

- Warranty: Check if the alternative parts come with a warranty for added assurance.

- Installation: Consider whether professional installation is necessary or if you can handle it yourself.

Ultimately, opting for aftermarket solutions can significantly enhance your experience and efficiency in maintaining your machinery, while also providing the flexibility to customize your equipment as needed.

Essential Tools for Repairs

Maintaining and fixing outdoor equipment requires a variety of specialized tools. Having the right instruments on hand not only simplifies the process but also enhances efficiency and effectiveness during repairs. Whether you are performing routine maintenance or addressing specific issues, certain tools are indispensable for achieving optimal results.

Basic Hand Tools

Start with essential hand tools that form the foundation of any repair task. A set of screwdrivers, pliers, and wrenches is crucial for handling various fasteners and components. These tools allow for easy disassembly and reassembly, ensuring that every part is secure and functioning properly. Additionally, a reliable torque wrench is vital for applying the correct amount of force to avoid damaging delicate components.

Power Tools and Accessories

Incorporating power tools can significantly streamline the repair process. An electric drill is beneficial for creating holes or removing stubborn screws, while a high-quality impact wrench can quickly loosen tight bolts. Moreover, accessories such as drill bits and cutting blades tailored for specific tasks enhance versatility, enabling users to tackle a wide range of projects efficiently.