The efficient functioning of powerful cleaning devices relies on a comprehensive understanding of their individual components. Each element plays a crucial role in delivering the performance users expect, ensuring that these machines operate at their best. Recognizing how these parts interact can enhance maintenance and troubleshooting efforts.

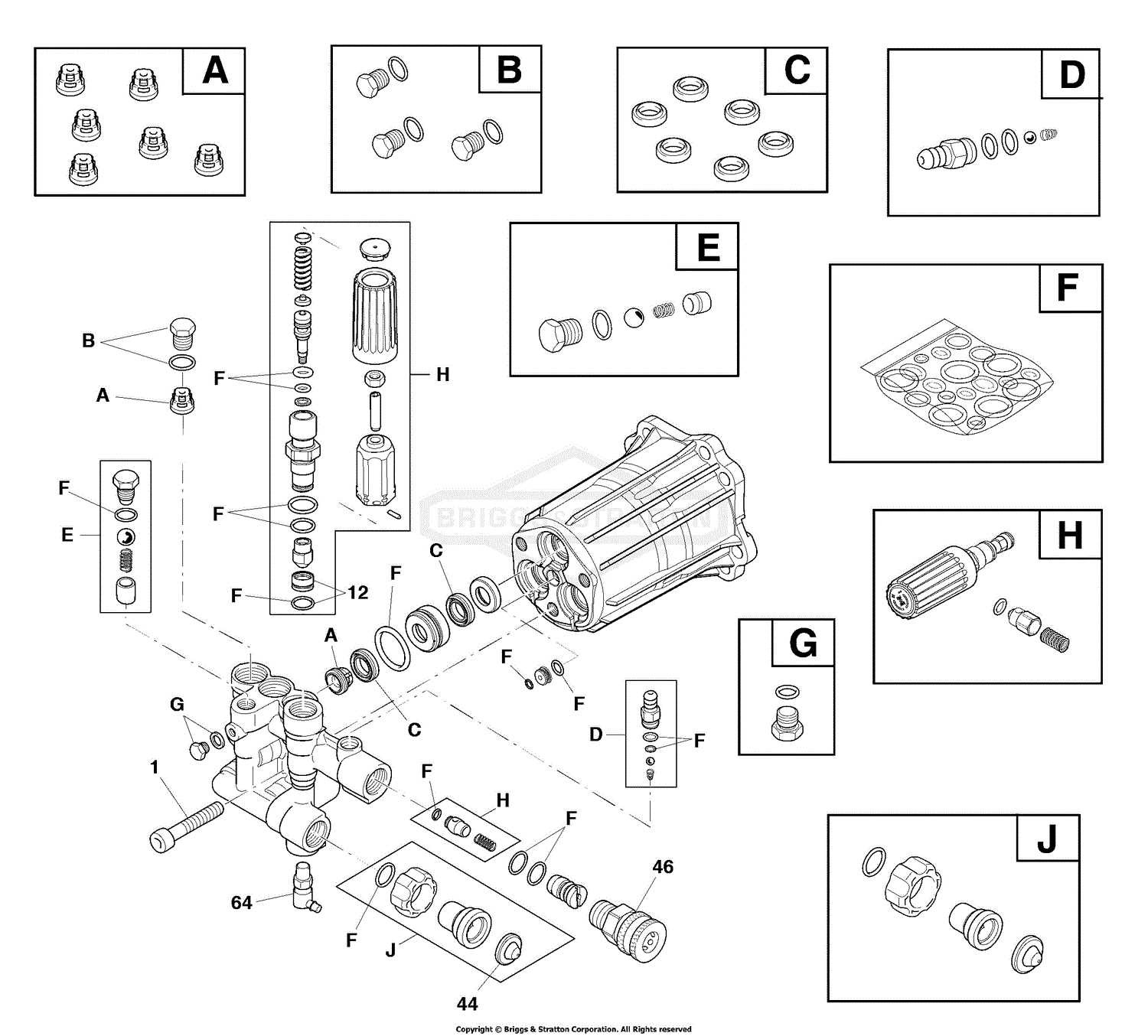

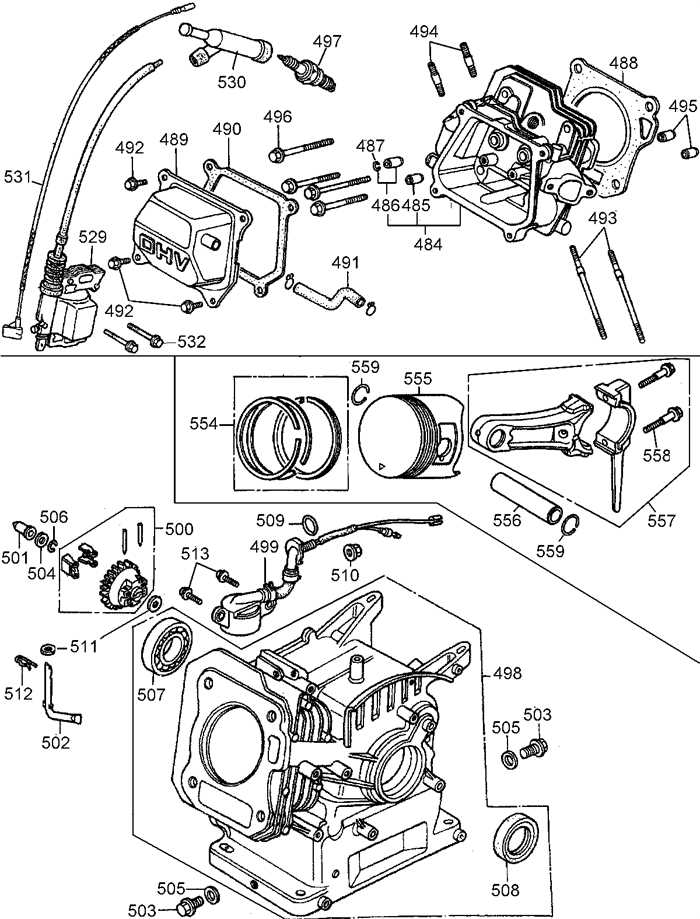

For those interested in optimizing their cleaning equipment, visual aids such as schematic representations can provide valuable insights. These illustrations not only highlight the layout of various components but also facilitate easier identification during repairs or upgrades. Understanding the structure of these devices can lead to improved longevity and functionality.

Whether you are a professional cleaner or a DIY enthusiast, having a clear grasp of the intricacies involved in these machines is essential. By familiarizing yourself with the essential components and their arrangement, you can ensure that your equipment remains in top condition, ready to tackle any cleaning task with ease.

Dewalt Pressure Washer Overview

This section provides an insightful look into a powerful cleaning tool designed for a variety of tasks. Known for its durability and efficiency, this equipment is suitable for both residential and commercial use, offering a robust solution for tackling tough grime and stains.

The machine features a high-performance motor, ensuring optimal functionality while minimizing downtime. Its various components work together seamlessly, enabling users to achieve remarkable results in cleaning driveways, patios, and vehicles.

With an ergonomic design and user-friendly controls, it enhances the overall experience, making maintenance and operation straightforward for everyone. Exploring the features and benefits can help users make informed decisions about their cleaning needs.

Understanding PSI and Its Importance

In various cleaning applications, the measurement of force exerted by a fluid plays a crucial role in determining effectiveness. Grasping this concept helps users select the right equipment for specific tasks, ensuring optimal results and efficiency. Knowing how this measurement influences performance can significantly enhance the overall experience.

The Impact on Cleaning Efficiency

Higher force levels can lead to faster and more thorough cleaning. Understanding how this measurement affects dirt removal, surface treatment, and time management allows users to tackle projects with confidence. Selecting the right intensity is key to achieving desired outcomes without causing damage.

Safety Considerations

With increased power comes the responsibility of using equipment safely. Being aware of potential risks associated with high-intensity tasks is essential. Proper protective measures and techniques can prevent injuries, making the cleaning process both effective and secure.

Key Components of Dewalt Washers

The essential elements of high-performance cleaning machines play a crucial role in their efficiency and functionality. Understanding these components helps users maximize their cleaning capabilities and maintain optimal performance over time.

Motor: The heart of the system, responsible for powering the entire unit. A reliable motor ensures consistent operation and effective cleaning.

Pump: This component elevates water pressure, enabling it to tackle stubborn dirt and grime. Quality pumps are vital for longevity and performance.

Spray Gun: A user-friendly interface that allows for precise control over the water stream. Different nozzles can be attached for various cleaning tasks.

Hose: A durable line that connects the water source to the machine, delivering the pressurized fluid efficiently. Length and flexibility are key for accessibility.

Chassis: The frame that supports all components, ensuring stability during operation. A sturdy chassis contributes to the overall durability of the unit.

Understanding these components empowers users to choose the right machine and maintain it effectively for ultimate cleaning results.

Common Issues with Pressure Washers

When operating high-powered cleaning machines, users may encounter a variety of typical challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintenance and troubleshooting.

One frequent issue is the motor failing to start, often caused by electrical problems or fuel supply issues. Additionally, inadequate water flow can lead to poor cleaning results, which might stem from clogs or incorrect hose connections. Users may also experience inconsistent spray patterns, typically due to nozzle blockages or wear over time.

Another prevalent concern is the overheating of the unit, which can occur from extended use without breaks or inadequate cooling. Regular maintenance checks can help mitigate these issues and enhance the overall lifespan of the equipment.

Benefits of Regular Maintenance

Consistent upkeep of equipment plays a crucial role in ensuring longevity and optimal performance. By prioritizing maintenance, users can significantly reduce the risk of unexpected failures and enhance overall efficiency.

- Extended Lifespan: Regular attention to machinery components helps prevent wear and tear, thereby increasing the overall lifespan.

- Improved Performance: Well-maintained equipment operates more smoothly and effectively, leading to better results.

- Cost Savings: Preventative maintenance can minimize repair costs and extend the intervals between major servicing.

- Safety Assurance: Keeping equipment in good condition reduces the likelihood of accidents and injuries, providing a safer working environment.

- Environmental Impact: Efficient machinery often consumes less energy and produces fewer emissions, contributing positively to environmental sustainability.

Incorporating a regular maintenance schedule not only safeguards the investment but also ensures that equipment functions at its best, yielding consistent results and reliability over time.

Where to Find Replacement Parts

Finding the right components for your cleaning equipment can be crucial for maintaining its efficiency and longevity. Whether you are looking for a specific piece or a complete assembly, there are several avenues to explore for sourcing high-quality alternatives. Understanding where to search can save you time and ensure you obtain reliable replacements.

Online Retailers

Many online platforms specialize in providing components for various equipment types. These retailers often have extensive catalogs and detailed descriptions to help you identify what you need. Some popular options include:

| Retailer | Website | Notes |

|---|---|---|

| Amazon | www.amazon.com | Wide selection, customer reviews available |

| eBay | www.ebay.com | Variety of new and used items |

| Specialty Stores | www.specialtystore.com | Expert advice, dedicated to specific brands |

Local Retail Shops

Visiting local hardware stores or specialized retailers can also yield good results. These shops often carry essential components and can provide guidance on the best choices for your equipment. Building a relationship with local suppliers can lead to better support and access to hard-to-find items.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with cleaning devices. By following these structured steps, users can effectively troubleshoot and resolve problems, ensuring optimal performance and longevity of their equipment.

Identify the Problem

Start by determining the specific issue. Common symptoms may include:

- Lack of water flow

- Inconsistent pressure

- Unusual noises during operation

- Difficulty starting the machine

Observe the equipment carefully to note any visible signs of damage or wear.

Gather Required Tools

Before beginning the repair process, assemble the necessary tools:

- Screwdrivers (flat and Phillips)

- Wrenches

- Pliers

- Replacement components (as identified)

- Cleaning supplies

Step-by-Step Repair Process

- Disconnect the Device: Ensure the equipment is unplugged and any water supply is turned off.

- Inspect Components: Check hoses, nozzles, and other elements for blockages or damage.

- Replace Damaged Parts: If any components are broken or worn out, carefully remove and replace them.

- Clean Filters: Remove and clean any filters to improve efficiency.

- Reassemble the Device: Put all parts back together securely, ensuring no loose connections.

- Test the Equipment: Reconnect everything and perform a test run to verify that the issue has been resolved.

By adhering to this guide, users can successfully troubleshoot and repair their cleaning devices, enhancing their effectiveness and reliability.

Safety Tips for Operating Washers

Ensuring safety while using high-powered cleaning equipment is crucial to prevent accidents and injuries. Understanding proper practices can enhance the effectiveness of your cleaning tasks while keeping you and others safe.

Preparation Before Use

- Read the user manual thoroughly to familiarize yourself with the device.

- Inspect the equipment for any damages or leaks before starting.

- Wear appropriate protective gear, including goggles, gloves, and sturdy footwear.

During Operation

- Maintain a safe distance from people and pets while operating.

- Avoid pointing the nozzle at yourself or others.

- Keep electrical connections away from water to prevent shock hazards.

Upgrading Your Pressure Washer Experience

Enhancing your cleaning device can significantly elevate its performance and efficiency. By exploring various components and accessories, you can transform a standard unit into a powerful tool, tailored to meet diverse cleaning tasks. This not only saves time but also improves results, making every project more enjoyable.

Consider investing in high-quality attachments that suit your specific needs. From nozzles designed for different surfaces to extended hoses that increase reach, each upgrade contributes to a more effective cleaning process. Additionally, regular maintenance and the use of superior fluids can prolong the lifespan of your equipment, ensuring that it remains a reliable ally in your cleaning endeavors.

Finally, researching user reviews and recommendations can help you make informed decisions. Understanding the latest innovations in cleaning technology will enable you to select options that provide the ultimate performance and satisfaction. Embrace the journey of enhancement, and enjoy the benefits of a well-equipped cleaning system.