In modern machinery, the integration of various elements is crucial to ensure efficient functionality. Whether for domestic or industrial purposes, understanding how different mechanical parts interact can be essential in maintaining long-term operational effectiveness. Knowing the structure of these systems allows for timely maintenance and quick identification of issues, ensuring optimal performance over time.

The mechanics behind such systems often rely on intricate connections between multiple sections. This makes it important to familiarize oneself with the internal workings of each component, ensuring that users can easily address any potential complications. Exploring these elements in detail can significantly extend the lifespan of your equipment, leading to reliable and consistent results.

By gaining a deeper insight into the specific configurations used in various mechanical setups, users are better equipped to make informed decisions when it comes to repairs and replacements. This knowledge not only enhances operational efficiency but also helps to avoid unnecessary downtimes and costly repairs.

Aaa Pressure Washer Pump Overview

High-efficiency cleaning devices rely on complex mechanical systems to deliver powerful results. The key component that drives the cleaning process involves a mechanism designed to move liquid at high speed and pressure. This essential system is known for its ability to ensure consistent water flow, making it integral to the overall operation of these devices.

| Feature | Description |

|---|---|

| Durability | Constructed from robust materials, ensuring long-lasting performance even under heavy use. |

| Efficiency | Engineered to optimize water flow, minimizing energy consumption while maximizing output. |

| Maintenance | Designed with easy-to-access components, allowing for straightforward maintenance and repairs. |

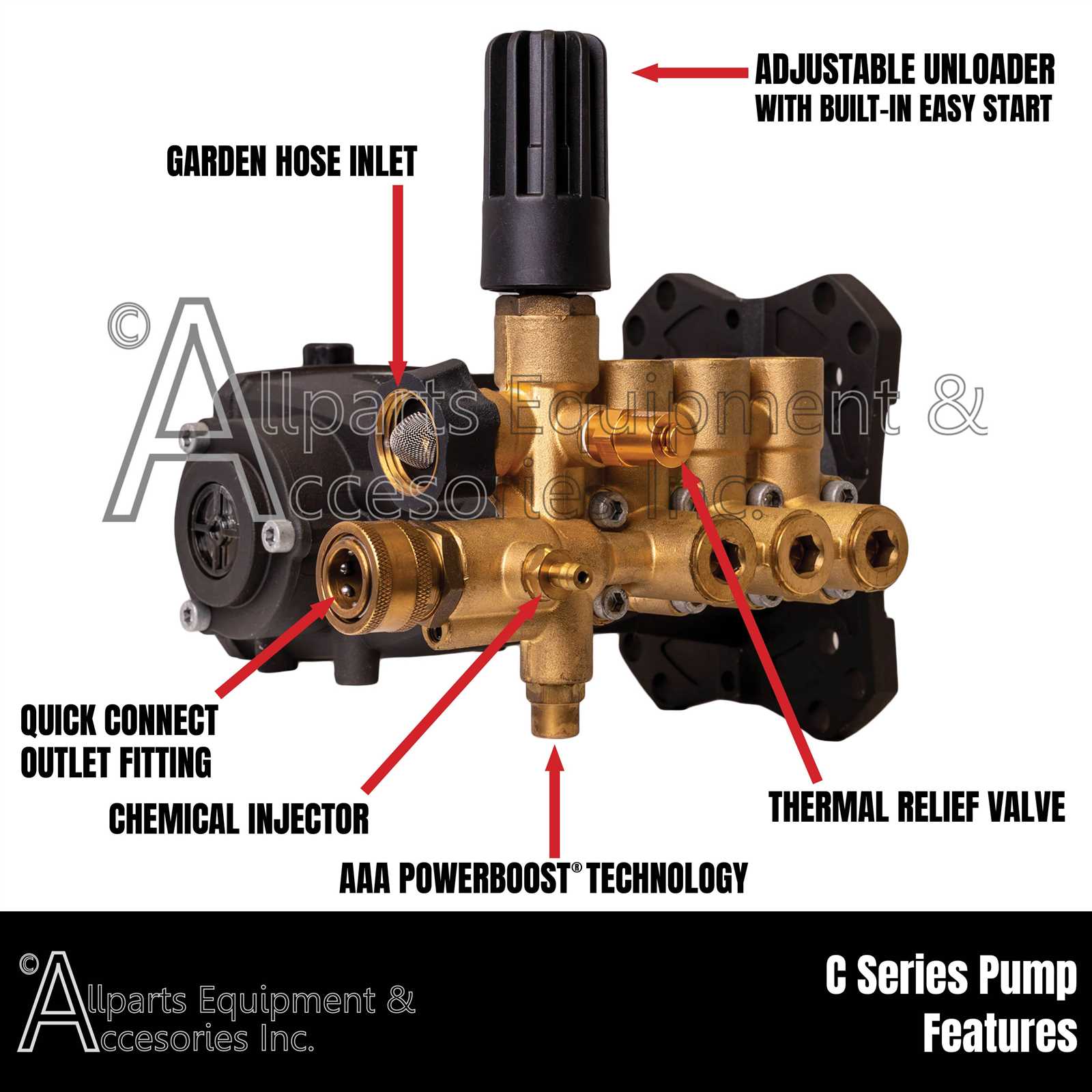

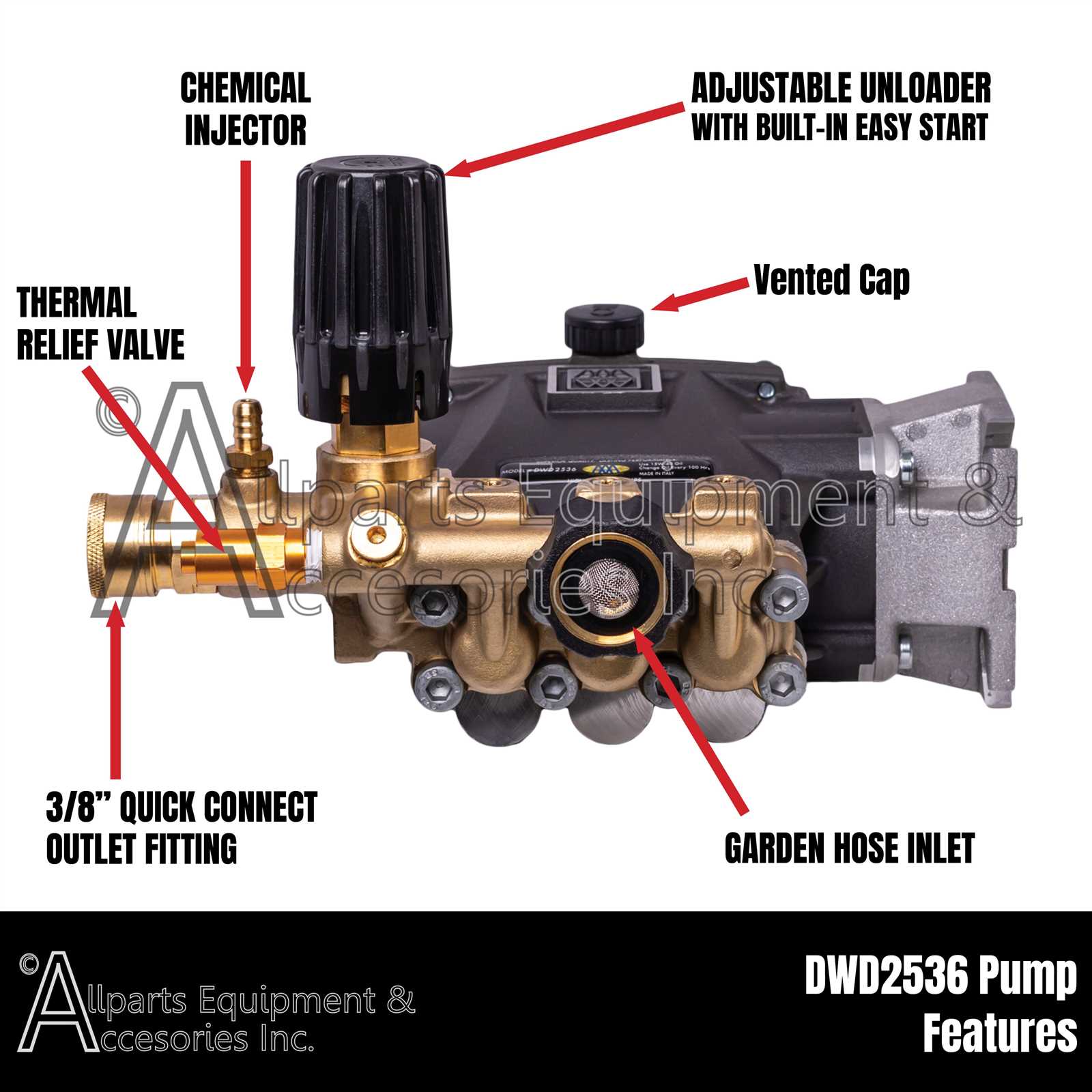

Key Components of the Aaa Pump

This section will focus on the most important elements that make up the core of this high-performance fluid delivery system. Each component plays a crucial role in ensuring the overall efficiency and durability of the device, contributing to its reliable functionality in various demanding applications.

Main Housing and Frame

The primary structure of the unit consists of a robust housing, designed to protect the internal mechanisms from external damage. The frame is often made from durable materials, ensuring long-term resistance to wear and tear while maintaining the overall integrity of the unit during operation.

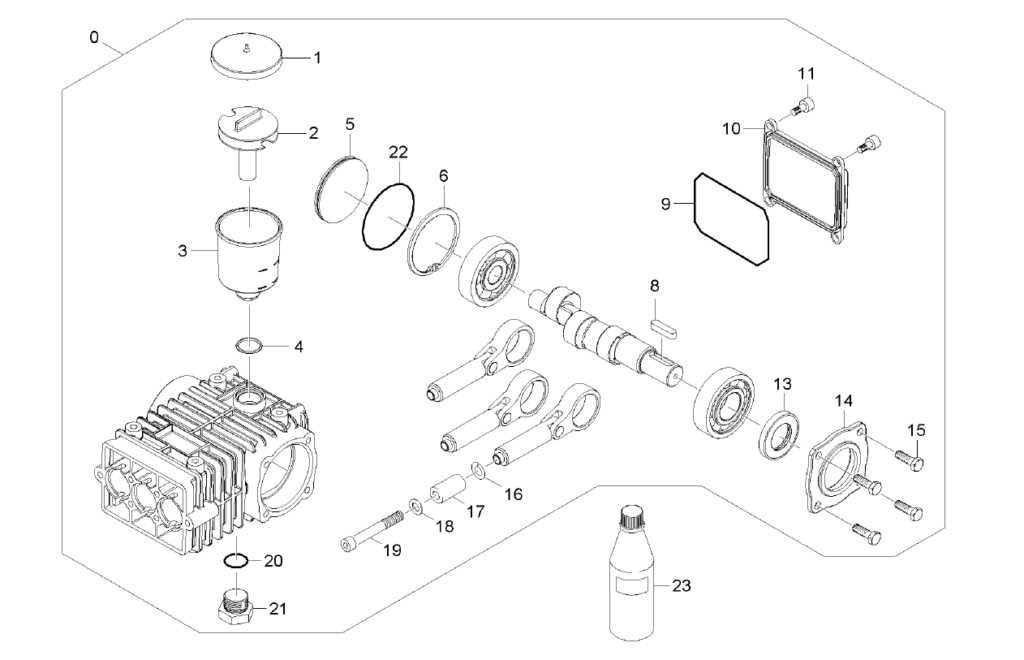

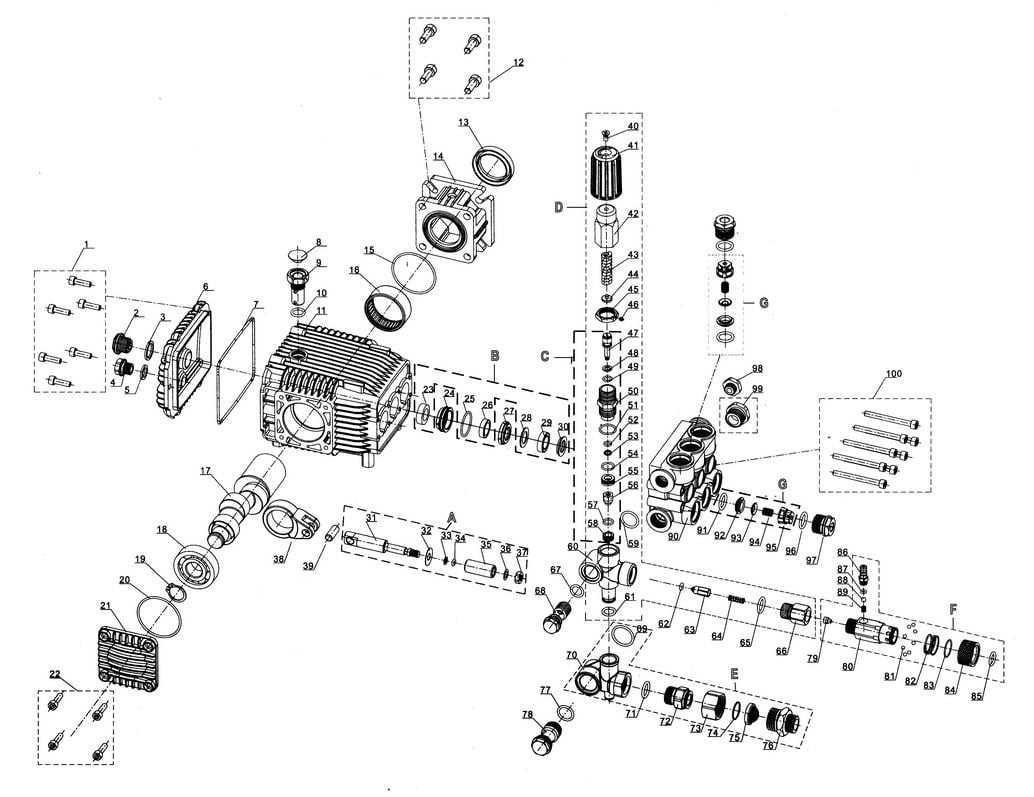

Internal Moving Parts

Within the assembly, several moving components work together to create a continuous flow. These include pistons, valves, and seals, which are all engineered to withstand high-pressure environments. Regular maintenance of these parts ensures smooth performance and prevents system breakdowns.

| Component | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston | Creates motion to generate fluid movement. | ||||||||||||||||||||||||

| Valve | Controls the direction of the fluid flow. | ||||||||||||||||||||||||

| Seal | Prevents leaks by

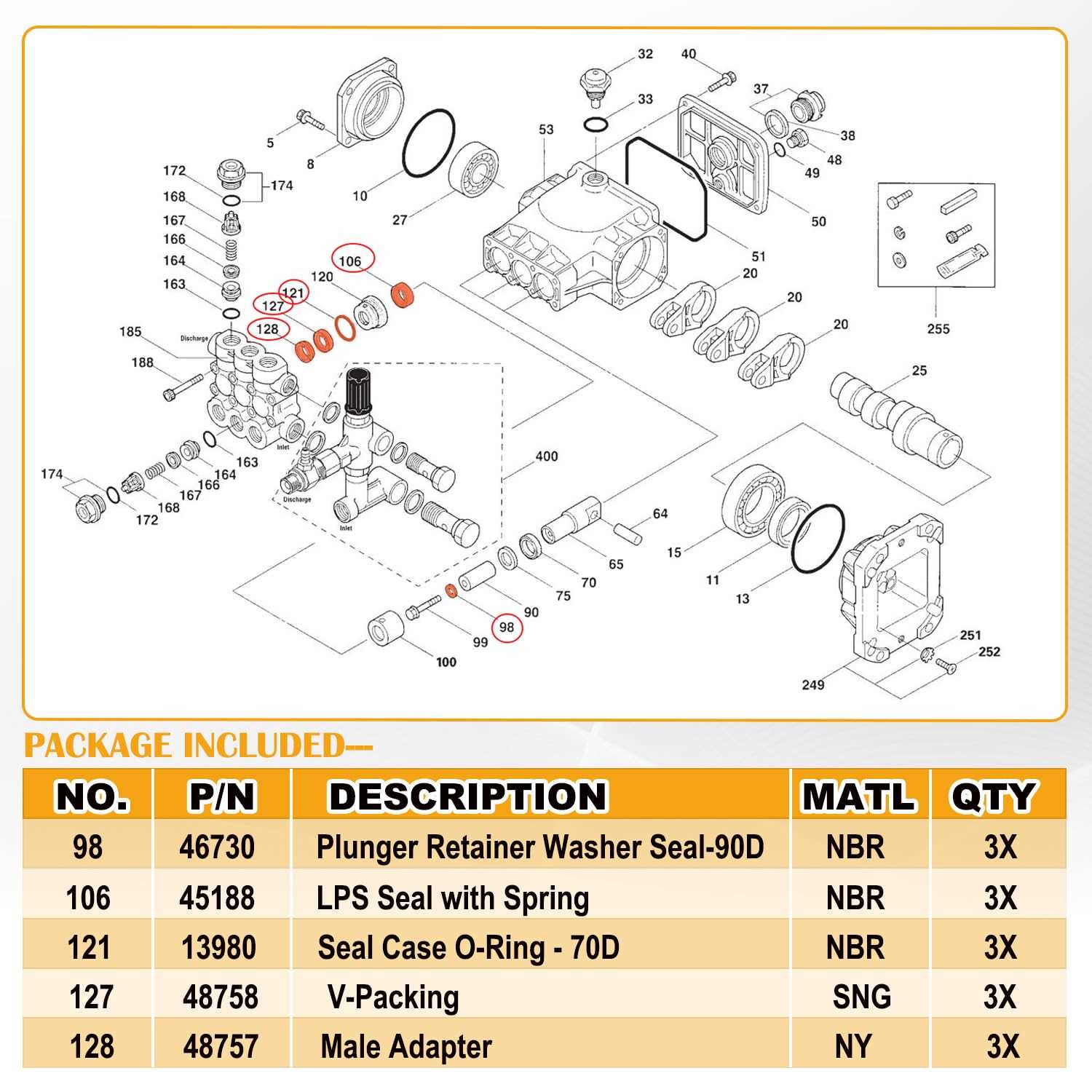

Common Wear and Tear Parts

Over time, various components in equipment exposed to regular use tend to degrade naturally. These elements often require periodic inspection and replacement to ensure smooth operation. Regular maintenance can extend the lifespan of machinery and help avoid unexpected breakdowns. Seals and Gaskets: These are among the most common components that wear down due to constant exposure to water and pressure. Over time, they may crack or lose their flexibility, leading to leaks and inefficiencies. O-rings: These small but essential rubber rings prevent fluid leaks in different connections. With continuous use, they may become brittle or deformed, requiring replacement to maintain proper function. Valves: Over time, internal valves may suffer from erosion or mineral buildup, which affects their ability to regulate flow. Cleaning or replacing them periodically is necessary to keep the system efficient. Nozzles: Frequently in contact with high velocity, nozzles can beco Pump Assembly and Disassembly Guide

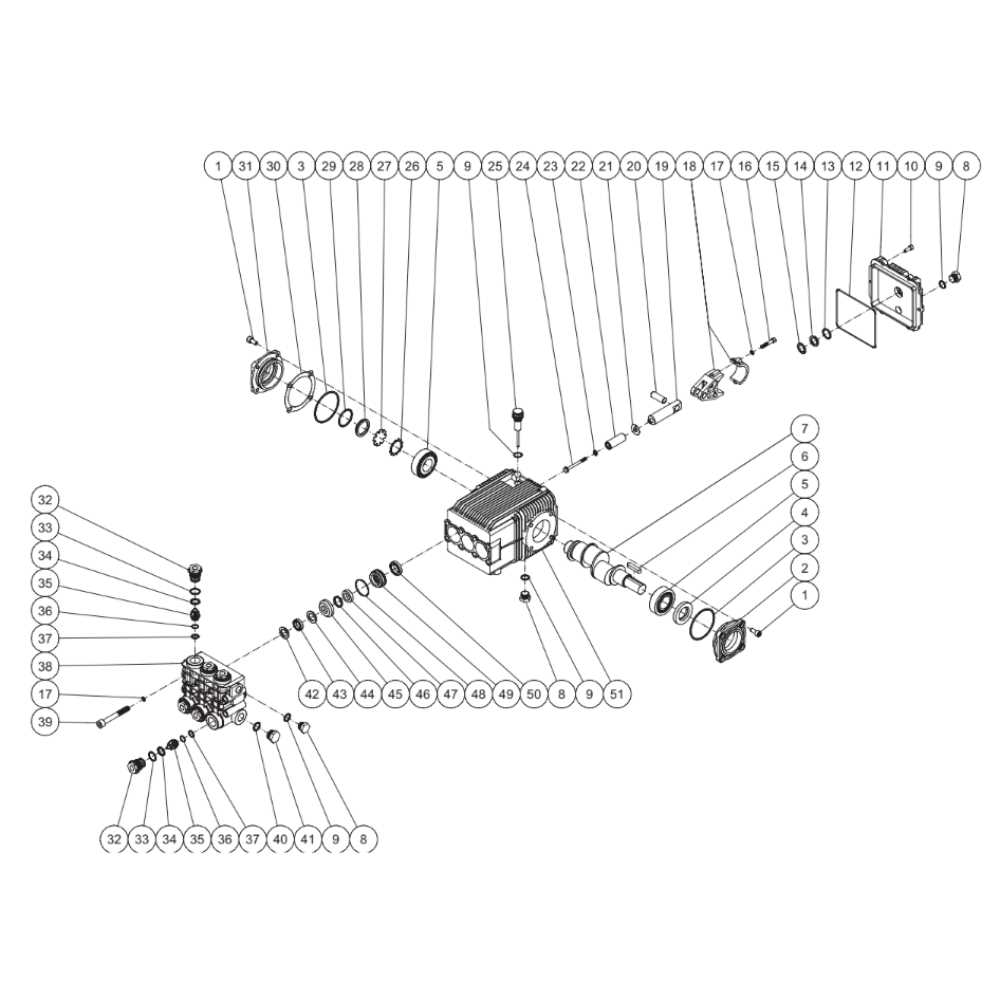

This section provides a comprehensive guide to putting together and taking apart mechanical components. By following the steps outlined, you can ensure that each part is correctly aligned and secured during both the setup and dismantling processes. The instructions are designed to help avoid errors that could lead to performance issues.

|