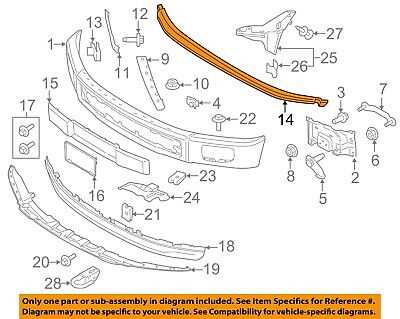

In the realm of heavy-duty vehicles, the integrity and functionality of the frontal structure play a crucial role in overall performance and safety. This section delves into the various elements that constitute the assembly at the front of a robust truck. A comprehensive grasp of these components aids in effective maintenance and repair, ensuring that the vehicle operates smoothly under demanding conditions.

Each element in the frontal assembly serves a specific purpose, contributing to the vehicle’s handling, stability, and aesthetic appeal. Familiarity with these components empowers owners and mechanics alike to identify issues promptly and address them efficiently. Whether considering upgrades or routine inspections, understanding the arrangement and function of these elements is essential for maintaining the reliability and longevity of the truck.

By exploring the configuration and interaction of these crucial components, one can gain valuable insights into the vehicle’s mechanics. This knowledge not only enhances troubleshooting skills but also fosters a deeper appreciation for the engineering that underpins heavy-duty trucks. As we dissect the various elements involved, readers will find a wealth of information aimed at demystifying the complexities of truck assembly.

This section delves into the essential components that comprise the forward assembly of a heavy-duty vehicle. Understanding these elements is crucial for maintenance and repair tasks, ensuring optimal performance and safety on the road. Each component plays a vital role in the vehicle’s handling, stability, and overall functionality.

The assembly typically includes key elements such as:

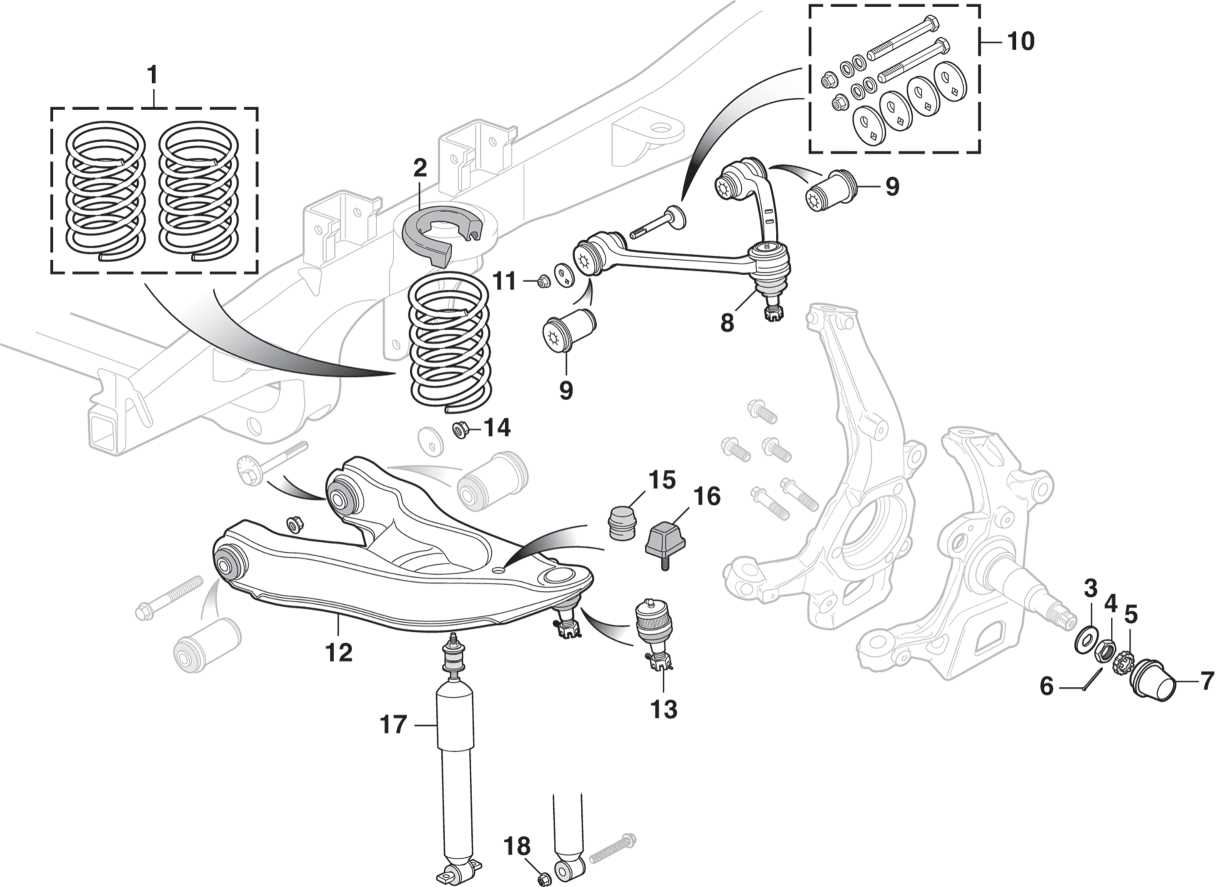

- Suspension system – This system is responsible for absorbing shocks and maintaining ride comfort.

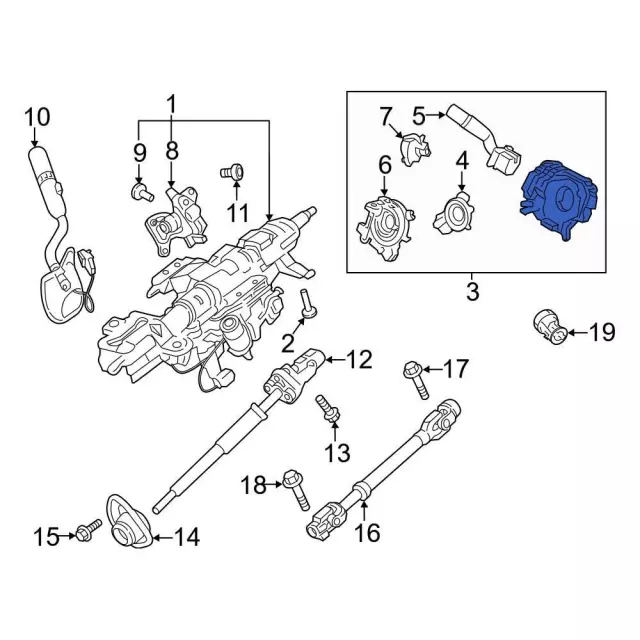

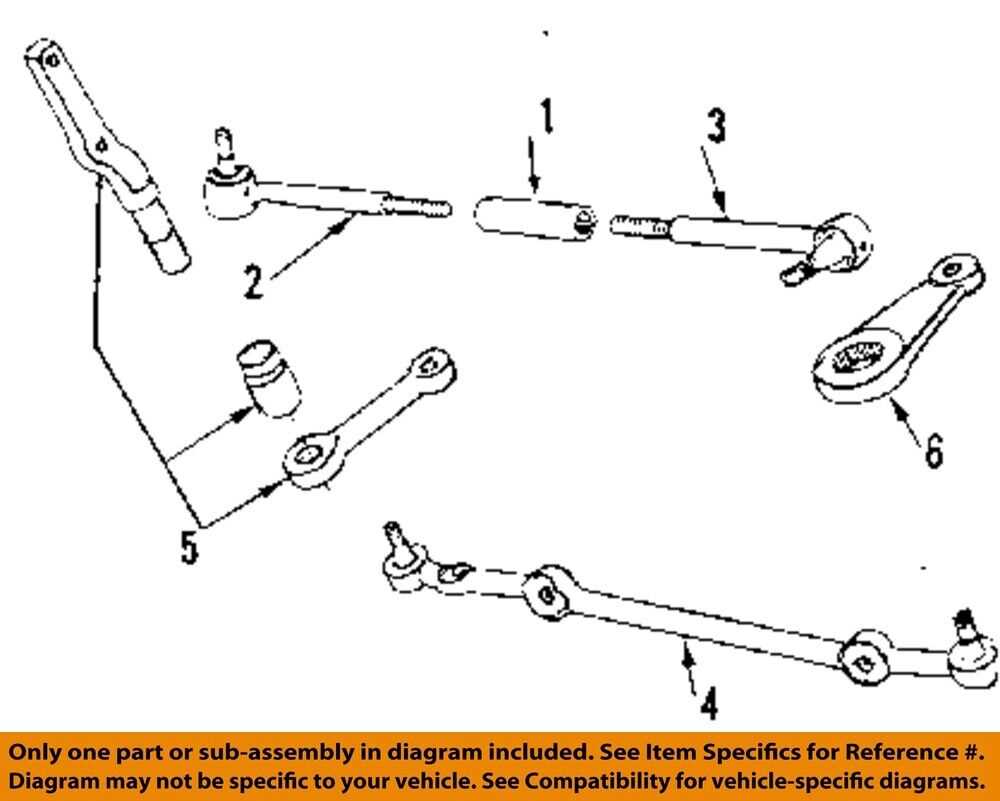

- Steering mechanism – Vital for maneuverability, this system allows for direction changes.

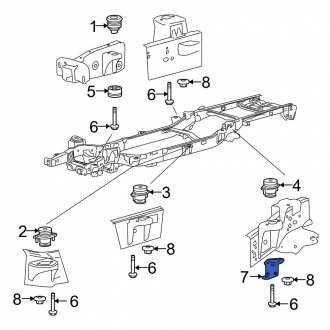

- Frame and crossmembers – Providing structural integrity, these parts support other components.

- Braking system – Essential for stopping power, this system ensures safety during operation.

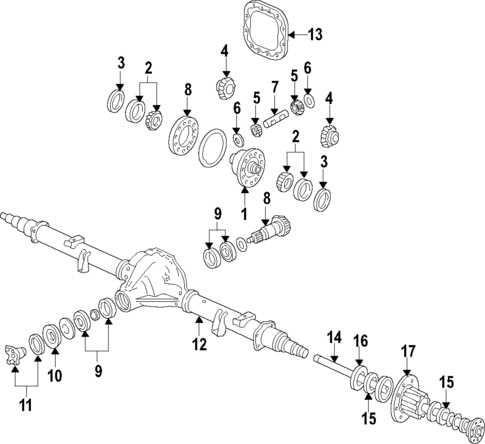

- Alignment components – These parts help maintain proper wheel orientation for efficient driving.

In summary, a comprehensive understanding of these components enhances one’s ability to diagnose issues and implement effective solutions, contributing to the vehicle’s longevity and performance.

Common Issues with Front End Parts

Components located at the front of a vehicle are crucial for both performance and safety. Over time, these elements may experience wear and tear, leading to various challenges that can impact drivability and comfort. Understanding the typical problems associated with these components can help in maintaining optimal functionality and preventing further damage.

One prevalent issue involves misalignment. This can occur due to accidents or normal wear, resulting in uneven tire wear and difficulty steering. Drivers may notice their vehicle pulling to one side or a steering wheel that is off-center.

Another common concern is the deterioration of bushings and ball joints. These elements are responsible for connecting various components, and their failure can lead to a loose feel in the steering system. Symptoms may include clunking noises during turns and a general lack of responsiveness.

Worn-out shock absorbers or struts can significantly affect ride quality. These components are essential for dampening road vibrations, and if they are compromised, drivers might experience a bouncy ride and decreased stability during maneuvers.

Finally, rust and corrosion can pose serious threats to the integrity of essential components. Environmental factors can accelerate this process, leading to structural weaknesses that compromise safety. Regular inspections and timely replacements are vital to mitigate these risks.

Importance of Regular Maintenance

Consistent upkeep of vehicles plays a vital role in ensuring their longevity and optimal performance. Regular checks and timely replacements of essential components can prevent minor issues from escalating into significant problems, ultimately saving time and money in the long run.

Staying proactive with maintenance not only enhances the reliability of the vehicle but also improves safety on the road. Routine inspections help identify wear and tear, ensuring that critical systems operate smoothly and efficiently. This practice also contributes to better fuel efficiency, as well-maintained machines tend to consume less energy.

Additionally, adhering to a maintenance schedule can positively impact resale value. Prospective buyers often favor vehicles with documented service histories, reflecting responsible ownership. By prioritizing regular maintenance, owners can enjoy a smoother driving experience while protecting their investment for the future.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration is essential for maintaining vehicle performance and safety. Regular inspections can help detect issues before they escalate into costly repairs. Look for indicators that suggest components may need attention or replacement.

Visual Inspection: Begin by closely examining the exterior surfaces for any noticeable damage, such as cracks, bends, or corrosion. Pay particular attention to areas that experience frequent movement or stress, as these are more prone to wear.

Unusual Noises: Listen for any strange sounds while driving or when the vehicle is stationary. Grinding, squeaking, or rattling noises can signal that certain elements are experiencing excessive friction or misalignment.

Performance Issues: Notice any changes in handling, steering responsiveness, or ride comfort. A decline in performance may indicate that specific components are no longer functioning as intended, necessitating further investigation.

Fluid Leaks: Check for any signs of leaking fluids under the vehicle. Fluid leaks can indicate a failing seal or gasket, which can lead to more significant problems if not addressed promptly.

Tire Wear: Regularly inspect tire condition and tread depth. Uneven or excessive wear patterns can reveal alignment issues or problems with suspension components that require immediate attention.

Replacement Options for Damaged Parts

When components sustain damage, it’s crucial to explore various alternatives for restoration. Opting for the right replacements can enhance both performance and durability, ensuring a reliable driving experience.

Types of Replacement Solutions

- OEM Components: These are original manufacturer items that match the specifications of the vehicle. They provide the highest quality and fit.

- Aftermarket Alternatives: Various companies produce parts that may offer cost savings while maintaining quality. However, compatibility should be thoroughly verified.

- Rebuilt Parts: Reconditioned components can serve as effective replacements, often available at a fraction of the cost of new ones. It’s essential to assess the warranty and reliability.

Factors to Consider

- Compatibility with the vehicle’s system and other components.

- Quality assurance and warranty provisions from the manufacturer.

- Cost-effectiveness versus long-term reliability and performance.

By evaluating these options carefully, vehicle owners can make informed decisions that ensure safety and efficiency on the road.

Aftermarket vs. OEM Components

When it comes to selecting components for vehicle repairs or enhancements, two primary options arise: original equipment manufacturer (OEM) items and aftermarket alternatives. Each type presents distinct advantages and disadvantages that can significantly influence the overall performance and cost-effectiveness of the vehicle.

OEM offerings are produced by the same manufacturer that made the original components. These parts are designed to meet specific quality standards, ensuring compatibility and performance similar to the initial components. Conversely, aftermarket items are produced by various third-party manufacturers and may vary widely in quality, price, and compatibility.

- Quality Assurance:

- OEM components typically adhere to strict quality control standards.

- Aftermarket products may lack consistent quality, though some brands offer high-quality options.

- Cost:

- OEM parts often come at a higher price point due to their brand recognition and quality assurance.

- Aftermarket options can be more budget-friendly, offering various price ranges for consumers.

- Warranty:

- Most OEM items come with a warranty that guarantees their performance and quality.

- Aftermarket warranties can vary, with some reputable brands offering competitive coverage.

- Availability:

- OEM components may require special ordering, potentially delaying repairs.

- Aftermarket parts are generally more widely available at local retailers and online.

Ultimately, the choice between OEM and aftermarket components depends on individual preferences, budget constraints, and specific needs. Weighing the pros and cons of each option will help vehicle owners make informed decisions that best suit their circumstances.

Tools Required for Installation

When undertaking the installation of various components in a heavy-duty vehicle, having the right tools is crucial for ensuring a smooth and efficient process. Proper equipment not only aids in the installation but also minimizes the risk of damage to both the vehicle and the new components.

Below is a list of essential tools that will facilitate the installation procedure:

- Socket Set: A complete set of sockets will help in loosening and tightening bolts and nuts effectively.

- Wrenches: Both standard and adjustable wrenches are necessary for various fastening tasks.

- Torque Wrench: This tool is essential for applying the correct amount of force to fasteners, preventing over-tightening.

- Pliers: Needle-nose and regular pliers will assist in gripping and bending components as needed.

- Jack and Jack Stands: These are vital for safely lifting the vehicle and securing it while working underneath.

- Screwdrivers: A variety of screwdrivers, including Phillips and flathead, will be useful for different types of screws.

- Hammer: A rubber mallet can help in positioning parts without causing damage.

- Safety Gear: Gloves, goggles, and other protective equipment should be worn to ensure safety during installation.

With these tools on hand, the installation process will be more manageable and efficient, ultimately leading to better results and enhanced vehicle performance.

Step-by-Step Assembly Guide

This section offers a comprehensive overview of the assembly process for the essential components of a specific vehicle model. By following these steps, you can ensure a seamless reconstruction that enhances performance and longevity.

Step 1: Begin by gathering all necessary components and tools to facilitate a smooth assembly experience.

Step 2: Carefully review the installation sequence, as adhering to the correct order is crucial for optimal fit and function.

Step 3: Start by securing the main structural elements. Ensure that all bolts and screws are tightened to the manufacturer’s specifications for safety and reliability.

Step 4: Next, attach the supporting components, verifying alignment and stability as you progress.

Step 5: Once all parts are in place, conduct a thorough inspection. Check for any potential issues or misalignments before finalizing the assembly.

Step 6: Finally, test the assembly to confirm that everything operates as intended, making adjustments as necessary to achieve the ultimate performance.