The intricate design and functionality of modern agricultural machinery hinge on the precise arrangement of various elements. Each component plays a crucial role in the overall efficiency and performance of the equipment, ensuring that it meets the demands of contemporary farming practices.

Familiarity with these components is essential for operators and technicians alike, as it allows for better maintenance, troubleshooting, and optimization of the machinery. By gaining insights into the specific roles and interactions of these parts, users can enhance their understanding and operational capabilities.

Moreover, having access to a detailed illustration of these elements enables users to identify wear and tear, facilitating timely repairs and replacements. This proactive approach not only extends the lifespan of the equipment but also maximizes productivity on the field.

Understanding the critical components represented in technical illustrations is vital for effective maintenance and troubleshooting. These visuals serve as a roadmap, guiding users through the intricacies of machinery and their assemblies. By becoming familiar with these representations, individuals can enhance their ability to identify and replace components when necessary.

When analyzing these illustrations, it is important to focus on the following elements:

- Labels: Each section typically contains clear identifiers that describe the function and purpose of each element.

- Connections: Pay attention to how different components are linked, as this can reveal the flow of operation and interactions between parts.

- Dimensions: Some illustrations provide measurements that can aid in understanding the scale and fit of various components.

In addition to these key aspects, users should be aware of the following strategies to enhance their comprehension:

- Compare with Actual Components: Having physical access to the elements can help in correlating visual representations with real parts.

- Consult Reference Materials: Manuals and guides often accompany technical drawings, providing further context and clarification.

- Practice Regularly: Familiarity increases with experience, making regular review of these visuals beneficial.

By focusing on these crucial elements and employing effective strategies, individuals can improve their proficiency in interpreting technical illustrations, leading to better performance in equipment management.

Common Issues with 630F Parts

When operating agricultural machinery, several challenges may arise concerning components and their functionality. Understanding these common issues can help ensure efficient performance and longevity of the equipment. Regular maintenance and awareness of potential problems are key to optimizing operations.

Wear and Tear of Components

Over time, certain components may experience significant wear, affecting their efficiency and performance. This deterioration can lead to decreased productivity and potential failure during operation. Regular inspection and timely replacement of worn parts are essential to maintaining optimal functionality.

Hydraulic System Malfunctions

Another frequent issue involves the hydraulic system, which is crucial for various functions of the machinery. Leaks or blockages within the hydraulic lines can cause erratic performance and even complete failure. Regular maintenance checks and prompt repairs can help mitigate these issues and ensure smooth operation.

Maintenance Tips for 630F Equipment

Ensuring the longevity and efficiency of agricultural machinery requires regular attention and care. Implementing a systematic maintenance routine can significantly enhance the performance of the equipment, reduce unexpected breakdowns, and extend its operational life.

Firstly, it is essential to perform routine inspections to identify any signs of wear or damage. Check for loose components, frayed belts, and signs of rust or corrosion. Addressing minor issues promptly can prevent them from escalating into more significant problems.

Regularly lubricating moving parts is crucial for maintaining optimal functionality. Use the recommended lubricants and ensure that all joints, bearings, and pivot points are adequately greased. This practice reduces friction and minimizes wear, ultimately enhancing performance.

Additionally, keeping the equipment clean is vital. Dirt and debris can lead to overheating and increased wear on mechanical parts. Schedule periodic cleaning sessions to remove accumulated grime, especially in hard-to-reach areas.

Lastly, always refer to the manufacturer’s guidelines for maintenance schedules and procedures. Following these recommendations will help ensure that the machinery operates efficiently and reliably for years to come.

Upgrading Components for Better Performance

Enhancing the functionality and efficiency of agricultural machinery can significantly impact productivity and longevity. By focusing on improving specific elements, operators can ensure optimal performance under various working conditions. Upgrades can lead to smoother operation, reduced wear and tear, and an overall increase in the effectiveness of the equipment.

Identifying Key Areas for Improvement

Before embarking on any enhancement project, it’s crucial to pinpoint which components will yield the best results. Common areas to consider include:

- Hydraulic systems

- Engine components

- Cutting attachments

- Electrical systems

Benefits of Upgrading Components

Investing in upgraded elements offers several advantages, including:

- Increased Efficiency: New components can improve the overall functionality of the machinery, allowing for faster and more efficient operations.

- Cost Savings: Upgraded systems often lead to lower fuel consumption and reduced maintenance costs over time.

- Enhanced Durability: High-quality replacements tend to withstand wear better, extending the life of the equipment.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be a straightforward process when you know where to look. Numerous sources offer a variety of options to ensure that your equipment remains in optimal working condition. Here are some recommended places to consider when searching for essential items.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers provide genuine components specifically designed for your machine, ensuring compatibility and reliability. |

| Online Marketplaces | Websites like eBay or Amazon often feature a wide range of components from various sellers, making it easy to compare prices and availability. |

| Local Salvage Yards | These facilities can offer used components at a fraction of the cost, perfect for those looking to save money while finding quality parts. |

| Manufacturer’s Website | Visiting the official site can provide access to a full catalog of available items, along with detailed information on each. |

| Specialty Retailers | Shops focusing on agricultural equipment often stock various components and can provide expert advice on your needs. |

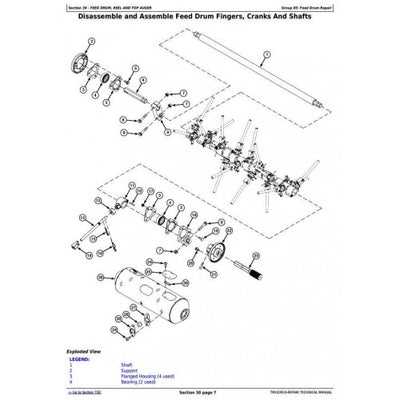

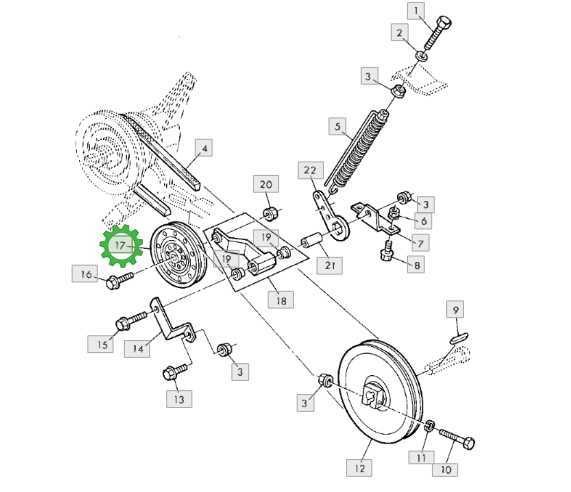

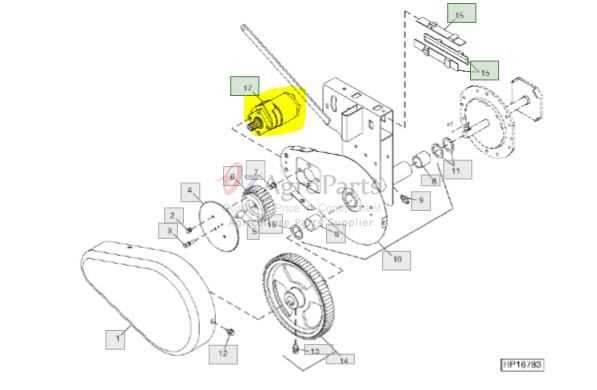

Visual Reference for Assembly Process

Having a visual guide can significantly streamline the assembly process of complex machinery. This section provides an overview of essential components and their arrangement, making it easier for users to follow assembly instructions. Utilizing diagrams can enhance understanding and improve efficiency during the construction of agricultural equipment.

Key Components Overview

- Frames: The foundational structure that supports other elements.

- Cutting Mechanism: The assembly responsible for performing the main task.

- Drive System: Transmits power and enables movement.

- Control System: Provides operators with the ability to manage functionalities.

Assembly Steps

- Begin by aligning the frame with the cutting mechanism.

- Secure the components using the designated fasteners.

- Attach the drive system, ensuring all connections are tight.

- Integrate the control system and check for compatibility.

- Perform a final inspection to ensure everything is assembled correctly.