Understanding the inner workings of professional equipment is crucial for efficient maintenance and repair. In this section, we will explore the various elements that make up these machines, providing a comprehensive view of how each part contributes to their overall functionality. This guide is designed to help you easily navigate through the complexities of mechanical systems.

Proper care and regular maintenance are essential for the longevity of any machinery. By familiarizing yourself with its core components, you’ll be better equipped to handle potential issues before they turn into costly repairs. Whether you’re dealing with routine upkeep or more complex fixes, knowing what to look for can make all the difference.

Each component plays a vital role in ensuring that the equipment runs smoothly. From power mechanisms to smaller moving parts, understanding these details can significantly improve your ability to manage and maintain machinery effectively. In the following sections, we’ll delve into the specifics of various mechanical elements and their functions.

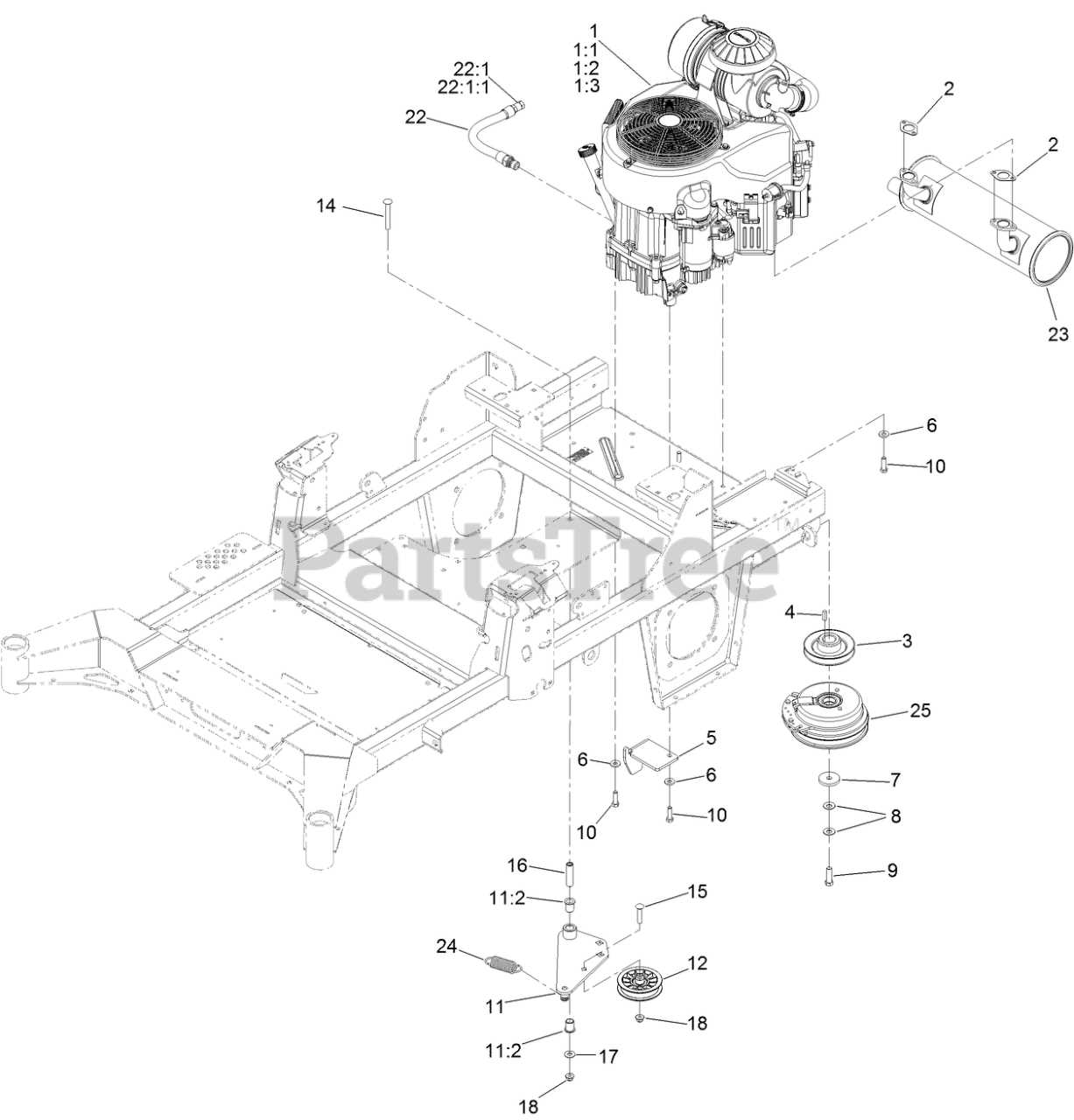

Understanding the Toro Z Master Commercial Parts Layout

The efficient organization of components in heavy-duty mowing equipment is key to its reliable performance. Every element, from the engine to the cutting deck, is strategically positioned to optimize functionality and ensure ease of maintenance. A clear understanding of how these elements are structured enhances both user experience and the machine’s longevity.

Component Groupings for Maximum Efficiency

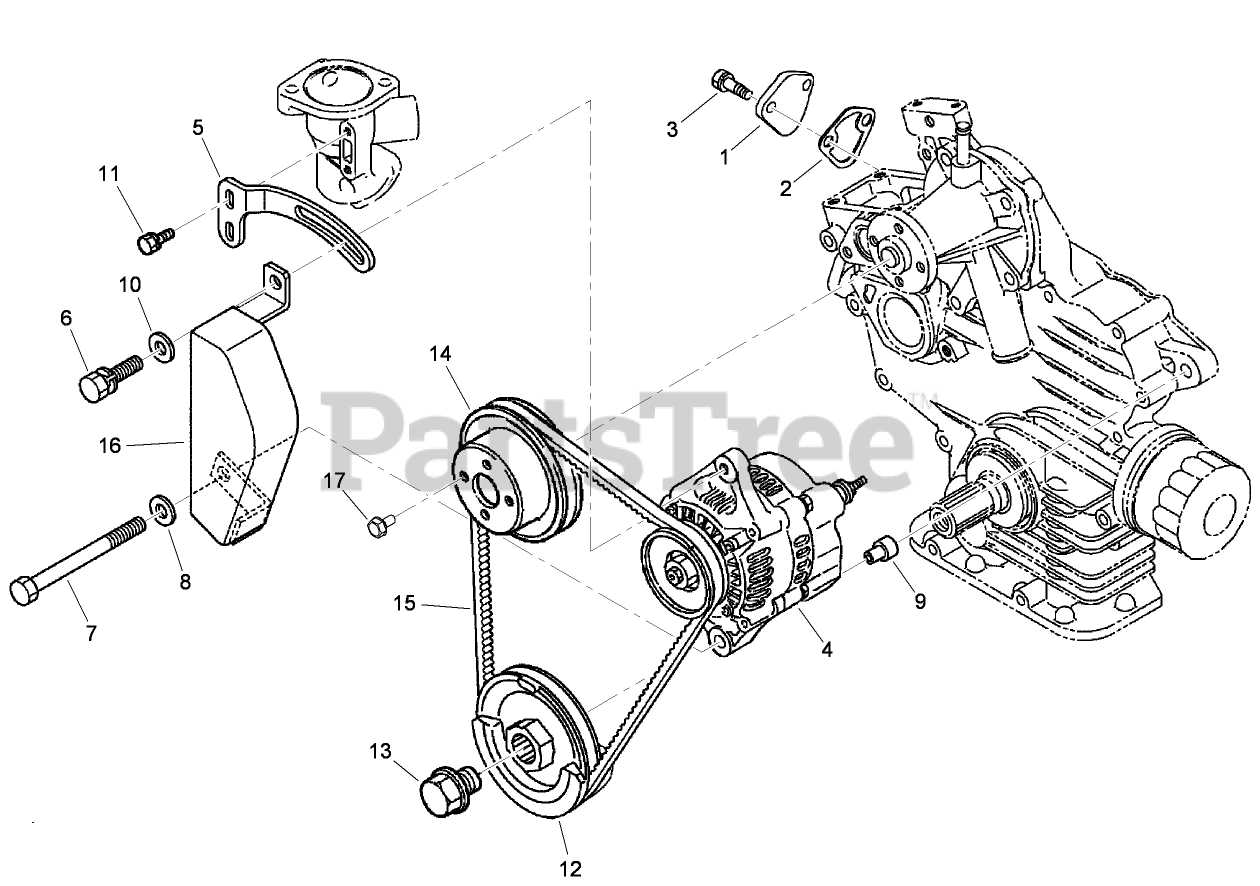

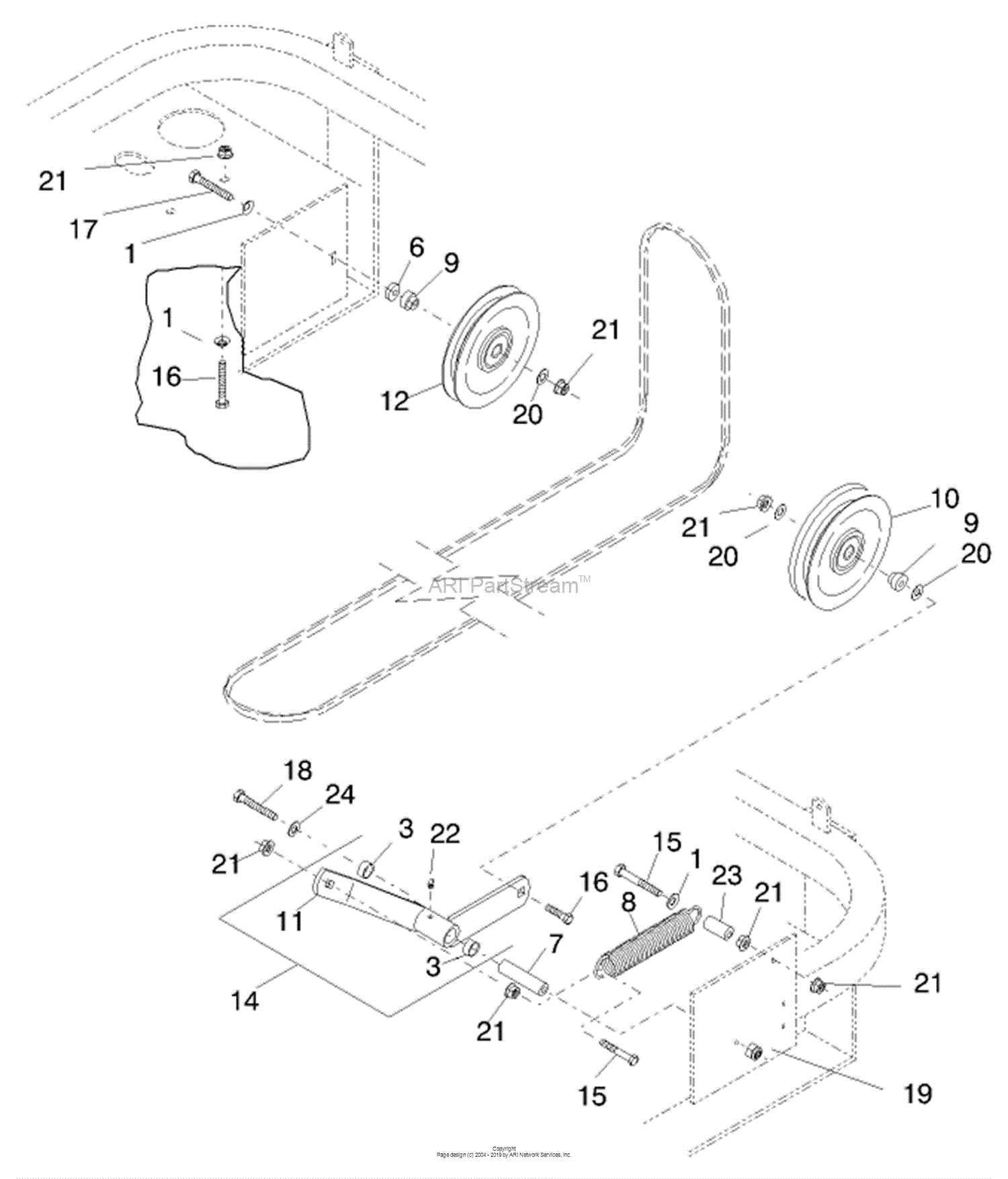

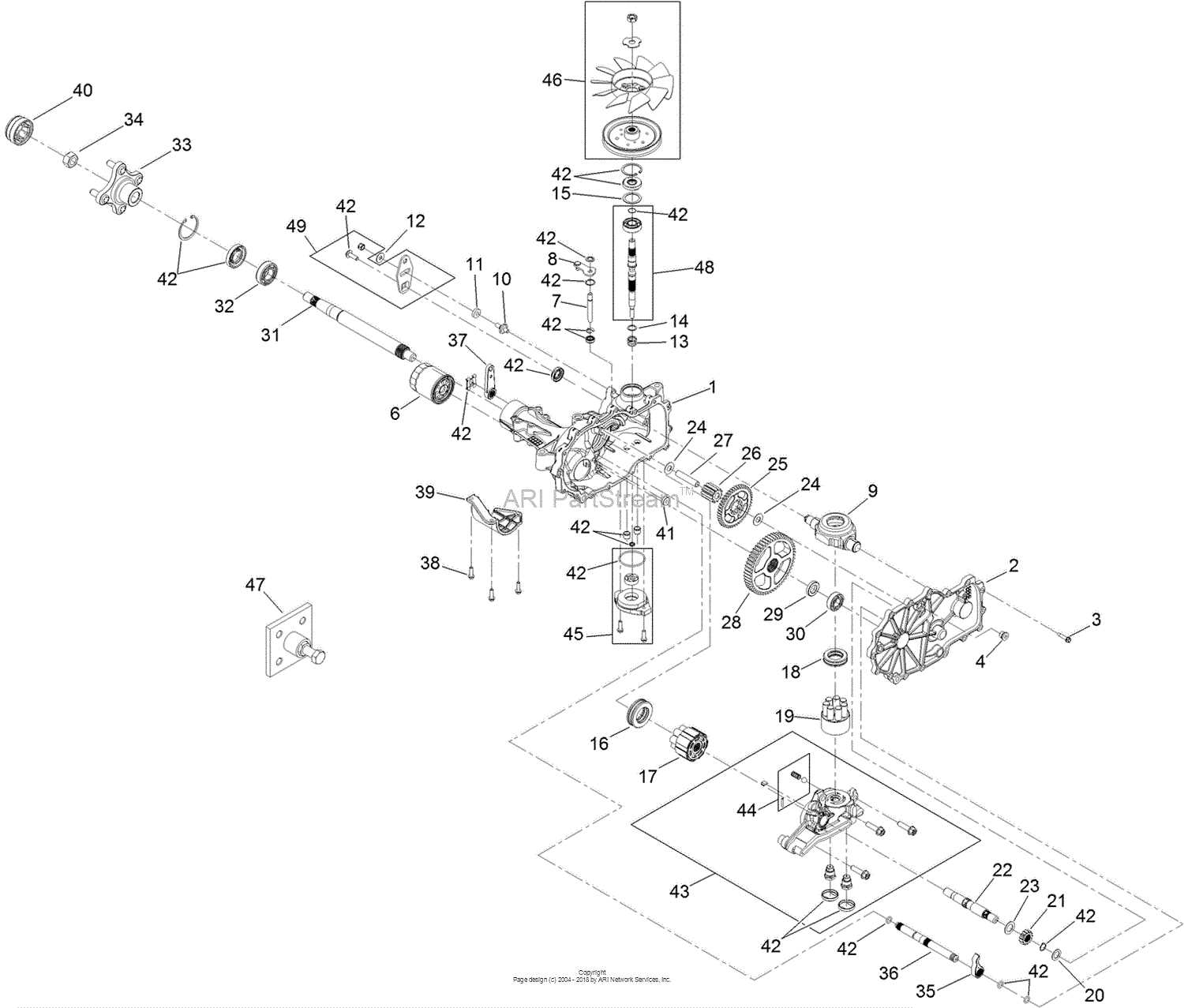

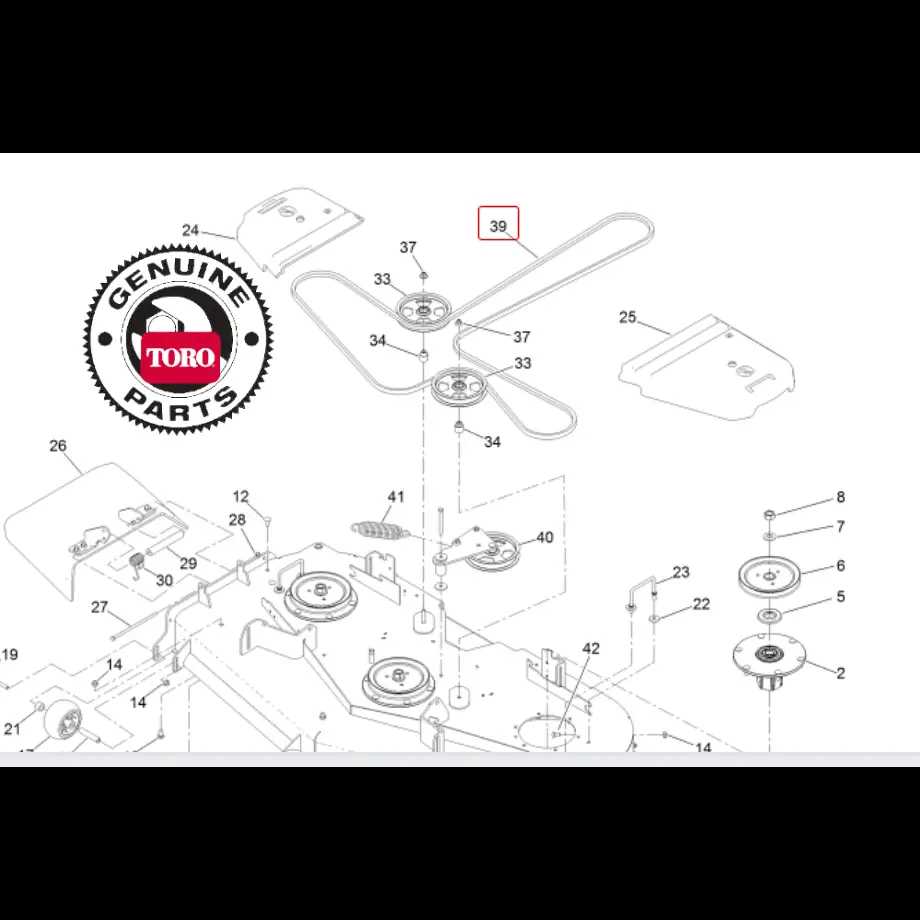

In complex machinery, different assemblies work together to provide a seamless mowing experience. Key sections include the power source, driving mechanisms, and cutting system. Each segment has been designed to not only perform its specific task but also to align with other systems for optimal workflow. By familiarizing yourself with how these assemblies interact, you can troubleshoot and maintain the equipment more effectively.

Critical Zones and Their Functions

Key operational zones of the equipment include the driving system, which handles movement, and the blade assembly, responsible for the cutting action. Additionally, the control mechanisms, ergonomically designed for user comfort, allow precise adjustments. Each zone plays a crucial role in the overall operation,

Key Components of Toro Z Master Mowers

When exploring the machinery designed for large-scale lawn maintenance, understanding the individual elements that work together is essential. Each part of these machines is crafted with precision, ensuring smooth operation and durability across various terrains. The balance between power, agility, and comfort provides efficiency for operators during long hours of use.

Engine System: The power source plays a pivotal role, driving the entire structure forward. Equipped with high-performance engines, these machines ensure consistent power output for cutting even the toughest grass with ease.

Hydraulic Controls: An efficient hydraulic system allows for seamless maneuverability. Operators can control movement effortlessly, enhancing both speed and precision while reducing strain during navigation.

Cutting Deck: The deck beneath the mower ensures an even and clean cut. Designed for optimal grass flow, it helps prevent clogs while maintaining the sharpness and precision needed for a professional finish.

Operator Comfort: The ergonomic design of the seating and control area ensures user comfort. Adjustable seating and intuitive control layouts reduce fatigue, allowing for extended use without compromising productivity.

How to Read Technical Schematics Effectively

Understanding technical schematics can be a critical skill when it comes to maintaining or repairing machinery. These visual representations contain essential details about the components, their relationships, and how they fit together. Knowing how to interpret these drawings efficiently can save time and prevent costly errors.

Break Down the Drawing into Sections

Start by focusing on one part of the schematic at a time. Trying to absorb everything at once can be overwhelming. Identify major assemblies first, then look at the smaller components connected to them.

- Locate the key or legend to understand the symbols and abbreviations used.

- Pay attention to the numbering system to track specific components.

- Follow the lines that indicate connections or mechanical relationships between parts.

Use the Reference Numbers Correctly

Each component is usually labeled with a unique number. These numbers correspond to a list, which provides more details such as the name

Identifying Essential Parts for Maintenance

Regular upkeep of any equipment is crucial to ensure its long-term functionality and efficiency. By knowing the key components that require attention, you can significantly reduce the chances of unexpected breakdowns and costly repairs. Whether you’re conducting routine inspections or preparing for a more in-depth overhaul, understanding which elements need the most care is the foundation of effective maintenance.

Focus on Wear and Tear

Some elements of machinery are prone to gradual deterioration due to constant use. Identifying these areas early on allows for timely replacements, avoiding further damage. Look out for components like belts, filters, and moving joints, as these are often the first to show signs of wear. Monitoring these critical areas helps in preventing larger issues down the line.

Pay Attention to Safety Features

Elements designed to protect the machinery and operators are just as important as functional parts. Regularly inspecting safety mechanisms ensures not only the smooth operation of the equipment but also the well-being

Troubleshooting Common Issues with Toro Z Master

Maintenance and timely repairs are essential to ensure the efficient performance of your mower. Identifying and addressing common problems early can help prolong the machine’s lifespan and avoid costly repairs. Below are some typical challenges that you might encounter, along with practical steps to resolve them.

- Engine Won’t Start

If the mower’s engine fails to start, it could be due to a variety of reasons. First, check the fuel level and ensure the fuel is fresh. A clogged air filter can also prevent the engine from starting. In some cases, the spark plug may need cleaning or replacement.

- Poor Cutting Performance

When the cutting results are uneven, dull blades are often the culprit. Sharpen the blades regularly and check for any debris stuck underneath. Adjusting the cutting height to suit the terrain can also improve the performance.

- Battery Issues

Best Practices for Replacing Toro Mower Parts

Maintaining lawn care equipment is essential for optimal performance and longevity. When it comes time to replace components, following best practices ensures that the process is efficient and effective, resulting in a well-functioning machine. Here are key guidelines to consider during the replacement process.

Preparation Steps

- Gather necessary tools and replacement items before starting the task.

- Consult the user manual for specific instructions related to your equipment model.

- Ensure a clean workspace to avoid losing small components during the replacement.

Replacement Process

- Disconnect the power source to prevent any accidents while working on the machine.

- Carefully remove the worn or damaged component, taking note of how it is installed for easy reassembly.

- Install the new component, ensuring it is securely fitted according to the guidelines.

- Reconnect the power source and test the equipment to verify the new installation works correctly.

Following these best practices will help you maintain your equipment in top condition, ensuring reliable performance and longevity.

Finding the Right Parts for Your Toro Model

Identifying the appropriate components for your equipment is crucial for ensuring optimal performance and longevity. Whether you are performing routine maintenance or repairs, having a clear understanding of the various elements involved will help you make informed decisions. This section aims to guide you in locating the ideal replacements tailored to your specific model.

Understanding Your Equipment

Before searching for suitable replacements, familiarize yourself with the specifications and features of your machine. Knowing the model number and its unique characteristics will streamline the process of finding the necessary replacements. This information is often located on the manufacturer’s label, making it easier to reference while shopping.

Where to Look for Replacements

Numerous resources are available for sourcing quality replacements. Local dealerships often stock genuine components, ensuring compatibility and reliability. Additionally, online retailers provide a broader selection and can be an excellent option for hard-to-find items. Always verify that the selected replacements match your machine’s requirements to avoid any compatibility issues.

In conclusion, investing time in identifying and acquiring the right components can significantly impact the efficiency and lifespan of your equipment. Utilize the available resources and knowledge to make the best choices for your maintenance and repair needs.

Maximizing the Lifespan of Toro Z Master Components

Ensuring the longevity of essential equipment elements is crucial for maintaining efficiency and performance. By implementing proper care and maintenance strategies, users can significantly extend the life of their machinery, reduce downtime, and optimize operational effectiveness. This section explores practical approaches to enhancing the durability of these vital components.

Regular Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Clean components regularly to prevent debris accumulation.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Replace worn or damaged items promptly to avoid further issues.

Operating Conditions and Best Practices

- Use the equipment within recommended parameters to avoid stress.

- Ensure proper storage in a dry, sheltered environment to protect from the elements.

- Train operators on the correct usage to minimize misuse.

- Monitor performance regularly to detect potential problems early.

By adhering to these guidelines, users can maximize the functionality and lifespan of their equipment elements, leading to enhanced productivity and reduced operational costs.

Where to Find Reliable Toro Parts Diagrams

When it comes to maintaining and repairing outdoor equipment, having access to accurate visual representations of components is essential. These illustrations serve as valuable resources for understanding the assembly and functionality of various tools. Whether you’re a professional technician or a DIY enthusiast, knowing where to locate trustworthy sources for these resources can save you time and ensure effective repairs.

Online Resources

The internet offers a wealth of information, making it easier than ever to find detailed visuals of machinery components. Numerous websites specialize in providing comprehensive guides and illustrations, often accompanied by user reviews to gauge their reliability. Look for sites that offer customer support or have a community forum where users share their experiences and tips.

Authorized Dealers and Service Centers

Visiting an authorized dealer or service center is another effective way to obtain accurate information. These locations typically have access to official documentation and can provide you with the most up-to-date visuals available. Additionally, staff members are often knowledgeable and can assist you in understanding the specifics of the equipment you are working with.

Source Type Benefits Examples Online Resource Wide variety of illustrations and user reviews Parts websites, forums Authorized Dealers Official documentation and expert assistance Local dealerships, service centers M