When it comes to maintaining your outdoor machinery, having a clear understanding of its assembly is crucial. This guide delves into the intricate layout of components, providing a visual representation that can aid in repairs and enhancements. By grasping how each part interacts, you can ensure your equipment runs smoothly and efficiently.

The visual representation serves as an invaluable resource for both novices and experienced users alike. It allows you to identify specific elements quickly, making troubleshooting more straightforward. Whether you are replacing worn-out pieces or performing routine maintenance, knowing the arrangement of components can significantly streamline the process.

In this section, we will explore various elements that contribute to the overall functionality of your machinery. From drive systems to control mechanisms, each part plays a vital role in performance. By familiarizing yourself with these components, you empower yourself to take better care of your equipment and prolong its lifespan.

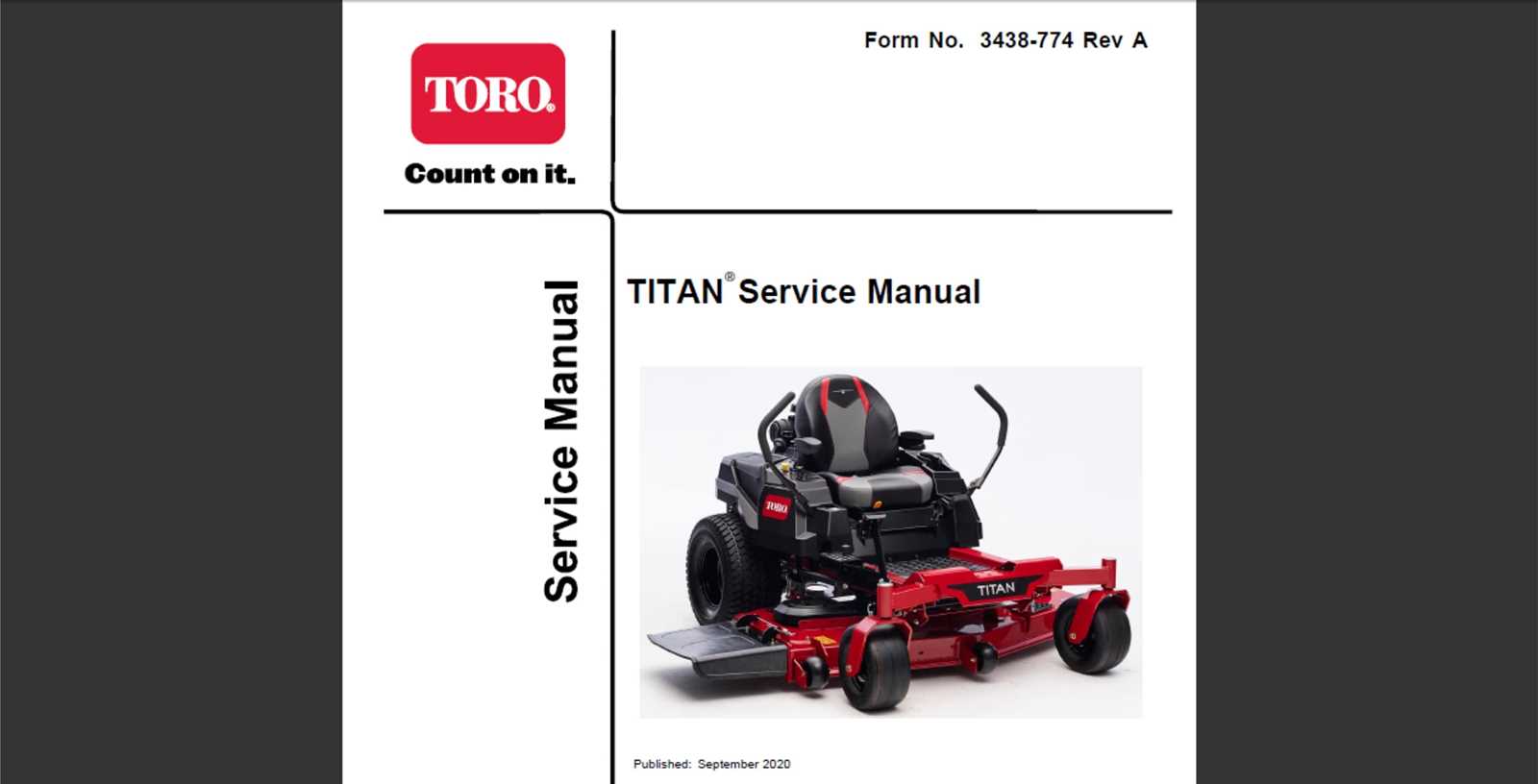

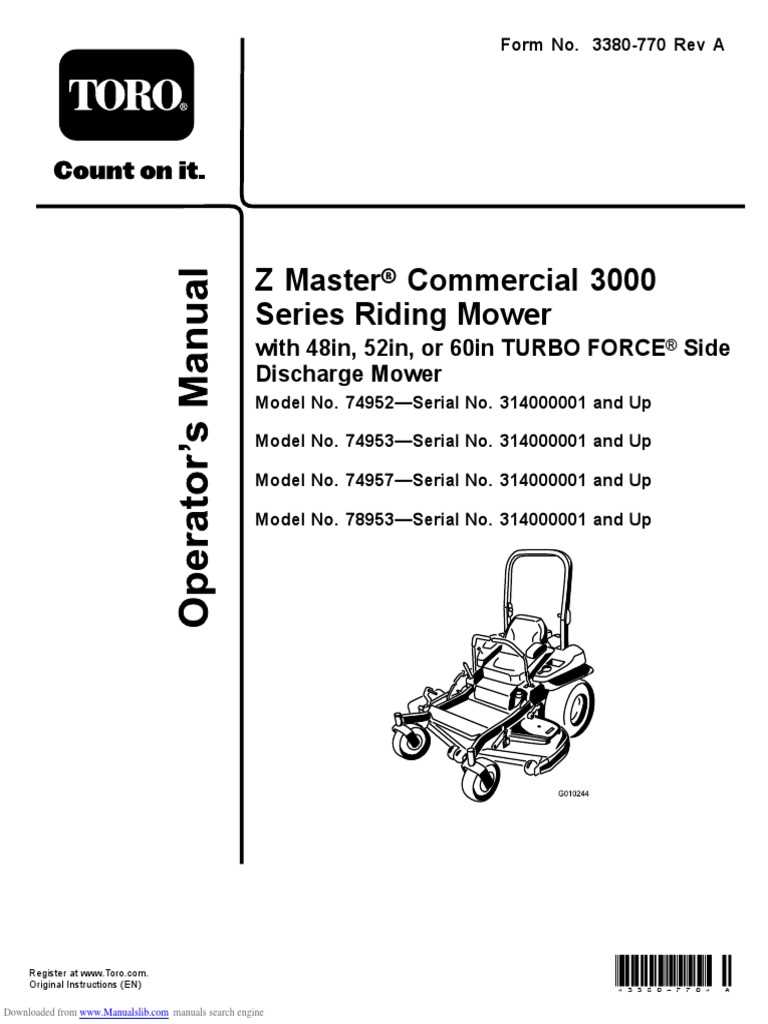

Toro Z Master 3000 Overview

This section provides an insight into a powerful piece of equipment designed for efficiency and precision in landscaping and maintenance tasks. With its robust build and advanced features, this machine is tailored for both professionals and enthusiasts who demand reliability and performance.

Engineered for Excellence: The unit boasts a high-performance engine that ensures optimal power delivery while maintaining fuel efficiency. Its innovative design allows for seamless operation across various terrains, making it ideal for a range of outdoor projects.

Ergonomics and Comfort: Comfort is key in extended work sessions, and this model features an ergonomic seat and controls that enhance user experience. Operators can navigate with ease, ensuring that tasks are completed efficiently without unnecessary strain.

Cutting Edge Technology: Equipped with state-of-the-art technology, this machine offers precise cutting capabilities. Users can easily adjust settings to achieve the desired finish, making it suitable for both fine and rough cuts.

Durability and Maintenance: Built to withstand the rigors of daily use, this equipment is made from high-quality materials that promise longevity. Routine maintenance is straightforward, allowing users to keep their machine in peak condition with minimal effort.

Key Features of the Toro Z Master

This segment highlights the essential characteristics that make this mowing machine a preferred choice among professionals and enthusiasts alike. Its design and functionality ensure efficiency and durability, catering to various landscaping needs.

- Powerful Engine: Equipped with a robust engine, it delivers exceptional performance for extensive mowing tasks.

- Efficient Cutting System: The advanced cutting technology ensures a clean and even cut, enhancing the overall appearance of the lawn.

- Ergonomic Design: The user-friendly interface and comfortable seating allow for prolonged use without fatigue.

- Durability: Constructed with high-quality materials, this machine withstands rigorous conditions and offers longevity.

- Versatile Attachments: Compatibility with various accessories enhances functionality for different tasks, from mowing to maintenance.

- Fuel Efficiency: Designed for optimal fuel consumption, it minimizes running costs while maximizing productivity.

- Easy Maintenance: Simple access to critical components facilitates quick service and upkeep, ensuring reliability over time.

Overall, the combination of power, efficiency, and user-focused design makes this machine an indispensable tool for any landscaping professional.

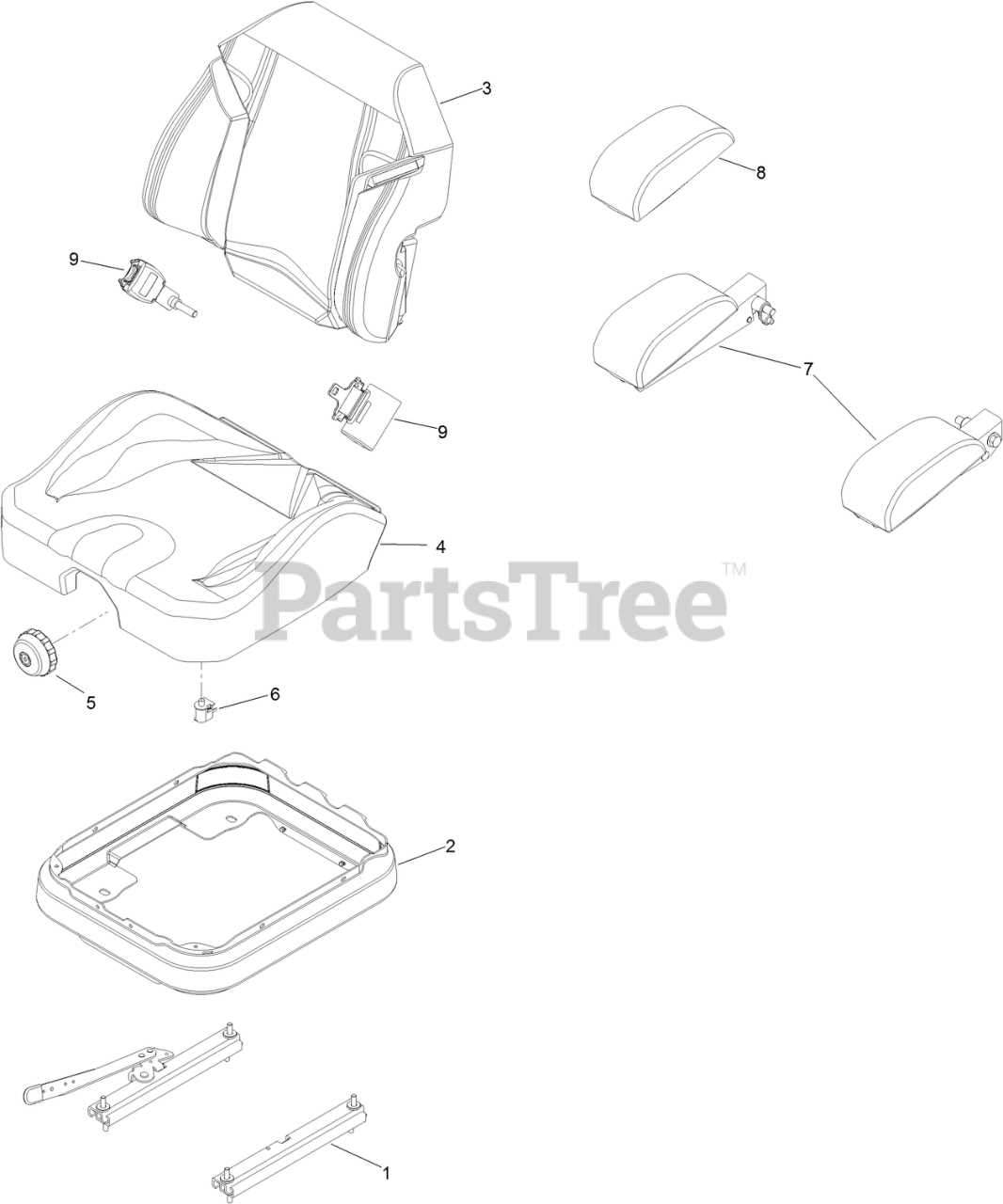

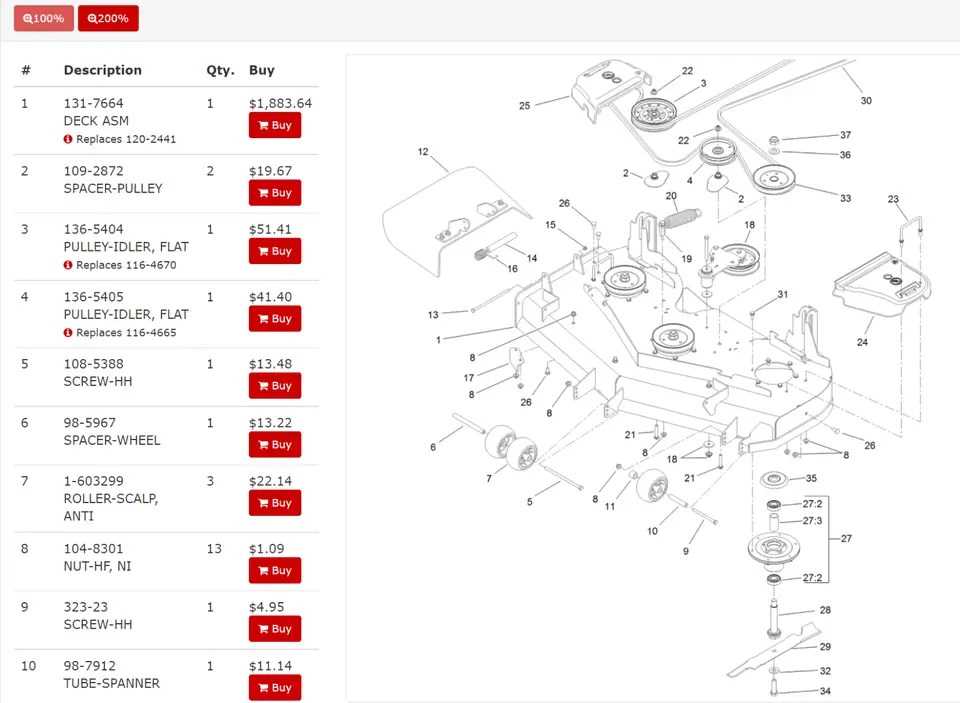

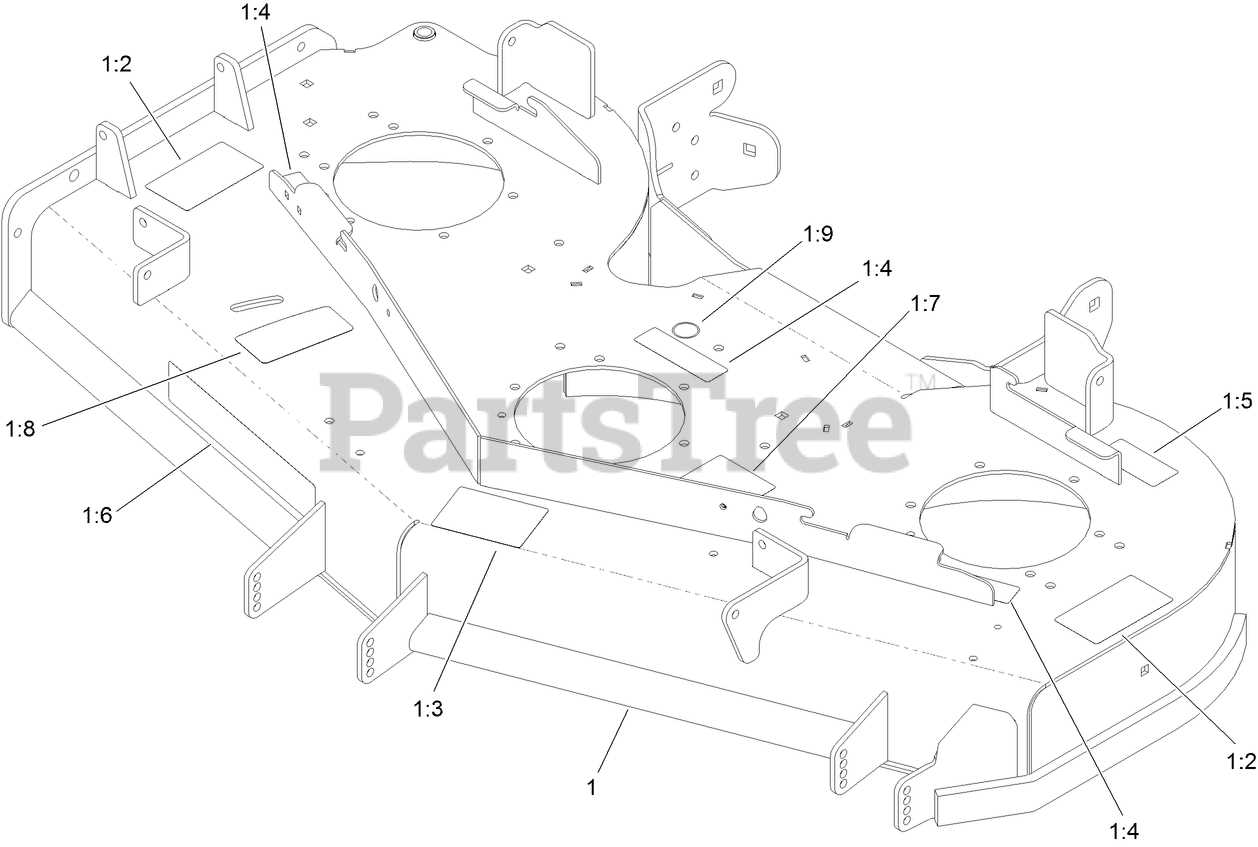

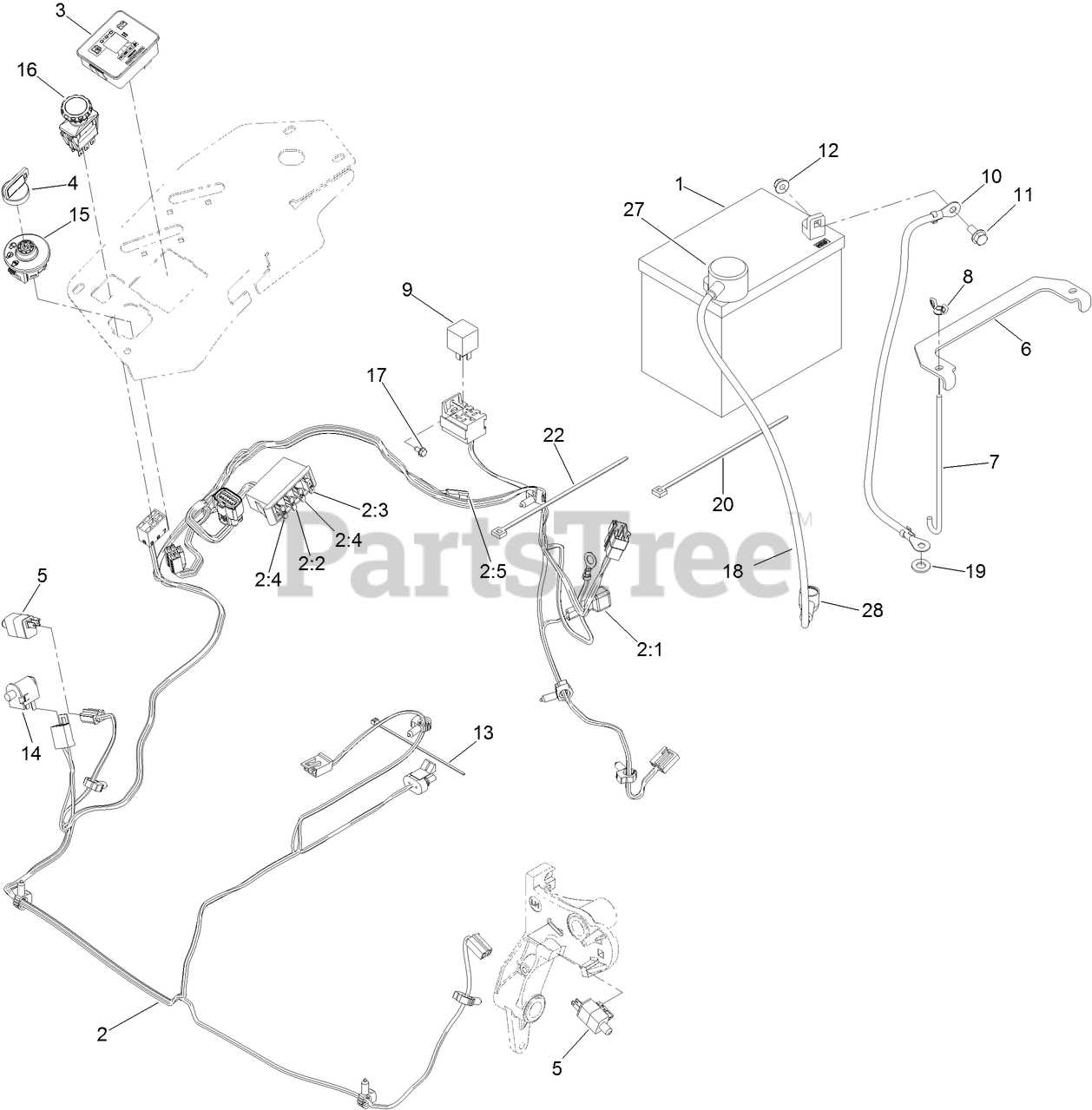

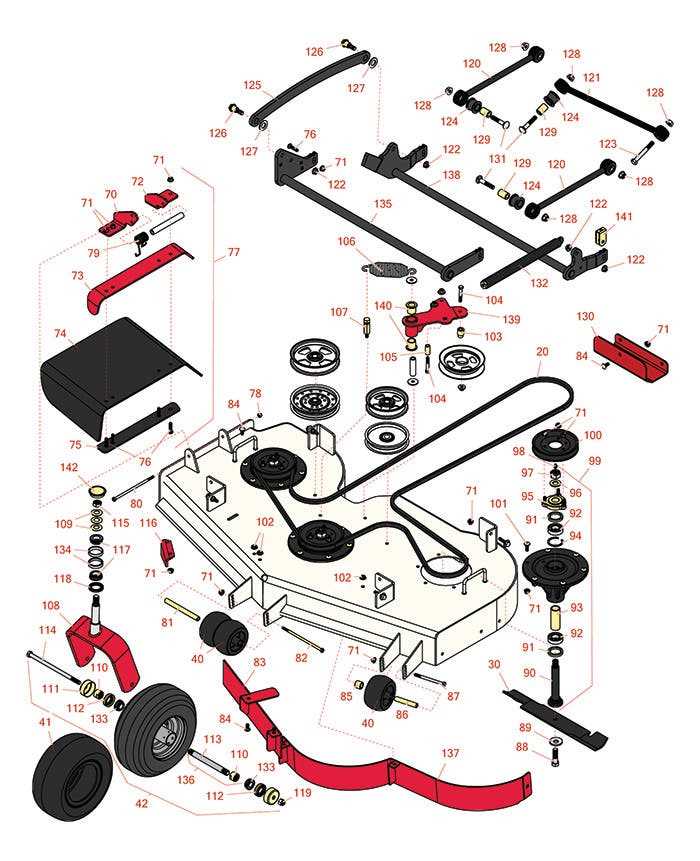

Understanding Parts Diagrams

Exploring visual representations of components is crucial for effective maintenance and repairs. These illustrations serve as essential tools for identifying individual elements, their arrangements, and how they interact within a larger system. By mastering these visuals, users can enhance their troubleshooting skills and streamline the repair process.

Importance of Visual Aids

Visual aids play a significant role in simplifying complex assemblies. They allow users to easily locate specific components and understand their functions. Moreover, these representations often include labels and part numbers, which facilitate ordering replacements and ensure accurate installations. Emphasizing clarity, such aids minimize confusion during repairs.

Reading and Interpreting Illustrations

To effectively utilize these visual guides, one must develop the ability to read and interpret them accurately. This involves understanding symbols, color codes, and reference numbers, all of which contribute to a comprehensive understanding of the assembly. Familiarity with these elements empowers individuals to approach repairs with confidence, ensuring they can address issues promptly and efficiently.

Importance of Parts Identification

Recognizing and understanding the components of machinery is crucial for effective maintenance and repair. Each element plays a specific role in the overall functionality, and knowing these roles helps in diagnosing issues and ensuring optimal performance. Accurate identification leads to more efficient troubleshooting, reducing downtime and enhancing productivity.

Furthermore, familiarity with individual components facilitates better communication with suppliers and service professionals. When discussing replacements or upgrades, precise terminology allows for clearer conversations and more effective solutions. This knowledge is especially vital for those involved in managing equipment, as it enables informed decision-making regarding repairs and replacements.

In addition, being well-versed in the various elements contributes to safety. Understanding how each part interacts with others can prevent accidents and promote a safer working environment. Ultimately, the ability to identify and comprehend the significance of each component is essential for maintaining the longevity and reliability of machinery.

Common Parts for Toro Z Master

In the realm of commercial lawn care equipment, certain components are essential for optimal performance and longevity. Understanding these key elements can significantly enhance the efficiency of your machine and ensure that it runs smoothly throughout its operational life.

- Blades: High-quality cutting edges are vital for achieving a clean and even cut. Regular maintenance or replacement is necessary to maintain performance.

- Filters: Air and oil filtration systems are crucial for preventing debris and contaminants from entering the engine, thus extending its lifespan.

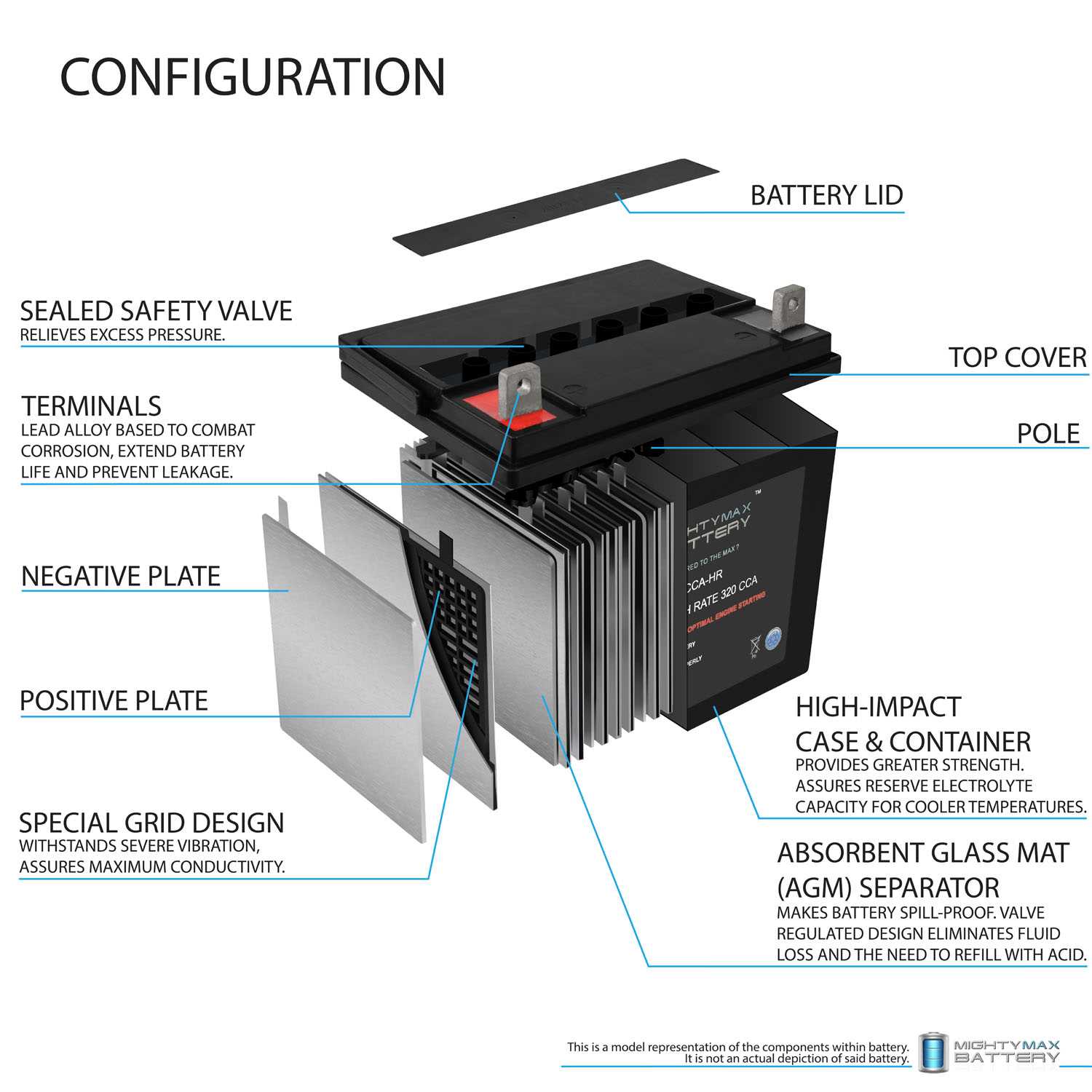

- Batteries: Reliable power sources are essential for starting and operating the equipment, and selecting the right type can enhance performance.

- Belts: Drive and deck belts transfer power effectively, and regular inspection is important to avoid breakdowns.

- Wheels: Durable tires and casters ensure stability and maneuverability on various terrains.

Each of these components plays a significant role in maintaining the overall functionality of your equipment, ensuring that it meets the demands of professional landscaping tasks.

How to Access Parts Diagrams

Gaining insight into the components of your equipment can greatly enhance maintenance and repair efforts. Understanding how to find these visual guides is essential for efficient service and longevity of machinery. Here are steps to help you navigate through the necessary resources.

Online Resources

Many manufacturers provide comprehensive online databases that house visual schematics. Accessing these sites is usually straightforward:

| Step | Description |

|---|---|

| 1 | Visit the official website of the manufacturer. |

| 2 | Navigate to the support or service section. |

| 3 | Look for a link to schematics or technical resources. |

| 4 | Enter your model information to retrieve relevant visuals. |

Utilizing Manuals

Another effective method is referring to user manuals. These often include detailed illustrations and can be found either physically or in digital format:

| Step | Description |

|---|---|

| 1 | Check the product packaging for a manual. |

| 2 | Search for downloadable versions on the manufacturer’s website. |

| 3 | Contact customer support if the manual is not available. |

Replacement Parts Options

When it comes to maintaining your equipment, exploring available alternatives is crucial for optimal performance. Various solutions can be found to ensure your machinery operates efficiently, reducing downtime and enhancing longevity. Understanding the types of replacements on the market can aid in making informed decisions for repairs or upgrades.

| Type of Replacement | Description | Benefits |

|---|---|---|

| OEM Components | Original equipment manufactured items designed specifically for your model. | Guaranteed compatibility and quality. |

| Aftermarket Alternatives | Third-party products that can serve as substitutes for original components. | Often more affordable with a variety of options. |

| Refurbished Units | Previously used items that have been restored to good working condition. | Cost-effective choice with reliable performance. |

| Custom Solutions | Tailored components designed to meet specific needs or modifications. | Perfect for unique requirements or enhancements. |

By assessing these options, you can select the most suitable replacements for your needs, ensuring your equipment remains functional and efficient for years to come.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By implementing a routine maintenance schedule, you can prevent potential issues and extend the lifespan of your machine. Simple practices can make a significant difference in performance and efficiency.

Regular Inspections

Conduct frequent assessments to identify wear and tear. Pay special attention to critical components and replace them as needed. This proactive approach helps mitigate serious malfunctions and keeps your device operating smoothly.

Proper Cleaning

Maintain a clean environment for your equipment. Dust and debris can accumulate, leading to overheating or damage. Use appropriate cleaning agents and tools to ensure all surfaces are clear, allowing for optimal function and safety.