In the realm of garden maintenance, a thorough comprehension of machinery elements is essential for optimal performance. This knowledge not only enhances the efficiency of the equipment but also extends its lifespan. By delving into the intricate details of each component, users can ensure that their tools operate smoothly and effectively.

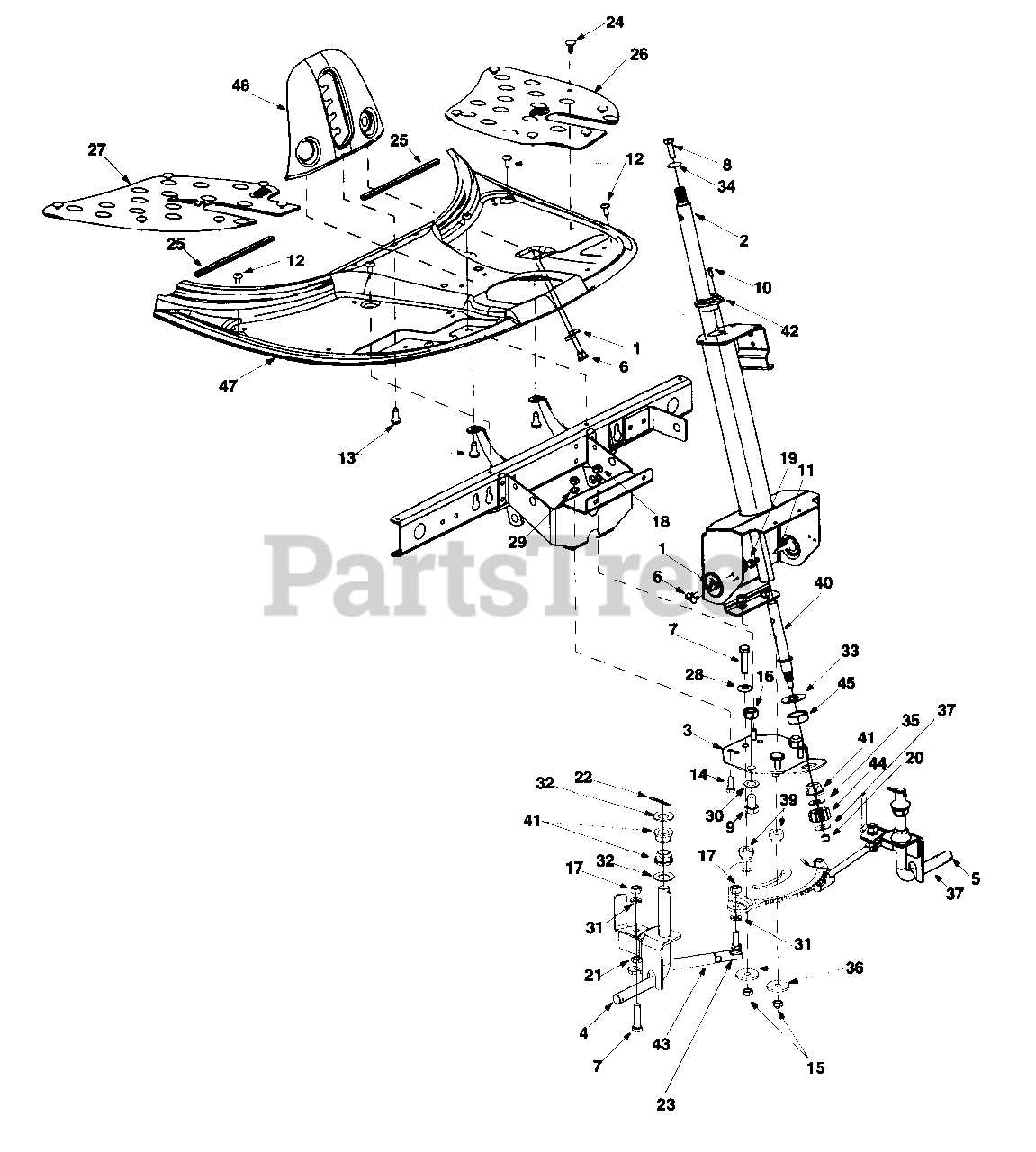

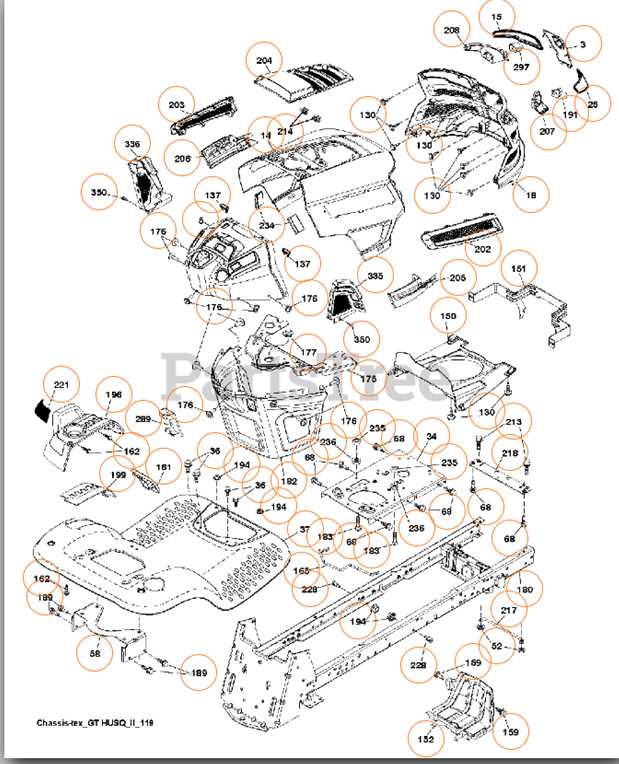

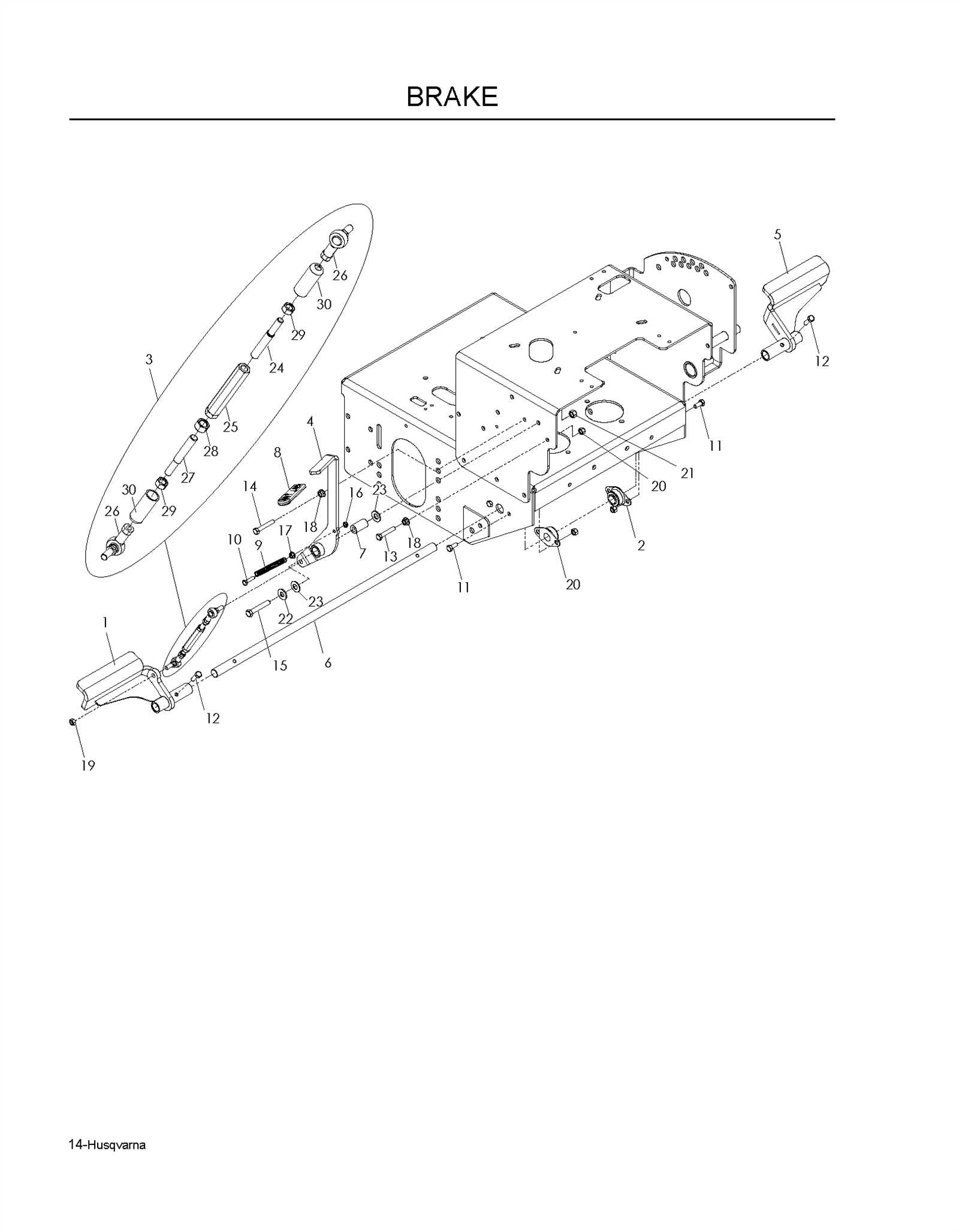

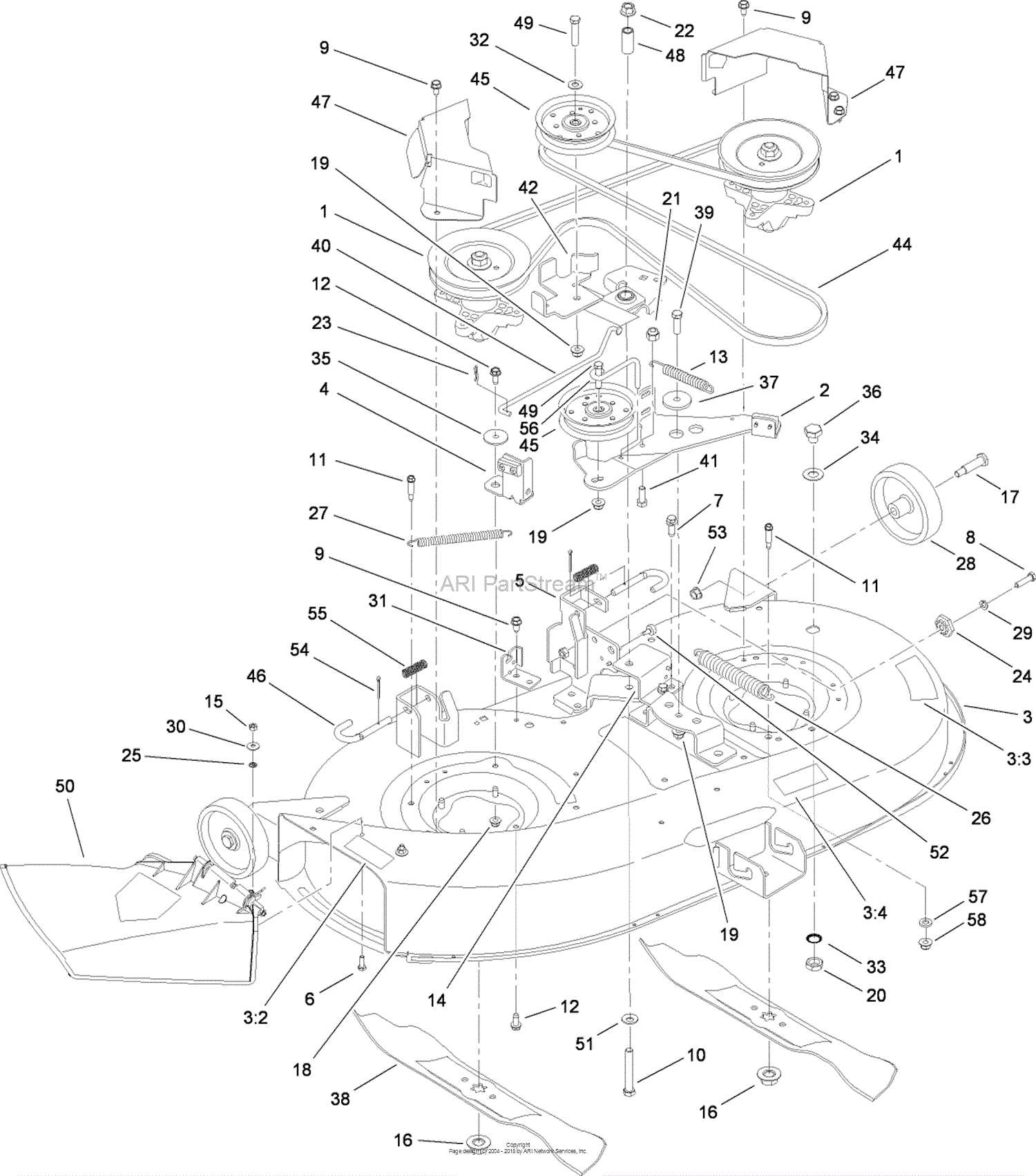

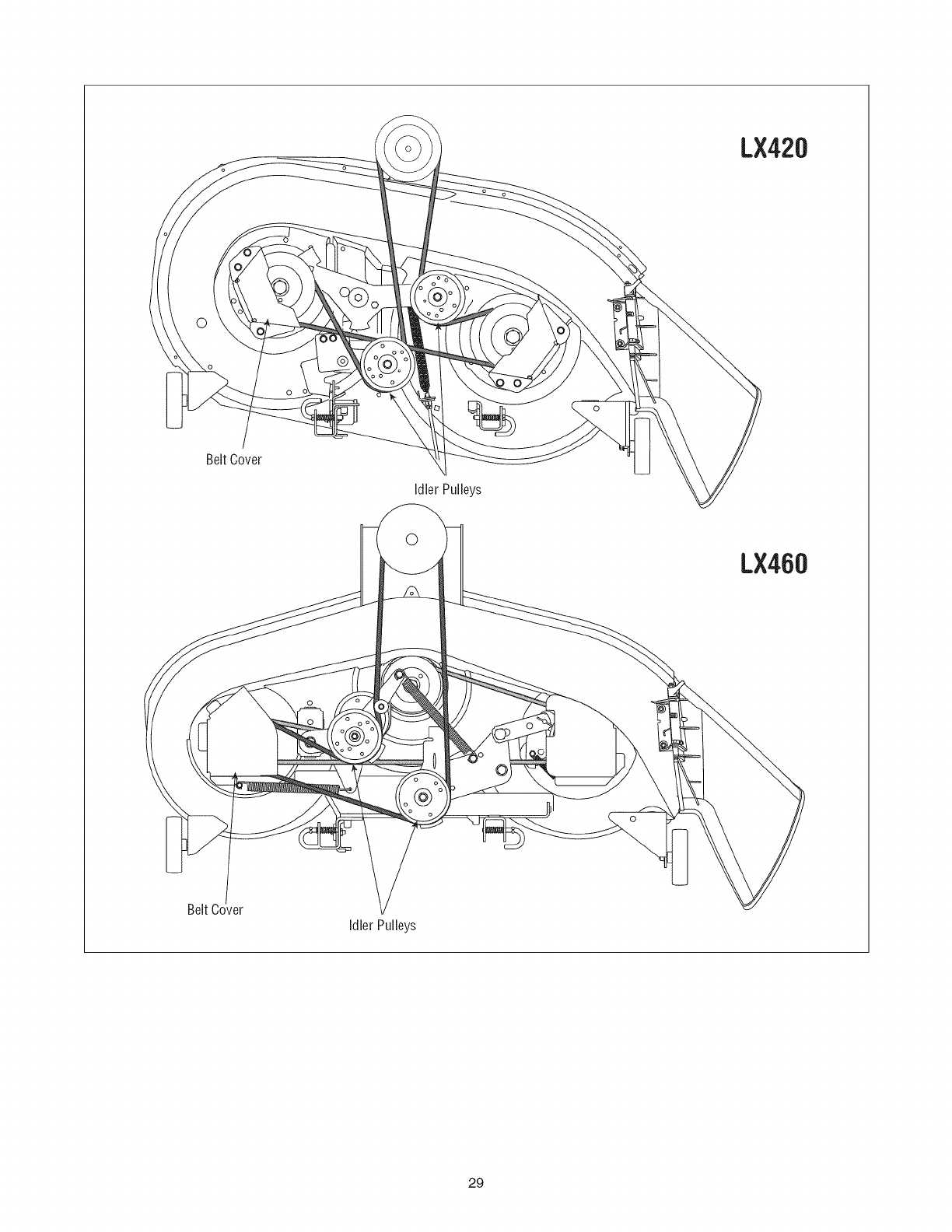

Visual representations of these mechanical assemblies play a critical role in identifying individual pieces and their functions. Such illustrations simplify the process of repairs and replacements, allowing users to navigate their equipment with confidence. Recognizing how each element fits into the overall system can transform the user experience, making maintenance more accessible and less daunting.

For those who engage in regular upkeep of their landscaping tools, having a clear understanding of each section’s role is invaluable. Whether tackling routine servicing or addressing unexpected malfunctions, familiarity with the internal structures is key. This guide aims to illuminate the various parts and their interconnections, empowering users to maintain their devices with precision.

Understanding Toro LX420 Parts

Grasping the intricacies of a lawn maintenance machine is essential for efficient operation and upkeep. Each component plays a critical role, contributing to the overall performance and longevity of the equipment. Recognizing these elements allows users to make informed decisions regarding maintenance, upgrades, and repairs.

Key Components

Essential elements include the engine, transmission, and cutting mechanism. Understanding how these parts interact enhances operational efficiency and ensures a smooth mowing experience.

Maintenance Tips

Regular inspections and timely replacements of worn components are vital. Establishing a routine maintenance schedule can prevent costly breakdowns and extend the lifespan of your equipment.

Key Components of Toro LX420 Lawn Mower

When maintaining a lawn mower, understanding its core elements is essential for proper care and performance. Each component plays a specific role in ensuring smooth operation, durability, and efficiency. Knowing how these parts interact can help in troubleshooting, repair, and routine maintenance. Below, we’ll explore the primary elements that make up this machine.

Engine and Power System

The engine serves as the heart of the mower, providing the necessary power for cutting grass and driving the wheels. It’s crucial to keep the engine in optimal condition by changing the oil regularly, cleaning the air filter, and ensuring the spark plug is functioning. Additionally, the fuel system, including the fuel tank and carburetor, works alongside the engine to supply and regulate power.

- Engine: Powers the machine and drives the cutting blades.

- Fuel System: Includes components like the fuel tank, fuel lines, and carburetor.

- Spark Plug: Ignites the fuel-air mixture to start the engine.

Cutting Mechanism and Deck

The cutting system is responsible for trimming grass evenly and efficiently. It consists of a rotating blade housed within a protective deck. The deck is designed to house the blade and ensure safe operation while also providing a pathway for grass to exit the mower. Regular cleaning and inspection of the deck help prevent clogging and ensure that the blades cut efficiently.

- Cutting Blade: Rotates to cut grass to the desired height.

- Deck: The outer casing that protects the cutting blade and directs clippings.

- Height Adjustment: Mechanism to set the desired grass length.

Transmission and Wheels

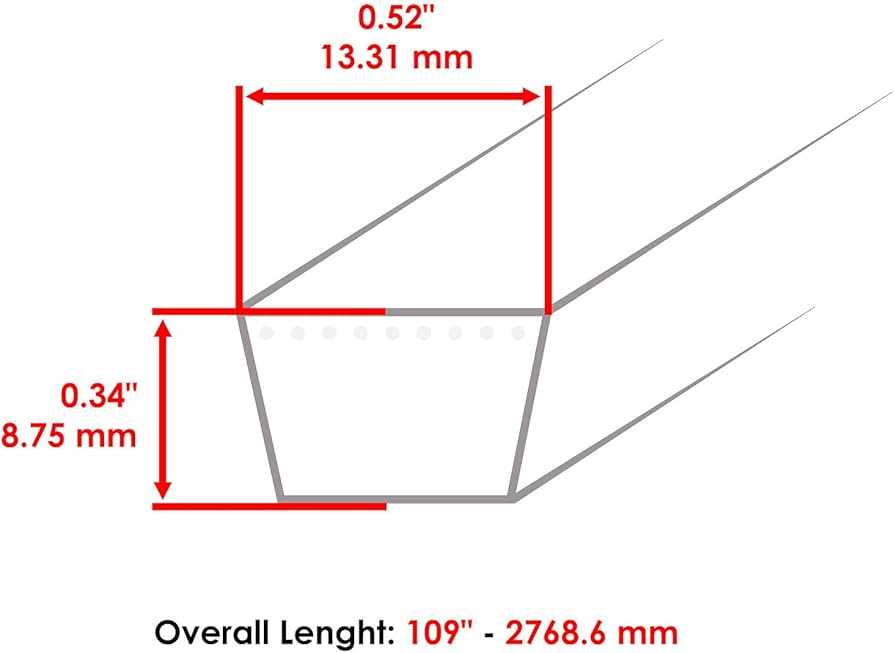

The transmission system is responsible for transferring power from the engine to the wheels, enabling the mower to move forward and backward. It includes belts, pulleys, and gears that work together to adjust the mower’s speed. The wheels, mounted on the axles, provide traction and stability, making it easier to maneuver the mower across uneven terrain.

- Transmission: Controls the speed and movement of the mower.

- Wheels: Provide traction for easy movement over various surfaces.

- Axles: Support the wheels and transmission system.

How to Identify Toro LX420 Parts

Understanding the components of your equipment is essential for efficient maintenance and repair. Familiarizing yourself with the various elements can significantly enhance your operational experience and prolong the life of your machine.

Visual Inspection

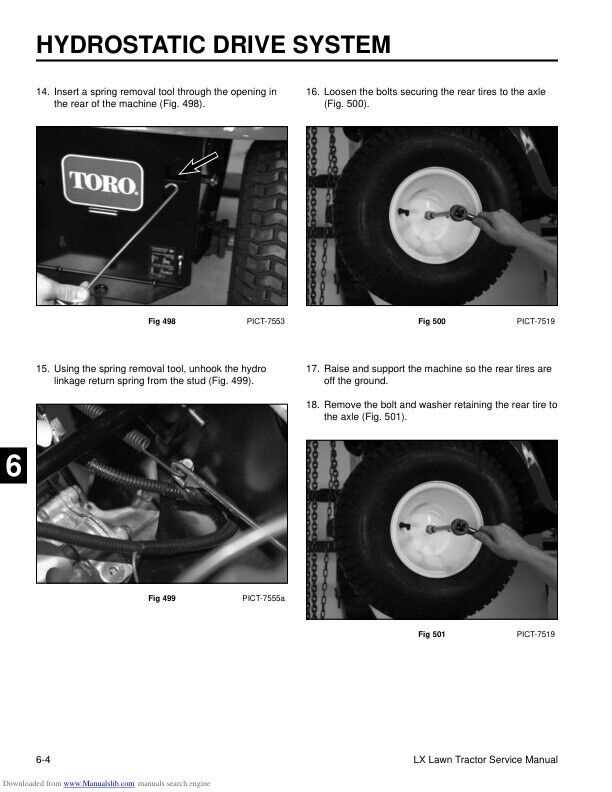

Start with a thorough visual examination to recognize different segments. Pay attention to:

- Shape and size variations

- Color differences

- Surface textures

Reference Guides

Utilizing reference materials can be incredibly beneficial. Consider the following sources:

- User manuals

- Online resources and forums

- Manufacturer’s catalogs

Common Replacement Parts for Toro LX420

Maintaining the efficiency and performance of your lawn care equipment often requires timely replacements of essential components. Understanding which elements are prone to wear and tear can help you ensure that your machine operates smoothly. Below is a list of frequently replaced items that can enhance the longevity of your equipment.

| Component | Description | Signs of Wear |

|---|---|---|

| Blades | Cutting implements that trim grass. | Uneven cuts, frayed edges. |

| Air Filter | Prevents dirt and debris from entering the engine. | Reduced power, increased fuel consumption. |

| Battery | Provides power for starting and running the machine. | Slow starting, dim lights. |

| Spark Plug | Ignites the fuel-air mixture in the engine. | Hard starting, misfires. |

| Fuel Filter | Filters impurities from the fuel. | Stalling, poor acceleration. |

By regularly checking and replacing these components, you can ensure optimal performance and extend the life of your equipment.

Benefits of Using Genuine Toro Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These original items are designed specifically for compatibility, reducing the risk of malfunction and enhancing efficiency.

One significant advantage is the assurance of quality. Genuine components undergo rigorous testing to meet high standards, providing peace of mind that your machinery will operate smoothly. Additionally, using original items often helps maintain warranties, protecting your investment in the long run.

Moreover, these components typically offer better durability compared to generic alternatives. With the right fit and design, they contribute to overall reliability, reducing the frequency of repairs and downtime. Ultimately, opting for authentic parts can lead to significant cost savings over time.

Incorporating genuine items into your maintenance routine can also enhance safety. Designed with precision, these components minimize the risk of accidents caused by improper fitting or inferior quality. Investing in original items ensures that your equipment remains dependable and safe for use.

How to Read Toro LX420 Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual guides provide valuable insights into the structure and components of machinery, making it easier to identify parts and troubleshoot issues. Familiarity with the symbols and layout of these illustrations can greatly enhance your ability to perform necessary tasks efficiently.

Key Elements of the Illustration

Before diving into the specifics, it’s important to recognize the fundamental elements commonly found in these visual aids. These include labels, symbols, and lines connecting different components. Each element serves a purpose in conveying information about the assembly and its various parts.

| Element | Description |

|---|---|

| Labels | Identify specific components and their functions. |

| Symbols | Represent different types of parts, such as electrical or mechanical components. |

| Connecting Lines | Indicate how components are related or connected to each other. |

Interpreting the Information

When analyzing these visuals, start by locating the main sections outlined in the illustration. Follow the connections between components to understand how they interact within the system. Pay attention to the labels, as they provide context for each part’s role and importance. By breaking down the information step-by-step, you can gain a comprehensive understanding of the overall assembly.

Maintenance Tips for Toro LX420 Parts

Ensuring the longevity and performance of your equipment requires regular attention and care. By adopting proactive maintenance practices, you can enhance functionality and prevent common issues that arise from neglect. This section will explore essential strategies to keep your machine operating smoothly.

Regularly inspect components for signs of wear or damage, addressing any issues immediately to prevent further deterioration. Clean all parts frequently to remove debris and buildup, which can impede performance. Lubrication is crucial; ensure all moving parts are adequately greased to minimize friction and prolong life.

Follow the manufacturer’s recommendations for replacement intervals, particularly for filters and belts. Keeping a maintenance log can help track when specific tasks were performed, making it easier to stay on schedule. Finally, consider seasonal checks to prepare your equipment for varying conditions throughout the year.

Where to Buy Toro LX420 Spare Parts

Finding the right components for your equipment is essential for maintaining performance and longevity. There are various reliable sources where you can purchase these essential items, ensuring your machine operates smoothly.

Online Retailers

- Major e-commerce platforms offer a wide selection, often at competitive prices.

- Specialized websites focus solely on outdoor machinery, providing detailed catalogs.

- Manufacturer’s official site often lists authorized dealers and genuine items.

Local Suppliers

- Home improvement stores typically stock common components for various models.

- Local repair shops may have inventory and can order specific items if needed.

- Garden centers often carry a range of replacement items for popular equipment.

Troubleshooting Toro LX420 Part Issues

Addressing component-related challenges can significantly enhance the performance and longevity of your equipment. Recognizing common problems and their solutions is crucial for efficient operation and maintenance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | Fuel Issues | Check fuel level and quality; replace if contaminated. |

| Uneven Cutting | Blade Condition | Inspect blades for wear and sharpen or replace as necessary. |

| Overheating | Blocked Cooling Vents | Clear debris from vents and ensure airflow. |

| Noisy Operation | Loose Components | Tighten all bolts and check for loose parts. |