The functionality and efficiency of outdoor machinery heavily rely on the interplay of its individual components. Each element plays a crucial role in ensuring optimal performance and longevity. A clear illustration of these elements can greatly assist users in understanding how their equipment operates and what specific sections require attention during maintenance or repair.

Visual representations of the various segments involved in such machinery provide invaluable insight. By examining these graphics, operators can quickly identify the necessary components needed for repairs or upgrades. This knowledge not only aids in enhancing the equipment’s performance but also contributes to making informed decisions about part replacements.

Furthermore, being familiar with the arrangement and functionality of the various segments can lead to improved troubleshooting skills. Understanding how each piece fits into the larger system empowers users to address issues more effectively, ultimately resulting in a smoother operational experience.

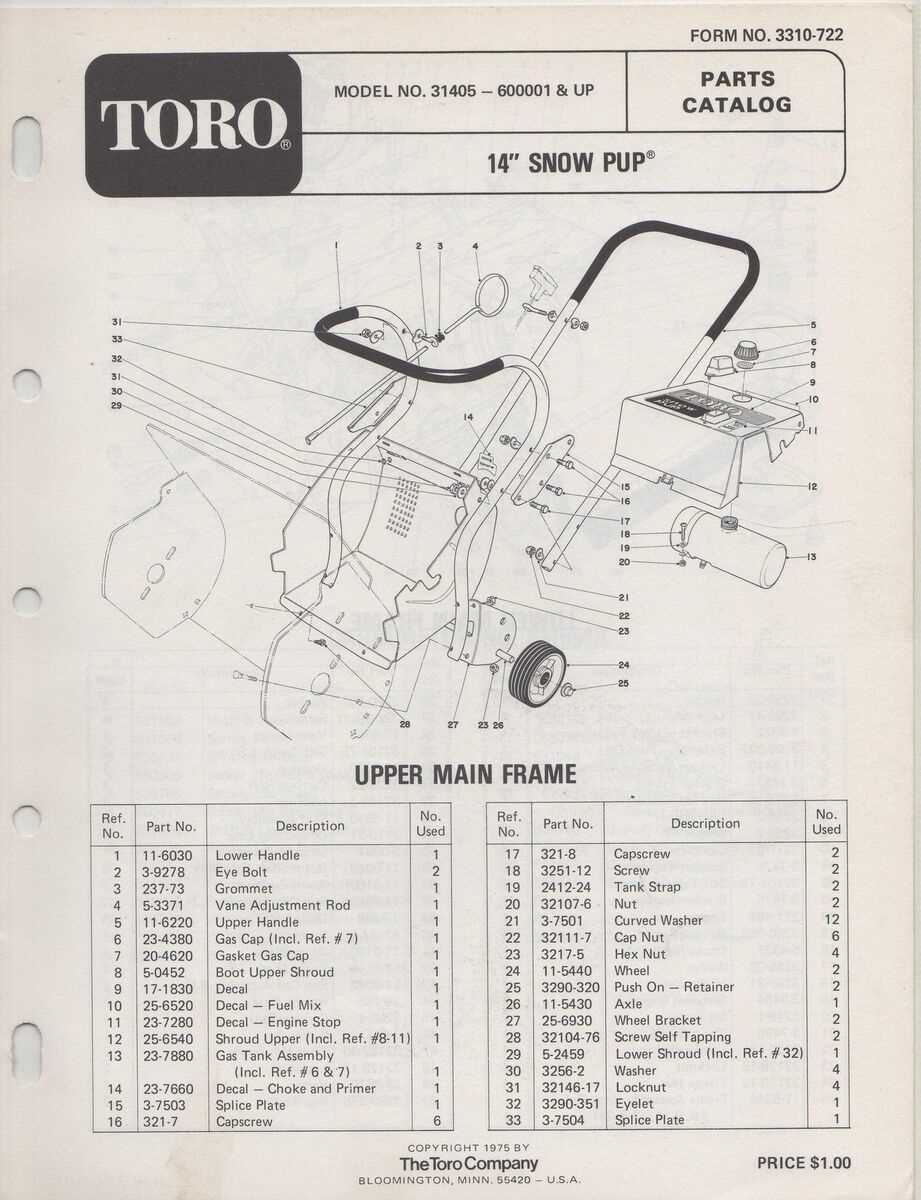

Key Components of Toro 521

This section explores the essential elements that contribute to the efficient operation of the equipment in question. Understanding these key components is crucial for maintenance and functionality, as they play significant roles in the overall performance and longevity of the machine.

Essential Elements

- Engine: The power unit responsible for driving the entire system. Its efficiency directly affects performance.

- Chassis: The main frame that houses various components, providing stability and support.

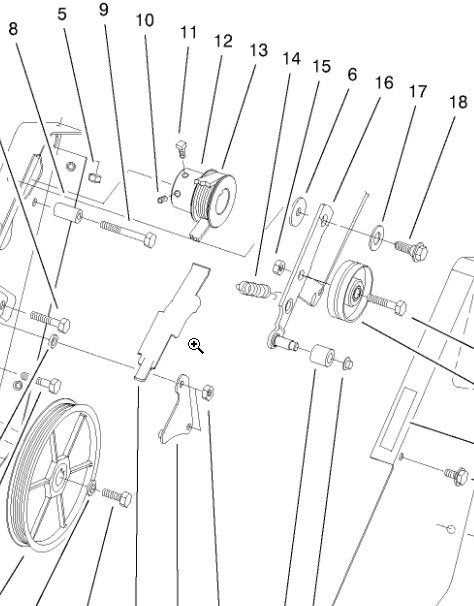

- Transmission: This system transfers power from the engine to the wheels, enabling movement.

- Control Panel: The interface used by the operator to manage settings and monitor performance.

Functional Accessories

- Blades: Cutting elements designed for precision and effectiveness in operation.

- Wheels: Essential for mobility, ensuring smooth navigation across different terrains.

- Fuel System: Components that store and supply fuel to the engine for combustion.

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

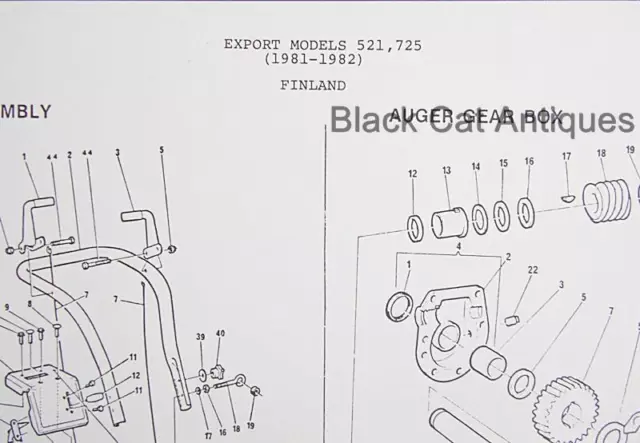

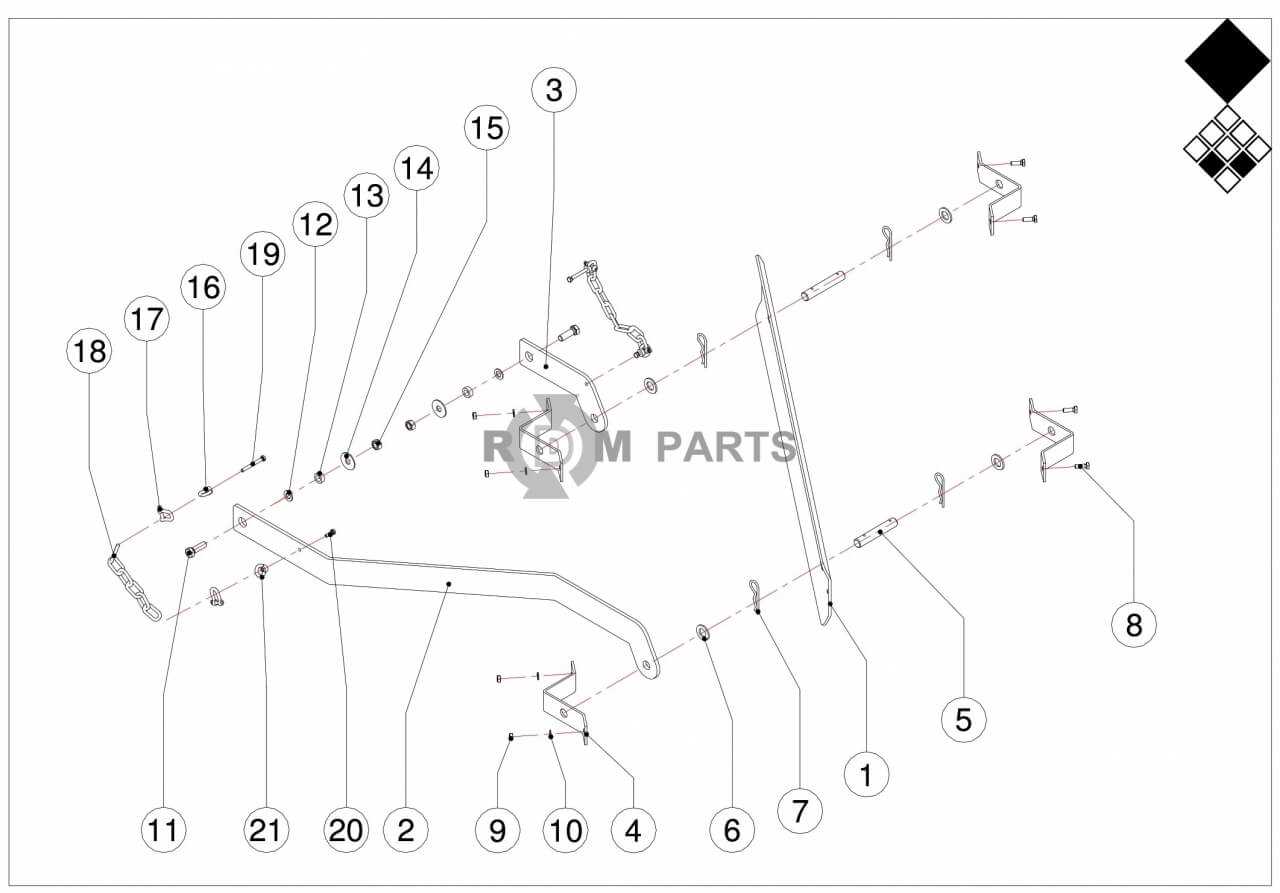

Understanding the Parts Diagram

This section provides a comprehensive overview of how to interpret the visual representation of components for a specific machine. By grasping the layout and relationships between various elements, users can enhance their knowledge and effectively engage in maintenance or repairs. The ability to decipher these illustrations can lead to improved functionality and longevity of the equipment.

Key Components

Each element within the visual representation plays a crucial role in the overall operation of the machine. Familiarity with these components allows users to identify potential issues and carry out necessary replacements or adjustments.

How to Navigate the Illustration

Understanding the arrangement and labeling of components is vital for effective troubleshooting. Familiarizing oneself with the keys and symbols utilized in the representation will aid in quickly locating and assessing specific elements.

| Component Name | Description | Function |

|---|---|---|

| Component A | Provides initial support and stability. | Ensures proper balance during operation. |

| Component B | Facilitates movement and control. | Enhances maneuverability of the equipment. |

| Component C | Acts as a protective element. | Safeguards internal mechanisms from damage. |

Maintenance Tips for Toro 521

Ensuring the longevity and efficiency of your outdoor equipment requires consistent care and attention. Adopting a regular maintenance routine not only enhances performance but also prevents costly repairs. Below are some essential practices to keep your machinery running smoothly.

Regular Inspections

- Check all moving components for wear and tear.

- Inspect belts and hoses for cracks or fraying.

- Ensure that fasteners and bolts are secure to prevent parts from loosening.

Cleaning and Lubrication

- Clean the machine after each use to remove dirt and debris.

- Apply lubricant to all pivot points to minimize friction.

- Empty the fuel tank if the equipment will not be used for an extended period to avoid stale fuel.

By following these maintenance tips, you can significantly extend the life of your outdoor machinery while ensuring it operates at peak performance.

Common Issues and Solutions

Understanding the frequent challenges that arise with outdoor maintenance equipment is essential for effective troubleshooting. By identifying typical problems and their resolutions, users can maintain optimal performance and extend the life of their machines.

Typical Challenges

- Engine struggles to start or runs erratically.

- Inadequate cutting performance.

- Excessive vibration during operation.

- Leaks from fuel or oil systems.

Resolutions

- Engine Issues: Check the fuel supply, ensuring it is fresh and free from contaminants. Examine the spark plug for wear and replace if necessary.

- Cutting Performance: Inspect the blades for damage or dullness. Sharpen or replace blades as needed to improve cutting efficiency.

- Vibration Problems: Tighten any loose components and ensure that all parts are properly secured. Examine the drive system for any misalignment.

- Leak Fixes: Inspect hoses and seals for wear. Replace any damaged components to prevent fluid loss.

How to Identify Replacement Parts

Understanding how to find suitable components for your equipment is essential for maintaining its functionality. Proper identification ensures that you select the right items that fit your model, which is crucial for seamless operation.

To accurately determine the necessary components, follow these steps:

| Step | Description |

|---|---|

| 1 | Refer to the user manual for detailed information about your model. This document often contains specifications and part numbers that are vital for identification. |

| 2 | Examine the existing components closely. Look for any visible markings, numbers, or labels that can provide clues regarding their specifications. |

| 3 | Consult online resources or manufacturer’s websites. Many manufacturers offer databases where you can search for compatible components based on model numbers. |

| 4 | If needed, seek assistance from professionals or parts suppliers. They can guide you in identifying the correct items and may have access to more detailed information. |

Ordering Parts for Toro 521

When maintaining equipment, sourcing the necessary components is crucial for optimal functionality. Whether for repairs or upgrades, knowing how to effectively acquire the required items can save time and ensure that machinery operates smoothly.

Here are some essential steps to follow when procuring components:

- Identify Requirements: Determine the specific components needed based on the maintenance or repair tasks at hand.

- Consult Manuals: Refer to the user guide or service manual to ensure you select the correct items compatible with your equipment.

- Search Online Retailers: Utilize online platforms to compare prices and availability. Look for trusted suppliers that specialize in machinery components.

- Check Local Dealers: Visit nearby dealers or repair shops that may have the needed items in stock or can order them for you.

- Consider Quality: Ensure that the components are of high quality and from reputable manufacturers to guarantee reliability and longevity.

- Review Return Policies: Before finalizing your purchase, check the return policies in case the items do not meet your expectations or requirements.

By following these steps, you can efficiently obtain the necessary components, ensuring your equipment remains in excellent working condition.

Benefits of Using Original Components

Utilizing authentic elements for machinery maintenance and repair provides numerous advantages. These components are specifically designed to fit and function perfectly within their designated systems, ensuring optimal performance and longevity.

Quality Assurance: Original elements undergo rigorous testing to meet high standards of quality and reliability. This means users can trust that these components will perform as expected, reducing the risk of failure.

Enhanced Performance: When genuine parts are used, they contribute to the overall efficiency of the equipment. They work seamlessly with existing systems, allowing for better operation and improved functionality.

Long-Term Savings: Investing in authentic components can lead to cost savings in the long run. While they may have a higher initial price, their durability and reliability minimize the need for frequent replacements and repairs.

Warranty Protection: Many manufacturers offer warranties on their products when original elements are utilized. This coverage provides peace of mind, knowing that any issues arising from these components will be addressed without additional costs.

In summary, choosing genuine components ensures enhanced efficiency, reliability, and long-term value for machinery. The investment in authenticity ultimately leads to greater satisfaction and performance.