When it comes to maintaining effective and reliable equipment, understanding the structure and layout of essential elements is key. Knowing each part’s role and how they connect can greatly enhance the performance and lifespan of the equipment. This section provides a clear and detailed look at the components, helping users recognize and identify each item for optimal use and maintenance.

Efficient upkeep relies on familiarity with each segment’s function. In this guide, you’ll find information about all the critical elements, from the mainframe to specialized parts. By understanding these components, users can better diagnose issues, replace worn-out elements, and carry out repairs more effectively.

Whether you are looking to improve your skills in basic maintenance or to understand the detailed workings of each part, this guide offers a user-friendly way to enhance your expertise. With a clear focus on each component, you’ll gain the confidence to handle repairs and adjustments, ensuring your equipment remains in prime condition over time.

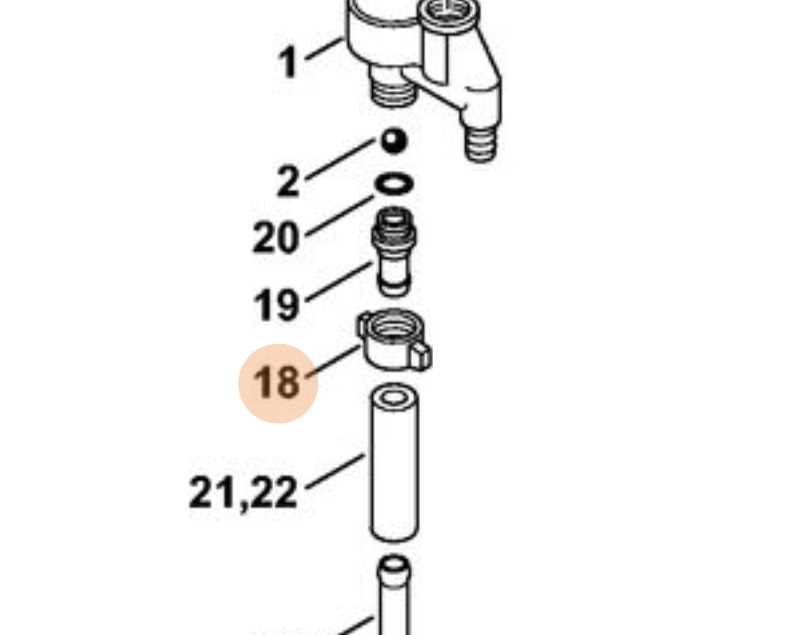

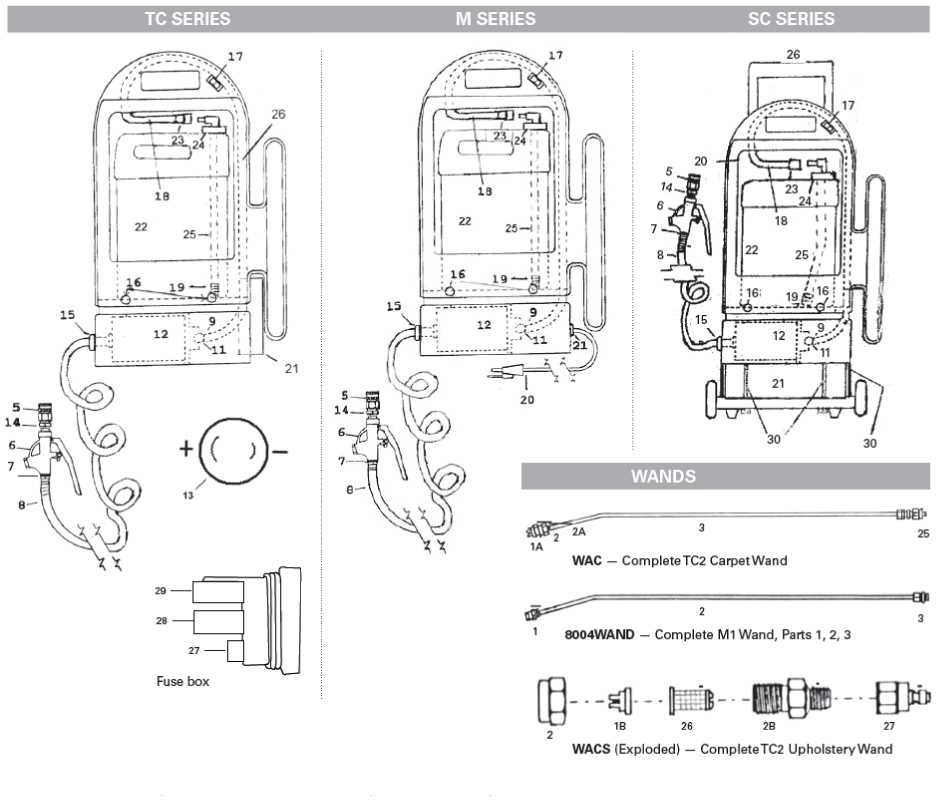

Overview of Stihl SG20 Components

The components in this manual sprayer are designed to work together seamlessly, delivering efficient performance and reliability. Each element plays a specific role, contributing to both the device’s usability and durability. Understanding these elements can enhance both maintenance and operation, ensuring consistent performance over time.

Pump Mechanism: The pump is crucial, generating the necessary pressure to propel liquids through the sprayer’s system. A well-maintained pump allows for smooth operation, optimizing flow rate and spray quality.

Fluid Reservoir: This container holds the liquid, allowing for easy storage and access. Its construction is often durable and resistant to chemicals, which preserves the sprayer’s interior and extends its lifespan.

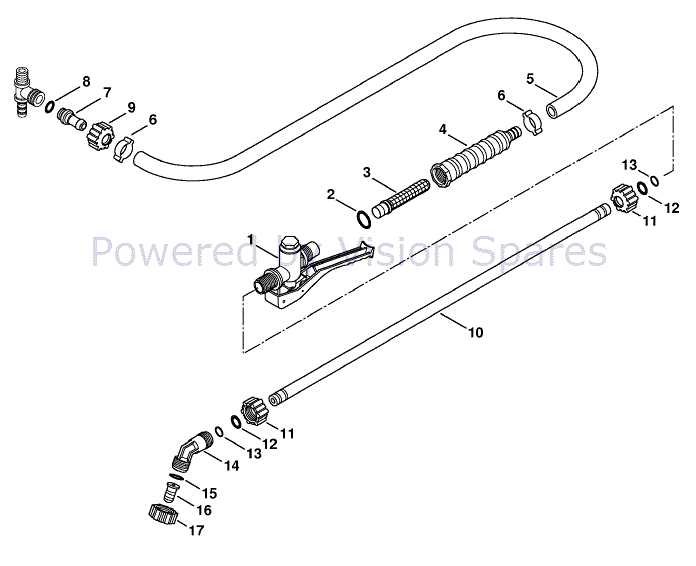

Hose and Wand Assembly: This assembly directs the flow, allowing precise application. The hose provides flexibility, while the wand gives control, making it easier to reach various areas accurately.

Harness and Frame: Designed for user comfort, these components help distribute the weight evenly,

Main Functions of the SG20 Parts

Each component within this sprayer design contributes to efficient and precise operation, ensuring reliable performance and ease of use. This section outlines the primary roles and functions of these individual elements, enhancing both the usability and maintenance of the tool.

Core Components and Their Purposes

- Pump Mechanism: Central to the sprayer’s operation, the pump creates the necessary pressure to evenly distribute the liquid, aiding in controlled and effective application.

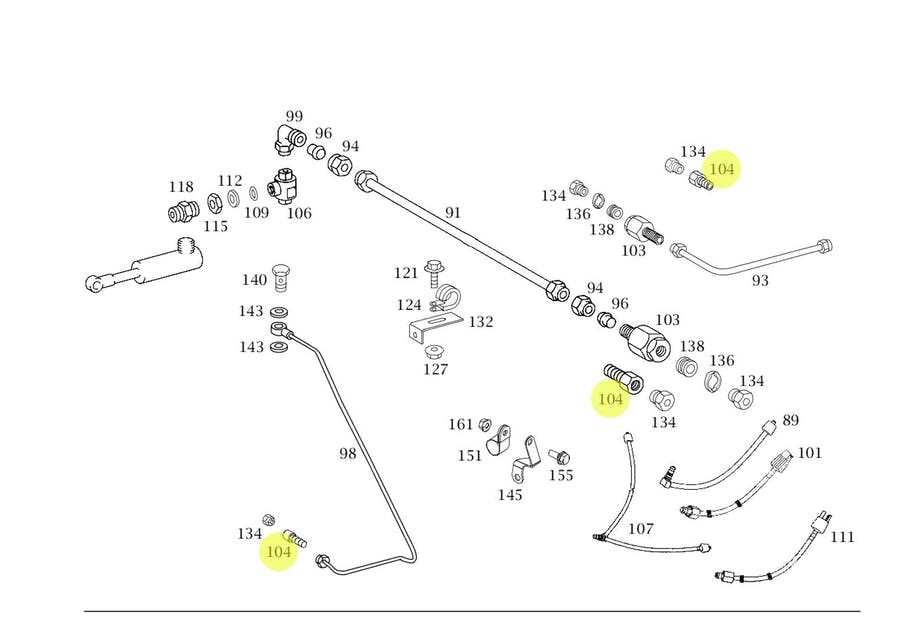

- Pressure Regulator: This part maintains a steady flow rate by adjusting the pressure level, allowing for consistent and adaptable usage across various spraying tasks.

- Hose Assembly: Connecting the tank and nozzle, the hose serves as the conduit through which the liquid travels, designed to be flexible yet durable under repeated use.

Additional Functional Parts

- Nozzle: At the front end, the nozzle shapes the spray pattern, providing options for different coverage types and enhancing the versatility of the tool.

- Shoulder Straps: These adjustable straps ensure comfort during prolonged use by evenly distributing weight, thus reducing user fatigue.

- Tank Lid: Sealing the liquid within the reservoir, this component prevents leaks and helps maintain pressure while securing the contents effectively.

Understanding the roles of these core and auxiliary components aids in ma

Common Issues with SG20 Parts

Maintenance and repair of this type of equipment often come with certain challenges due to the various components involved. Understanding common issues that arise can help identify problems early and keep the device in top shape.

- Leaks: Over time, seals and gaskets can wear out, leading to fluid leaks. Regular checks can prevent minor leaks from turning into larger issues.

- Clogging: Residue buildup in tubes or nozzles may cause blockages, reducing efficiency. Cleaning after each use helps keep all channels clear.

- Pump Malfunction: The pump may lose pressure or fail if not maintained. Checking seals and ensuring lubrication can keep it functioning smoothly.

- Handle and Straps Wear: Handles and straps are subject to wear, especially under heavy use. Replacing them when they show signs of wear improves safety and comfort.

By staying proactive with these issues, users can extend the longevity of their equipment and minimize downtime due to repairs.

Choosing Replacement Parts for SG20

When maintaining your equipment, it’s essential to find the most suitable replacements to ensure long-lasting functionality and efficiency. Selecting compatible components requires understanding the individual elements, their specific roles, and how they work together to optimize performance.

Identify Key Elements – Before purchasing any replacements, consider the primary sections and frequently used elements that may need renewal. These could include seals, valves, or critical connection points. Choosing compatible options ensures that the original efficiency is maintained.

Consider Durability and Quality – Opt for components made from materials that offer resistance to wear and tear. Quality materials not only improve reliability but can also reduce maintenance needs over time, allowing for smoother operation.

Match Specifications – Check the exact specifications of each component to ensure precise compatibility. This helps avoid performance issues and prolongs the lifespan of the equipment by minimizing strain on other parts.

By carefully selecting each component with attention to quality, compatibility, and durability, you can effectively maintain the performance and longevity of your equipment, making each usage more efficient and reliable.

Maintaining Stihl SG20 for Longevity

Regular upkeep of this equipment ensures it remains reliable and performs effectively over time. Proper care prevents wear, extends operational life, and reduces the need for frequent repairs, making it a cost-effective solution for long-term use.

Key Areas for Routine Maintenance

To keep the device in top condition, focus on several crucial components that often require attention:

- Clean filters regularly to prevent clogs and maintain efficient operation.

- Inspect seals and connections to prevent leaks and ensure a secure assembly.

- Check hoses for any signs of cracks or wear, which could impact functionality if ignored.

Steps for Periodic Servicing

- Flush the tank: Clean the tank after each use, especially if different solutions have been used, to avoid buildup and clogging.

- Lubricate moving parts: Periodically apply a suitable lubricant to maintain smooth operation of components.

- Inspect straps and fasteners: Make sure that straps are intact and fasteners remain secure for user comfort and safety.

By following these maintenance tips, users can

Understanding the Sprayer’s Mechanism

The mechanism of a sprayer operates through a combination of components that work in harmony to deliver liquid efficiently. This system is designed to provide effective coverage while ensuring that the substance is distributed evenly. By grasping how each element interacts, users can appreciate the engineering behind these devices and optimize their performance during operation.

Key Components of the Sprayer

At the heart of the sprayer’s function lies the pump, responsible for generating the necessary pressure to propel the liquid through the nozzle. The tank serves as the reservoir, holding the liquid until it is needed. Additionally, the nozzle plays a critical role in determining the spray pattern, allowing for customization based on the task at hand.

Operational Principles

When the trigger is engaged, the pump activates, creating pressure that forces the liquid from the tank through the hose and into the nozzle. The nozzle’s design dictates the flow rate and dispersion, ensuring the liquid is atomized appropriately. Understanding this process enables users to troubleshoot and maintain their sprayer more effectively, leading to improved results and longevity.

Proper Installation of SG20 Parts

Ensuring the correct assembly of components is vital for the optimal performance and longevity of your equipment. Following precise guidelines and utilizing the right tools can significantly impact functionality. Properly connecting elements not only enhances efficiency but also prevents potential damage.

Begin by reviewing the manufacturer’s guidelines to understand the specific requirements for each component. Ensure that all necessary tools are available and that the workspace is organized. Begin with the larger components, securing them firmly before proceeding to smaller elements. Pay close attention to alignment, as misalignment can lead to operational issues.

After assembling the primary components, inspect all connections to confirm they are tight and secure. It is also essential to double-check for any missing parts. Once everything is in place, conduct a thorough test to ensure that the equipment functions as intended. Regular maintenance and inspections post-assembly will help to identify any issues early on, ensuring a seamless operation.

Cleaning and Storage Tips for SG20

Proper maintenance of your equipment is crucial for ensuring its longevity and optimal performance. This section provides essential guidelines on how to keep your tools clean and stored effectively. By following these recommendations, you can prevent wear and tear, maintain functionality, and ensure that your device is ready for use when needed.

Cleaning Techniques

Start by removing any debris and residues from the exterior surfaces. Use a soft cloth or a brush to gently wipe away dirt without damaging the finish. For stubborn spots, a mild detergent mixed with water can be effective. Avoid using harsh chemicals that might corrode or degrade materials. Pay special attention to the nozzles and openings, as blockages can affect performance.

Optimal Storage Practices

When it comes to storing your equipment, ensure it is in a cool, dry place away from direct sunlight. If possible, keep it in a protective cover to prevent dust accumulation. It is advisable to store it upright or in a secure position to avoid any accidental damage. Additionally, regularly check the condition of the unit and perform any necessary maintenance tasks before storing it for an extended period.

Upgrading and Enhancing SG20 Functionality

Improving the efficiency and performance of your equipment can significantly enhance your overall experience and productivity. Whether you seek to increase power output, reduce operational noise, or improve durability, a range of upgrades is available to tailor the machine to your specific needs. This section explores various enhancements that can elevate functionality and optimize user satisfaction.

Performance Boosts

One of the primary goals when upgrading is to boost the operational performance. Consider investing in high-quality fuel systems or enhancing the ignition components. Upgrading these elements can lead to improved fuel efficiency and smoother operation, allowing you to maximize the potential of your machinery.

Durability Improvements

Enhancing the longevity of your equipment is another crucial aspect. Replacing standard components with premium materials, such as reinforced casings or rust-resistant parts, can significantly extend the lifespan. Additionally, implementing regular maintenance practices ensures that your machine remains in optimal condition, reducing the likelihood of unexpected breakdowns.