When working with complex machinery, understanding the arrangement and functionality of individual elements is key to maintaining optimal performance. Each component plays a critical role in ensuring smooth operation, making it essential to have a clear view of their interconnections and roles.

Visualizing the structure and positioning of various elements helps in identifying potential issues and allows for efficient repairs or replacements. By familiarizing yourself with the internal workings of the system, you’ll be able to keep the equipment running smoothly and minimize downtime.

In this guide, we will explore the intricate network of mechanical elements that come together to form a cohesive and efficient system. This knowledge will empower you to take a proactive approach in maintaining and troubleshooting your equipment, ensuring long-term reliability.

Comprehensive Overview of the Stihl MM55 Model

Designed for versatility and efficiency, this machine offers a solution for various tasks, combining power and precision. With its compact structure, it allows users to work in tight spaces while maintaining effective performance across a range of applications. Built with durability in mind, this tool serves as a reliable companion for both light and heavy-duty projects.

Core Functions and Capabilities

This model is engineered to handle multiple jobs with ease, providing an array of interchangeable attachments to suit different needs. Whether you’re working on soil cultivation or other landscaping tasks, the machine adapts to each requirement.

- Compact design for easy maneuverability

- Enhanced power for tackling demanding projects

- Interchangeable components for various applications

Key Benefits

Offering a balance of strength and user-friendly features, this equipment is perfect for both professionals and hobbyists. Its ease of use, combined with

Essential Components of the MM55

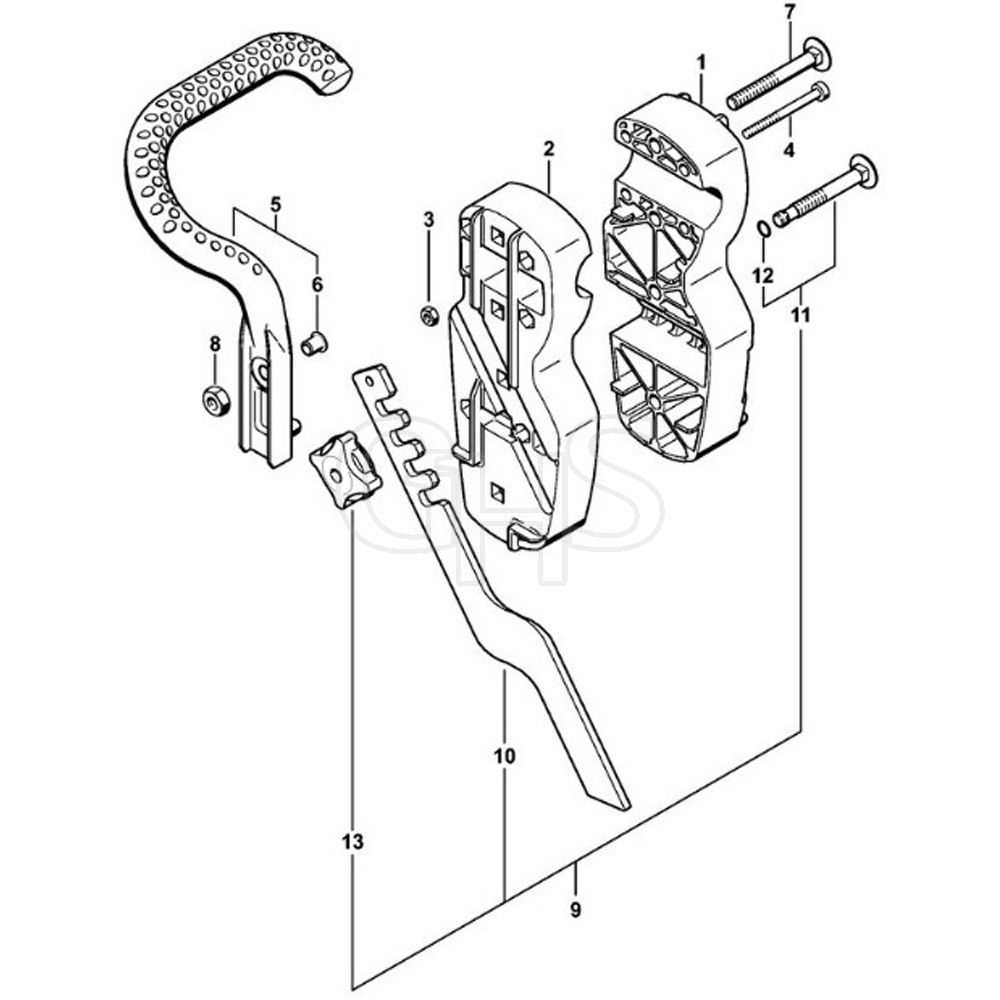

The structure of this versatile equipment relies on several key elements that work together to ensure reliable operation. Each element plays a specific role, contributing to the overall efficiency and performance of the machine in various applications.

Engine Unit: The central power source that drives the entire system, ensuring the necessary energy is supplied to other mechanisms. This component needs to be well-maintained to guarantee optimal functionality.

Transmission System: Responsible for converting the power from the main source to motion, allowing the machine to perform its designated tasks. Proper function of this system is critical for smooth operation.

Drive Shaft: This connecting element links the power unit with the working parts of the equipment. It transfers energy from the motor, enabling the active parts to function effectively.

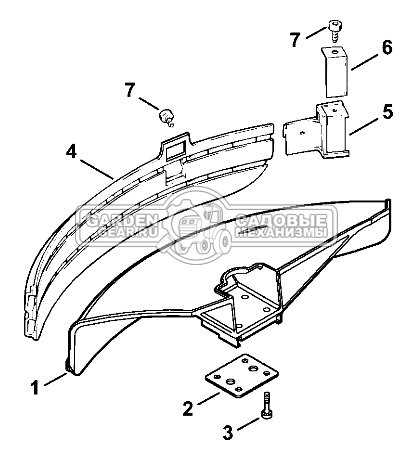

Handle Assembly: Provides the user with control over the machine, allowing for precise maneuvering. Its design ensures comfort and ease of use during extended operation periods.

Attachment Mechanism: A crucial system that allows various

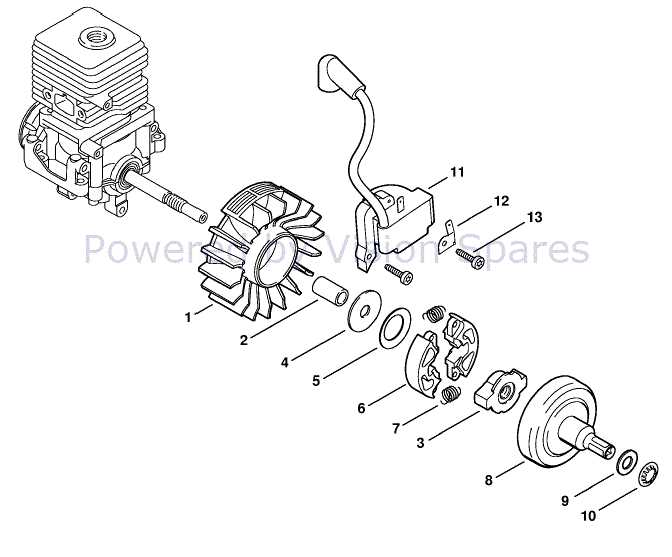

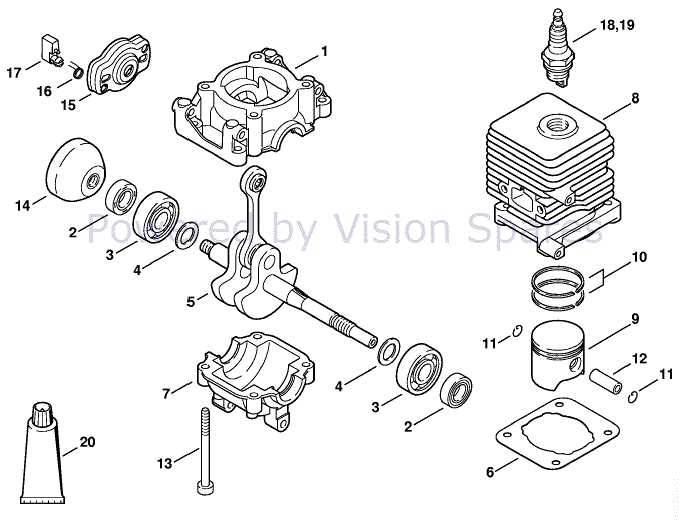

Exploring the Engine Assembly Structure

Understanding the intricate design of a machine’s internal mechanism is crucial for optimal performance and maintenance. The engine assembly consists of several interrelated components, each playing a key role in the overall operation and efficiency of the system.

The primary structure of the engine is built around key elements that work together to convert fuel into mechanical energy. These components must be carefully aligned and maintained to ensure smooth operation and prevent wear over time.

- Cylinder: Houses the piston and is a critical part of the combustion process.

- Piston: Moves within the cylinder, driven by the expansion of gas during combustion.

- Crankshaft: Converts the linear motion of the piston into rotational motion.

- Valves: Regulate the flow of fuel and air into the cylinder and allow exhaust gases to escape.

Each of these components must function in harmony for the engine to run efficiently. Regular inspection and maintenance of these elements

Fuel System Parts Breakdown

The fuel system is essential for ensuring the proper operation of any machine that relies on an internal combustion engine. It manages the flow and mixture of the fuel and air, playing a critical role in maintaining efficient performance and power output. Understanding the various elements involved in this system can help with troubleshooting and maintaining optimal functionality.

Key Components of the Fuel Pathway

The fuel supply mechanism consists of several interconnected elements designed to deliver a precise mixture of air and fuel to the engine. The most common components include the fuel tank, responsible for storing the liquid, and the lines that transport it. These elements work in unison to ensure consistent delivery under different operating conditions.

Maintaining Efficiency and Functionality

To preserve efficiency, regular maintenance of the fuel delivery mechanism is required. This includes inspecting hoses for leaks, cleaning filters to prevent blockages, and ensuring that all seals remain intact. Consistent upkeep ensures that the system operates smoothly, preventing performance issues and extending the lifespan of the equipment.

Understanding the Carburetor and Its Role

The carburetor is a crucial component in the operation of small engines, ensuring that the right balance of air and fuel is mixed to create optimal combustion. This balanced mixture is key to the engine’s performance and efficiency, directly affecting its ability to function properly in various conditions. A clear understanding of how this part works allows for better maintenance and troubleshooting, keeping the engine running smoothly over time.

How the Carburetor Works

The carburetor operates by drawing air through an intake valve, which then combines with fuel in a specific ratio. This mixture is sent to the combustion chamber, where it ignites and powers the engine. Adjustments to the air-to-fuel ratio can be made to improve engine performance or reduce emissions, depending on the operating conditions.

Air Filter and Intake System Components

The air filtration and intake system play a crucial role in maintaining optimal performance for small engine machinery. This assembly ensures that clean air enters the combustion chamber, enabling efficient fuel combustion while protecting the engine from harmful debris and contaminants. Understanding the individual components involved is essential for proper maintenance and functionality.

Key elements within this system include the air filter, intake manifold, and related fittings. Each part contributes to the overall efficiency of air delivery, impacting engine performance and longevity.

| Component | Description |

|---|---|

| Air Filter | This element captures dust, dirt, and other particles from the air before they enter the engine, promoting cleaner combustion. |

| Intake Manifold | A channel that directs the filtered air into the combustion chamber, ensuring proper air-fuel mixture for efficient operation. |

| Intake Fittings | Connect various components within the intake system, ensuring a secure and leak-free pathway for air flow. |

| Throttle Body | Regulates the amount of air entering the engine based on the operator’s input, allowing for controlled acceleration and power. |

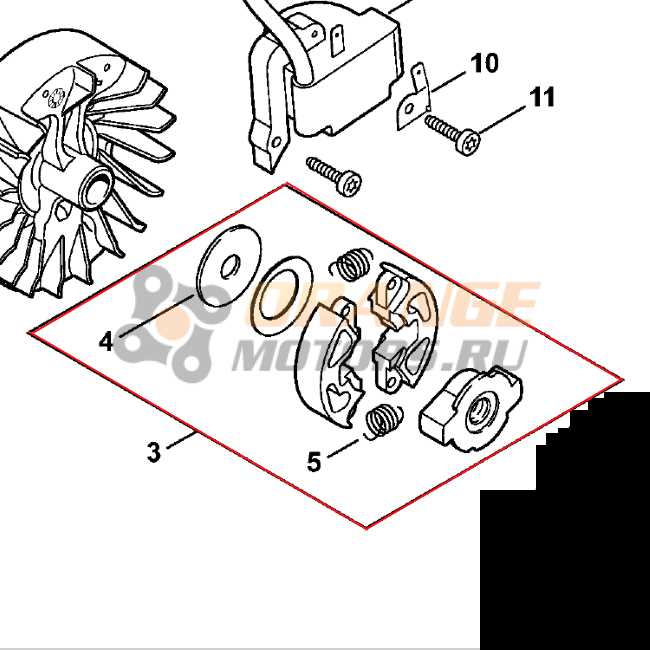

Drive System and Transmission Elements

The efficiency of a machine’s operation significantly depends on its drive mechanism and transmission components. These elements work in tandem to convert power into motion, ensuring optimal performance during various tasks. Understanding the intricacies of these systems is crucial for effective maintenance and troubleshooting.

Key Components of the Drive Mechanism

The drive system comprises several essential components that facilitate smooth operation. Among these, the motor plays a vital role in generating power, while the drive belt serves to transmit this energy to the wheels or cutting tools. Additionally, the presence of pulleys aids in adjusting speed and torque, contributing to the overall effectiveness of the mechanism.

Importance of Transmission Elements

Transmission components are integral in regulating the flow of power. Gear systems are particularly significant, as they determine the speed and force delivered to the working parts. Understanding how these elements interact enables users to enhance performance and prolong the lifespan of the equipment. Regular inspection and timely replacement of worn parts ensure continued reliability in various applications.

Handlebars and User Controls Layout

The arrangement of grips and control mechanisms is essential for achieving a seamless user experience. A well-designed layout enhances maneuverability and provides intuitive access to various functions, ensuring that the operator can work efficiently and safely.

In this section, we will explore the different components associated with the grip assembly and their functionalities. Understanding these elements allows users to appreciate how they interact with the equipment.

| Component | Description |

|---|---|

| Grip Handle | The primary point of contact for the operator, designed for comfort and control. |

| Throttle Control | Allows the user to regulate the power and speed of the engine, providing better handling. |

| Starter Switch | Initiates the engine operation, typically located within easy reach of the grip. |

| Safety Switch | A critical feature that prevents accidental start-ups, enhancing user safety during operation. |

| Height Adjustment Lever | Facilitates the adjustment of the handle height for improved ergonomics. |

Common Replacement Parts and Maintenance Tips

Proper upkeep of garden equipment is essential for ensuring optimal performance and longevity. Regularly checking and replacing key components can prevent breakdowns and improve efficiency. Understanding the common elements that may require attention can help users maintain their tools effectively.

One frequently replaced component is the cutting blade, which can become dull or damaged over time. Regular sharpening or replacement is crucial for achieving a clean cut. Additionally, filters play a vital role in keeping the engine clean and efficient; replacing air and fuel filters periodically helps maintain optimal airflow and fuel flow.

Moreover, inspecting and replacing spark plugs is important for reliable ignition and performance. Worn-out spark plugs can lead to starting issues and reduced power. Finally, lubrication of moving parts is essential for smooth operation and preventing wear and tear. Regular maintenance not only enhances performance but also extends the lifespan of the equipment.