When it comes to maintaining a beautiful garden, having the right equipment is essential. Among the various tools available, one model stands out for its efficiency and reliability. This section aims to explore the intricate details of its construction, providing insights into how each element contributes to its overall performance.

By examining the individual components, users can gain a clearer understanding of the assembly and functionality of this garden helper. Familiarity with the internal structure not only aids in troubleshooting but also empowers users to make informed decisions regarding maintenance and upgrades.

Whether you are a novice or an experienced gardener, diving deep into the layout of this tool can ultimately enhance your gardening experience. Knowledge of its workings allows for better handling, ensuring that your efforts in the garden yield the best results.

Understanding Stihl FS 55 RC Parts

Gaining insight into the components of a brushcutter enhances its maintenance and efficiency. Each element plays a crucial role in ensuring optimal performance and longevity.

Key components include:

- Engine: Powers the machine, providing the necessary force.

- Cutting Head: Responsible for trimming and cutting vegetation.

- Handle: Offers control and maneuverability during operation.

- Fuel System: Supplies energy to the engine, impacting performance.

Understanding these elements helps users effectively manage their equipment, ensuring it operates at its best.

Importance of Accurate Parts Diagram

Understanding the components of any machinery is crucial for efficient maintenance and repair. A precise representation of these elements aids users in identifying the necessary replacements and ensures that each part fits seamlessly into the assembly. This clarity not only enhances the overall performance but also prolongs the lifespan of the equipment.

Facilitating Efficient Repairs

Having a detailed visualization allows technicians to quickly pinpoint issues and address them without unnecessary delay. This efficiency minimizes downtime, ensuring that the equipment is back in operation swiftly. Furthermore, it reduces the likelihood of errors during reassembly, leading to a smoother repair process.

Enhancing User Confidence

When users have access to accurate illustrations, they gain confidence in their ability to manage repairs independently. This empowerment encourages a proactive approach to maintenance, fostering a deeper understanding of how each element functions together. As a result, individuals can make informed decisions when it comes to upkeep and troubleshooting.

Common Issues with Stihl FS 55 RC

When operating a grass trimmer, users often encounter several prevalent challenges that can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintenance, ensuring a smoother experience during yard work.

One frequent issue is difficulty starting the machine, which can stem from various factors such as fuel contamination, a clogged air filter, or a malfunctioning spark plug. Regular checks and maintenance can prevent these starting troubles.

Another common concern involves the cutting mechanism, where users might notice decreased cutting power or uneven trimming. This can be due to dull blades, improper line length, or incorrect installation. Keeping the cutting tools sharp and well-adjusted is essential for optimal performance.

Overheating is also a typical problem, often caused by inadequate lubrication or prolonged use without breaks. Ensuring proper oil levels and allowing the engine to cool can help mitigate this issue.

Finally, vibration and noise levels can increase over time, indicating possible wear or misalignment in the internal components. Regular inspections and prompt repairs are crucial to maintaining both comfort and safety while operating the device.

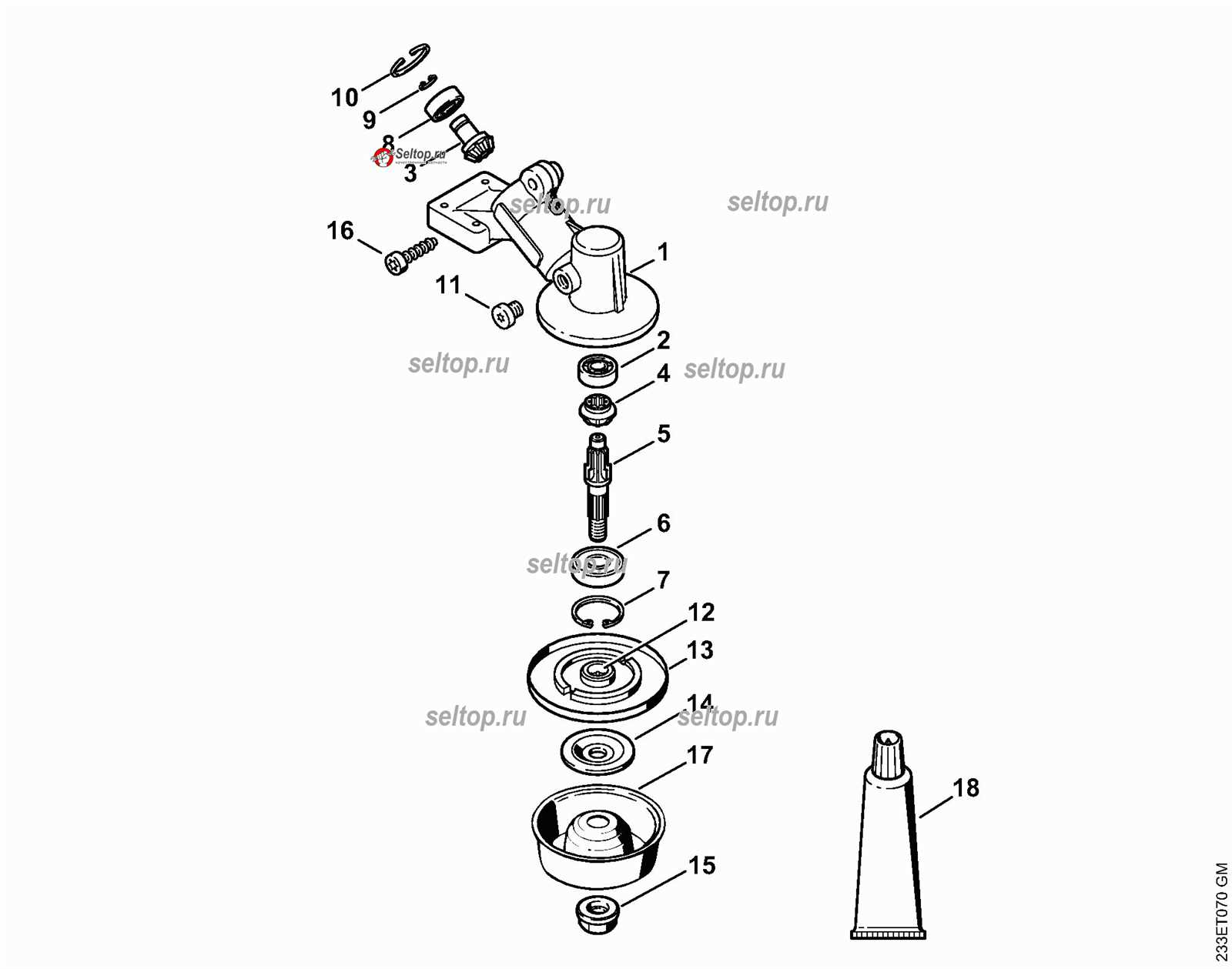

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the intricate layout, allowing you to identify and locate each element with ease. By familiarizing yourself with the symbols and organization of the illustration, you can streamline your service tasks.

Key Elements to Note

- Labels: Each item is usually marked with a unique identifier. Take note of these numbers as they correspond to specific components.

- Grouping: Parts are often grouped by function or assembly, making it easier to find related items.

- Connections: Pay attention to lines and arrows that indicate how components are connected or interact with one another.

Steps to Interpret the Illustration

- Start by familiarizing yourself with the overall layout and structure.

- Identify the section relevant to your repair or maintenance needs.

- Cross-reference the labels with a reference list, if available, to find the exact specifications of each item.

- Note any assembly instructions that may be included, as they can assist in proper reinstallation.

With practice, you will gain confidence in interpreting these visuals, ensuring that you can carry out repairs efficiently and accurately.

Essential Replacement Parts Overview

Maintaining optimal performance in outdoor power tools requires a good understanding of critical components that may need replacement over time. Regular wear and tear can affect efficiency and safety, making it essential to identify which elements might require attention. This section provides an overview of the key components that are vital for the smooth operation of your equipment.

Key Components

Several integral components play a crucial role in the functionality of your tool. The cutting system, including blades and trimmers, is fundamental for achieving precise results. Additionally, the engine’s air filter and spark plug are essential for maintaining power and fuel efficiency. Regular inspection and timely replacement of these elements can significantly extend the lifespan of your equipment.

Maintenance Tips

To ensure long-lasting performance, it’s advisable to adhere to a routine maintenance schedule. This includes cleaning filters, checking fuel lines, and replacing worn-out components as needed. Keeping a close eye on these aspects will not only enhance performance but also prevent more serious issues from developing, ensuring your equipment remains reliable for years to come.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment functions efficiently and lasts longer. By following a few simple practices, you can enhance performance and minimize the risk of unexpected breakdowns.

Routine Cleaning

Keep your machinery clean to prevent dirt buildup that can hinder performance. Regularly inspect and remove debris from air filters and cooling fins to maintain optimal airflow. Proper cleaning not only helps in efficiency but also extends the life of components.

Regular Inspections

Conducting consistent checks on your tools is vital. Look for signs of wear and tear, especially in critical areas such as the ignition system and fuel lines. Identifying issues early can save time and money, ensuring your equipment remains in top shape.

Where to Find Authentic Parts

Finding genuine components for your outdoor equipment is crucial for maintaining its performance and longevity. Authentic elements ensure reliability, compatibility, and the best results in your maintenance efforts. Below are some reliable sources to consider when searching for these essential items.

Authorized Dealers

- Visit local authorized retailers that specialize in outdoor machinery.

- Check their inventory or ask for specific components you need.

- Take advantage of their expertise and ask questions about compatibility and installation.

Online Marketplaces

- Explore reputable e-commerce platforms that focus on outdoor tools.

- Look for seller ratings and reviews to ensure authenticity.

- Utilize search filters to find specific models and components quickly.

By focusing on these trusted sources, you can be confident in acquiring the right items for your equipment, ensuring it remains in optimal working condition.

DIY Repair Techniques for Owners

For those who take pride in maintaining their equipment, understanding how to perform repairs can save time and money. Engaging in do-it-yourself fixes not only enhances your skills but also allows you to keep your tools in optimal condition. This section explores essential techniques for tackling common issues and ensuring longevity.

Basic Tools and Materials

Before embarking on any repair project, it’s crucial to have the right tools and materials at hand. Here’s a list of essentials:

- Screwdrivers (flathead and Phillips)

- Wrenches (various sizes)

- Pliers (needle-nose and standard)

- Safety goggles and gloves

- Lubricants and cleaning solutions

Common Repair Techniques

Here are several methods that can be applied to various issues:

- Cleaning: Regularly clean components to prevent buildup that can lead to malfunction.

- Replacement: Identify worn-out parts and replace them promptly to avoid further damage.

- Tightening: Ensure all screws and bolts are secure to maintain stability during use.

- Lubrication: Apply lubricant to moving parts to reduce friction and wear.

- Testing: After repairs, always perform a test run to confirm that the issue has been resolved.

By familiarizing yourself with these techniques, you empower yourself to address minor repairs and enhance the performance of your equipment effectively.

Upgrading Components for Enhanced Efficiency

Improving the efficiency of your outdoor equipment can significantly enhance performance and reduce operational costs. By focusing on specific enhancements, you can achieve greater power, better fuel efficiency, and improved overall functionality. This section explores various components that can be upgraded to optimize your machine’s capabilities.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Air Filter | High-flow filters | Increased airflow, improved combustion |

| Fuel System | Performance carburetors | Enhanced fuel delivery, better throttle response |

| Cutting Head | Multi-line trimmers | Wider cutting path, reduced work time |

| Clutch | High-performance clutches | Improved durability, reduced slippage |