Maintaining your outdoor power tool in optimal condition is essential for achieving peak performance. A thorough understanding of its individual elements can greatly enhance your ability to troubleshoot issues and ensure longevity. By familiarizing yourself with the structure of these machines, you can make informed decisions regarding repairs and upgrades.

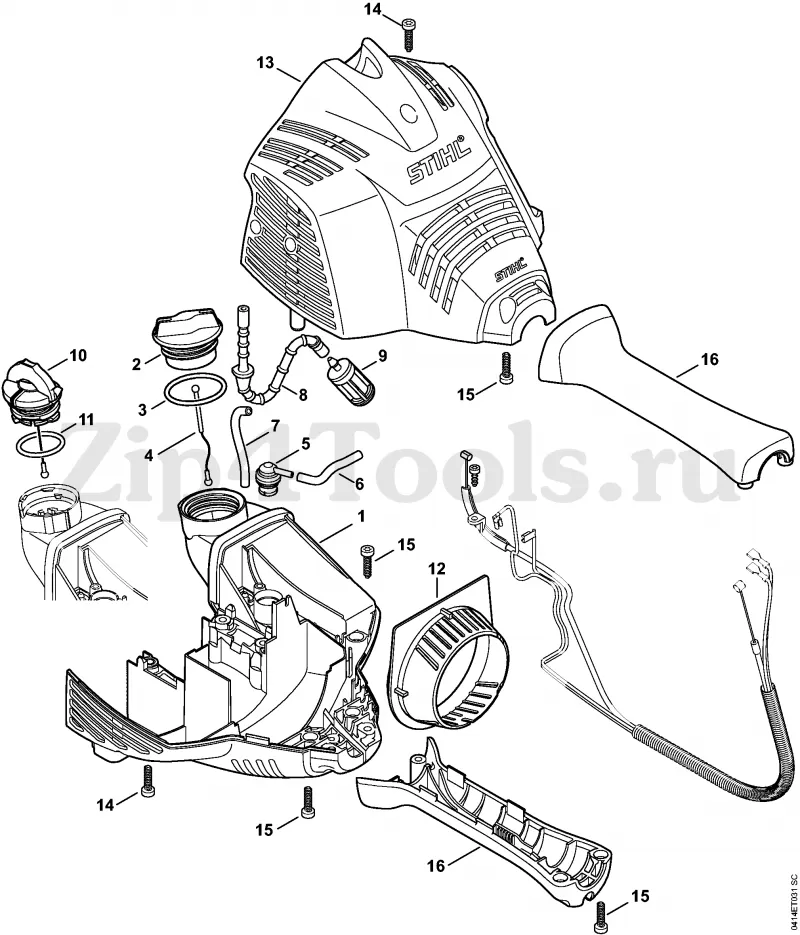

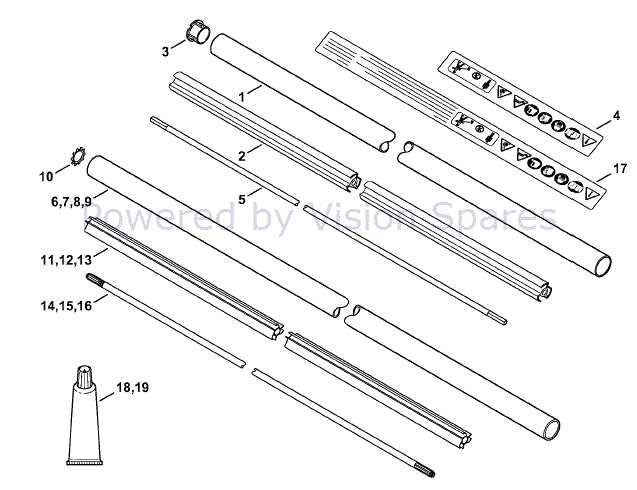

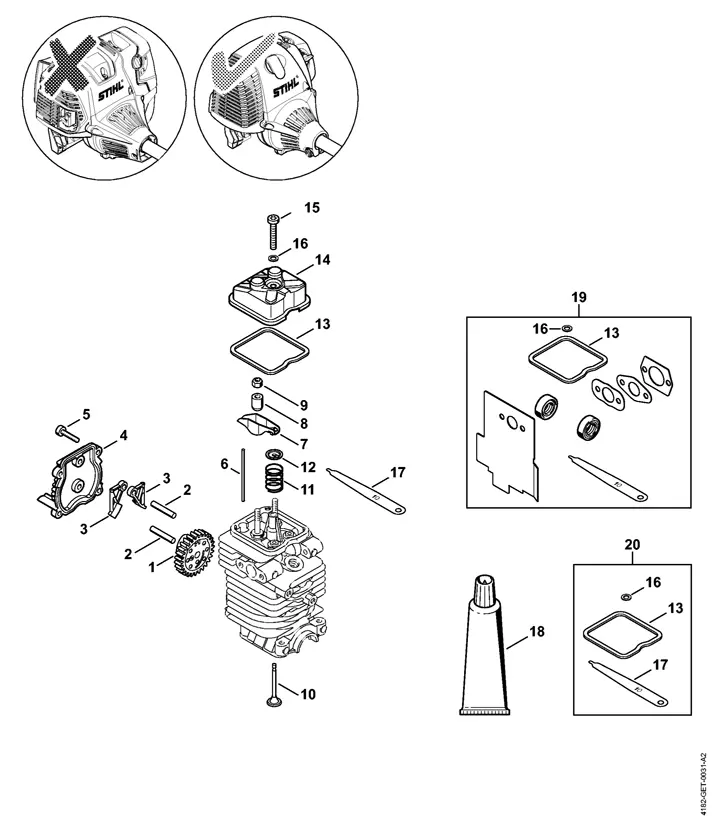

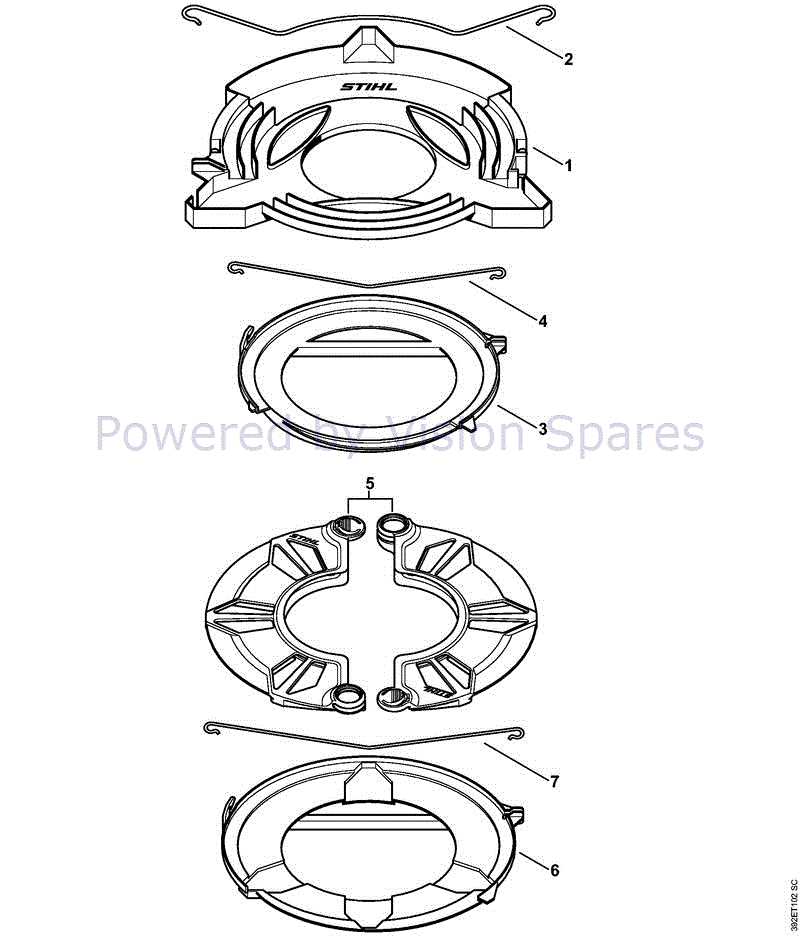

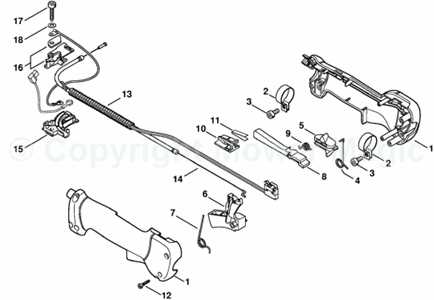

In this section, we will explore the intricate layout of the various components that make up your machine. By visualizing the arrangement and function of each piece, you can develop a clearer picture of how they interact to deliver efficiency and reliability. This knowledge is crucial for both novice users and seasoned professionals alike.

Additionally, recognizing the specific names and roles of each element will empower you to undertake maintenance tasks with confidence. Whether you are looking to replace a worn-out component or simply want to enhance your understanding, having access to a detailed visual guide will prove invaluable. Let’s dive into the essential features of your equipment and unlock the potential for better upkeep.

Understanding Stihl FS 111 R Components

Grasping the intricacies of a brushcutter’s elements is essential for optimal performance and maintenance. Each component plays a crucial role in the machine’s functionality, contributing to its overall efficiency and longevity. Familiarity with these parts can empower users to troubleshoot issues and ensure proper care.

The engine serves as the powerhouse, generating the necessary energy for operation. Complementing it are the cutting tools, designed for various tasks, from trimming grass to clearing dense vegetation. The fuel system is equally important, ensuring a steady supply of energy, while the control mechanisms allow for seamless operation.

Understanding how these components interact helps users make informed decisions regarding repairs and upgrades. Proper maintenance can significantly enhance the lifespan of the equipment, ensuring it remains reliable for years to come. Ultimately, knowledge of each part transforms the user experience and maximizes the utility of the machine.

Importance of Parts Diagrams

Understanding the assembly of complex machinery is crucial for effective maintenance and repair. Visual representations of components enable users to identify and locate essential elements within a device, ensuring proper functioning and longevity.

Enhanced Understanding

Visual aids simplify the comprehension of intricate systems. By illustrating how various pieces fit together, these resources allow technicians and users to gain a clearer perspective on the overall structure. This understanding aids in troubleshooting and facilitates timely repairs.

Efficient Repairs

Quick and efficient fixes are vital in any repair process. Access to visual layouts minimizes the risk of errors during disassembly and reassembly. When individuals can reference a clear guide, they can locate the necessary components swiftly, leading to reduced downtime.

| Benefit | Description |

|---|---|

| Clarity | Visual guides provide a clear view of assembly and organization. |

| Accuracy | Reduces the likelihood of mistakes during repairs. |

| Speed | Accelerates the repair process through easy identification of parts. |

Key Features of the FS 111 R

This cutting tool is designed for efficiency and ease of use, making it a reliable choice for both professionals and enthusiasts. Its construction emphasizes durability while ensuring optimal performance in various conditions. The following highlights showcase the unique attributes that set this model apart from others in its class.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust motor that delivers high torque for effective cutting. |

| Lightweight Design | Crafted to reduce user fatigue, allowing for extended use without discomfort. |

| Advanced Vibration Dampening | Incorporates technology that minimizes vibrations, enhancing user comfort during operation. |

| Versatile Attachment Options | Compatible with various accessories, enabling multiple applications for different tasks. |

| User-Friendly Controls | Features intuitive controls that simplify operation, making it accessible for all skill levels. |

Common Parts and Their Functions

Understanding the various components of a brushcutter is essential for effective maintenance and optimal performance. Each element plays a significant role in the overall functionality of the machine, contributing to its efficiency and longevity. Below is a detailed overview of some key components and their respective purposes.

| Component | Function |

|---|---|

| Engine | Generates power to drive the cutting mechanism. |

| Cutting Head | Houses the cutting line or blade, responsible for trimming grass and weeds. |

| Fuel Tank | Stores the fuel necessary for engine operation. |

| Handlebar | Provides control and stability during operation, allowing for maneuverability. |

| Shaft | Transmits power from the engine to the cutting head. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring optimal performance. |

| Starter Mechanism | Facilitates the initial ignition of the engine. |

| Vibration Dampeners | Minimize vibrations for user comfort during extended use. |

Maintenance Tips for Stihl Trimmers

Regular upkeep is essential for optimal performance and longevity of your outdoor cutting tools. Following a structured maintenance routine ensures that these devices operate efficiently and remain in excellent condition throughout their lifespan.

Routine Checks

Perform regular inspections to identify any wear and tear. Look for signs of damage, such as frayed cables or worn blades, and address these issues promptly.

Cleaning and Care

Keep your equipment clean by removing debris after each use. This prevents buildup that can hinder performance. Utilize appropriate cleaning agents and tools to maintain the exterior and internal components.

| Maintenance Task | Frequency |

|---|---|

| Inspect Blades | After every use |

| Clean Air Filter | Every 10 hours |

| Check Fuel Lines | Monthly |

| Sharpen Blades | Every 25 hours |

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is essential for ensuring optimal performance and longevity. Various sources are available to help you acquire the necessary items to keep your machinery running smoothly. Here are some of the most reliable options for sourcing these crucial elements.

| Source | Description | Benefits |

|---|---|---|

| Authorized Dealers | Official distributors that specialize in specific brands. | Genuine components with warranty, expert advice. |

| Online Retailers | Websites that sell a wide variety of equipment accessories. | Convenience, often competitive pricing, customer reviews. |

| Local Hardware Stores | Community stores that stock general and specialized items. | Immediate availability, personalized service. |

| Second-hand Marketplaces | Platforms for buying used or refurbished components. | Cost-effective options, potential for rare finds. |

Exploring these various avenues will enhance your chances of finding exactly what you need, whether you’re looking for something brand new or a cost-effective alternative.

Tools Required for Assembly

Assembling your equipment requires a specific set of tools to ensure everything fits perfectly and functions efficiently. Having the right instruments on hand not only simplifies the process but also enhances safety and effectiveness during assembly.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will be essential for tightening or loosening screws.

- Wrenches: Adjustable wrenches and socket sets are crucial for securing nuts and bolts.

- Pliers: Needle-nose and standard pliers can help grip small components and wires.

- Hex Keys: Also known as Allen wrenches, these are necessary for assembling parts that require hexagonal screws.

- Torque Wrench: Ensuring that bolts are tightened to the manufacturer’s specifications requires a reliable torque wrench.

- Utility Knife: A sharp utility knife will be handy for cutting packaging materials and trimming components as needed.

- Safety Gear: Always wear protective gloves and goggles to safeguard against accidental injuries during assembly.

By having these tools at your disposal, you can ensure a smooth and effective assembly process, leading to optimal performance of your machinery.

Assembly Process Overview

The assembly process of outdoor power equipment involves a series of systematic steps designed to ensure that each component fits together seamlessly. Understanding this procedure is crucial for both novice and experienced users, as it aids in the maintenance and troubleshooting of the machine. A well-organized assembly can enhance performance and longevity, making it essential to follow the guidelines carefully.

Step-by-Step Approach

Beginning with a thorough examination of each component is vital. Gather all necessary tools and parts in a clean workspace to avoid confusion. Start with the base unit and progressively add components, ensuring each piece is securely attached. This methodical approach helps to prevent potential issues that could arise from improper installation.

Final Checks and Adjustments

Once the assembly is complete, conducting final inspections is important. Verify all connections and make any necessary adjustments to ensure everything operates smoothly. This final stage is key to achieving optimal functionality and safety. Regular maintenance checks post-assembly can further enhance the equipment’s performance, extending its service life.

FAQs About Stihl FS 111 R Parts

This section addresses common inquiries related to components of a well-known trimming tool. Whether you’re a seasoned user or new to this equipment, understanding the essential elements can enhance your maintenance and repair experience.

What are the common issues with the equipment?

Frequent problems include engine starting difficulties, fuel leaks, and excessive vibrations. Regular maintenance can mitigate these issues, ensuring smooth operation and longevity.

How can I find replacement components?

Replacement items can typically be sourced from authorized retailers or online marketplaces. It’s important to verify compatibility to ensure optimal performance. Always consult the user manual for specifications and recommendations.

Note: Regular inspections can help identify worn or damaged elements early, preventing further complications.

Maintaining your equipment properly will extend its lifespan and improve efficiency.