When it comes to maintaining your outdoor machinery, having a clear understanding of its components is crucial. This knowledge not only enhances your ability to perform routine maintenance but also helps in troubleshooting issues effectively. Familiarity with the internal structure can save time and resources, ensuring that your equipment operates at peak efficiency.

Every model comes with its unique assembly of elements, each serving a specific function. Whether you are replacing a worn-out part or simply inspecting the unit, a visual reference can greatly facilitate this process. By knowing how the various components interact, you can approach repairs with confidence and precision.

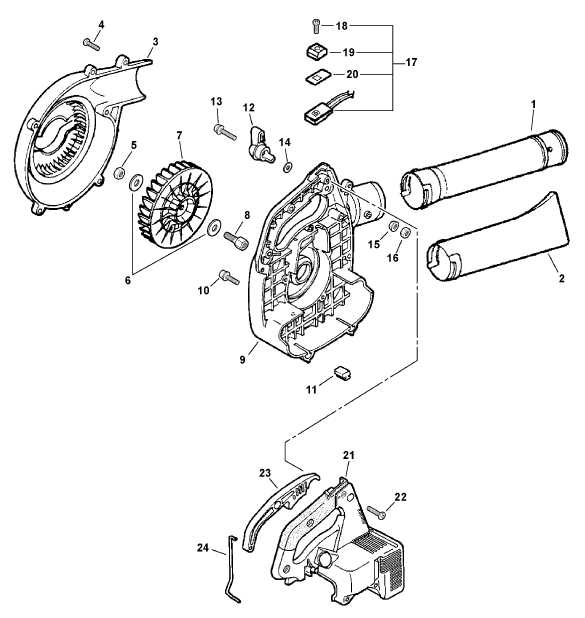

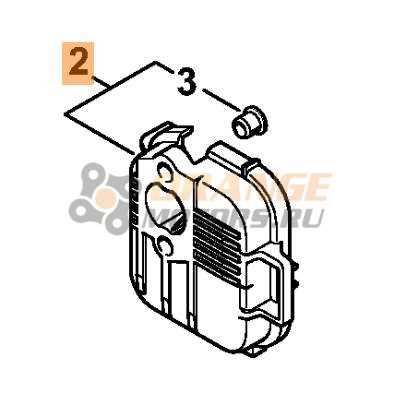

In this section, we will provide a detailed visual representation of the assembly, highlighting the key components and their respective roles. This guide will serve as a valuable resource for both seasoned users and newcomers alike, offering insights into the inner workings of your machinery.

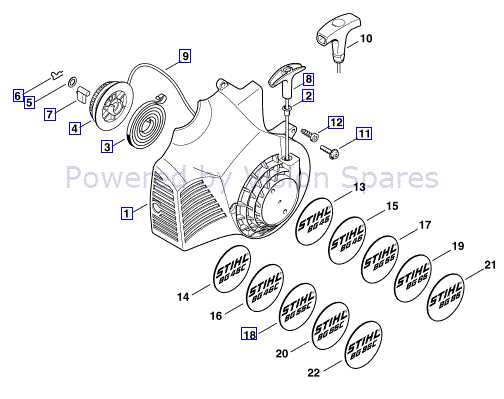

Understanding the Stihl BG55 Components

When delving into the intricacies of outdoor power tools, it’s essential to recognize the various elements that contribute to their functionality. Each component plays a crucial role in ensuring efficiency and performance, making it vital for users to have a clear understanding of how these parts interact.

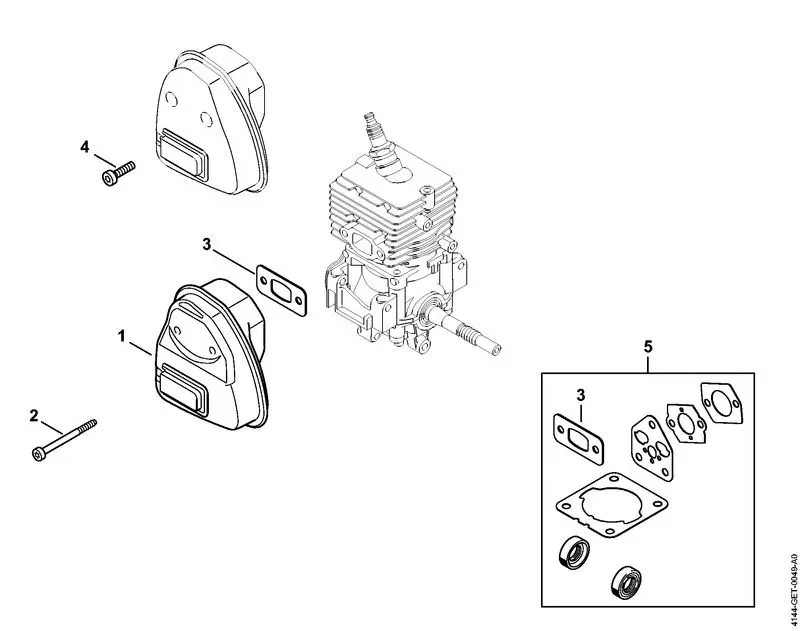

Engine is the heart of the device, providing the necessary power for operation. It converts fuel into mechanical energy, driving the overall performance.

Fuel System includes the tank and lines, responsible for transporting the fuel to the engine. A clean and efficient fuel delivery system is critical for optimal performance.

Air Filter protects the engine from dust and debris, ensuring a clean airflow. Regular maintenance of this component can significantly extend the life of the engine.

Ignition System ignites the fuel-air mixture, enabling the engine to start and run smoothly. Troubles with ignition can lead to performance issues, making it essential to monitor this system closely.

Exhaust System manages the byproducts of combustion, directing them away from the engine and minimizing emissions. A well-functioning exhaust system is vital for both efficiency and environmental considerations.

Understanding these components and their functions can greatly enhance the user experience, ensuring that the tool operates at its best for various tasks.

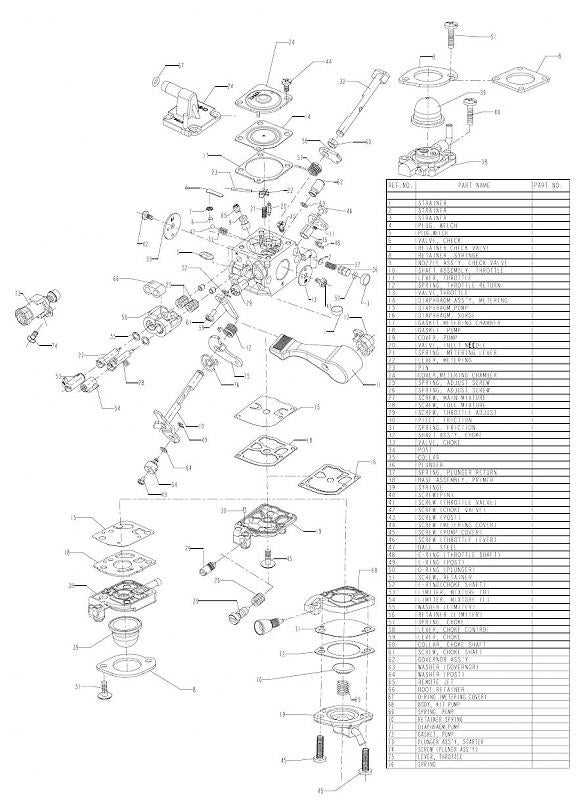

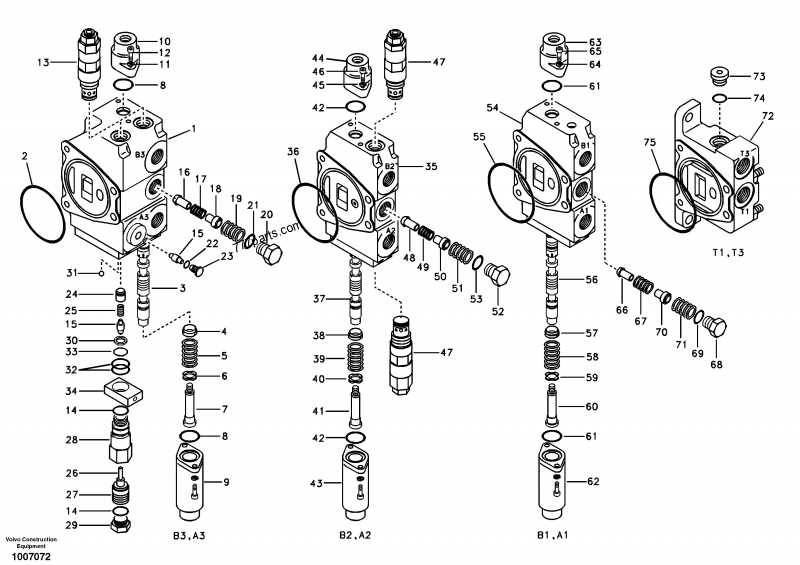

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair of equipment. These visual guides provide a clear representation of various components, helping users identify and locate each piece within the machinery. Familiarity with these images can streamline the process of disassembly and reassembly, ensuring that tasks are performed efficiently.

Components of an Assembly Illustration

When examining an illustration, it is important to recognize its key features:

- Numbering System: Each item is usually labeled with a unique number corresponding to a list of components.

- Legend: Often included, this explains the symbols or colors used to indicate different types of parts.

- Views: Multiple perspectives may be provided, allowing for a comprehensive understanding of the assembly.

Steps to Interpret the Illustration

- Identify the overall layout and orientation of the machinery.

- Locate the numbering system to find specific components of interest.

- Refer to the legend to understand any symbols or color codes.

- Use the various views to gain a complete perspective on how parts fit together.

By following these steps, users can effectively navigate through assembly illustrations and enhance their understanding of the equipment’s structure and function.

Common Issues with BG55 Parts

When operating outdoor power equipment, certain components may encounter problems that affect overall performance. Understanding these common challenges can help users identify and address issues promptly, ensuring smoother operation and longevity of the machine.

Frequent Problems Encountered

- Fuel System Issues:

- Clogs in the fuel lines

- Contaminated fuel

- Faulty fuel filters

- Ignition Troubles:

- Defective spark plugs

- Weak ignition coils

- Wiring issues affecting the ignition system

Signs of Wear and Tear

- Reduced power output

- Unusual noises during operation

- Difficulty starting the machine

Being aware of these common issues allows for proactive maintenance and timely repairs, ultimately enhancing the efficiency and reliability of your equipment.

Replacing Components

Maintaining outdoor power equipment often involves the replacement of various parts to ensure optimal performance. Understanding the process of swapping out essential components can enhance the longevity and efficiency of your device. This section outlines key considerations and steps to successfully replace specific elements within your equipment.

Common Components for Replacement

When it comes to servicing your equipment, certain components are more frequently replaced than others. Below are some typical parts that may require attention:

| Component | Function |

|---|---|

| Air Filter | Prevents dirt and debris from entering the engine |

| Spark Plug | Ignites the fuel-air mixture for combustion |

| Fuel Filter | Ensures clean fuel reaches the engine |

| Blower Fan | Moves air efficiently for optimal operation |

Steps for Replacement

To ensure a smooth replacement process, follow these basic steps:

- Gather necessary tools and replacement parts.

- Disconnect the power source for safety.

- Carefully remove the old component, noting any specific attachments or connections.

- Install the new part, ensuring a secure fit.

- Reconnect the power source and test the equipment for proper functionality.

By following these guidelines, you can effectively maintain your equipment and enhance its performance for years to come.

Maintenance Tips for BG55 Equipment

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential breakdowns, allowing you to get the most out of your investment.

Here are some key maintenance practices to follow:

- Clean the Air Filter: Regularly check and clean the air filter to prevent debris from clogging the engine. A clean filter promotes better airflow and performance.

- Inspect Fuel Lines: Examine the fuel lines for cracks or leaks. Replace any damaged sections to avoid fuel loss and ensure safe operation.

- Check Spark Plug: Inspect the spark plug for wear and carbon buildup. Replace it if necessary to maintain proper ignition and efficiency.

- Sharpen Blades: Keep blades sharp for effective cutting. Dull blades can strain the engine and reduce performance.

- Monitor Lubrication: Ensure that all moving parts are adequately lubricated. Use the recommended lubricant to minimize friction and wear.

By incorporating these practices into your routine, you can extend the life of your equipment and enhance its overall performance. Regular maintenance not only saves you money in the long run but also contributes to a safer working environment.

Where to Find Genuine Parts

Finding authentic components for your equipment is essential for maintaining performance and longevity. Using original replacements ensures compatibility and reliability, preventing potential issues that might arise from using inferior alternatives.

| Source | Description |

|---|---|

| Authorized Dealers | Visit local retailers that specialize in equipment to find genuine offerings and receive expert advice. |

| Online Stores | Many reputable online platforms provide original items directly from manufacturers. |

| Manufacturer’s Website | The official site often features a dedicated section for purchasing components securely. |

| Repair Shops | Local repair services frequently have access to authentic replacements and can assist with installation. |

Benefits of Using Original Stihl Parts

Choosing authentic components for your equipment ensures optimal performance and longevity. While aftermarket options may seem appealing due to their lower price, they often compromise quality, leading to increased wear and potential failures. Investing in original components is not just a matter of preference; it’s a smart choice for maintaining the efficiency and reliability of your tools.

Enhanced Performance

Original components are designed specifically for your equipment, providing a perfect fit and superior functionality. This precision enhances overall performance, allowing your machinery to operate smoothly and effectively. With genuine components, you can expect better fuel efficiency and reduced emissions, contributing to a more environmentally friendly operation.

Long-term Cost Savings

While the initial investment in authentic components may be higher, the long-term savings are significant. Genuine parts typically have a longer lifespan, reducing the need for frequent replacements. Additionally, they minimize the risk of damage to your equipment, saving you from costly repairs and downtime.

In summary, opting for original components not only ensures reliable performance but also promotes the longevity of your tools, making it a wise investment for any user.

DIY Repairs for the BG55

When it comes to maintaining your outdoor equipment, tackling minor repairs on your own can save time and money. Understanding the essential components and how they function will empower you to troubleshoot and resolve common issues. With a little guidance, even those without extensive mechanical experience can undertake straightforward fixes to keep their device running smoothly.

Identifying Common Issues

Before diving into repairs, it’s crucial to recognize frequent problems that may arise. Issues such as poor performance, unusual noises, or starting difficulties are often indicators that something needs attention. By observing these symptoms, you can narrow down potential causes, allowing for a more focused approach to repairs.

Basic Repair Techniques

Once you’ve identified the problem, several basic techniques can help in resolving it. For instance, cleaning or replacing the air filter can significantly improve airflow and overall efficiency. Additionally, ensuring that the fuel system is free of debris can prevent performance issues. Always remember to consult the user manual for guidance on specific tasks, and take the necessary safety precautions before starting any work.

By engaging in these simple repair practices, you’ll not only extend the life of your equipment but also gain valuable skills that can be applied to future maintenance tasks. Remember, regular upkeep is key to optimal functionality.

Comparing BG55 with Other Models

In the world of outdoor power equipment, various models cater to different needs and preferences. By examining the features, performance, and usability of one specific model in relation to its peers, users can make informed decisions. This comparison highlights key aspects such as weight, engine power, and ease of use, helping potential buyers choose the right tool for their gardening tasks.

When looking at alternatives, some models offer more powerful engines, making them suitable for larger areas or tougher debris. However, this increased power often comes at the cost of added weight and reduced maneuverability. Conversely, lighter options might excel in portability but may struggle with heavier materials, emphasizing the importance of finding the right balance based on individual requirements.

Additionally, features such as fuel efficiency and maintenance needs play crucial roles in long-term satisfaction. Some alternatives may provide advanced filtration systems that enhance performance and reduce downtime, while others focus on straightforward operation and easy maintenance, appealing to users who prioritize simplicity. By evaluating these factors, one can better understand how this particular model stands against its competition.