When it comes to maintaining your machinery, having a clear overview of its individual elements is essential. Each component plays a vital role in ensuring the overall functionality and longevity of the device. This section will delve into the intricacies of these parts, helping you grasp their significance and interrelations.

By familiarizing yourself with the structure and organization of these elements, you can enhance your troubleshooting skills and streamline maintenance processes. Knowing where each piece fits can also aid in the efficient assembly and disassembly of your tools, making repairs and upgrades more manageable.

Moreover, a thorough understanding of your equipment’s anatomy empowers you to make informed decisions regarding replacements and enhancements. Whether you’re a seasoned user or a novice, gaining insights into the various sections can significantly improve your operational efficiency and overall experience.

Understanding the Stihl 011 AVT

This section aims to provide an overview of a well-known handheld device, focusing on its components and how they function together. Understanding these elements is crucial for both maintenance and effective usage. The device is recognized for its efficiency and reliability in various applications.

Key Features and Benefits

One of the standout qualities of this equipment is its lightweight design, which enhances maneuverability during operation. Additionally, its robust engine delivers powerful performance, making it suitable for both professional and recreational tasks. The user-friendly controls allow for seamless operation, reducing the learning curve for new users.

Common Components

Familiarizing oneself with the essential elements can significantly improve maintenance practices. Below is a table outlining some of the major components and their functions:

| Component | Function |

|---|---|

| Engine | Powers the device, providing necessary thrust. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Cutting Mechanism | Facilitates precise cutting of various materials. |

| Handle Assembly | Offers control and comfort during operation. |

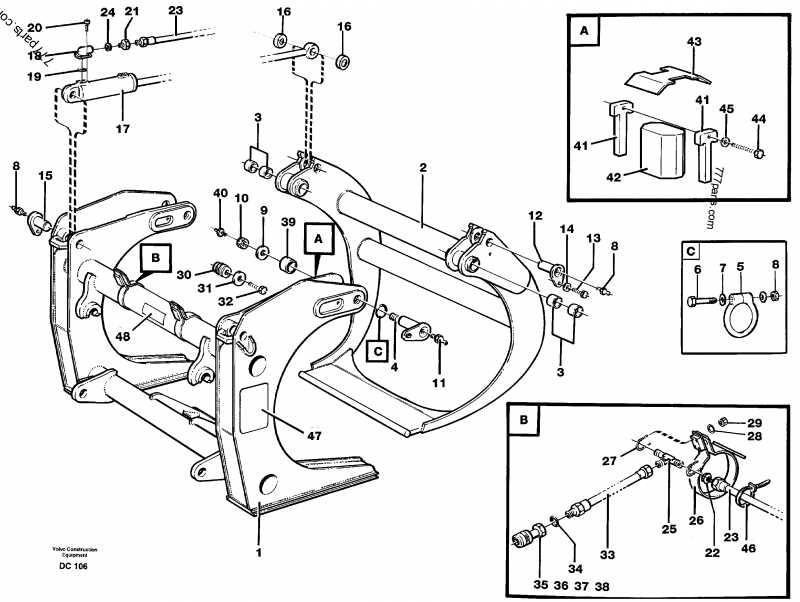

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations offer a clear view of each element’s function and placement, enabling users to identify issues quickly and accurately. This clarity ultimately enhances efficiency and prolongs the lifespan of the equipment.

Visual aids serve as essential tools for technicians and enthusiasts alike. They simplify complex assemblies and help in recognizing compatible components, ensuring that repairs are performed correctly. Without these illustrations, the risk of errors increases significantly, potentially leading to costly mistakes.

Moreover, diagrams promote a deeper comprehension of the mechanical systems at play. By delving into these resources, individuals can gain insights into how different parts interact, fostering a more thorough understanding of the entire apparatus. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades or replacements.

Common Issues with Stihl 011 AVT

Many users encounter a variety of challenges when operating this particular model. Understanding these common problems can enhance performance and prolong its lifespan. Below are some frequently reported issues.

Fuel System Problems

- Difficulty starting due to clogged fuel filters.

- Inconsistent power output from improper fuel mixture.

- Leaks from the fuel lines or tank.

Mechanical Failures

- Chain tensioning issues leading to poor cutting performance.

- Worn bearings causing noise and vibration.

- Malfunctioning spark plug resulting in starting difficulties.

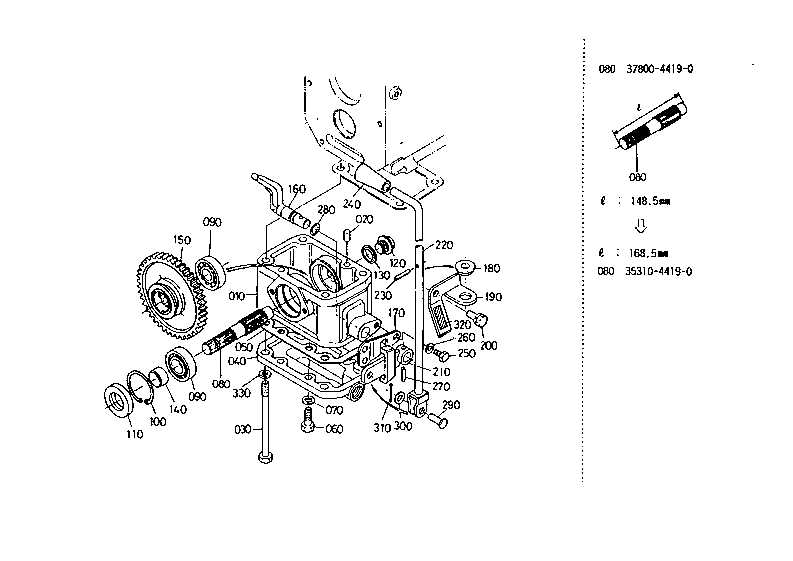

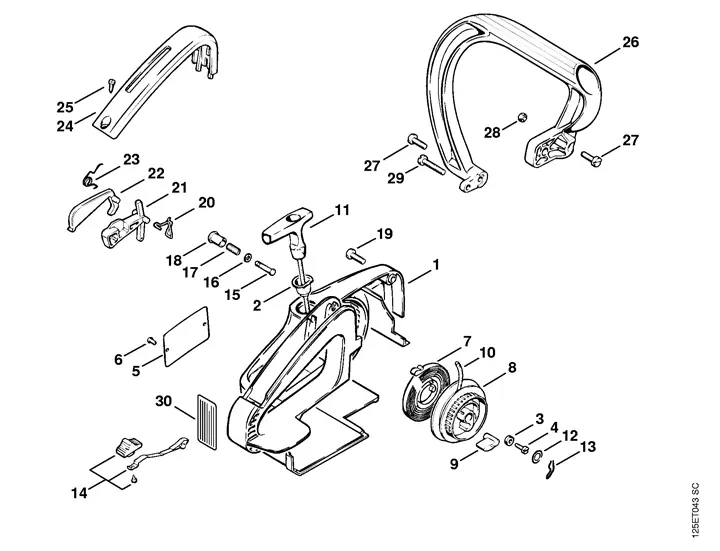

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each part plays a significant role in the performance, safety, and durability of the machine, contributing to its overall efficiency in various tasks.

Engine and Power System

The heart of any cutting device lies in its engine, which generates the necessary power to drive the chain. This component converts fuel into mechanical energy, enabling the tool to perform its cutting functions. A well-maintained engine ensures optimal performance, while regular checks can prevent issues that may arise from wear and tear.

Cutting Mechanism

The cutting mechanism consists of the chain and bar, which work together to slice through materials. The chain features sharp teeth that engage with the surface being cut, while the bar provides stability and guidance. Understanding the different types of chains and bars available can enhance cutting efficiency and adapt the tool for specific tasks.

Regular inspection and maintenance of these critical components are vital for safety and longevity. By familiarizing oneself with the key elements, users can ensure their equipment remains in top condition, ready to tackle any challenge.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visuals serve as a guide, showcasing the components and their relationships within a device. Familiarity with these representations can significantly enhance your ability to identify, source, and replace necessary elements.

Begin by observing the overall layout. Often, these visuals are organized to show how various components fit together. Look for a legend or key that may explain symbols or color codes used throughout the illustration. This will provide context and clarity for each part depicted.

Next, pay attention to the numbering system. Each item is typically labeled with a specific number, corresponding to a list that details its specifications, availability, and function. Cross-referencing these numbers with the accompanying list can aid in pinpointing the exact component you need.

Additionally, note any directional arrows or connection lines. These indicators often illustrate how parts interact or are assembled. Understanding these connections can prevent misalignment during reassembly, ensuring the machinery operates smoothly.

Lastly, don’t hesitate to seek out additional resources. Many manufacturers provide supplementary materials, such as repair manuals or video tutorials, which can enhance your comprehension of the illustrated components and their roles. With practice, interpreting these technical illustrations will become a valuable skill in your repair toolkit.

Where to Find Replacement Parts

Locating the necessary components for maintenance or repairs can be crucial for ensuring optimal performance. Various resources are available, ranging from official retailers to online marketplaces, catering to diverse needs and budgets.

Authorized dealers often provide genuine items that guarantee compatibility and quality. Their expertise can also assist in identifying specific components needed for your equipment.

For those seeking more options, online platforms like auction sites and specialty stores can offer a wide array of alternatives, including both new and refurbished items. User reviews and ratings can help guide your purchasing decisions.

Additionally, local repair shops may have spare components on hand or can order them for you, providing a personal touch and expert advice throughout the process.

Community forums and social media groups dedicated to equipment enthusiasts can also be valuable resources, where members share tips on sourcing hard-to-find items and their experiences with various suppliers.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires regular care and attention. Proper maintenance not only enhances functionality but also extends the lifespan of vital components.

Regular Cleaning

Keep your tools clean to prevent dirt and debris from causing wear and tear. After each use, wipe down surfaces and remove any buildup that could affect performance.

Routine Inspections

Conduct periodic checks to identify signs of wear or damage early. Look for frayed wires, loose connections, and other issues that could compromise efficiency. Addressing these problems promptly can save time and money in the long run.

Compatibility with Other Stihl Models

Understanding the interchangeability of components among various models can significantly enhance the efficiency and longevity of equipment. This aspect is crucial for users looking to maintain or upgrade their tools without the need for extensive research into individual specifications.

Models with Similar Components

Several units share compatible elements, making it easier for users to find replacements or upgrades. Here are some models that might use similar components:

- Model A – Known for its durability and efficiency.

- Model B – Offers comparable performance with a different design.

- Model C – Features shared technology that allows for cross-compatibility.

Benefits of Compatibility

Utilizing interchangeable components provides several advantages:

- Cost-effectiveness – Reduces the need for unique parts.

- Accessibility – Increases availability of components in the market.

- Ease of maintenance – Simplifies repairs and replacements.

Overall, understanding compatibility can lead to better maintenance practices and a more seamless experience for users of various equipment.

Customer Reviews and Feedback

This section explores the insights and opinions of users regarding their experiences with the product. Customer feedback plays a vital role in understanding performance, reliability, and overall satisfaction, helping potential buyers make informed decisions.

Positive Experiences

Many users appreciate the efficiency and ease of use of the equipment. Reliability and durability are frequently highlighted, with customers noting that it performs well in various conditions and tasks. This feedback often reflects a high level of confidence in the brand’s reputation.

Areas for Improvement

Some reviews indicate challenges with specific components, suggesting that there could be enhancements in accessibility and serviceability. Constructive criticism helps manufacturers identify potential areas for development, ensuring continuous improvement and customer satisfaction.