Understanding the layout and functionality of crucial systems within an all-terrain vehicle is essential for maintaining its optimal performance. When tackling repairs or upgrades, having a clear visual representation of various elements can be invaluable. This section provides an in-depth look at the assembly and structure of the most vital mechanical components, offering a detailed view of how each piece fits into the broader system.

With the right insights, even the most complex configurations become more approachable. This breakdown is designed to guide you through each element’s role, helping to identify areas for improvement or attention. Whether you’re addressing maintenance or troubleshooting specific issues, these visual aids offer clarity, ensuring that each task is carried out efficiently and effectively.

For those seeking a clear understanding of how each unit interacts within the system, these diagrams serve as an essential tool. Equipped with this knowledge, handling various adjustments or replacements becomes a streamlined process, leading to better results and prolonged vehicle longevity.

Polaris Sportsman 500 HO Essential Components

When examining the construction of this robust vehicle, it’s crucial to understand the core elements that contribute to its reliable performance. These key components ensure smooth operation across various terrains, offering durability and efficient power management. Below is an overview of the essential mechanical systems that enable this off-road machine to excel in a variety of conditions.

Powertrain Elements

- Engine: The heart of the machine, this part generates the force required to propel the vehicle, delivering consistent energy under demanding circumstances.

- Transmission: This system seamlessly transfers power from the engine to the wheels, providing the necessary torque to navigate challenging surfaces.

- Cooling System: Helps maintain optimal engine temperature, preventing overheating and ensuring longevity during extended rides.

Chassis and Suspension

- Frame: The backbone that supports all other elements, designed to withstand rough environments while maintaining stability

Engine and Transmission Overview

The power system and drivetrain in this off-road machine are designed to provide a robust combination of performance and durability. This section offers an overview of the key mechanical components, emphasizing the interaction between the motor and the gear system to ensure smooth and efficient operation on various terrains.

Key Engine Features

- Liquid-cooled design for maintaining optimal operating temperatures.

- Efficient fuel management system that balances power and economy.

- Precision-engineered components to withstand demanding conditions.

- Responsive throttle control for quick adjustments in power output.

Transmission System

The transmission is engineered to deliver consistent power to the wheels, ensuring smooth transitions between gears. It is specifically designed to handle varying terrain and conditions, offering both reliability and ease of use.

- Automatic shifting system for easy control without manual intervention.

- Built-in safeguards to prevent overheating and wear.

- Fuses: Designed to protect the system from electrical overload by breaking the circuit when necessary.

- Relays: These control

Braking Mechanism Structure and Parts

The stopping system in vehicles serves a crucial role in ensuring both safety and control during operation. The arrangement of components in this system is designed to provide effective control over the speed and halt the movement when necessary. Understanding the layout of these components is key to maintaining the system’s efficiency and longevity.

Main Components of the Stopping System

The core elements of the system include the energy transfer unit, the force amplifying device, and the friction-based components. The energy transfer unit is responsible for converting the rider’s input into mechanical action, while the force amplifier increases the applied pressure, making it easier to engage the stopping mechanism. Finally, the friction elements provide the necessary resistance to slow down or stop the movement.

Operation and Maintenance

Regular inspection and upkeep of the friction components and the force amplifier are essential to prevent wear and ensure smooth operation. Over time, these elements may lose their effectiveness, leading to reduced stopping power. Timely replacement of worn components is critical for maintaining optimal performance.

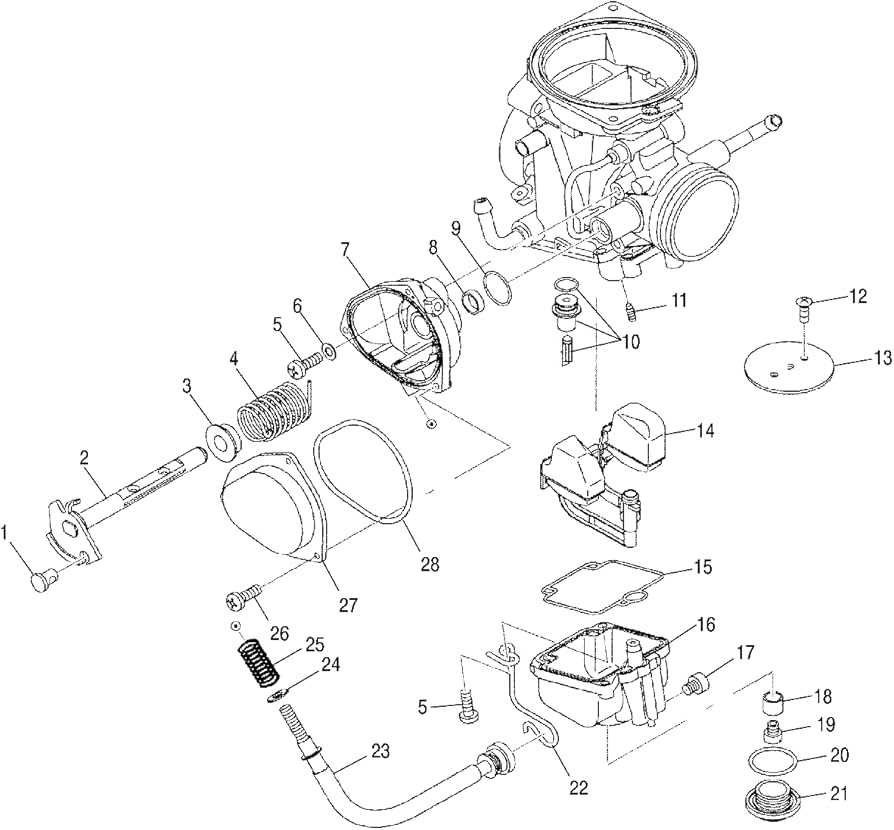

Fuel System and Related Components

The fuel system plays a crucial role in the efficient operation of any all-terrain vehicle, ensuring that the engine receives the correct mixture of fuel and air for optimal performance. This system consists of several interconnected parts that work harmoniously to deliver fuel from the tank to the combustion chamber. Understanding these components is essential for proper maintenance and troubleshooting.

At the heart of this system is the fuel tank, which stores the gasoline and provides it to the engine when needed. Connected to the tank is the fuel pump, responsible for transporting fuel through the lines to the carburetor or fuel injector. The pump’s performance is vital, as insufficient pressure can lead to poor engine performance or starting issues.

The fuel filter is another essential element that prevents contaminants from entering the fuel system, ensuring that only clean fuel reaches the engine components. Regular replacement of this filter is necessary to maintain the longevity and efficiency of the vehicle. Additionally, the carburetor or fuel injectors mix the fuel with air, creating a combustible mixture for the engine. Proper calibration of these parts is crucial for achieving the desired performance and fuel efficiency.

Finally, various hoses and connectors facilitate the movement of fuel throughout the system. These components must be inspected regularly for leaks or wear, as any failure can lead to significant operational issues. Overall, maintaining the fuel system and its components is key to ensuring the reliable operation of the vehicle.

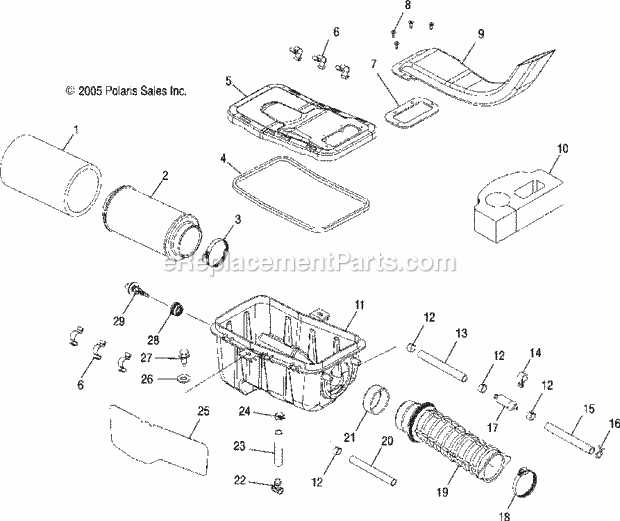

Cooling System Layout and Parts

The cooling system is a vital component in maintaining optimal engine performance and preventing overheating. It operates by circulating a coolant to absorb and dissipate heat generated during operation. Understanding its configuration and individual elements is essential for effective maintenance and repair.

Key components of the cooling system include:

- Radiator: A heat exchanger that cools the coolant by allowing airflow through its fins.

- Water Pump: Responsible for circulating the coolant throughout the engine and radiator.

- Thermostat: Regulates coolant flow based on temperature, ensuring efficient operation.

- Coolant Hoses: Flexible tubes that transport coolant between various components.

- Expansion Tank: Collects excess coolant and allows for pressure regulation within the system.

Proper functioning of each element is crucial for the overall efficiency of the cooling mechanism. Regular inspections and timely replacements can help prevent potential issues that may arise from wear or damage.

Frame and Bodywork Assembly Details

The assembly of the chassis and outer structure is crucial for the overall integrity and functionality of any off-road vehicle. This section delves into the essential components and their configuration, highlighting how each part contributes to the robustness and aesthetics of the machine.

Chassis Components

The frame serves as the backbone, providing support for all other elements. Constructed from durable materials, it is designed to withstand significant stress and impact. Key components include the main frame, subframe, and mounting points for various accessories. Proper alignment and secure fastening of these parts are vital to maintain stability during operation.

Bodywork Integration

The external panels not only enhance the visual appeal but also protect the internal mechanisms from environmental elements. These panels are typically made from lightweight yet strong materials, ensuring minimal weight while maximizing durability. Attention to detail in the fitting of these components is essential, as gaps or misalignments can lead to performance issues or increased wear.

Steering System Parts and Function

The steering mechanism of an all-terrain vehicle is crucial for maneuverability and control, allowing the operator to navigate various terrains with precision. This system comprises several components that work together seamlessly to ensure responsive handling and stability while driving. Understanding the individual elements and their roles is essential for effective maintenance and troubleshooting.

Key Components of the Steering Mechanism

At the core of the steering assembly lies the steering wheel, which serves as the primary interface for the operator. Attached to this wheel is the steering column, a vital component that transmits the driver’s input to the system. Additionally, the rack and pinion setup facilitates the conversion of rotational motion into linear motion, enabling the front wheels to pivot accurately. The tie rods connect the steering mechanism to the wheels, ensuring synchronized movement.

Functionality and Importance

The effective functioning of the steering system is paramount for safety and performance. Each component must work harmoniously to provide precise control, allowing for smooth navigation through tight corners and rough landscapes. Regular inspection and maintenance of these elements are necessary to prevent wear and tear, ensuring the longevity of the vehicle and enhancing the overall driving experience.

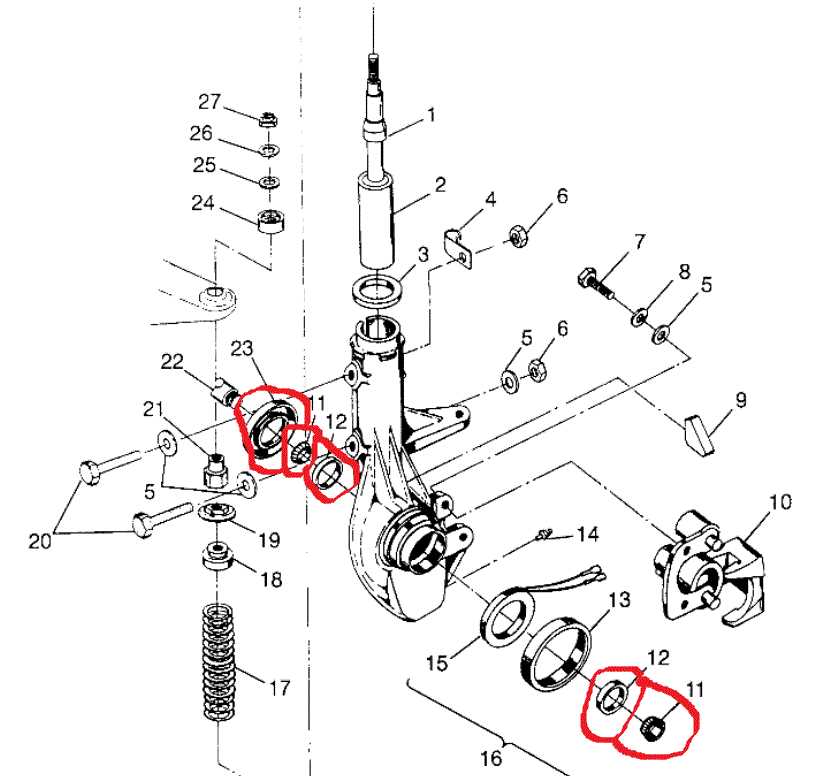

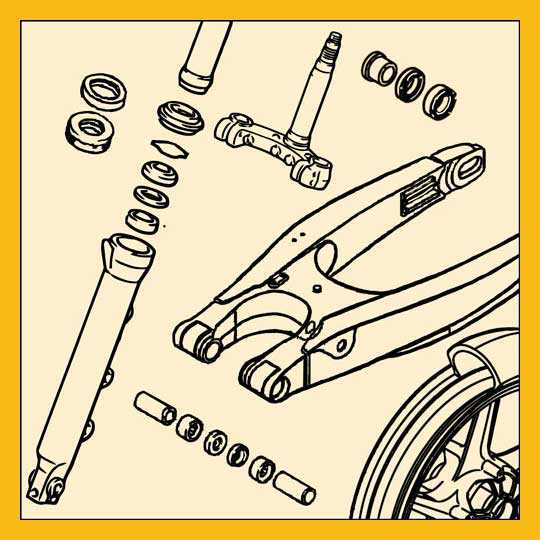

Suspension System Parts Breakdown

The suspension system is crucial for providing stability, comfort, and control during off-road adventures. It absorbs the impact from uneven terrains, ensuring a smooth ride while maintaining the vehicle’s balance. Understanding the individual elements that make up this system helps in identifying any issues and enhancing overall performance.

The core of the system includes shock absorbers, which dampen the motion and minimize vibrations, along with springs that handle the vertical load. Control arms connect the wheels to the chassis, enabling precise movement while traversing different surfaces. Ball joints, tie rods, and bushings are smaller yet vital components that contribute to the flexibility and alignment of the system.

Additionally, the system integrates stabilizers to reduce body roll during turns and sway bars to enhance cornering ability. These elements work in harmony to deliver superior handling and adaptability, allowing for safe and enjoyable operation on various types of terrain.

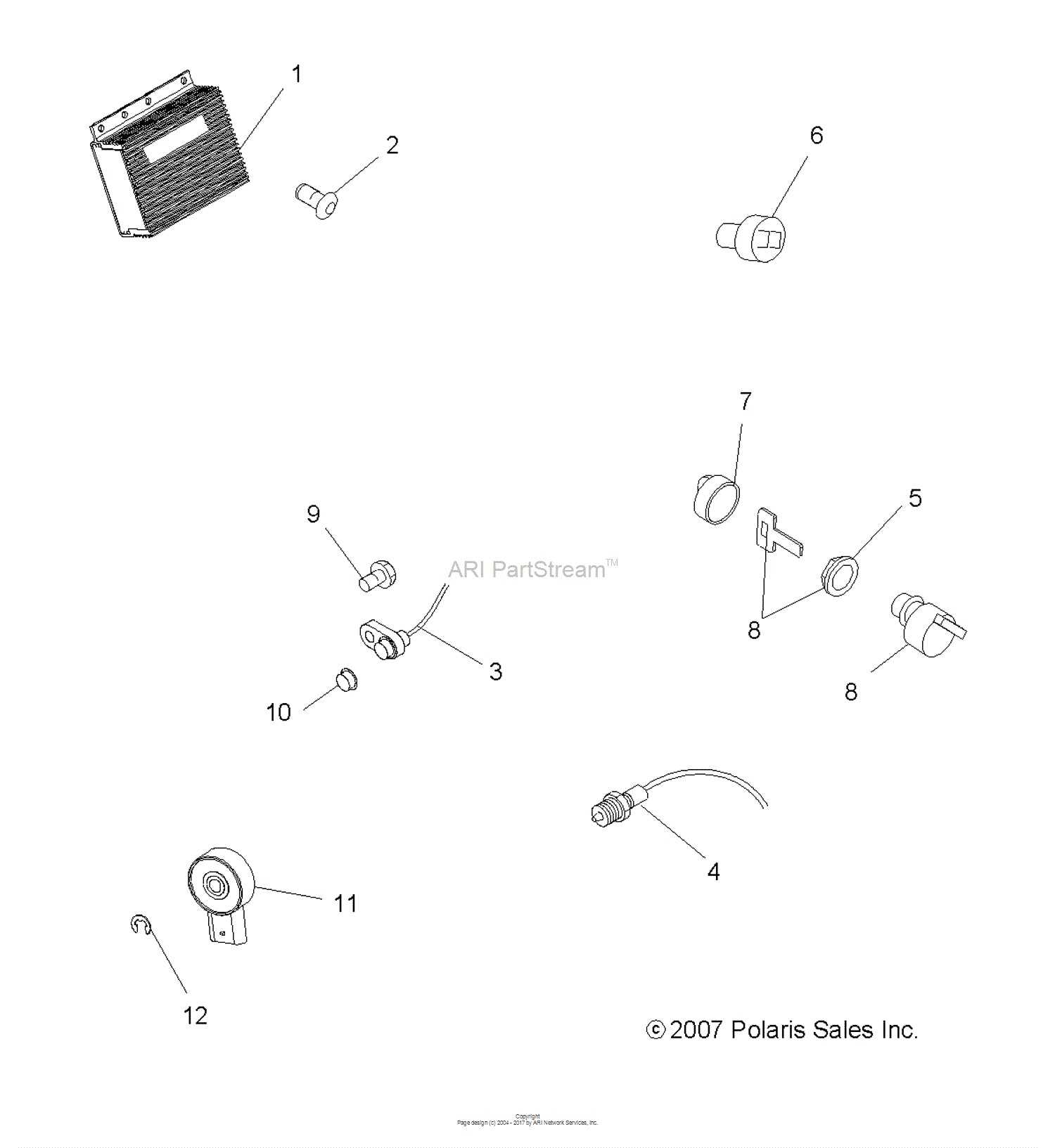

Electrical System Key Components

The electrical system is fundamental to the overall functionality of any off-road vehicle, ensuring that various features operate smoothly and reliably. Understanding the key components of this system helps in maintaining and troubleshooting electrical issues that may arise over time.

Main Power Source

At the heart of the electrical network is the main power unit, which supplies energy to the entire system. This component is responsible for starting the engine and powering essential functions. It requires regular inspection to ensure steady performance, as any disruption in its operation can affect the entire vehicle.

Wiring and Connectors

Wiring and connectors serve as the backbone of the electrical system, linking different devices and transmitting power between them. Quality connections are vital to avoid voltage drops or short circuits, which can lead to malfunction. Maintaining these connections free of corrosion is critical for the long-term health of the system.