Exploring the detailed setup and structure of mechanical systems can greatly enhance maintenance and upgrade procedures. Knowing how different elements interconnect allows for a smoother disassembly and reassembly process, reducing potential errors during repairs or adjustments.

Each mechanical unit contains a range of elements that are meticulously arranged to ensure optimal functionality. By delving into the arrangement specifics, you can uncover insights into the proper handling and replacement of individual components, leading to a more efficient workflow when dealing with technical fixes or modifications.

Whether you’re an experienced technician or just beginning to familiarize yourself with machinery, understanding the detailed layouts of these systems is crucial. This knowledge aids in not only identifying specific elements but also in diagnosing and resolving issues with greater precision.

The electrical network in off-road vehicles plays a crucial role in maintaining performance and ensuring smooth functionality. Understanding the setup of this system helps in diagnosing issues and making necessary improvements.

- Battery and Power Distribution: The power source drives the entire circuit, providing energy to the essential components like lights, ignition, and other electrical units.

- Wiring Harness: This assembly of cables connects various elements of the system, delivering power and communication signals to ensure synchronized operation.

- Switches and Controls: These components regulate the flow of electricity, allowing the operator to control functions such as lighting and other auxiliary features.

- Charging Mechanism: An integrated alternator or similar device works to replenish the power supply, ensuring that the energy levels remain stable during use.

- Fuses and Relays: Safety devices like fuses protect the circuit from overloads, while relays manage the high-current flow to prevent damage to sensitive parts.

Proper knowledge of these elements and their interactions is key to optimizing the vehicle’s electrical setup, leading to better performance and reliability

Main Electrical Components and Wiring Details

The electrical system of an off-road vehicle plays a crucial role in its overall performance and functionality. Understanding the core components and their connections is essential for maintaining optimal operation and ensuring that the power flows efficiently to all necessary areas.

Key Wiring Components

Several fundamental components are integral to the vehicle’s electrical setup. These include elements responsible for power distribution, safety mechanisms, and signal transmission. Recognizing the function of each part helps in diagnosing issues and performing effective repairs.

Wiring Connection Overview

The wiring layout of these vehicles consists of various circuits that interlink different modules and ensure the smooth flow of electricity. Each connection has a specific role, from starting the engine to powering auxiliary features like lights and indicators.

| Component | Function | Location | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ignition Coil | Transforms voltage to ignite the engine | Near the e

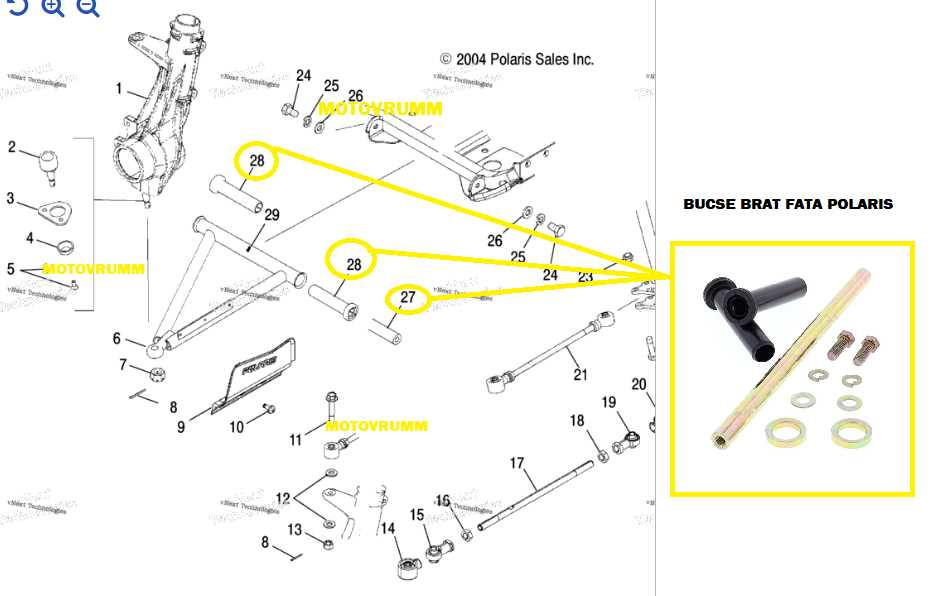

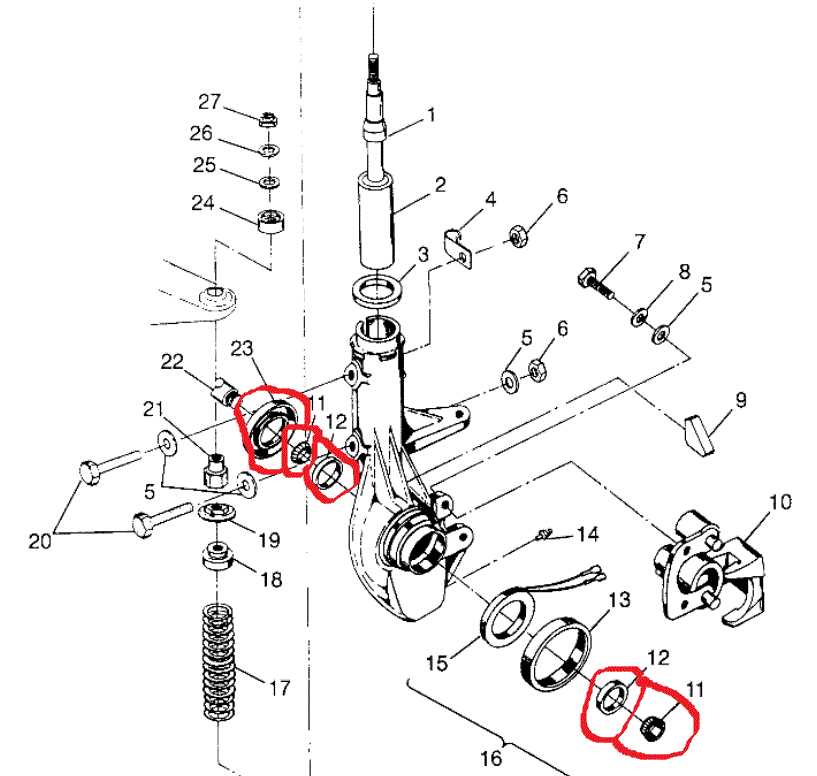

Transmission Parts Layout

The arrangement of components within the transmission system plays a crucial role in ensuring smooth functionality and efficient power transfer. Understanding this layout can assist in maintenance and repair tasks, enabling a more streamlined approach to resolving issues that may arise within this mechanical assembly. Main Components OverviewThe core elements in this setup include gears, shafts, and synchronizers. Each part has a specific purpose, contributing to the overall operation of the mechanism. Proper alignment and interaction between these elements are essential for optimal performance and to prevent any disruptions in the drivetrain’s movement. Gear Assembly DetailsThe gears are meticulously arranged to manage different speed ratios, allowing for a versatile driving experience. Each gear is positioned in a sequence to ensure that the transition between different speeds is as seamless as possible. This setup minimizes wear and maximizes the system’s longevity.

|