Maintaining outdoor machinery is essential for ensuring long-lasting performance and efficient operation. One of the keys to successful upkeep lies in understanding the individual elements that make up these devices. Identifying the various sections of the machine and how they interact allows users to troubleshoot issues and carry out necessary repairs with confidence. Every machine is designed with specific pieces that contribute to its overall functionality, and knowing their layout can make a significant difference in performance.

Whether it’s for regular maintenance or repairs, having a visual guide to the internal and external systems of the equipment can be incredibly helpful. By breaking down the machine into its distinct components, you can identify which parts need attention and how they interact with one another. This detailed understanding ensures that any adjustments or replacements are done efficiently and correctly, enhancing the life cycle of the equipment.

For anyone looking to delve deeper into machine management, an overview of the configuration can serve as a critical tool. It’s not just about knowing what each piece is, but also about understanding how they contribute to the overall effectiveness of the equipment. Properly caring for and assembling these parts ensures smooth operation throughout the year.

Essential Components of a Lawn Care Machine

Understanding the core elements that make up a lawn care machine is crucial for proper maintenance and repair. These essential components work together to ensure optimal performance and durability, allowing the machine to effectively handle large outdoor spaces. Each key part serves a specific function, contributing to the overall efficiency and safety of the equipment.

Key Mechanical Elements

- Engine: Powers the machine, enabling it to move and operate various functions like the cutting mechanism.

- Transmission: Controls the speed and direction, allowing the user to maneuver the machine efficiently.

- Steering Mechanism: Provides the ability to control the direction and navigate around obstacles.

- Drive Wheels: Assist with movement and provide traction on different types of terrain.

Operational Features

- Blades: The cutting elements that trim grass and manage lawn height.

- Fuel System: Supplies energy to the engine, which is essential for prolonged use.

- Brake System: Ensures safe stopping and control of the machine’s speed when necessary.

- Cooling System: Maintains optimal operating temperature by preventing overheating.

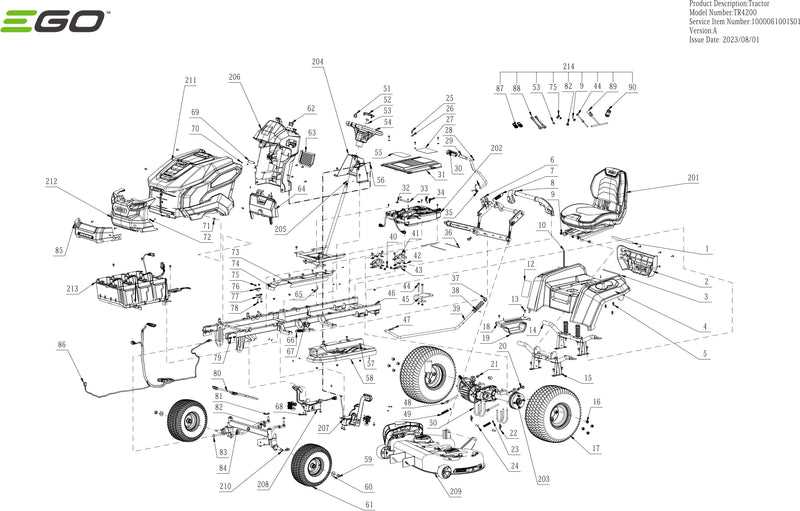

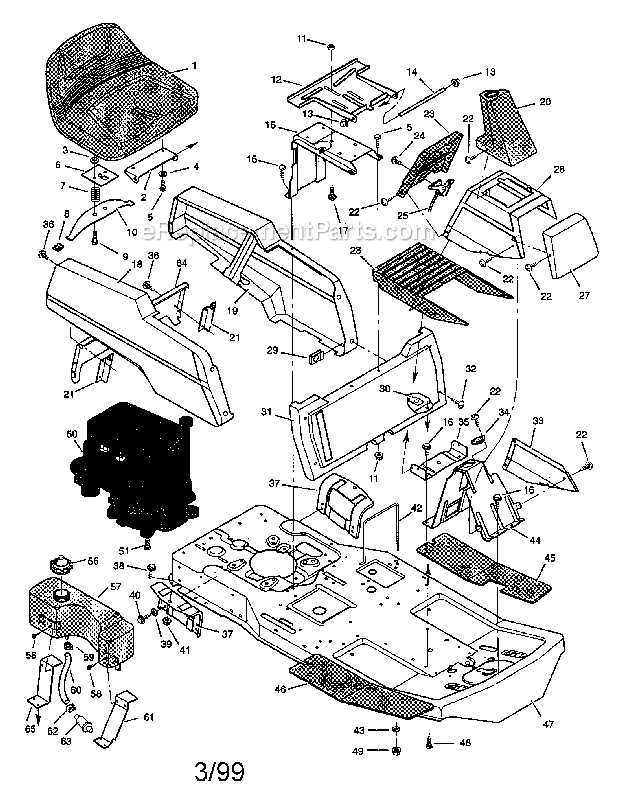

Understanding the Craftsman Lawn Tractor Layout

To effectively maintain and troubleshoot a garden tractor, it’s essential to familiarize yourself with the general layout of its components. A clear understanding of how the key elements are arranged and function together can significantly enhance your ability to diagnose issues and perform necessary repairs.

Key Components of the Tractor’s Structure

The structure of a typical garden tractor is designed for ease of use and efficiency. The main section houses the engine, transmission, and essential controls, allowing smooth operation and adjustments during various tasks. In addition, the seating area and control panel are positioned for maximum comfort and accessibility, ensuring that operators can easily manipulate the machine while in use.

How the Parts Interact

The interaction between the different sections of the machine is crucial for its performance. Understanding how power flows from the engine to the wheels and how each control affects the overall operation will help troubleshoot issues like power loss or uneven movement. Components such as belts, pulleys, and levers must be carefully maintained to ensure smooth interaction.

Recognizing the layout of a tractor can also help with identifying when something is out of alignment or worn out, preventing costly repairs by addressing minor issues early. Knowing the placement of each part and its function ensures that the machine runs efficiently and reliably during every use.

Key Replacement Parts for Efficient Operation

Maintaining the smooth functioning of any outdoor vehicle requires attention to critical components that ensure optimal performance. Regular replacement of worn-out elements is key to avoiding unnecessary breakdowns and prolonging the lifespan of the machine. These components, when replaced on time, not only improve efficiency but also contribute to a safer and more reliable experience.

Engagement mechanism is essential for seamless operation. This element is responsible for initiating the key functions of the vehicle and should be regularly inspected for wear or damage. Replacing this part ensures the machine starts and operates smoothly each time.

Another crucial component is the drive belt. Over time, it can stretch or snap, leading to malfunction. A fresh drive belt guarantees proper power transmission, enhancing movement efficiency. Also, regular checks on the brake system ensure timely stopping, minimizing the risk of accidents or damage.

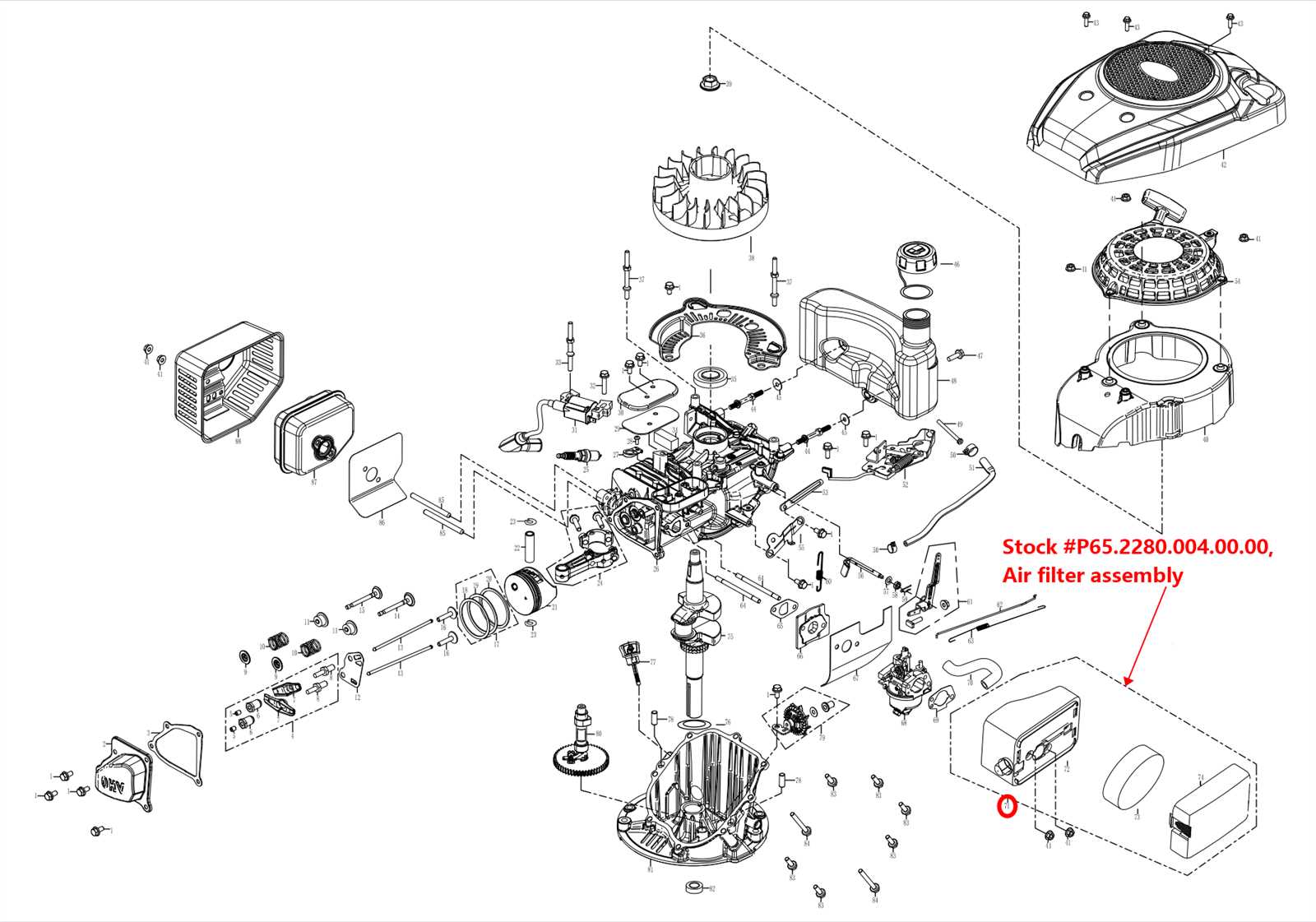

Lastly, the air filter needs attention. A clean and functional air filter helps maintain proper engine performance by ensuring that only clean air enters the system. Regular replacement of this filter can prevent engine clogging and optimize fuel efficiency.

Identifying Common Wearable Items in Mowers

Every machine that undergoes frequent operation experiences some level of wear and tear. In particular, the components that come into direct contact with the ground or other surfaces are susceptible to quicker deterioration. Recognizing the most commonly affected elements can help in maintaining optimal performance and extending the life of the equipment. By understanding which parts require regular attention or replacement, users can ensure a smoother, more efficient operation throughout the year.

Key Components to Monitor

When evaluating the lifespan of key machine elements, it’s important to focus on the items that are exposed to the most stress. These components typically face friction, pressure, and environmental conditions that accelerate their degradation. Regular inspections and timely replacements can prevent costly breakdowns or reduced functionality.

| Component | Purpose | Signs of Wear | Replacement Frequency |

|---|---|---|---|

| Belts | Transfers motion from engine to working components | Cracking, fraying, slipping | Every 2-3 years or as needed |

| Blades | Cuts grass and other vegetation | Chipping, dull edges, uneven cuts | Every season or after heavy use |

| Wheels | Provide stability and movement | Worn treads, cracks, irregular rotation | Every 2 years or when damage is noticed |

| Air Filter | Prevents dirt and debris from entering the engine | Clogged or dirty, reduced engine power | Every 6 months or after extensive use |

Importance of Timely Replacements

Failure to replace worn items can lead to further damage and decreased efficiency. For instance, a dull blade not only performs poorly but can also strain the engine, leading to unnecessary wear on more expensive components. Regular attention to these frequently used parts can improve performance and save on repair costs over time.

How to Read a Parts Diagram

Understanding an illustration that shows individual components of a machine can be essential for identifying, assembling, or replacing specific items. These visuals often display all the necessary elements in a structured way, with each piece labeled for easy reference. This guide will help you navigate through these technical charts with clarity, ensuring you can locate the right components quickly and efficiently.

Each component in the visual is typically numbered, and these numbers correspond to a list of descriptions or a reference guide. By matching the number to the list, you can identify the part and determine its function in the system. Additionally, you’ll often find arrows or lines connecting the components to illustrate how they interact or fit together within the entire structure.

It is important to pay attention to the orientation of the parts in the visual. Some illustrations will depict them from a top-down perspective, while others may use side views. Make sure to study the perspective and layout to fully grasp how the parts relate to one another. This understanding will also help prevent mistakes during assembly or disassembly.

Finally, always refer to the accompanying key or legend for additional information. Sometimes, these visuals include color-coding or special symbols that give extra clues about the nature of each part, such as its material or whether it is an upgrade or replacement item. By carefully examining these features, you’ll enhance your ability to work with complex mechanical systems.

Decoding the Craftsman Maintenance Schematics

Understanding maintenance layouts can be crucial for efficient upkeep of your outdoor equipment. These visual guides offer a comprehensive view of how each component fits together, enabling users to carry out repairs or replacements with ease. By breaking down the various sections and symbols, anyone can quickly identify where to look when troubleshooting issues or performing regular servicing.

Each layout is designed to represent the intricate network of components, from the engine to the wheels, in a clear and organized manner. Whether you’re dealing with belts, pulleys, or blades, the schematics provide a helpful reference point. It is essential to familiarize yourself with these diagrams, as they will assist in preventing unnecessary errors during maintenance processes.

Precise understanding of these visuals helps ensure that every action is aligned with the correct procedure. Recognizing each part’s location and function in relation to others minimizes risks and promotes smoother repairs. Mastering these layouts can transform your maintenance efforts, making tasks more intuitive and efficient.

Maintaining Your Craftsman Mower for Longevity

Regular upkeep is essential for ensuring the long-term performance and efficiency of your outdoor equipment. By following a routine maintenance schedule, you can significantly extend the life of your machine, keeping it running smoothly and preventing costly repairs. Proper care includes cleaning, lubrication, and timely replacement of worn-out components. Consistent attention to these areas will ensure that your investment continues to serve you well season after season.

Routine Cleaning and Inspection

Maintaining cleanliness is crucial for preventing dirt and debris from interfering with the smooth operation of your equipment. After each use, it is important to remove any accumulated grass or dirt from the undercarriage and blades. This prevents clogs that can lead to overheating and inefficient operation. Additionally, inspecting for loose bolts, nuts, and fasteners will help identify potential issues before they cause further damage.

Lubrication and Component Replacement

Keep all moving parts well-lubricated to reduce friction and prevent premature wear. Regularly check the engine oil and change it according to the manufacturer’s recommendations. Additionally, inspect belts, filters, and tires for signs of wear or damage. Replacing worn components promptly will help maintain optimal performance and avoid unnecessary strain on the machine.

Choosing the Right Parts for Repairs

When it comes to maintaining outdoor equipment, selecting the appropriate components for replacements is crucial. Ensuring compatibility and durability can significantly extend the life of your machine. It’s essential to consider the specific requirements of the device, such as the size, material, and functionality of each element. Knowing how to match the right replacements with the existing system will help avoid unnecessary costs and frustration.

Start by identifying the exact issue. A careful inspection will provide insights into which components are worn out or damaged. Next, compare the original specifications with available options, ensuring they meet the same performance standards. While aftermarket options may be cheaper, they sometimes compromise quality, so it’s important to choose wisely. Always verify the authenticity and quality of the replacements before making a purchase to avoid future repairs.

Common Issues with Craftsman Riding Mowers

Many users experience challenges with their lawn care equipment, especially when it comes to machines designed for larger properties. These machines, while reliable, are prone to several common problems that can affect performance, safety, and ease of use. Understanding these typical issues can help users troubleshoot and maintain their equipment more effectively.

1. Engine Difficulties

One of the most frequent concerns is engine malfunction. Whether it’s trouble starting the engine, irregular running, or stalling, these problems often stem from issues like fuel contamination, faulty spark plugs, or air filter blockages. Regular checks and timely maintenance can help keep the engine running smoothly.

2. Transmission and Steering Issues

Another common issue involves the machine’s transmission system. Difficulty with shifting gears or an unresponsive steering mechanism can make operation cumbersome and may signal problems with the belt system or internal components. Ensuring that these elements are regularly inspected can prevent serious mechanical failures.

| Issue | Potential Cause | Solution |

|---|---|---|

| Engine not starting | Faulty spark plug, old fuel | Replace spark plug, use fresh fuel |

| Irregular running | Clogged air filter | Clean or replace air filter |

| Steering difficulty | Worn out steering components | Inspect and replace worn parts |

| Transmission slipping | Loose or damaged belts | Check and replace belts as needed |

Diagnosing Problems Using a Parts Diagram

When troubleshooting machinery, understanding how each component fits together is essential for identifying issues. A visual representation of the system can serve as a valuable tool, offering a clear overview of all individual elements and their connections. This approach can help pinpoint where malfunctions may be occurring and what specific parts require attention.

Step-by-Step Approach to Identifying Issues

Begin by thoroughly examining the visual guide, ensuring you are familiar with every part of the equipment. Pay close attention to common areas where failures are likely to occur. Understanding the function of each element will help you focus on critical areas for potential problems.

- Inspect connections between moving parts for signs of wear or damage.

- Check for missing or misaligned components, as they may affect overall performance.

- Identify areas where debris may have accumulated, causing interference with function.

Using the Visual Guide to Track Down Common Issues

Once a possible issue is identified, use the guide to track down the exact component that might be malfunctioning. This can save time by narrowing down the list of possible problems and leading to more efficient repairs.

- Note any unusual sounds or vibrations and refer to the guide to see which part is responsible.

- Look for worn-out or damaged components, which may indicate the need for replacement.

- Verify the alignment and position of components to ensure they are functioning correctly.