Ensuring the longevity and efficiency of your garden machinery is essential for a well-kept outdoor space. Understanding the various components and how they work together can make all the difference when it comes to keeping your equipment running smoothly. By familiarizing yourself with the layout and the roles of each part, you can easily diagnose issues and perform maintenance without unnecessary complications.

In this guide, we will delve into the essential aspects of mechanical upkeep, exploring key elements that contribute to the seamless operation of your machine. With a focus on functionality and performance, you’ll gain insights into how to handle common repairs, replace elements when necessary, and optimize your device for the best possible results. Knowing these details can significantly reduce downtime and enhance your overall experience.

From essential maintenance tips to troubleshooting advice, the following sections will provide you with a thorough understanding of the intricate workings of your outdoor equipment. By having a clear view of its internal structure, you can ensure that everything functions efficiently, improving both its lifespan and reliability.

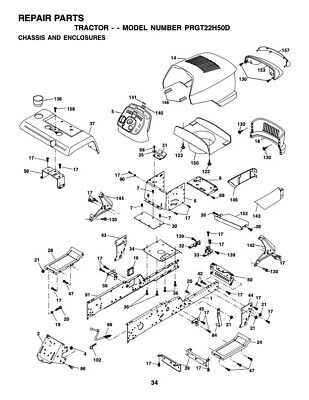

Poulan Pro Riding Mower Overview

This section provides a detailed look at a versatile outdoor machine designed for efficient lawn care. Known for its robust construction and user-friendly features, this equipment stands out in its category, offering a blend of power and convenience for a wide range of users.

The device is engineered to handle various terrains, making it suitable for small to large yards. Its design emphasizes durability and ease of maintenance, ensuring long-term reliability.

- Built with a strong frame for extended service life

- Comfortable seating and intuitive controls for easy operation

- Multiple cutting heights to suit different lawn types

- Fuel-efficient engine delivering consistent performance

- Easy-access maintenance points for quick servicing

In addition to its performance, this machine integrates smart solutions for better maneuverability and control, making lawn care a more streamlined experience.

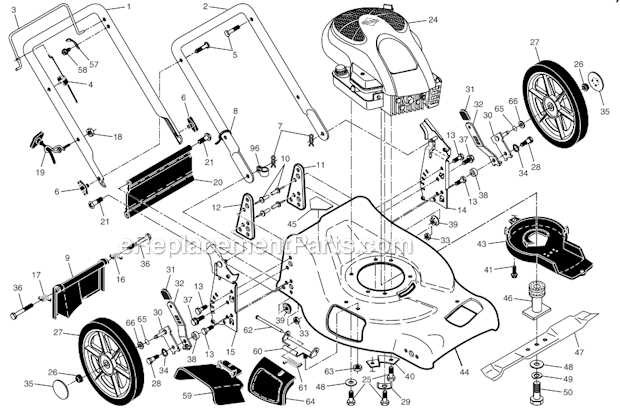

Main Components of the Mower

The machinery designed for lawn maintenance consists of several essential elements that work in harmony to achieve efficient operation. Understanding these key components is crucial for both maintenance and optimal performance. Each part plays a specific role in the overall functionality, contributing to the machine’s effectiveness in cutting grass and handling various terrains.

At the forefront is the engine, which provides the necessary power to drive the entire system. Coupled with the engine, the transmission allows for smooth gear shifts, enabling the operator to navigate different speeds and inclines effortlessly. The cutting deck is another vital component, featuring sharp blades that ensure a clean and even cut across the lawn surface.

The chassis serves as the backbone, supporting all other elements and providing stability during operation. Additionally, the wheels and tires are designed for traction and maneuverability, allowing the equipment to traverse diverse landscapes with ease. Lastly, the control system, including the steering and braking mechanisms, ensures the operator can maintain precise control while operating the equipment.

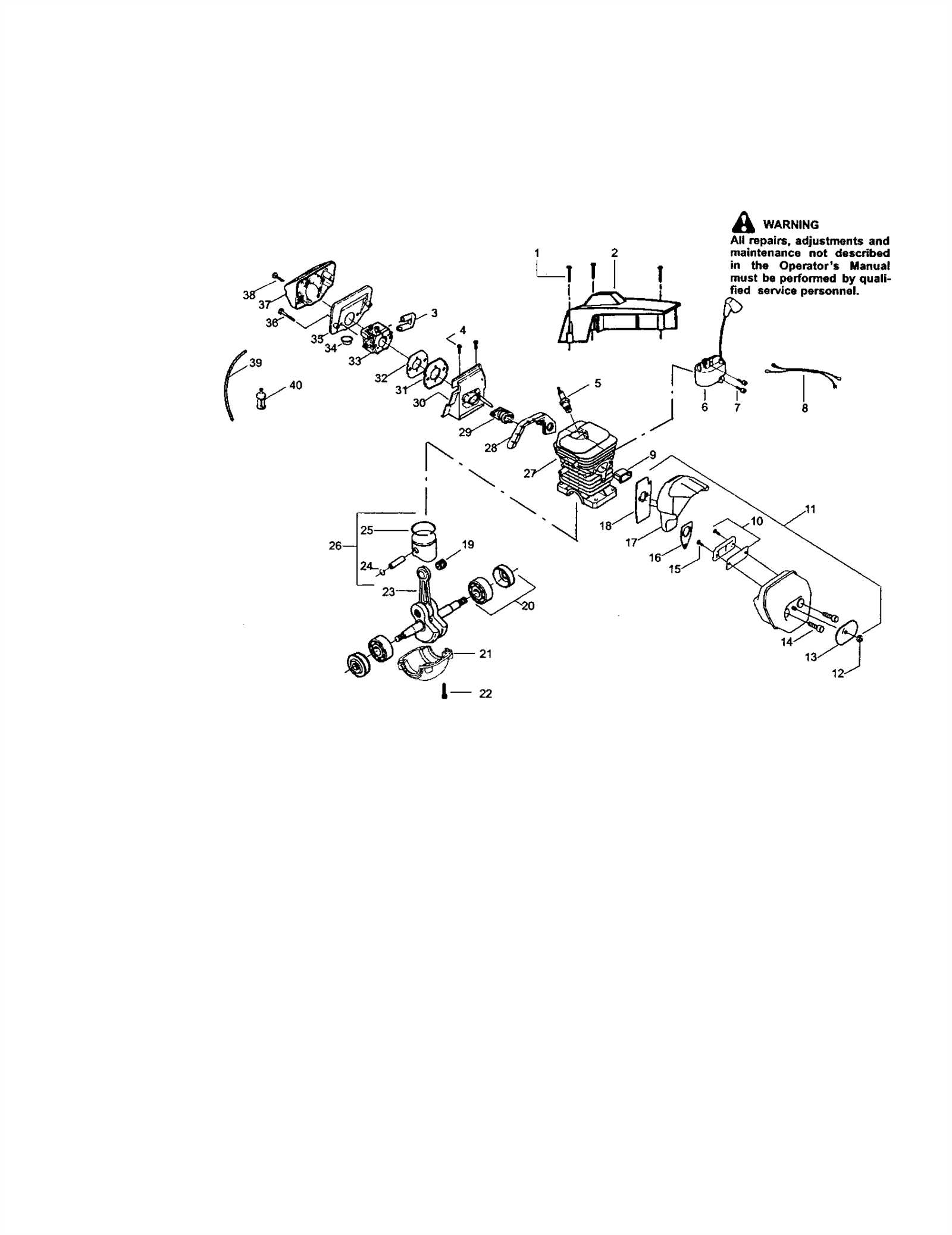

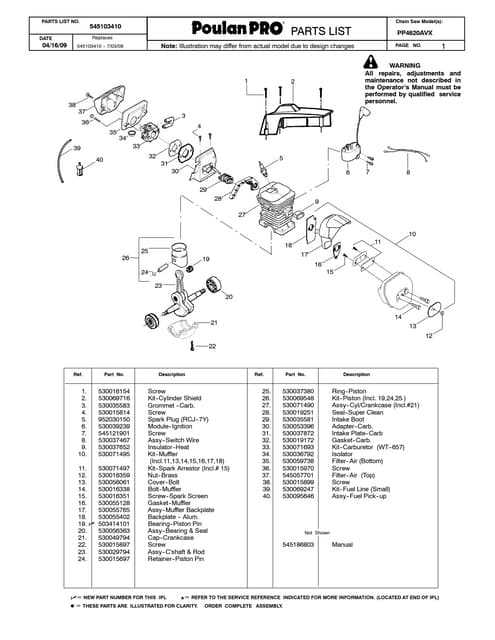

Engine and Power System Layout

This section provides an overview of the engine configuration and power delivery mechanisms utilized in lawn care equipment. Understanding the arrangement and function of these components is essential for effective maintenance and troubleshooting.

The engine serves as the heart of the system, converting fuel into mechanical energy. This energy is transmitted through a series of interconnected components, including belts, pulleys, and gears, ensuring efficient operation. Proper alignment and condition of these elements are crucial for optimal performance.

Additionally, the power system incorporates various control systems that manage speed and direction. Features such as throttle control and ignition systems play a vital role in regulating engine output and ensuring user-friendly operation. Familiarity with these systems aids in diagnosing issues and enhances overall functionality.

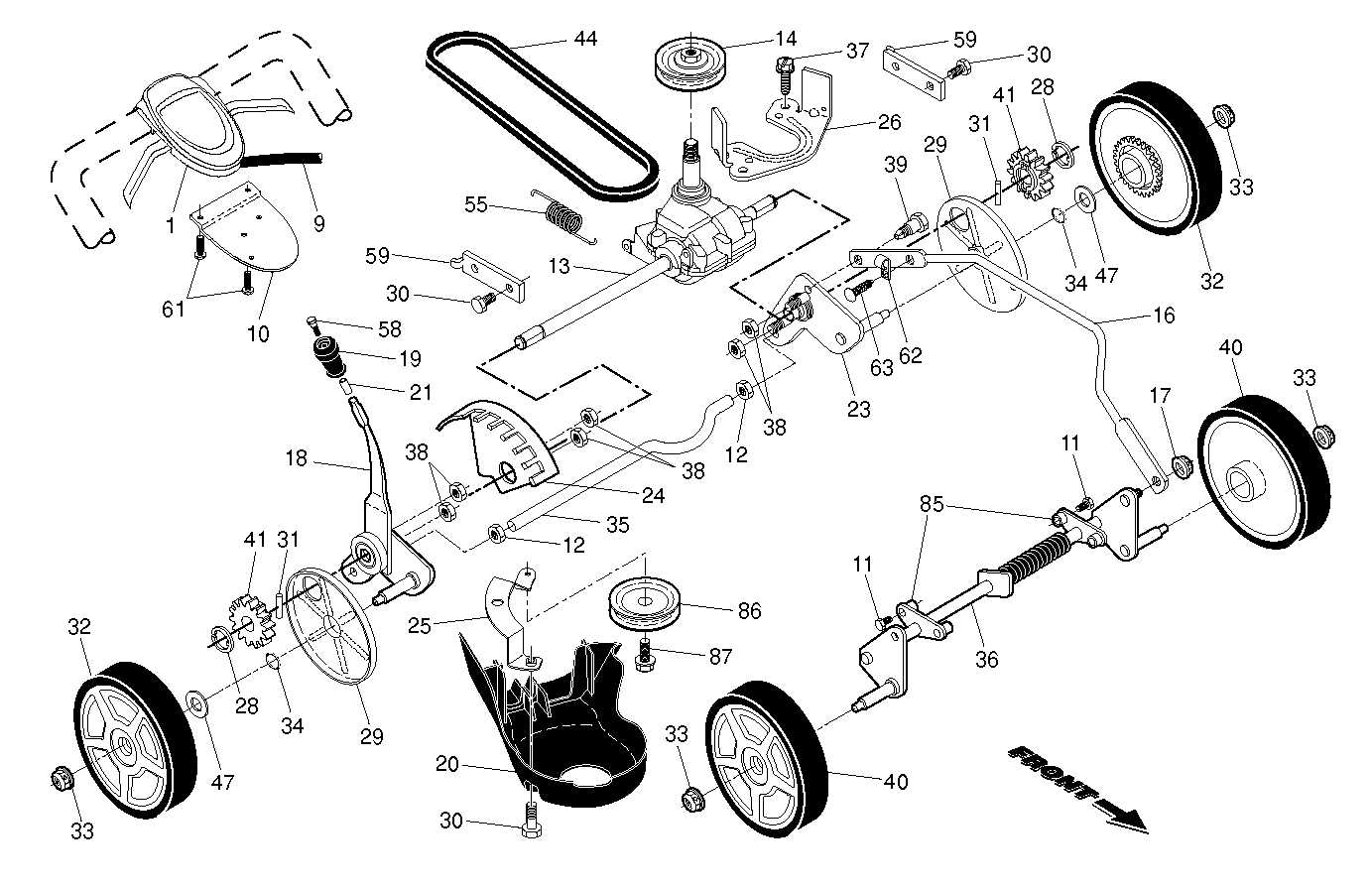

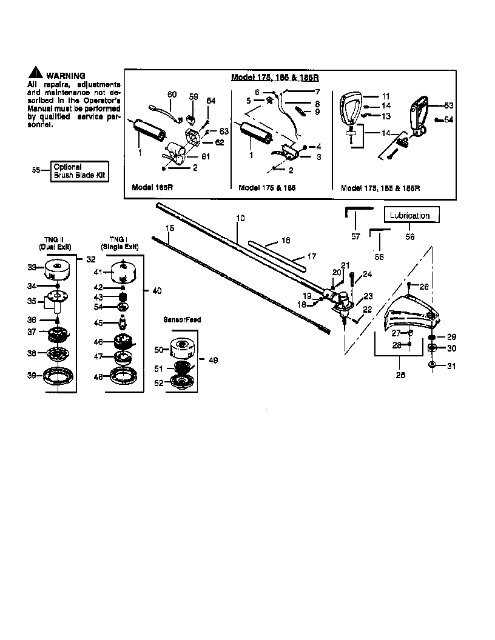

Deck Assembly and Blade Setup

This section focuses on the construction of the cutting platform and the installation of the blades essential for optimal performance. Proper assembly and alignment are crucial for achieving a clean and efficient cut. Understanding the components and their arrangement will enable smooth operation and maintenance.

Components Overview

The cutting platform comprises several key elements that work together. Familiarizing yourself with each component ensures a successful assembly process.

| Component | Description |

|---|---|

| Deck | The main structure that houses the blades and provides stability. |

| Blades | Sharp metal pieces responsible for cutting the grass. |

| Spindles | Housings that hold the blades and allow them to rotate. |

| Belt | A mechanism that transfers power from the engine to the spindles. |

Assembly Steps

To achieve proper functionality, follow these steps for assembling the cutting platform:

- Begin by securely attaching the deck to the main frame.

- Install the spindles, ensuring they are properly aligned.

- Attach the blades to the spindles, making sure they are tightened appropriately.

- Connect the belt to the pulleys, ensuring it is taut and aligned.

Following these guidelines will enhance the efficiency and longevity of your equipment, making maintenance and operation more manageable.

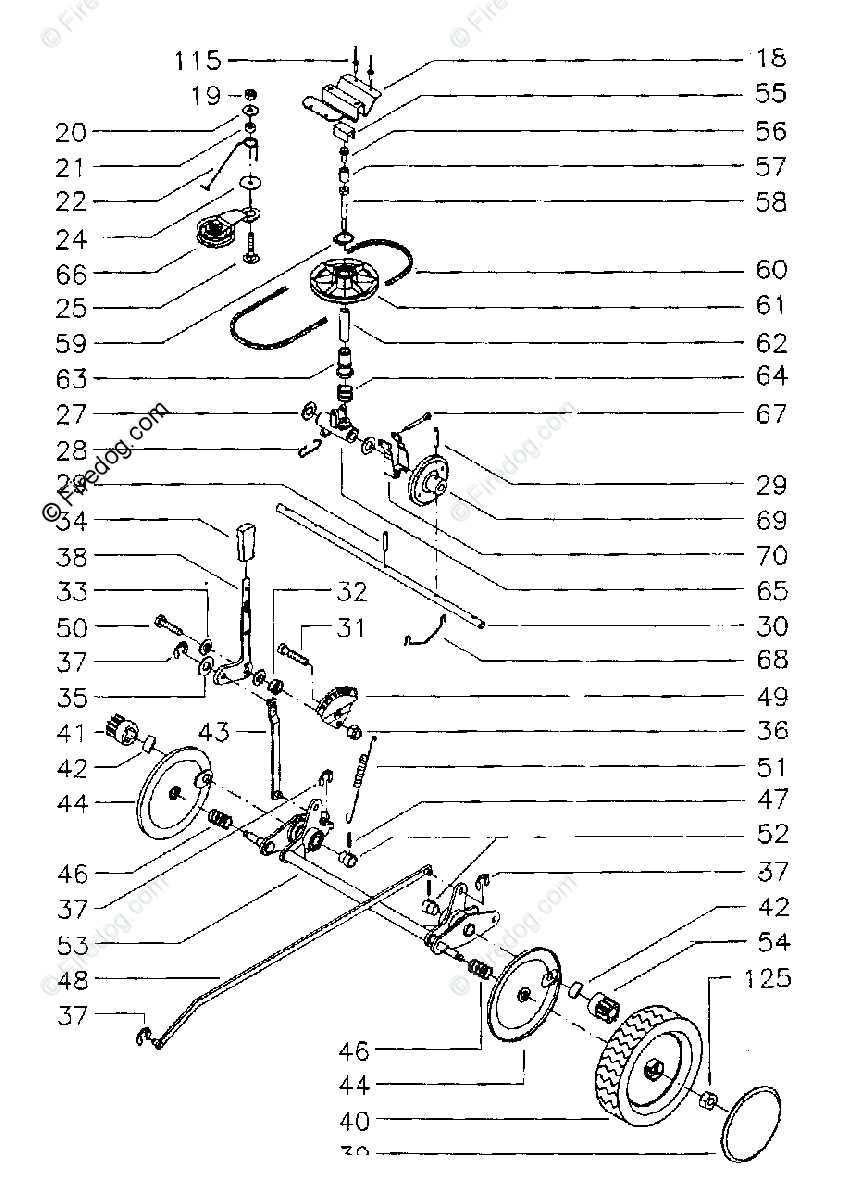

Transmission and Drive Mechanism

The transmission and drive system play a crucial role in the operation of lawn care equipment, providing the necessary power and control to maneuver effectively across various terrains. This section delves into the components and functionality of these essential systems, ensuring optimal performance during usage.

Key Components

- Transmission: This element is responsible for transferring power from the engine to the wheels, allowing for efficient movement.

- Drive Belt: A vital component that connects the engine to the transmission, ensuring smooth power delivery.

- Gear System: It includes various gears that regulate speed and torque, enabling adjustments based on terrain conditions.

- Wheel Drive: The mechanism that converts the rotational power into forward or reverse motion.

Functionality Overview

The effective operation of the transmission and drive assembly depends on the seamless interaction of its components. When the engine generates power, it travels through the drive belt to the transmission, where it is converted into the appropriate speed and torque. The gear system then fine-tunes this power, allowing the equipment to adapt to different mowing scenarios. Regular maintenance of these components is essential to ensure longevity and efficiency.

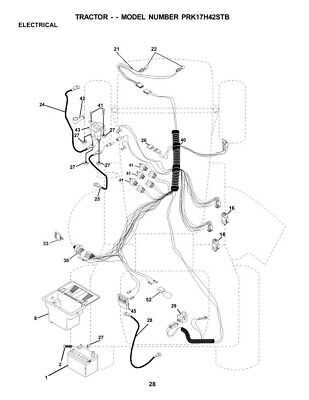

Electrical System and Wiring Diagram

This section provides a comprehensive overview of the electrical configuration and circuitry involved in the operation of the machine. Understanding the layout and function of the electrical components is crucial for effective maintenance and troubleshooting. A well-structured wiring system ensures that all parts work harmoniously, facilitating optimal performance.

Key Components of the Electrical System

The electrical setup comprises several essential elements, including the battery, ignition switch, and various sensors. Each component plays a vital role in the overall functionality. The battery provides the necessary power to start the engine, while the ignition switch controls the flow of electricity, allowing the operator to start and stop the machine. Additionally, sensors monitor various parameters, contributing to safety and efficiency.

Understanding the Wiring Connections

Proper wiring connections are fundamental for seamless operation. Each wire must be connected according to the specified layout to prevent electrical failures. Regular inspection of the wiring can help identify any wear or damage, which is essential for maintaining the machine’s reliability. Adhering to the correct wiring procedures ensures that all components receive the appropriate electrical supply, minimizing the risk of malfunctions.

Steering and Control Components

The steering and control elements are crucial for the effective operation of any outdoor vehicle. These components are designed to provide the user with a reliable and smooth driving experience, allowing for precise navigation and maneuverability in various terrains. Understanding these mechanisms is essential for proper maintenance and troubleshooting.

Key Components

Several fundamental parts comprise the steering and control system, each playing a vital role in functionality. The following table outlines these components and their respective functions:

| Component | Function |

|---|---|

| Steering Wheel | Controls the direction of the vehicle by turning the front wheels. |

| Steering Shaft | Transfers motion from the steering wheel to the steering mechanism. |

| Control Levers | Regulate speed and direction, enhancing operational control. |

| Linkage System | Connects the steering wheel and wheels, ensuring accurate movement. |

Maintenance Tips

To ensure optimal performance, regular inspection and maintenance of the steering and control components are necessary. Keeping these parts in good condition not only enhances the vehicle’s maneuverability but also contributes to overall safety during operation. Lubricating moving parts and checking for wear or damage can prevent potential issues down the line.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your outdoor equipment. Implementing a few straightforward practices can ensure optimal performance and reliability. By dedicating time to routine care, you can prevent major issues and maintain efficiency throughout the seasons.

Regular Cleaning

Cleaning the exterior and undercarriage is crucial for preventing debris buildup. Grass clippings, dirt, and dust can impede performance and lead to rust. Use a brush or compressed air to remove residue after each use. Additionally, ensure that air filters are free from blockages to promote proper airflow.

Scheduled Inspections

Conducting periodic checks on key components such as blades, belts, and tires can help identify wear and tear early. Replace or sharpen blades as necessary for efficient cutting. Inspect belts for signs of cracking or fraying, and keep tire pressure within the recommended range to enhance stability and handling.

Troubleshooting Common Part Failures

When working with outdoor machinery, it is not uncommon to encounter various issues related to component functionality. Identifying and resolving these failures promptly can enhance performance and extend the lifespan of the equipment. This section aims to provide guidance on recognizing typical malfunctions and implementing effective solutions.

Signs of Malfunction

- Unusual noises during operation

- Difficulty in starting the engine

- Inconsistent or uneven cutting

- Excessive vibration

- Leaking fluids

Common Solutions

- Check the fuel level and quality; replace stale fuel.

- Inspect the battery for corrosion and ensure a secure connection.

- Examine belts and blades for wear and replace as necessary.

- Clean or replace air and fuel filters to improve airflow and fuel delivery.

- Ensure all connections are tight and components are properly aligned.